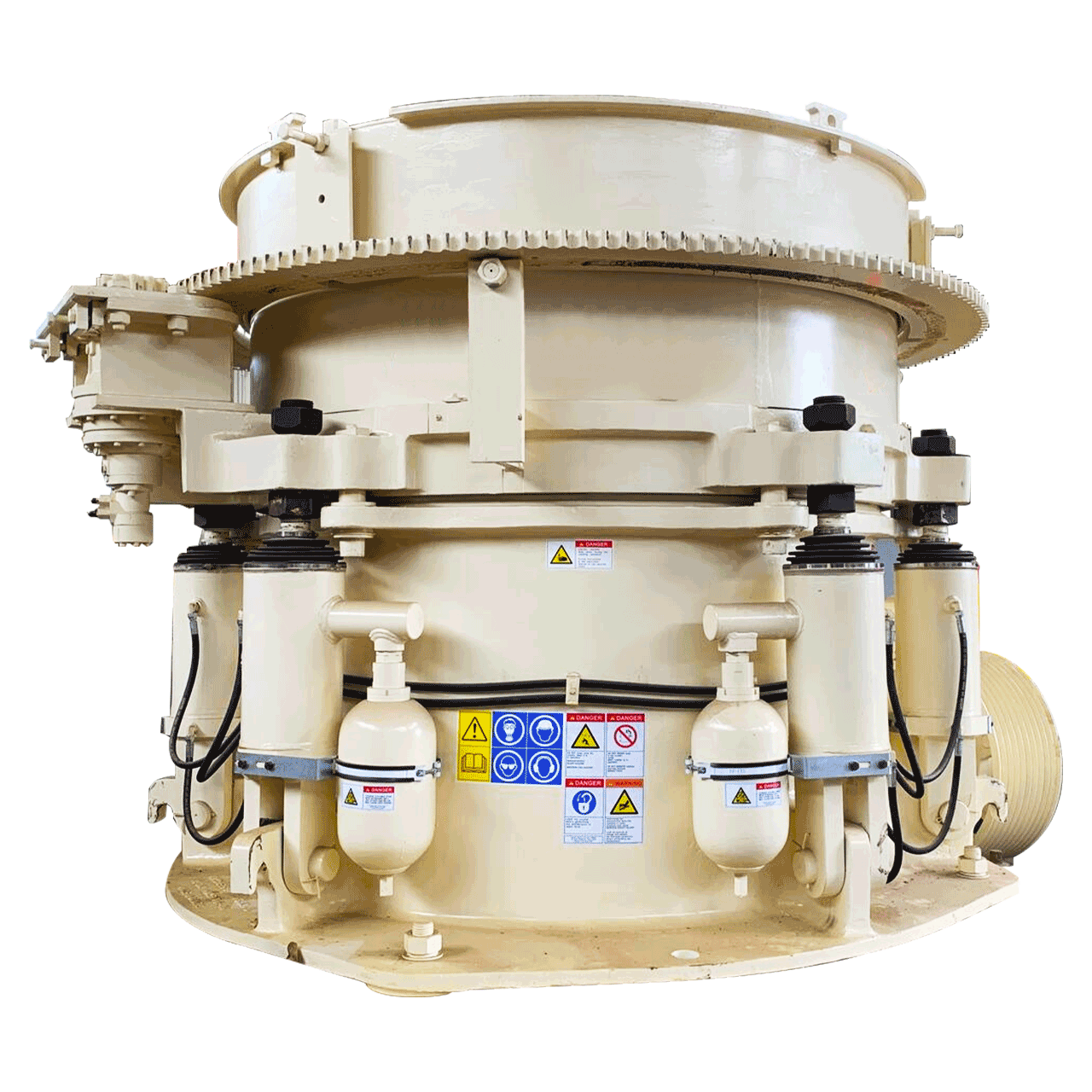

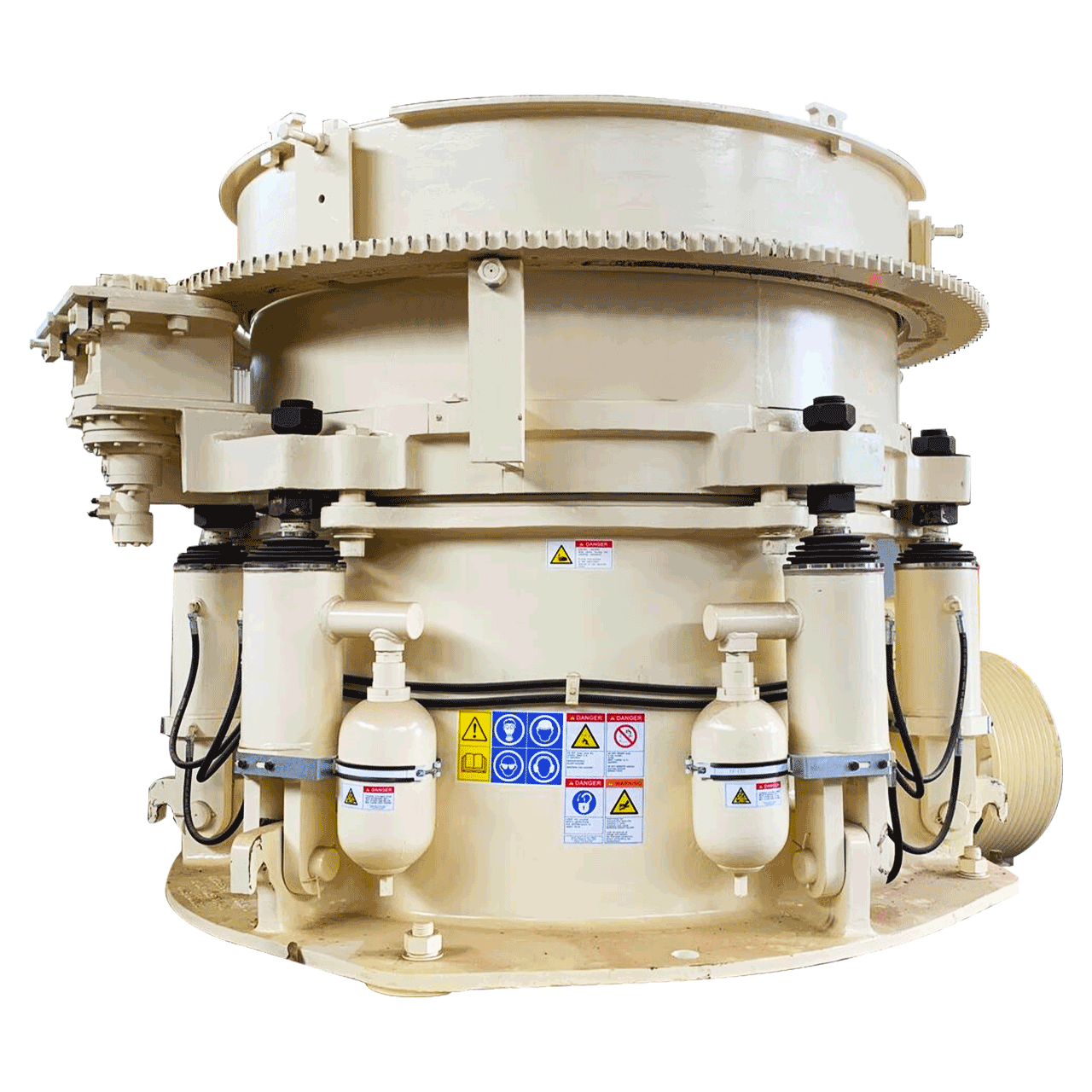

HP500 Cone crusher High performance crushing HP Series™cone crushers

Manufacturer : MORETEC

Part number : HP500

OEM Compatibility :

Category :Crusher / Cone crusher

Description

Description

HP Series™

cone crusher

The most popular modern cone crusher in the world

The HP series cone crusher combines crusher speed, throwing force, crushing force and cavity design.

