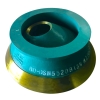

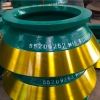

OEM Cone Crusher Parts Mantle and Bowl Liner HP200

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

The cone crusher has less steepness in the crushing chamber and more parallel belts between the crushing zones. The cone crusher uses an abnormally rotating shaft covered with a wear-resistant layer to crush the stone, while the closed concave hopper of the crusher is covered with a groove or bowl-shaped lining made of manganese. When the rock enters the top of the cone, it is squeezed between the cover and the bowl-shaped lining or groove. Large pieces of ore are crushed once, then lowered to a lower position and crushed again. This process will continue until the pieces are small enough to be discharged through a small opening at the bottom of the crusher.

Cone crusher wear parts are widely used in mining, metallurgy, construction, chemical industry and silicate industry, for crushing hard and medium hardness of ore and rock, such as pebble, granite, basalt, iron ore, limestone, quartzite, diabase, iron ore, gold ore, copper ore, etc.

Main materials: high manganese steel, manganese chromium alloy (Mn13, Mn13Cr2, Mn18, Mn18Cr2), hard alloy or customized materials.

Main technology: water glass sand casting and lost foam casting process.

MORETEC have strong technical advantages and rich experience in the production of wear-resistant castings. Our products have smooth surface, accurate size, high wear resistance and longer life. We can customize according to customers' drawings and requirements, and perfect our products according to customers' feedback.

Cone crusher wear parts are widely used in mining, metallurgy, construction, chemical industry and silicate industry, for crushing hard and medium hardness of ore and rock, such as pebble, granite, basalt, iron ore, limestone, quartzite, diabase, iron ore, gold ore, copper ore, etc.

Main materials: high manganese steel, manganese chromium alloy (Mn13, Mn13Cr2, Mn18, Mn18Cr2), hard alloy or customized materials.

Main technology: water glass sand casting and lost foam casting process.

MORETEC have strong technical advantages and rich experience in the production of wear-resistant castings. Our products have smooth surface, accurate size, high wear resistance and longer life. We can customize according to customers' drawings and requirements, and perfect our products according to customers' feedback.

Parts List