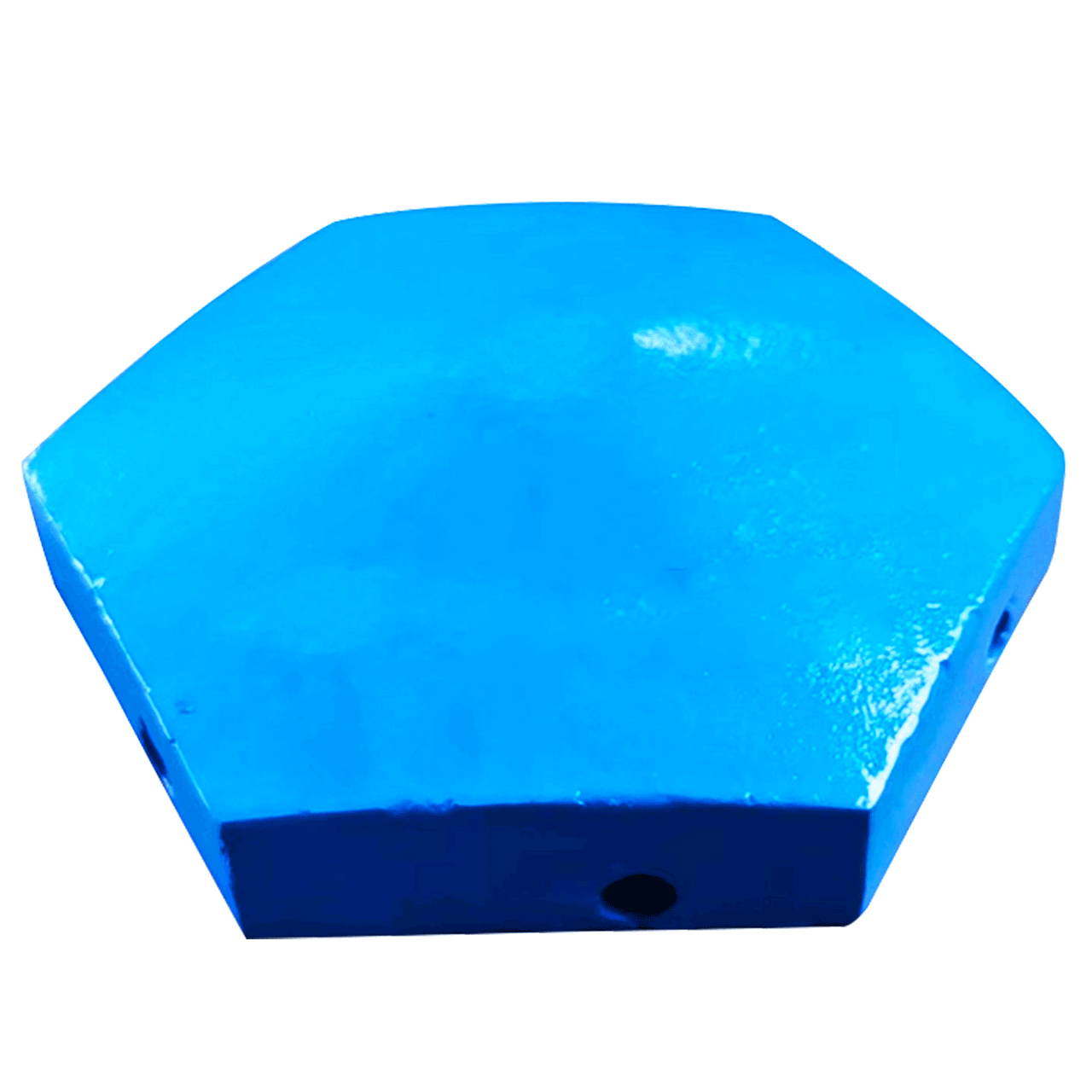

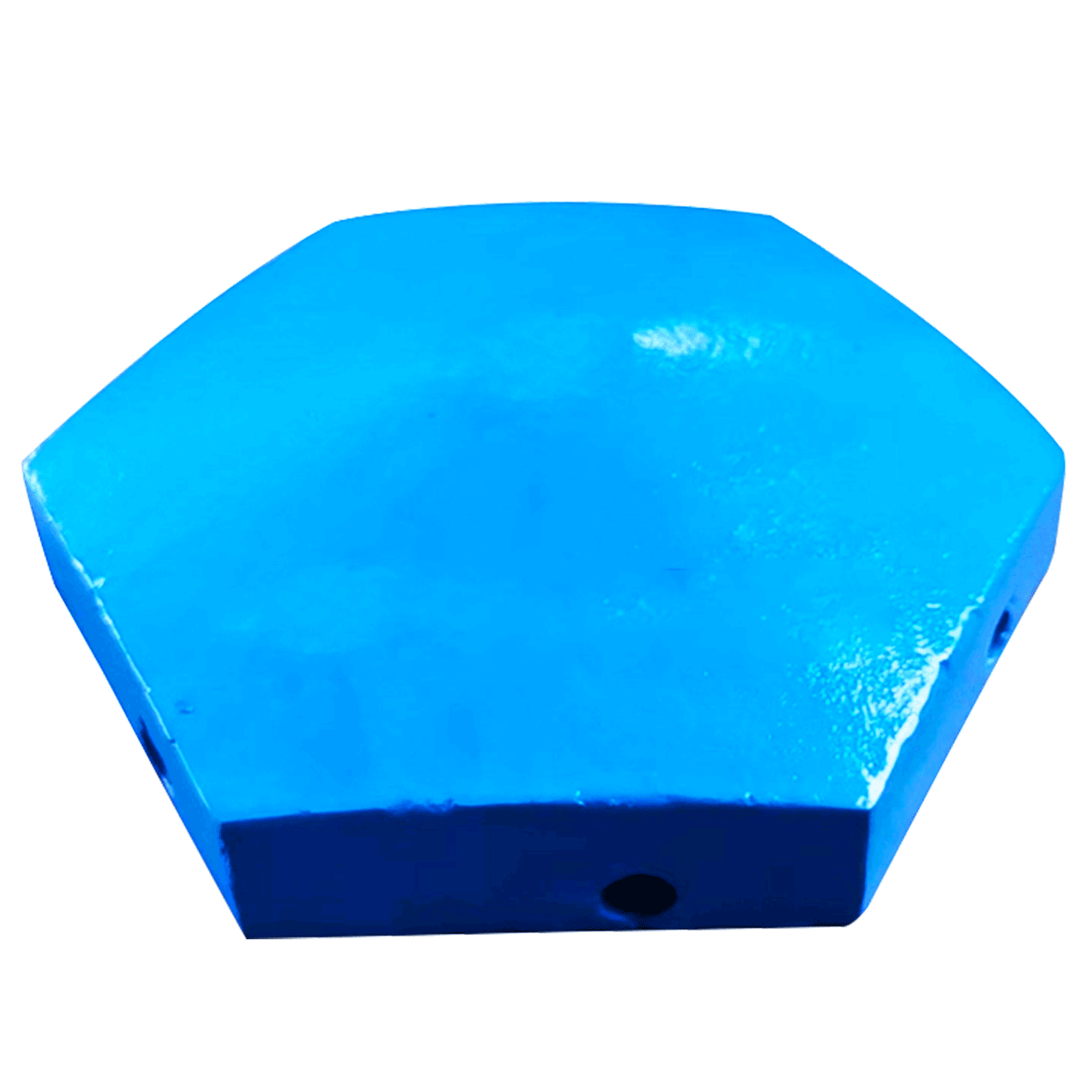

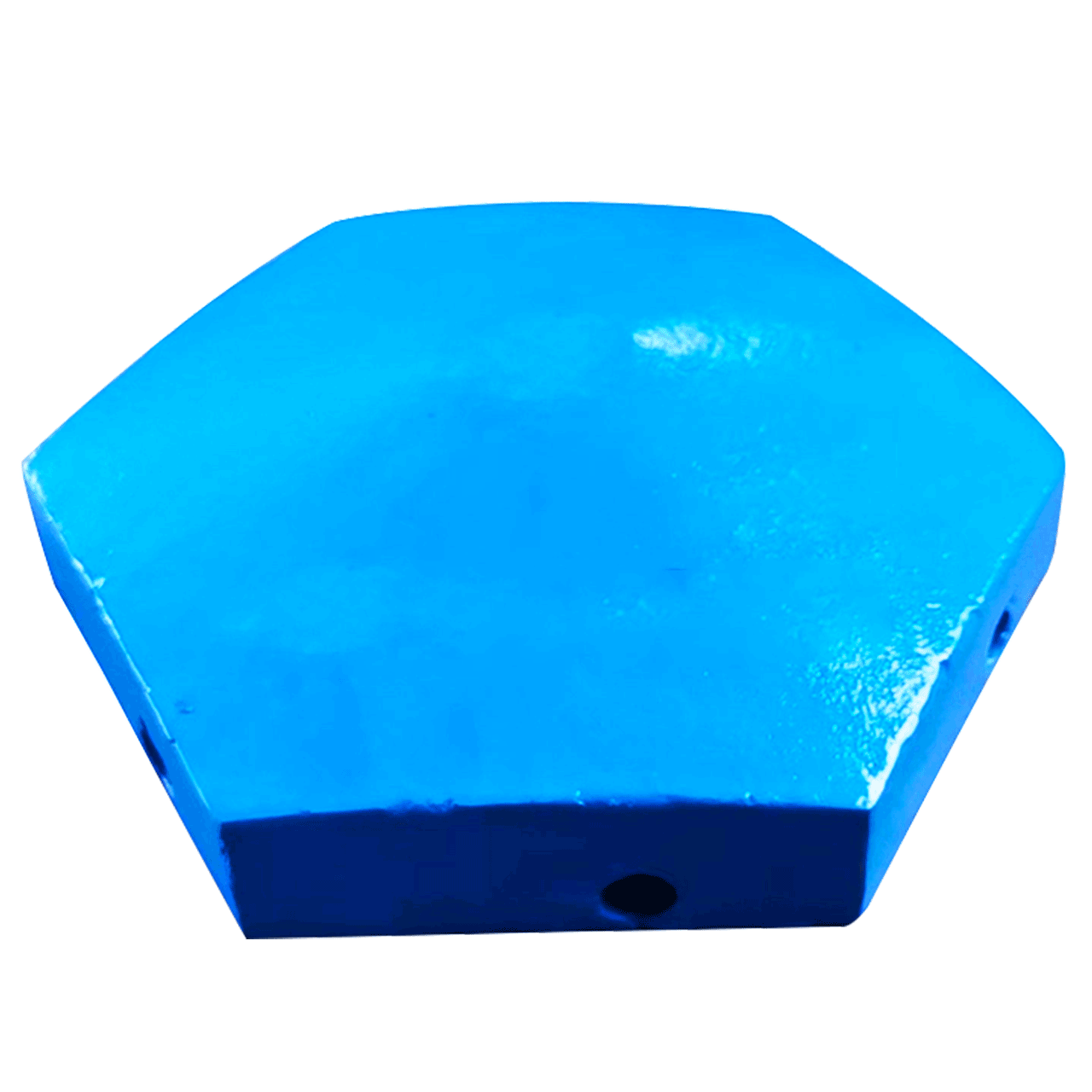