They provide predictable and consistent production, and are trouble-free, simple and safe to operate and maintain.

Through practice, it has been proved that HP series multi-cylinder hydraulic cone crusher can provide higher production capacity, better product shape, easy automatic control, greater reliability and flexibility. It combines the essence of these technologies to create more value for customers.

Whether in the mining industry or the stone industry, if you want to increase productivity, reduce operating costs, produce ideal fine materials, and require long equipment life and high output, HP series multi-cylinder hydraulic cone crusher is your ideal choice.

HP cone crusher adaptability, is a real universal crusher. This means that the same crusher model can be used for any type of application, including all applications from coarse to ultra-fine applications, from aggregates to mining operations. They have a wide range of speed, feeding and cavity options, so you can set them up for different roles, including secondary, tertiary and quaternary crushing applications.

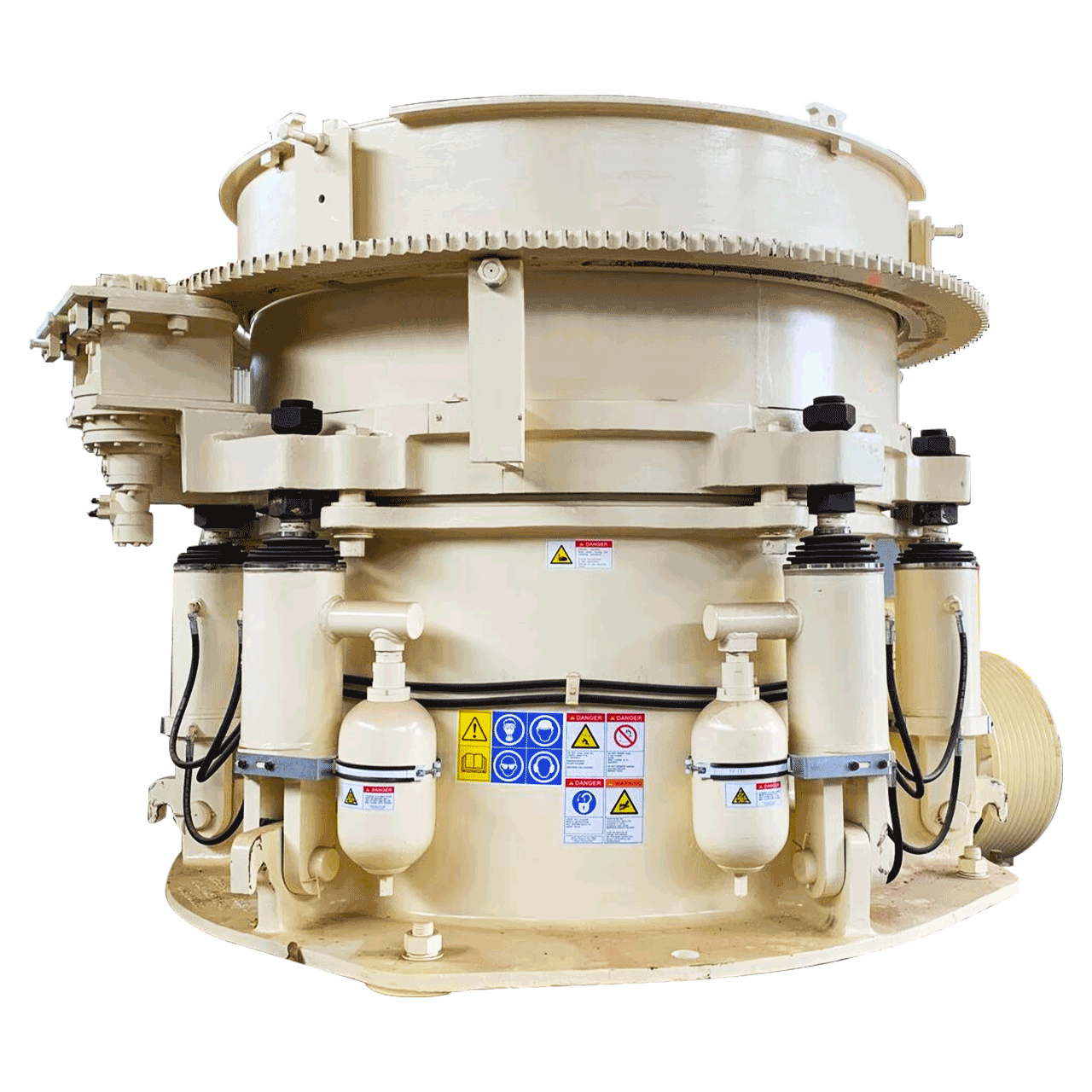

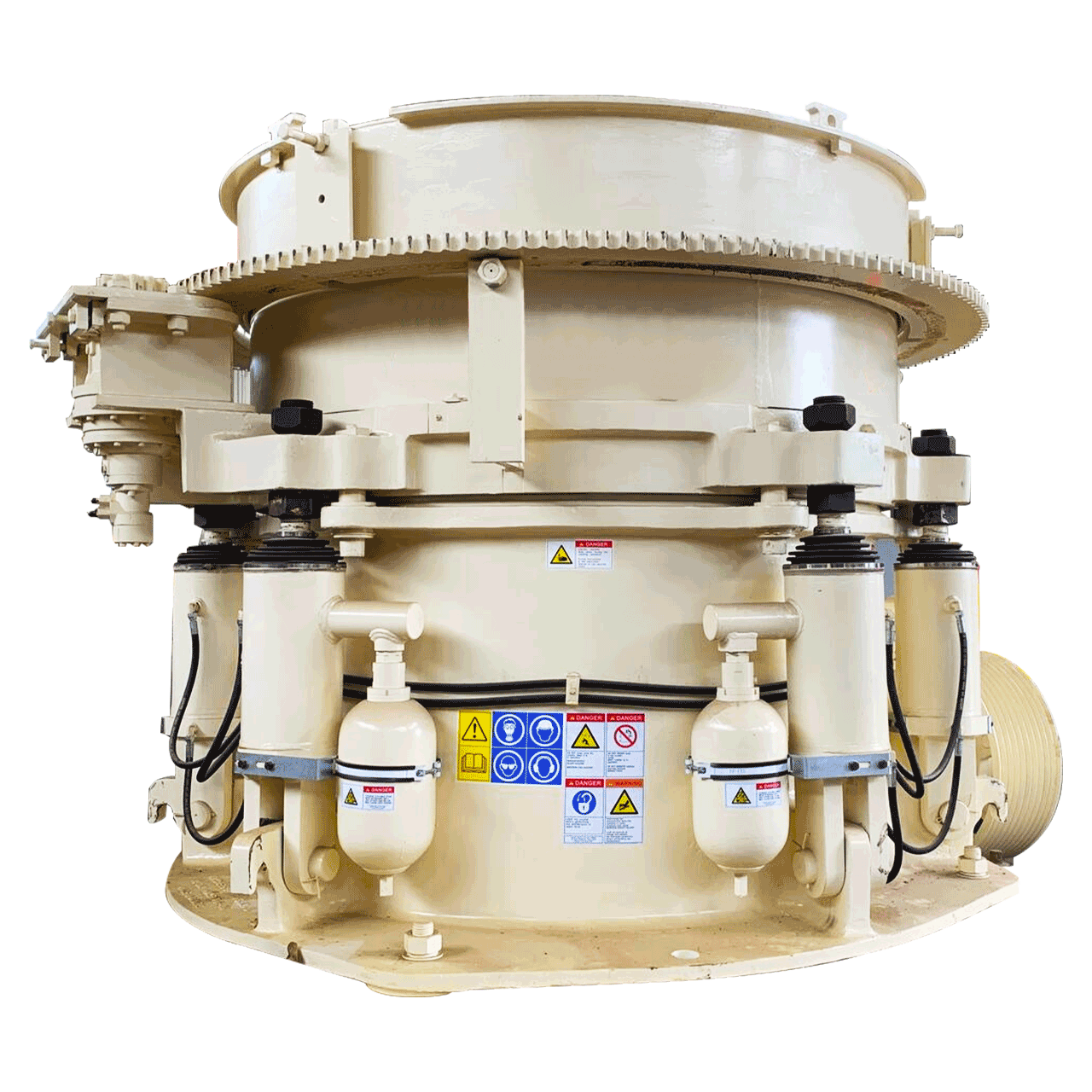

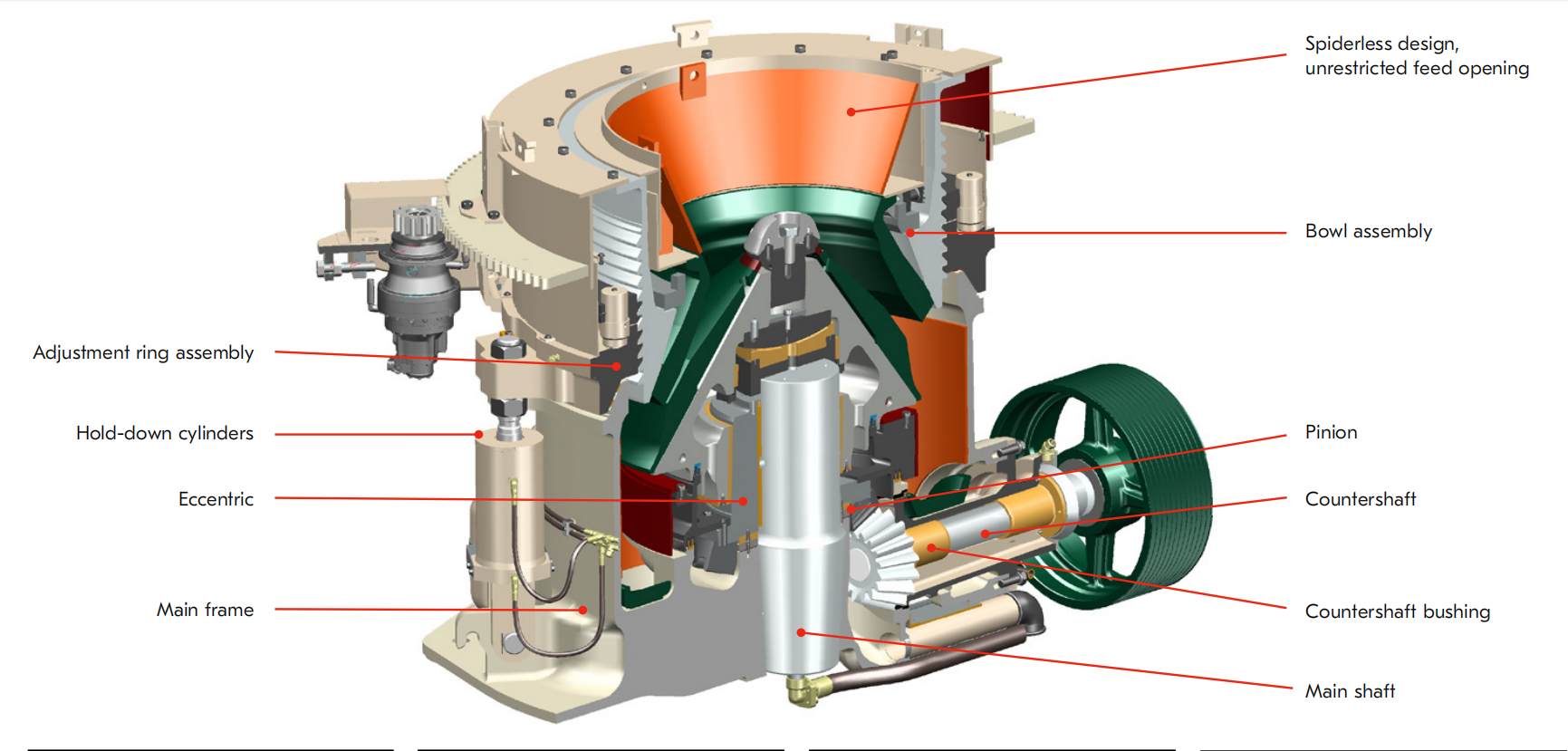

The HP Series features a spider-free design. This is in the second stage, because it significantly reduces the risk of clogging to ensure that the feed flows into the crusher cavity without restriction

The HP Series has built-in ease of use and is designed to make maintenance tasks fast, easy and secure. The crusher is easy to open and has a very effective impurity release system, which can effectively clean the cavity.

With the HP series, you can use a hydraulic motor to open the drum of the crusher so that the liner can be easily replaced. The hydraulic motor also rotates the drum to adjust the crusher settings.

The impurity release function is efficient and reactive, ensuring immediate opening, immediate recovery and continuous operation in the event of overload. The large cleaning stroke allows uncrushable objects to pass through the crusher cavity.

The large cleaning stroke, coupled with the double-acting hydraulic pressing cylinder, ensures that the cavity is quickly, easily and safely cleaned when the crusher stops under load due to any unexpected reason (such as a power failure in the power grid). In addition, all major components are accessible from the top for easy maintenance.

Equipment advantages:

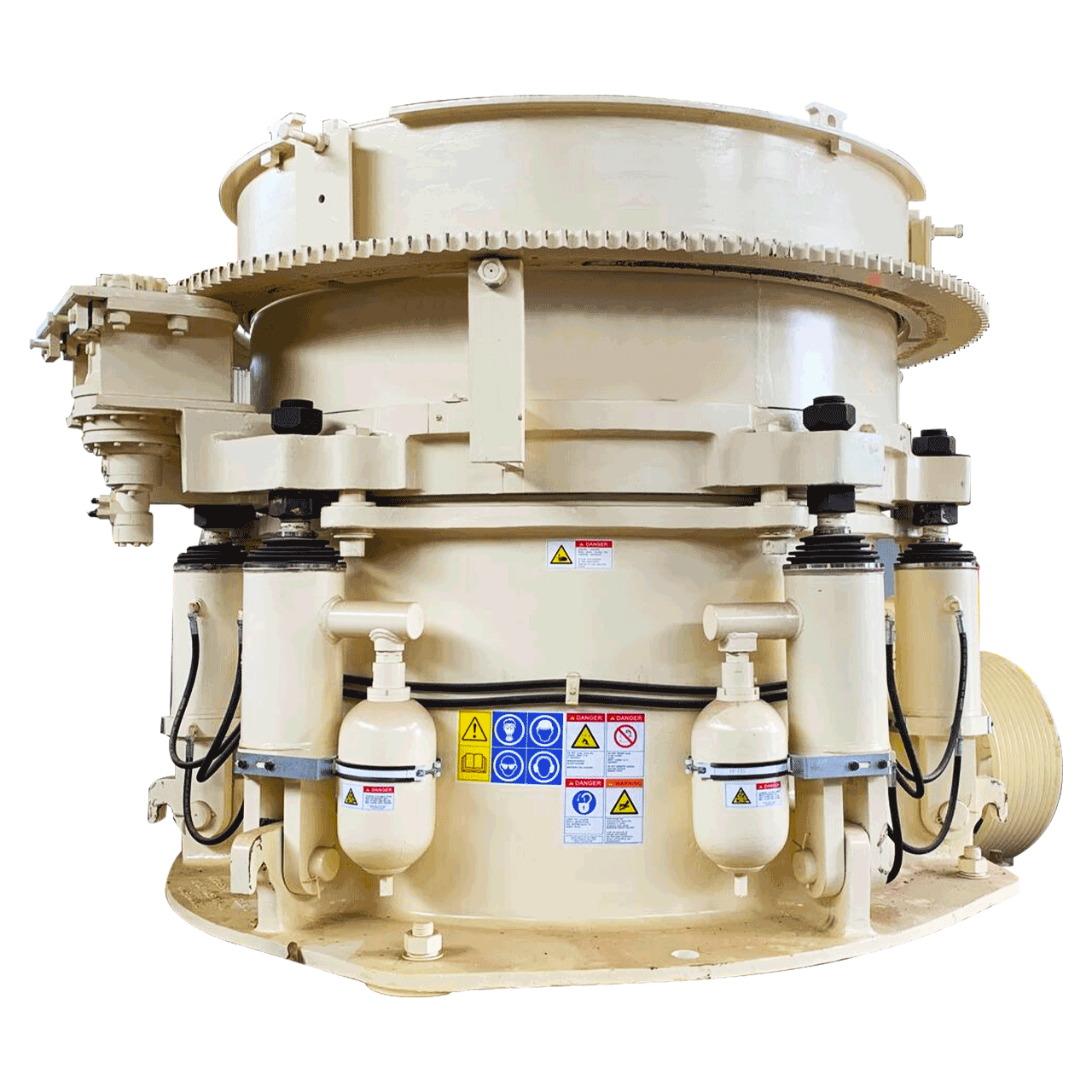

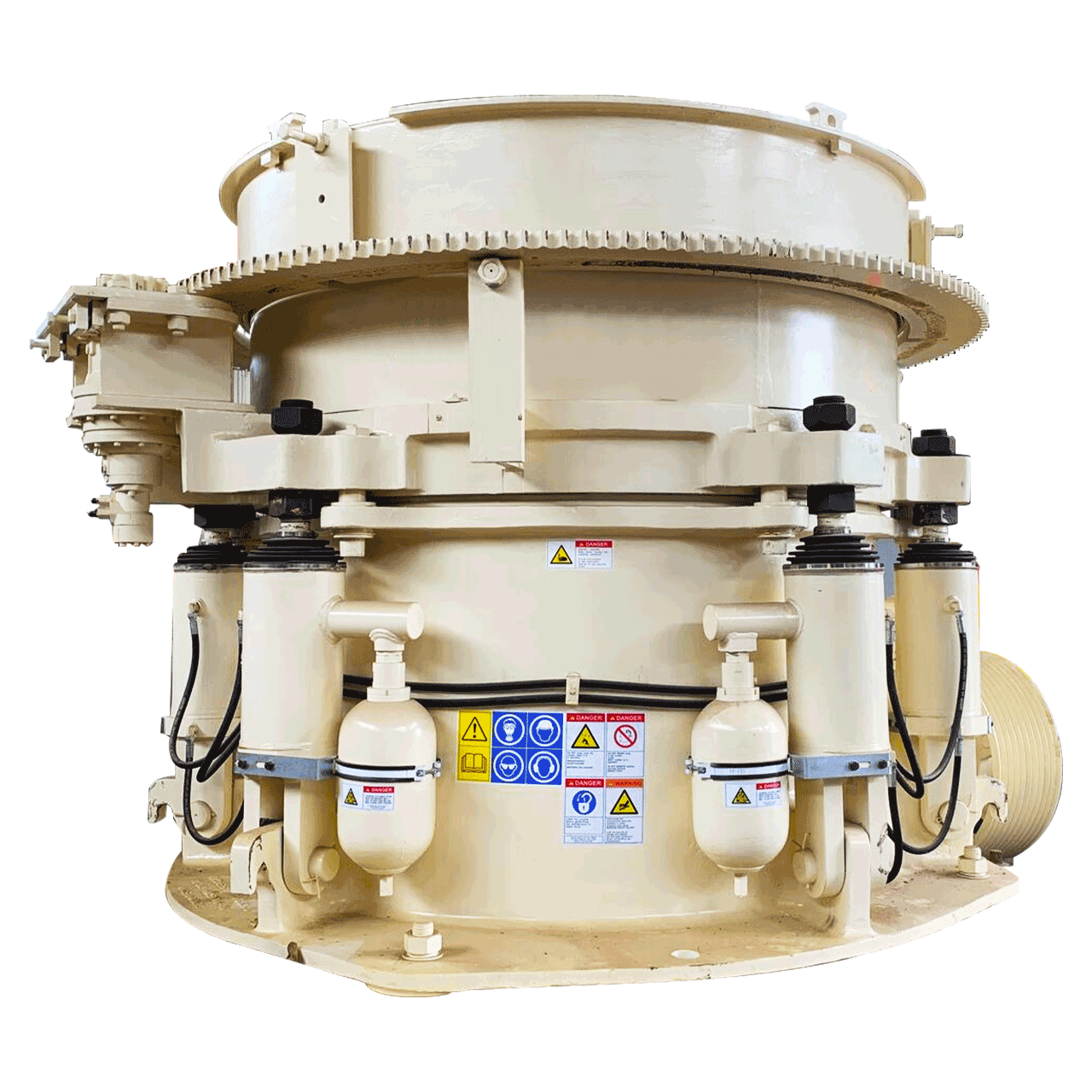

Higher production capacity:

The key technology of HP series cone crusher is to combine higher speed and stroke, so that the rated power and passing capacity of PYH series cone crusher are significantly improved, and it becomes a crusher with large capacity in the same specification.

Higher quality:

HP series cone crusher adopts the principle of "laminated crushing between particles" to make the material grade more uniform, and is used to produce stone materials. The shape of the product is more neat (mostly cubic), thus improving the advantages of the product. It is used for fine crushing in the concentrator, with finer particle size and high fine material content, thus achieving better "more crushing and less grinding" effect. The HP series cone crusher can work under a constant discharge port. By rotating the fixed cone, the discharge port is kept constant and the smoothness of the entire production process is improved. In addition, the over-iron protection device can ensure that the crusher can be reset immediately after passing through the iron block and maintain a stable discharge port. HP series cone crushers can produce finer products with fewer crushing sections, reducing costs and saving energy.

Higher yield:

By running the HP series cone crusher at a lower speed, the gradation of the product can be changed to produce less fines, better products and higher output.

