|

|

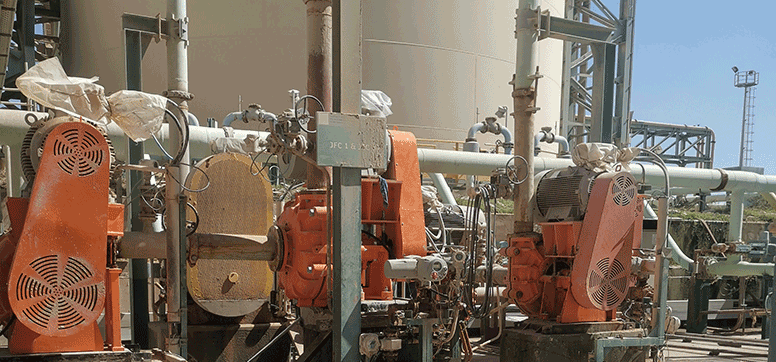

Selection steps for slurry pumps

Slurry pump selection steps are followed in the selection of slurry pumps, today share with you summarize

1, according to the slurry parameters S, D, Cw calculate the critical flow rate VL

2, according to the given flow rate and pipeline conditions to calculate the head loss in the clear water pipeline, drawing the clear water pipeline characteristic curve

3、Draw the characteristic curve of slurry pipeline, and find out the head under the given flow rate

4、Calculate the head of clear water, increase the head by 10%, the required head

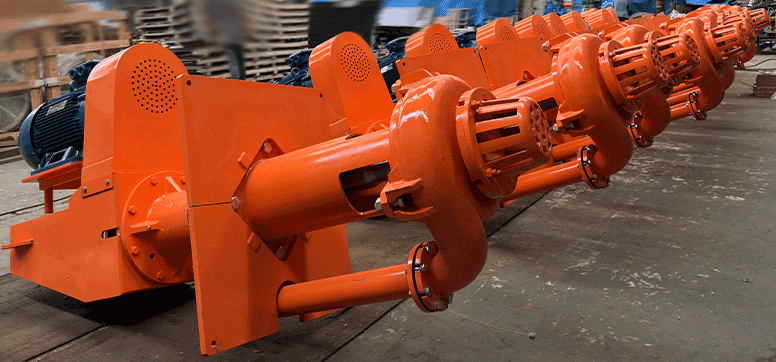

5、According to the slurry characteristics to determine the model of slurry pumps

6, according to the given flow rate and calculate the pump head of fresh water to choose the pump specifications, a pump can not meet the head requirements should be considered in series. Tandem pumps should be calculated pump pressure, bearing life and determine whether it can meet the requirements

7, will be clear water and slurry pipeline characteristic curve drawn in the selected pump performance curve, get the working condition of the pump, and find out the pump's n, NPSHr, η values

8, calculate NPSHa, determine whether the pump is running without cavitation, in the calculation should take into account the increase in head margin after the operating point flow (such as: NPSHa

9, calculate the pump slurry shaft power, and check whether the shaft power is less than the selected pump bracket power, (in the calculation of the head should be increased margin after the head) select the standard motor

10, according to the speed and power to determine the transmission type, installation type and shaft seal type

11, calculate the bungee outlet pressure, determine the packing shaft seal of the shaft seal water and water pressure

After a series of selection calculations, we first view the performance curve to determine the model of slurry pump, and then calculate the power of the motor and so on.

Slurry pump selection and calculation of the required parameters requirements

First, the basic parameters required for selection:

Basic conditions, flow, head

1 through the working conditions to determine whether to use our pumps, the working conditions described here are understood as the application of industries such as, mineral processing, coal processing, sand pumping, etc. (This step is very important, but also to do the selection of the prerequisite work). (This step is very important, but also to do the selection of the premise work)

2 flow, head is the selection of the basic two parameters of the pump:

a: through the working conditions to determine the general situation of the pump, such as which series of models or whether to consider the material, etc.

b: Determine the series model of the pump, through the flow, head read performance curve, so as to determine the specific type and size of the pump.

c: read the curve, calculate the power: pump shaft power calculation must know the parameters include flow, head, efficiency, slurry specific gravity; efficiency (η) by the flow, head decision, by reading the performance curve to read out; slurry specific gravity customers can not provide can only be through the empirical value. Generally between (1-2), technical calculations will give an estimate to calculate the power.

d:Calculate the slurry pump shaft power P=m*g*h/η its derived formula: P=ρ*Q*H/102η (the actual calculation should pay attention to the use of safety factor)

e: motor power, through the shaft power to take its close and larger than the shaft power for the motor power.

Second, accurate selection of the required parameters:

Working condition, flow, head, slurry specific gravity, solid specific gravity, concentration PH value temperature

In accordance with the basic process of Ⅰ, except that the C step in the slurry specific gravity parameters directly with the values provided by the customer, or through the solid specific gravity and concentration to calculate the slurry specific gravity.

Weight concentration is generally mainly considered the degree of abrasiveness of the slurry, specific to a certain slurry, the higher the concentration of abrasiveness will certainly be relatively higher, while the slurry specific gravity will also be higher. So there is also a heavy, neutral, light slurry pumps, is based on the content of the slurry roughly to change the score so a concept, there is no strict boundaries.

Ph value is one of the factors that we judge is to select the material of the slurry pump overflow parts (generally 5-12 ph value is to consider the range of metal overflow parts, the rest of the range to consider using rubber or other special materials, here is also a theoretical range of figures can not be dead set, to be applied flexibly);

Temperature is also to determine whether the material can be used as one of the factors, the general temperature of most cases is rarely considered factors, but sometimes there are special conditions on the temperature requirements.

Third, accurate selection of detailed parameters:

Working conditions, flow, head, slurry specific gravity, specific gravity of solids, concentration PH value, temperature, D50, D80, piping (pipe, elbow, valve, gradient (shrink, expand), viscosity, etc.)

Still in accordance with the basic process of Ⅰ, only in this detailed parameters, generally are bidding for the project, or the client is very professional to provide so many detailed parameters. Generally can provide to Ⅱ parameters have been considered detailed. Some big projects, big bids will have a specialized design unit or department to provide a detailed data for the client, so it is possible to provide Ⅲ such a level of detail. This detailed parameters in fact mainly increased the pipeline parameters, and pipeline is the calculation of TDH (dynamic head) parameters, generally a lot of customers can not provide details of the pipeline, or pipeline is simple, so they are ignored, directly provide a head only, we do not have to count, but once the pipeline to provide details, we need to calculate their own TDH, the specific calculation of the TDH is relatively complex, but there are ready-made TDH. The specific calculation of TDH is also relatively complex, but there are ready-made formulas to apply.