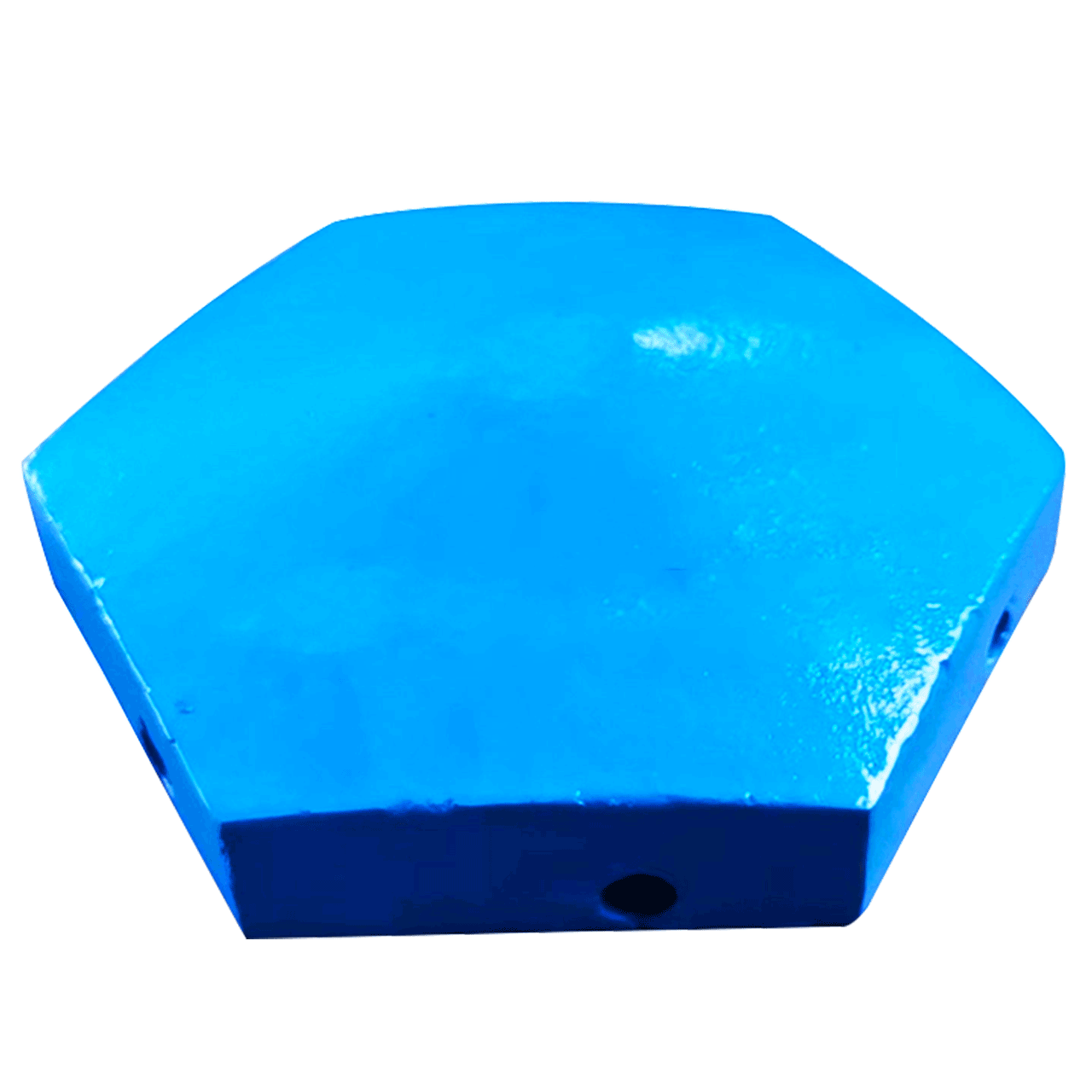

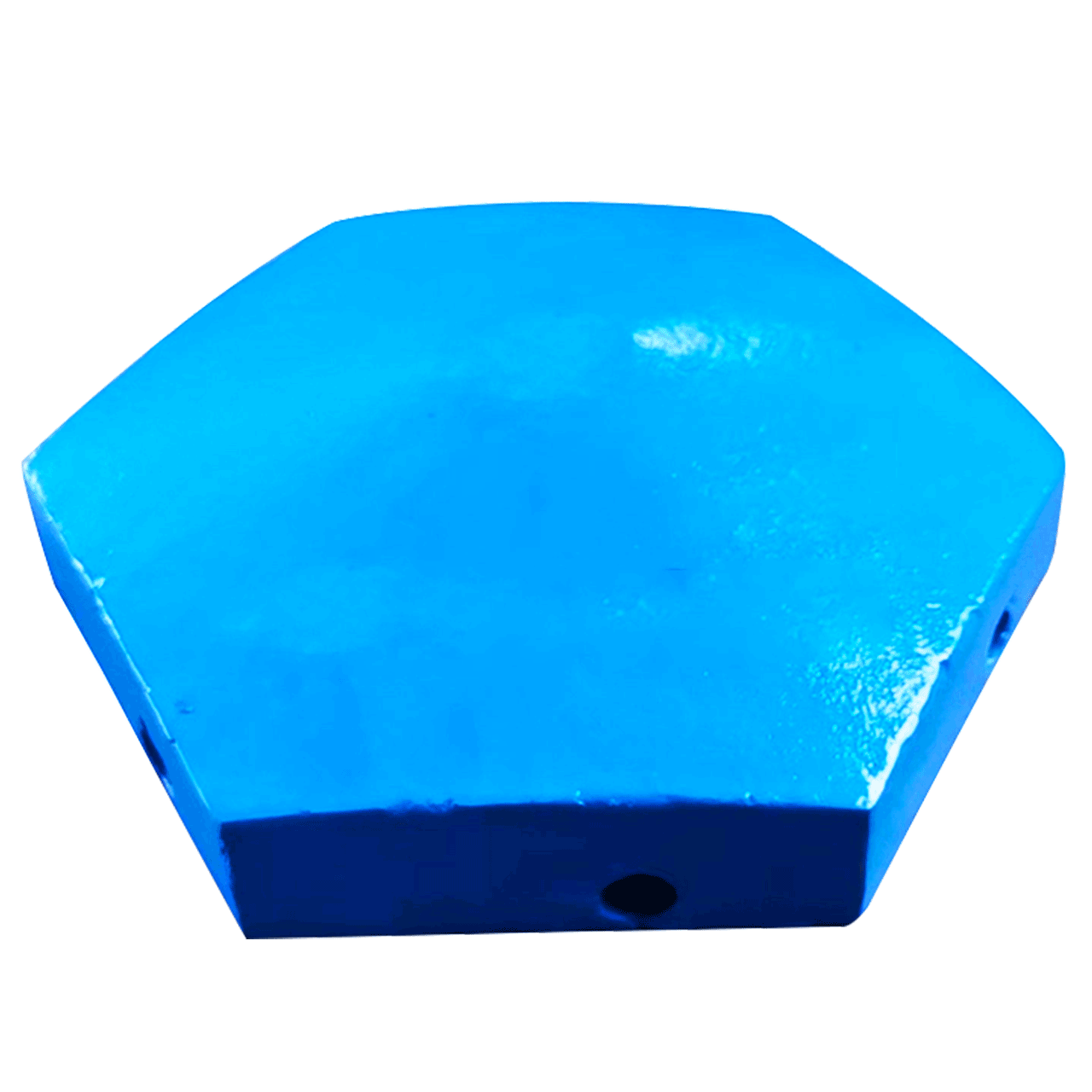

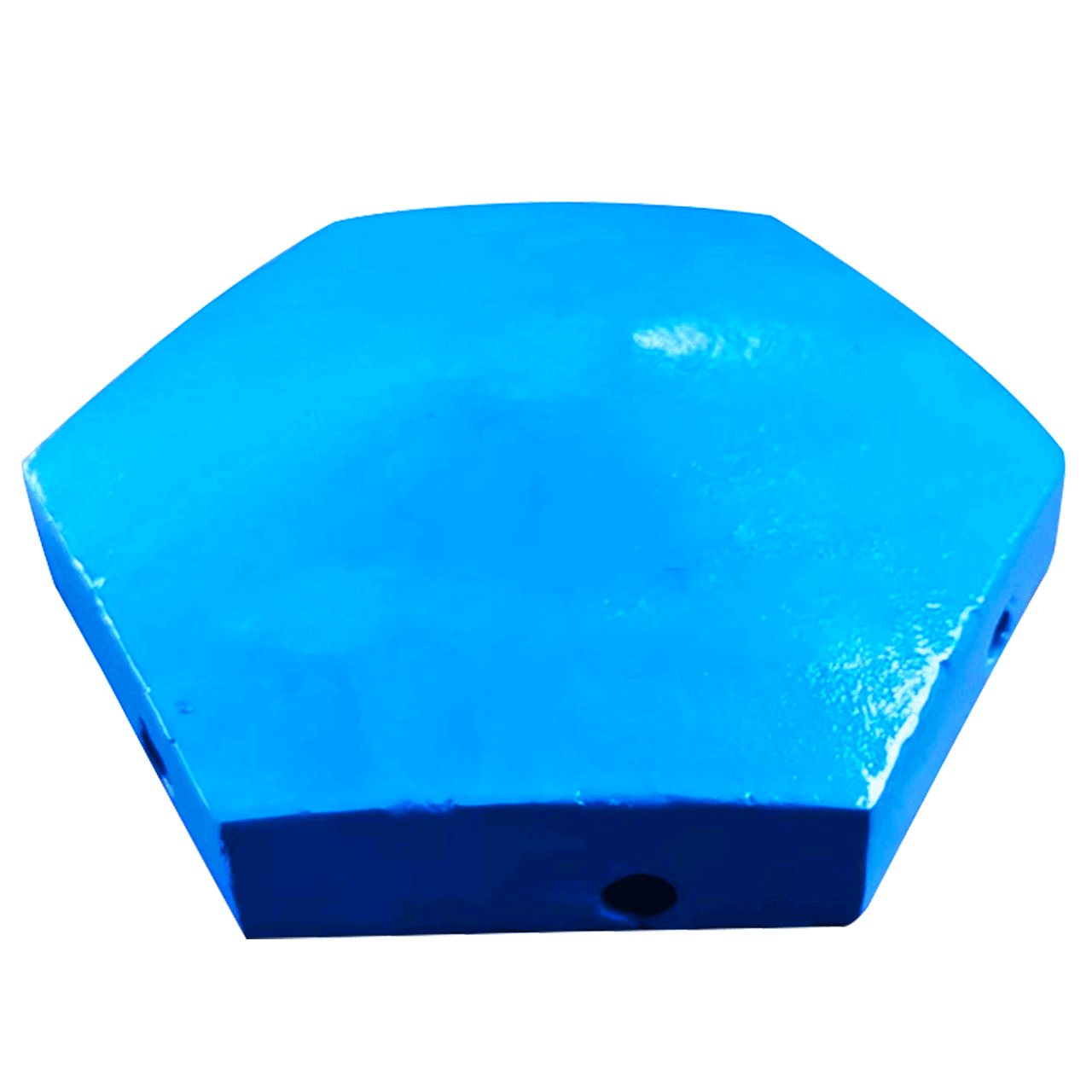