Less downtime;

Under normal circumstances, HP series cone crusher two-way through the iron release hydraulic cylinder can let the iron block through the crushing chamber, while many other manufacturers of the crusher will be due to the iron stuck and stop. It may even damage the main shaft, gear, frame and other components. The hydraulic cleaning of the crushing chamber has a large stroke and has nothing to do with the wear of the lining plate, which reduces the workload required to clear the blocked material in the crushing chamber and can quickly clean the chamber, thereby shortening the downtime and reducing the labor intensity of the operator.

The hydraulic motor drives the fixed cone, which can accurately adjust the discharge port; the hydraulic motor can also make the fixed cone all turn out of the adjusting ring thread to replace the liner, thereby greatly shortening the liner replacement downtime.

The advanced lining plate fixing technology improves the reliability of the lining plate; the fixed cone lining plate is engaged with the spiral inclined surface on the upper part of the fixed cone lining plate by the wedge block to form a self-locking; and the moving cone lining plate is fastened by a self-locking lock bolt.

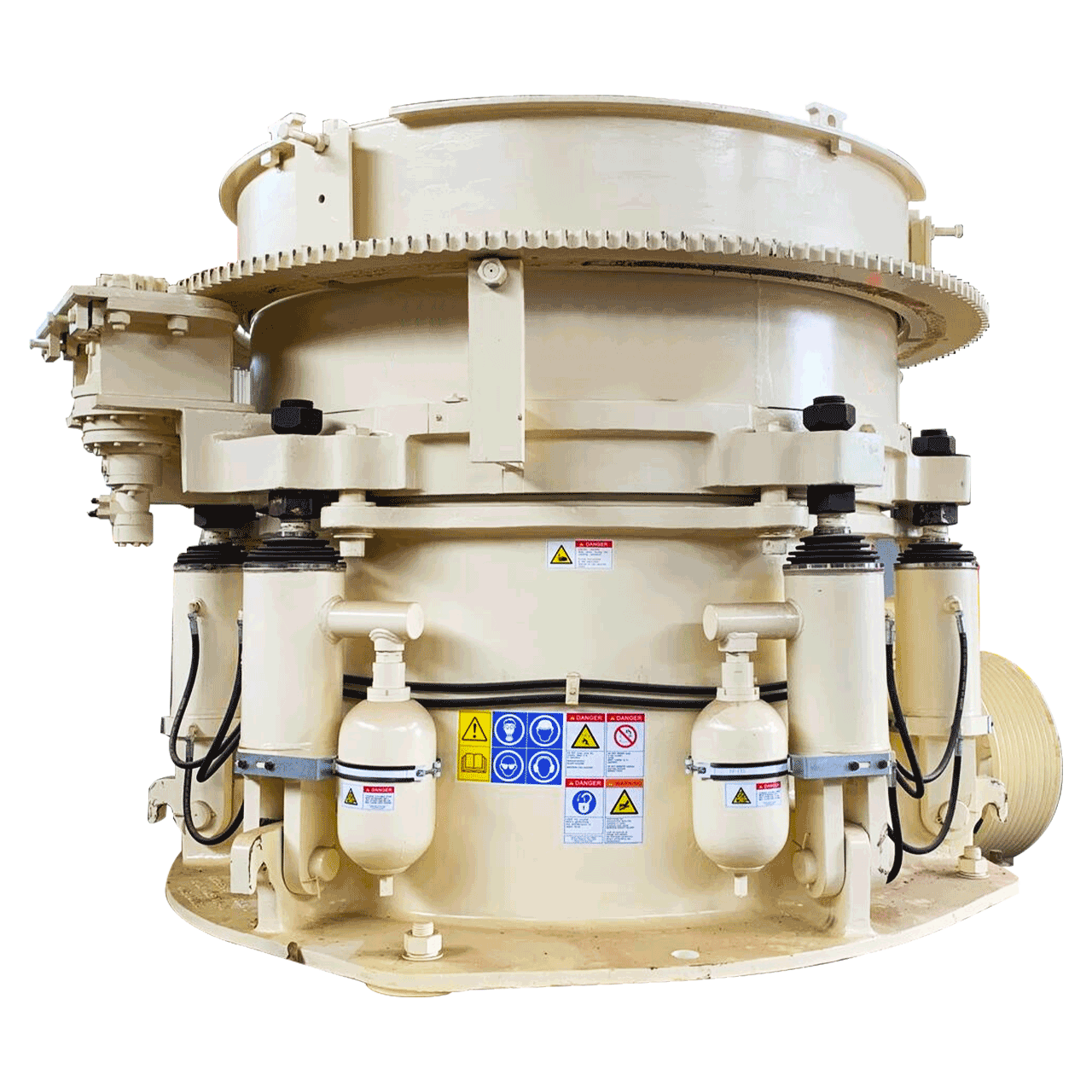

Easy to repair:

The bronze sleeve of HP series cone crusher can provide greater load capacity in the crushing environment with large vibration and dust. All parts of HP series cone crusher can be disassembled and maintained from the top or side. The moving cone and fixed cone are convenient to disassemble and assemble, and there is no need to disassemble and assemble the frame and fasten bolts. Therefore, it is more convenient to replace the lining plate of PYH series cone crusher on a daily basis.

Low maintenance costs:

High-performance non-contact labyrinth seals are wear-free and improve dust blocking reliability. The design is simple, resulting in fewer moving components in contact with rocks and dust. All parts of the crusher have wear-resistant protection: including replaceable moving cone spherical body, main frame seat liner, main frame pin sleeve, transmission shaft sleeve guard plate, counterweight guard plate, main frame liner and dead angle feed hopper, so as to reduce the maintenance cost to a low limit.

Flexible application:

HP series cone crusher can be changed from standard ultra-thick cavity type to short-head ultra-fine cavity type by replacing fixed cone lining plate, moving cone lining plate, adapter ring and crushing cavity type.

Easy to operate:

The hydraulic motor can flexibly adjust the discharge port, adjust the crushing output and other equipment to achieve balanced production, so that the crusher production efficiency is good.