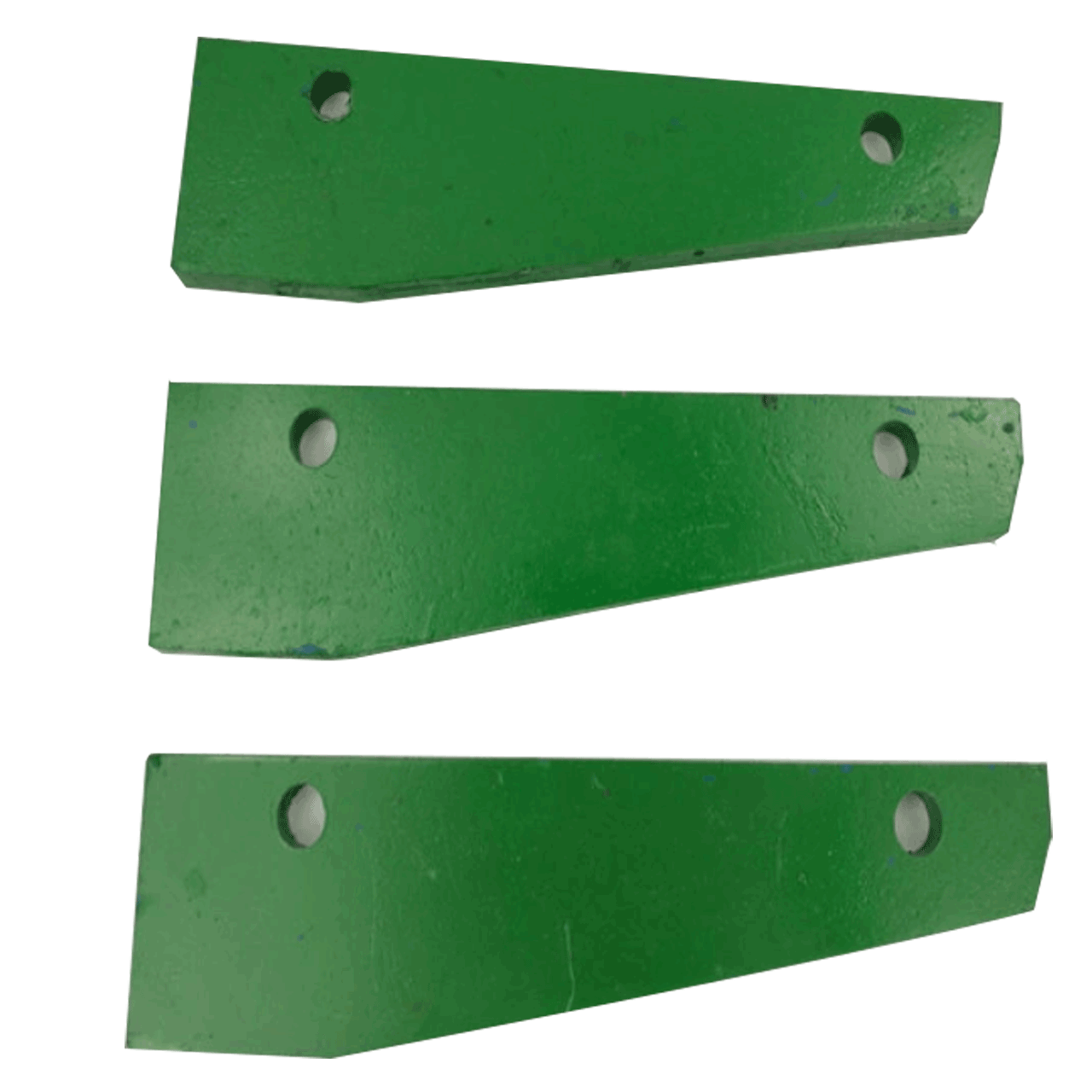

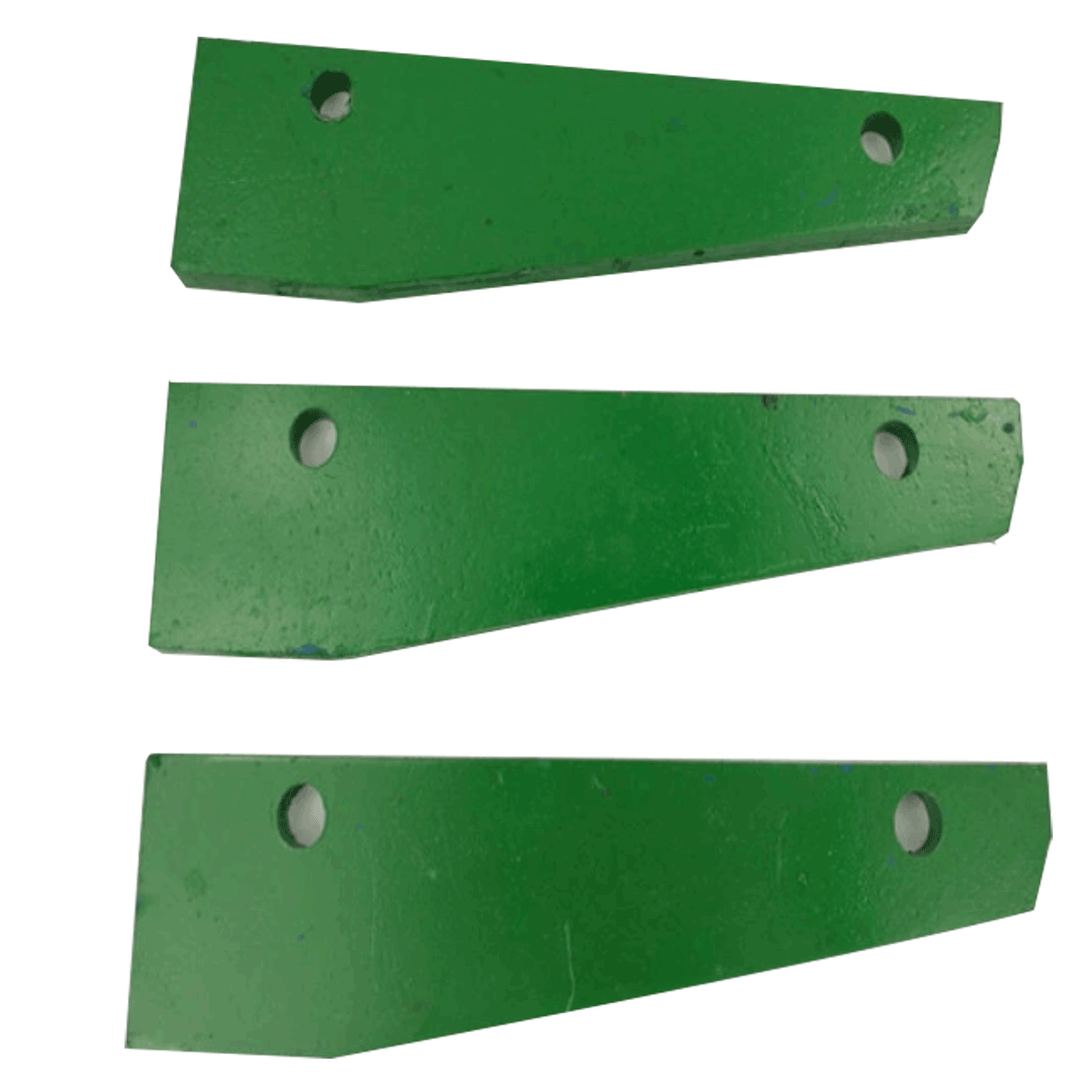

VSI Crusher Upper and Lower Wear Plate

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

In a VSI (Vertical Shaft Impact) crusher, the upper and lower wear plates are key components that protect the internal structure of the crusher from wear and damage caused by the high impact environment. Below is a detailed overview of these wear plates, including material information:

Upper Wear Plate

Function: Upper wear plates are typically located at the top of the crushing chamber to help direct incoming material to the rotor and protect the internals from wear.