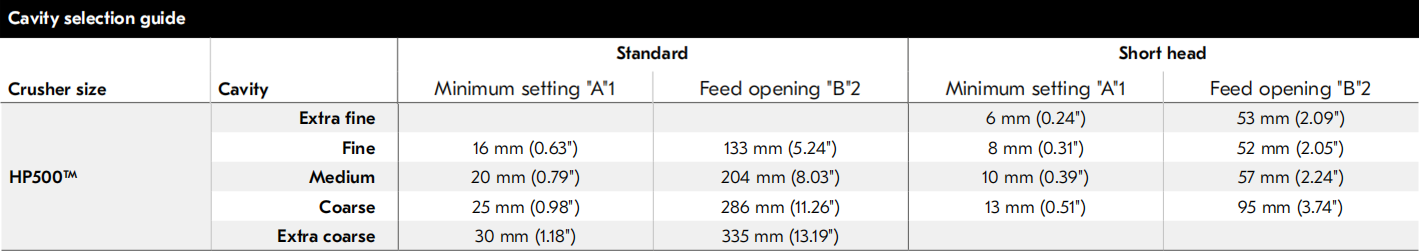

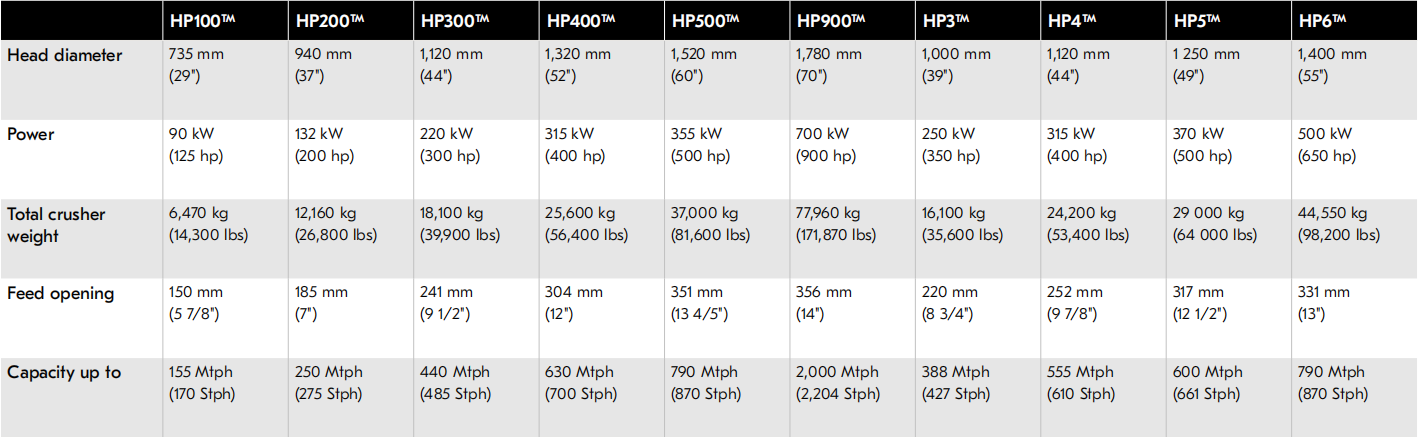

HP Series™Cone Crusher Cavity Selection Guide

cone crusher

The most popular modern cone crusher in the world

The HP series cone crusher combines crusher speed, throwing force, crushing force and cavity design.

They provide predictable and consistent production, and are trouble-free, simple and safe to operate and maintain.

Through practice, it has been proved that HP series multi-cylinder hydraulic cone crusher can provide higher production capacity, better product shape, easy automatic control, greater reliability and flexibility. It combines the essence of these technologies to create more value for customers.

Whether in the mining industry or the stone industry, if you want to increase productivity, reduce operating costs, produce ideal fine materials, and require long equipment life and high output, HP series multi-cylinder hydraulic cone crusher is your ideal choice.

HP cone crusher adaptability, is a real universal crusher. This means that the same crusher model can be used for any type of application, including all applications from coarse to ultra-fine applications, from aggregates to mining operations. They have a wide range of speed, feeding and cavity options, so you can set them up for different roles, including secondary, tertiary and quaternary crushing applications.

The HP Series features a spider-free design. This is in the second stage, because it significantly reduces the risk of clogging to ensure that the feed flows into the crusher cavity without restriction

The HP Series has built-in ease of use and is designed to make maintenance tasks fast, easy and secure. The crusher is easy to open and has a very effective impurity release system, which can effectively clean the cavity.

With the HP series, you can use a hydraulic motor to open the drum of the crusher so that the liner can be easily replaced. The hydraulic motor also rotates the drum to adjust the crusher settings.

The impurity release function is efficient and reactive, ensuring immediate opening, immediate recovery and continuous operation in the event of overload. The large cleaning stroke allows uncrushable objects to pass through the crusher cavity.

The large cleaning stroke, coupled with the double-acting hydraulic pressing cylinder, ensures that the cavity is quickly, easily and safely cleaned when the crusher stops under load due to any unexpected reason (such as a power failure in the power grid). In addition, all major components are accessible from the top for easy maintenance.

Equipment advantages:

Higher production capacity:

The key technology of HP series cone crusher is to combine higher speed and stroke, so that the rated power and passing capacity of PYH series cone crusher are significantly improved, and it becomes a crusher with large capacity in the same specification.

Higher quality:

HP series cone crusher adopts the principle of "laminated crushing between particles" to make the material grade more uniform, and is used to produce stone materials. The shape of the product is more neat (mostly cubic), thus improving the advantages of the product. It is used for fine crushing in the concentrator, with finer particle size and high fine material content, thus achieving better "more crushing and less grinding" effect. The HP series cone crusher can work under a constant discharge port. By rotating the fixed cone, the discharge port is kept constant and the smoothness of the entire production process is improved. In addition, the over-iron protection device can ensure that the crusher can be reset immediately after passing through the iron block and maintain a stable discharge port. HP series cone crushers can produce finer products with fewer crushing sections, reducing costs and saving energy.

Higher yield:

By running the HP series cone crusher at a lower speed, the gradation of the product can be changed to produce less fines, better products and higher output.

Less downtime;

Under normal circumstances, HP series cone crusher two-way through the iron release hydraulic cylinder can let the iron block through the crushing chamber, while many other manufacturers of the crusher will be due to the iron stuck and stop. It may even damage the main shaft, gear, frame and other components. The hydraulic cleaning of the crushing chamber has a large stroke and has nothing to do with the wear of the lining plate, which reduces the workload required to clear the blocked material in the crushing chamber and can quickly clean the chamber, thereby shortening the downtime and reducing the labor intensity of the operator.

The hydraulic motor drives the fixed cone, which can accurately adjust the discharge port; the hydraulic motor can also make the fixed cone all turn out of the adjusting ring thread to replace the liner, thereby greatly shortening the liner replacement downtime.

The advanced lining plate fixing technology improves the reliability of the lining plate; the fixed cone lining plate is engaged with the spiral inclined surface on the upper part of the fixed cone lining plate by the wedge block to form a self-locking; and the moving cone lining plate is fastened by a self-locking lock bolt.

Easy to repair:

The bronze sleeve of HP series cone crusher can provide greater load capacity in the crushing environment with large vibration and dust. All parts of HP series cone crusher can be disassembled and maintained from the top or side. The moving cone and fixed cone are convenient to disassemble and assemble, and there is no need to disassemble and assemble the frame and fasten bolts. Therefore, it is more convenient to replace the lining plate of PYH series cone crusher on a daily basis.

Low maintenance costs:

High-performance non-contact labyrinth seals are wear-free and improve dust blocking reliability. The design is simple, resulting in fewer moving components in contact with rocks and dust. All parts of the crusher have wear-resistant protection: including replaceable moving cone spherical body, main frame seat liner, main frame pin sleeve, transmission shaft sleeve guard plate, counterweight guard plate, main frame liner and dead angle feed hopper, so as to reduce the maintenance cost to a low limit.

Flexible application:

HP series cone crusher can be changed from standard ultra-thick cavity type to short-head ultra-fine cavity type by replacing fixed cone lining plate, moving cone lining plate, adapter ring and crushing cavity type.

Easy to operate:

The hydraulic motor can flexibly adjust the discharge port, adjust the crushing output and other equipment to achieve balanced production, so that the crusher production efficiency is good.

HP Series™Cone Crusher Cavity Selection Guide

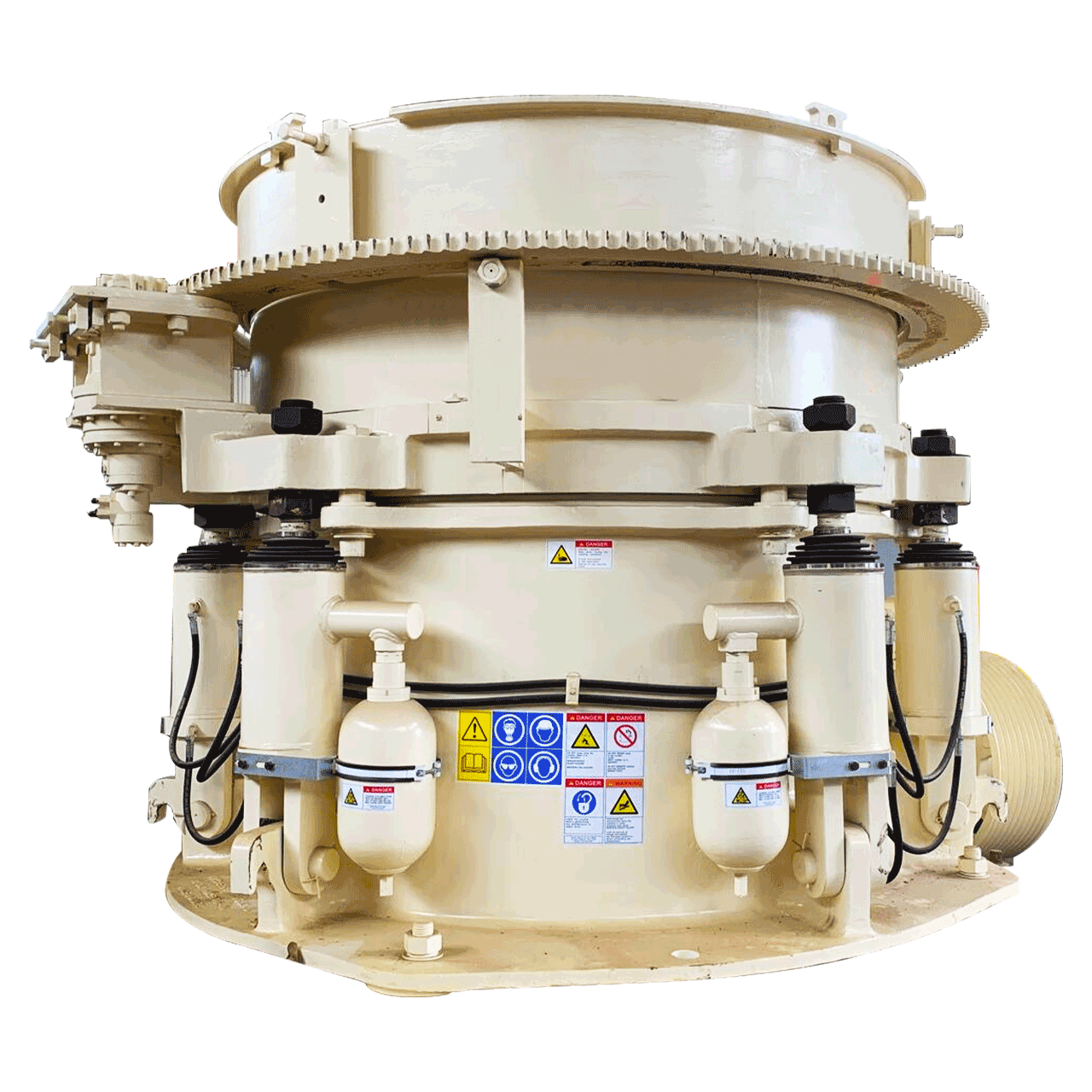

Parts List

Parts List

| Machine type | Part number |

| HP500 | 1001551459 |

| HP500 | 1001979650 |

| HP500 | 1002076250 |

| HP500 | 1002076251 |

| HP500 | 1003086077 |

| HP500 | 1003350131 |

| HP500 | 1003722043 |

| HP500 | 1003766801 |

| HP500 | 1003784543 |

| HP500 | 1003784544 |

| HP500 | 1003877072 |

| HP500 | 1003894082 |

| HP500 | 1004101991 |

| HP500 | 1005194260 |

| HP500 | 1005416097 |

| HP500 | 1010212939 |

| HP500 | 1013301443 |

| HP500 | 1013340732 |

| HP500 | 1018780324 |

| HP500 | 1019559607 |

| HP500 | 1019578940 |

| HP500 | 1019578985 |

| HP500 | 1019891330 |

| HP500 | 1020962080 |

| HP500 | 1022065500 |

| HP500 | 1022074809 |

| HP500 | 1022139802 |

| HP500 | 1022147321 |

| HP500 | 1024545540 |

| HP500 | 1025566350 |

| HP500 | 1026740202 |

| HP500 | 1026740212 |

| HP500 | 1026887780 |

| HP500 | 1027471761 |

| HP500 | 1028563422 |

| HP500 | 1031143420 |

| HP500 | 1033785562 |

| HP500 | 1035715063 |

| HP500 | 1036831527 |

| HP500 | 1036831535 |

| HP500 | 1038067481 |

| HP500 | 1038067482 |

| HP500 | 1038069595 |

| HP500 | 1044180284 |

| HP500 | 1044250910 |

| HP500 | 1044251346 |

| HP500 | 1044251593 |

| HP500 | 1044252375 |

| HP500 | 1044252612 |

| HP500 | 1044254097 |

| HP500 | 1044259094 |

| HP500 | 1044259220 |

| HP500 | 1045376019 |

| HP500 | 1047009530 |

| HP500 | 1047009535 |

| HP500 | 1047098035 |

| HP500 | 1048314236 |

| HP500 | 1048314240 |

| HP500 | 1048314241 |

| HP500 | 1048314242 |

| HP500 | 1048314243 |

| HP500 | 1048314244 |

| HP500 | 1048516296 |

| HP500 | 1048723201 |

| HP500 | 1050759592 |

| HP500 | 1051495300 |

| HP500 | 1051495302 |

| HP500 | 1054351501 |

| HP500 | 1054602417 |

| HP500 | 1055981159 |

| HP500 | 1056167923 |

| HP500 | 1057605124 |

| HP500 | 1057605167 |

| HP500 | 1057605168 |

| HP500 | 1059239349 |

| HP500 | 1059239350 |

| HP500 | 1059239430 |

| HP500 | 1059239456 |

| HP500 | 1061875592 |

| HP500 | 1061876294 |

| HP500 | 1061940190 |

| HP500 | 1062440044 |

| HP500 | 1062807442 |

| HP500 | 1063084705 |

| HP500 | 1063192846 |

| HP500 | 1063437875 |

| HP500 | 1063437877 |

| HP500 | 1063519847 |

| HP500 | 1063915542 |

| HP500 | 1063915668 |

| HP500 | 1063917605 |

| HP500 | 1064668566 |

| HP500 | 1065634356 |

| HP500 | 1068634890 |

| HP500 | 1068867278 |

| HP500 | 1070589811 |

| HP500 | 1070589813 |

| HP500 | 1070589815 |

| HP500 | 1073044085 |

| HP500 | 1073817084 |

| HP500 | 1077940062 |

| HP500 | 1080960121 |

| HP500 | 1080960122 |

| HP500 | 1083390620 |

| HP500 | 1086420534 |

| HP500 | 1086420535 |

| HP500 | 1086428322 |

| HP500 | 1093050026 |

| HP500 | 1093050057 |

| HP500 | 1093050058 |

| HP500 | 1093050067 |

| HP500 | 1093050077 |

| HP500 | 1093050095 |

| HP500 | 1093050142 |

| HP500 | 1093050156 |

| HP500 | 1093050177 |

| HP500 | 1093055002 |

| HP500 | 1093055003 |

| HP500 | 7001530252 |

| HP500 | 7001530260 |

| HP500 | 7001530881 |

| HP500 | 7001619361 |

| HP500 | 7001619362 |

| HP500 | 7001624042 |

| HP500 | 7001632042 |

| HP500 | 7002063007 |

| HP500 | 7002118071 |

| HP500 | 7002150038 |

| HP500 | 7002152733 |

| HP500 | 7002153011 |

| HP500 | 7002153021 |

| HP500 | 7002154556 |

| HP500 | 7002445612 |

| HP500 | 7002480765 |

| HP500 | 7002496011 |

| HP500 | 7002496013 |

| HP500 | 7002701335 |

| HP500 | 7003234746 |

| HP500 | 7003241826 |

| HP500 | 7003468240 |

| HP500 | 7005419218 |

| HP500 | 7015778303 |

| HP500 | 7055208502 |

| HP500 | 7055208512 |

| HP500 | 7055208514 |

| HP500 | 7055208515 |

| HP500 | 7055208516 |

| HP500 | 7055208519 |

| HP500 | 7055208520 |

| HP500 | 7055308501 |

| HP500 | 7055308503 |

| HP500 | 7055308508 |

| HP500 | 7055308509 |

| HP500 | 7055308510 |

| HP500 | 7068606758 |

| HP500 | 7070005002 |

| HP500 | 7082404310 |

| HP500 | 7086401294 |

| HP500 | 7090058016 |

| HP500 | 80210808000 |

| HP500 | MM0201915 |

| HP500 | MM0204786 |

| HP500 | MM0206355 |

| HP500 | MM0206356 |

| HP500 | MM0208694 |

| HP500 | MM0209393 |