Material: Typically made from a high chrome alloy (e.g. high chrome cast iron) or other wear-resistant material (e.g. composite ceramic material) to withstand the impact and abrasion of the material being crushed.

Maintenance: Regular inspections are essential as wear can lead to reduced efficiency and increased operating costs. Replacement should be made when significant wear is observed.

Lower Wear Plate

Function: Located at the bottom of the crushing chamber, the lower wear plate absorbs the impact of the material being discharged from the rotor and helps shape the output product.

Material: Usually also made of high chrome alloy or wear-resistant steel (e.g., wear-resistant steel plate or high wear-resistant alloys) to extend its service life.

Maintenance: As with the upper wear plate, it should be monitored for wear and replaced as necessary to maintain efficient operation.

Key Considerations

Wear Patterns: Understanding wear patterns can help adjust the crushing process and optimize the use of wear plates.

Installation: Correct installation is critical to the effective operation of wear plates. Ensure they are installed correctly to avoid gaps that could lead to premature wear.

Cost management: Regular monitoring and timely replacement of wear plates can prevent more extensive damage and costly repairs.

Why you need these spare parts

Increased productivity: Wear plates provide protection against wear and ensure that the crusher continues to operate efficiently, avoiding production stoppages due to wear and tear.

Reduce maintenance costs: Regular replacement of wear plates prevents wider plant damage, reducing costly repairs and downtime.

Extend equipment life: High-quality wear plates protect the internal structure, extending the life of the entire crusher and improving return on investment.

Optimize product quality: Maintaining crusher stability and efficiency helps ensure consistency and quality of the final product.

Enhance safety: Good wear plates reduce the risk of equipment failure and protect the safety of operators.

Summarize

The upper and lower wear plates in a VSI crusher are key to ensuring proper operation and efficient production. If you want to increase productivity, reduce maintenance costs and extend the life of your equipment, investing in high-quality wear plates is the smart choice. For more information or advice, please feel free to ask!

Upper Wear Plate

Function: Upper wear plates are typically located at the top of the crushing chamber to help direct incoming material to the rotor and protect the internals from wear.

Material: Typically made from a high chrome alloy (e.g. high chrome cast iron) or other wear-resistant material (e.g. composite ceramic material) to withstand the impact and abrasion of the material being crushed.

Maintenance: Regular inspections are essential as wear can lead to reduced efficiency and increased operating costs. Replacement should be made when significant wear is observed.

Lower Wear Plate

Function: Located at the bottom of the crushing chamber, the lower wear plate absorbs the impact of the material being discharged from the rotor and helps shape the output product.

Material: Usually also made of high chrome alloy or wear-resistant steel (e.g., wear-resistant steel plate or high wear-resistant alloys) to extend its service life.

Maintenance: As with the upper wear plate, it should be monitored for wear and replaced as necessary to maintain efficient operation.

Key Considerations

Wear Patterns: Understanding wear patterns can help adjust the crushing process and optimize the use of wear plates.

Installation: Correct installation is critical to the effective operation of wear plates. Ensure they are installed correctly to avoid gaps that could lead to premature wear.

Cost management: Regular monitoring and timely replacement of wear plates can prevent more extensive damage and costly repairs.

Why you need these spare parts

Increased productivity: Wear plates provide protection against wear and ensure that the crusher continues to operate efficiently, avoiding production stoppages due to wear and tear.

Reduce maintenance costs: Regular replacement of wear plates prevents wider plant damage, reducing costly repairs and downtime.

Extend equipment life: High-quality wear plates protect the internal structure, extending the life of the entire crusher and improving return on investment.

Optimize product quality: Maintaining crusher stability and efficiency helps ensure consistency and quality of the final product.

Enhance safety: Good wear plates reduce the risk of equipment failure and protect the safety of operators.

Summarize

The upper and lower wear plates in a VSI crusher are key to ensuring proper operation and efficient production. If you want to increase productivity, reduce maintenance costs and extend the life of your equipment, investing in high-quality wear plates is the smart choice. For more information or advice, please feel free to ask!

Parts List