| HP500 | MM0210796 |

| HP500 | MM0211462 |

| HP500 | MM0212288 |

| HP500 | MM0214476 |

| HP500 | MM0215024 |

| HP500 | MM0215746 |

| HP500 | MM0216285 |

| HP500 | MM0216362 |

| HP500 | MM0216363 |

| HP500 | MM0216563 |

| HP500 | MM0217030 |

| HP500 | MM0217273 |

| HP500 | MM0219075 |

| HP500 | MM0221950 |

| HP500 | MM0221951 |

| HP500 | MM0225904 |

| HP500 | MM0225905 |

| HP500 | MM0228707 |

| HP500 | MM0231028 |

| HP500 | MM0232494 |

| HP500 | MM0232508 |

| HP500 | MM0232512 |

| HP500 | MM0232517 |

| HP500 | MM0232715 |

| HP500 | MM0232725 |

| HP500 | MM0232727 |

| HP500 | MM0232736 |

| HP500 | MM0232739 |

| HP500 | MM0232783 |

| HP500 | MM0233599 |

| HP500 | MM0233613 |

| HP500 | MM0233614 |

| HP500 | MM0234583 |

| HP500 | MM0234584 |

| HP500 | MM0237246 |

| HP500 | MM0237480 |

| HP500 | MM0237695 |

| HP500 | MM0237699 |

| HP500 | MM0255476 |

| HP500 | MM0257859 |

| HP500 | MM0269710 |

| HP500 | MM0271334 |

| HP500 | MM0271994 |

| HP500 | MM0276792 |

| HP500 | MM0276804 |

| HP500 | MM0276823 |

| HP500 | MM0300842 |

| HP500 | MM0308927 |

| HP500 | MM0309026 |

| HP500 | MM0309058 |

| HP500 | MM0309068 |

| HP500 | MM0309072 |

| HP500 | MM0309776 |

| HP500 | MM0309778 |

| HP500 | MM0309779 |

| HP500 | MM0324789 |

| HP500 | MM0349516 |

| HP500 | MM0349563 |

| HP500 | N01530197 |

| HP500 | N01530414 |

| HP500 | N01530891 |

| HP500 | N01540213 |

| HP500 | N01602100 |

| HP500 | N01619334 |

| HP500 | N01626010 |

| HP500 | N01632012 |

| HP500 | N01632014 |

| HP500 | N01632020 |

| HP500 | N02016028 |

| HP500 | N02111021 |

| HP500 | N02111024 |

| HP500 | N02111025 |

| HP500 | N02111026 |

| HP500 | N02111027 |

| HP500 | N02111028 |

| HP500 | N02111029 |

| HP500 | N02111201 |

| HP500 | N02111931 |

| HP500 | N02123603 |

| HP500 | N02125057 |

| HP500 | N02150053 |

| HP500 | N02152742 |

| HP500 | N02420171 |

| HP500 | N02430306 |

| HP500 | N02440354 |

| HP500 | N02440355 |

| HP500 | N02445272 |

| HP500 | N02445275 |

| HP500 | N02445277 |

| HP500 | N02445305 |

| HP500 | N02445735 |

| HP500 | N02445787 |

| HP500 | N02445788 |

| HP500 | N02482104 |

| HP500 | N02482131 |

| HP500 | N02482132 |

| HP500 | N02701314 |

| HP500 | N03225200 |

| HP500 | N03239265 |

| HP500 | N03241799 |

| HP500 | N05227167 |

| HP500 | N05472060 |

| HP500 | N05551004 |

| HP500 | N05551508 |

| HP500 | N05551509 |

| HP500 | N05551510 |

| HP500 | N10150005 |

| HP500 | N12504014 |

| HP500 | N15655252 |

| HP500 | N15656212 |

| HP500 | N15778310 |

| HP500 | N16200141 |

| HP500 | N21900353 |

| HP500 | N22072102 |

| HP500 | N22300505 |

| HP500 | N22300512 |

| HP500 | N23508202 |

| HP500 | N28453766 |

| HP500 | N29201519 |

| HP500 | N29201537 |

| HP500 | N29201550 |

| HP500 | N29201796 |

| HP500 | N29201814 |

| HP500 | N41060201 |

| HP500 | N43358025 |

| HP500 | N44453803 |

| HP500 | N47811527 |

| HP500 | N53001021 |

| HP500 | N53140025 |

| HP500 | N55208528 |

| HP500 | N55208532 |

| HP500 | N55308514 |

| HP500 | N55308515 |

| HP500 | N55308516 |

| HP500 | N55308520 |

| HP500 | N65900105 |

| HP500 | N68606505 |

| HP500 | N68606766 |

| HP500 | N68607258 |

| HP500 | N70000754 |

| HP500 | N70002001 |

| HP500 | N70009501 |

| HP500 | N80200504 |

| HP500 | N80500504 |

| HP500 | N80500516 |

| HP500 | N80500524 |

| HP500 | N80500682 |

| HP500 | N81108010 |

| HP500 | N84500506 |

| HP500 | N85701305 |

| HP500 | N86129603 |

| HP500 | N86401300 |

| HP500 | N86402572 |

| HP500 | N86402576 |

| HP500 | N86402801 |

| HP500 | N86402802 |

| HP500 | N86402803 |

| HP500 | N86402806 |

| HP500 | N86402809 |

| HP500 | N86402810 |

| HP500 | N90008044 |

| HP500 | N90148029 |

| HP500 | N90158014 |

| HP500 | N90158036 |

| HP500 | N90198522 |

| HP500 | N90198829 |

| HP500 | N90228123 |

| HP500 | N90248014 |

| HP500 | N90248508 |

| HP500 | N90258006 |

| HP500 | N90390002 |

| HP500 | N90390011 |

| HP500 | ZX11216799 |

| HP500 | ZX93000224 |

Can't see the part number you are looking for?

Please conact us

Please conact us

People who seen this item also look

Ratings and Reviews