circular-vibrating-screen

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Category :Screening /

Description

Description

Circular vibrating screen is designed to use a single excitation source drive to produce inertia force around the fixed axis, the direction of sinusoidal law change, to realize the circular vibration of the screen box assembly.

Moretec circular vibrating screen can be applied to the classification, coarse separation and dewatering of silica sand, feldspar, coal, iron ore, gold ore and other materials. The screen box assembly of the equipment is arranged in a single layer with multiple segments, and a vibration motor is used as a single excitation source to drive and realize the circular vibration of the screen box assembly. The equipment has the advantages of large screening area, adjustable screen box angle, compact structure, excellent performance and high cost performance. The equipment has unique vibration mode, energy saving, high screening efficiency, large capacity, advanced technology, simple structure, stable and reliable operation, and it is the advanced equipment in the field of fine-grained material screening at present.Mizztech high shear circular vibrating screen can all adopt flexible polyurethane fine screen mesh, with a high rate of opening (28-45%), and an average service life of more than 6 months.

Circular vibrating screen features

Moretec circular vibrating screen adopts a single vibrating motor as the vibration source to make the screen box assembly do circular motion.

It adopts advanced technology imported excitation motor (Martin motor or OLI motor), which is reliable and has long trouble-free operation time.

The screen box assembly is arranged in multiple sections, which has the advantages of large handling capacity, high screening efficiency, low power consumption, small dynamic load, simple operation, stable performance, safety and durability, and low maintenance.

The angle adjustment of the screen box assembly is convenient and reliable, and the reclaimed slurry water spray is added between each section of screen mesh to increase the screening effect of materials.

The overall heat treatment of the screen box can meet the high vibration intensity for a long time.

International famous brand electrical components, Siemens or Schneider components.

Flexible polyurethane screen mesh, good elasticity, not easy to block the mesh, can be installed four to five mesh, and low noise in the vibration of the equipment.

The screen mesh is fixed by pulling mesh bolt assembly, which is convenient to operate, reliable to fasten, and easy to check, dismantle and install the screen mesh.

The surface treatment of vibrating screen adopts sand blasting treatment process, spraying heavy anticorrosion paint with good anticorrosion performance, and the contact surface with materials adopts the form of spraying polyurea resin wear-resistant anticorrosion layer or pasting wear-resistant rubber plate to protect the surface of the sieve machine and prolong the service life of the sieve machine.

Moretec circular vibrating screen can be applied to the classification, coarse separation and dewatering of silica sand, feldspar, coal, iron ore, gold ore and other materials. The screen box assembly of the equipment is arranged in a single layer with multiple segments, and a vibration motor is used as a single excitation source to drive and realize the circular vibration of the screen box assembly. The equipment has the advantages of large screening area, adjustable screen box angle, compact structure, excellent performance and high cost performance. The equipment has unique vibration mode, energy saving, high screening efficiency, large capacity, advanced technology, simple structure, stable and reliable operation, and it is the advanced equipment in the field of fine-grained material screening at present.Mizztech high shear circular vibrating screen can all adopt flexible polyurethane fine screen mesh, with a high rate of opening (28-45%), and an average service life of more than 6 months.

Circular vibrating screen features

Moretec circular vibrating screen adopts a single vibrating motor as the vibration source to make the screen box assembly do circular motion.

It adopts advanced technology imported excitation motor (Martin motor or OLI motor), which is reliable and has long trouble-free operation time.

The screen box assembly is arranged in multiple sections, which has the advantages of large handling capacity, high screening efficiency, low power consumption, small dynamic load, simple operation, stable performance, safety and durability, and low maintenance.

The angle adjustment of the screen box assembly is convenient and reliable, and the reclaimed slurry water spray is added between each section of screen mesh to increase the screening effect of materials.

The overall heat treatment of the screen box can meet the high vibration intensity for a long time.

International famous brand electrical components, Siemens or Schneider components.

Flexible polyurethane screen mesh, good elasticity, not easy to block the mesh, can be installed four to five mesh, and low noise in the vibration of the equipment.

The screen mesh is fixed by pulling mesh bolt assembly, which is convenient to operate, reliable to fasten, and easy to check, dismantle and install the screen mesh.

The surface treatment of vibrating screen adopts sand blasting treatment process, spraying heavy anticorrosion paint with good anticorrosion performance, and the contact surface with materials adopts the form of spraying polyurea resin wear-resistant anticorrosion layer or pasting wear-resistant rubber plate to protect the surface of the sieve machine and prolong the service life of the sieve machine.

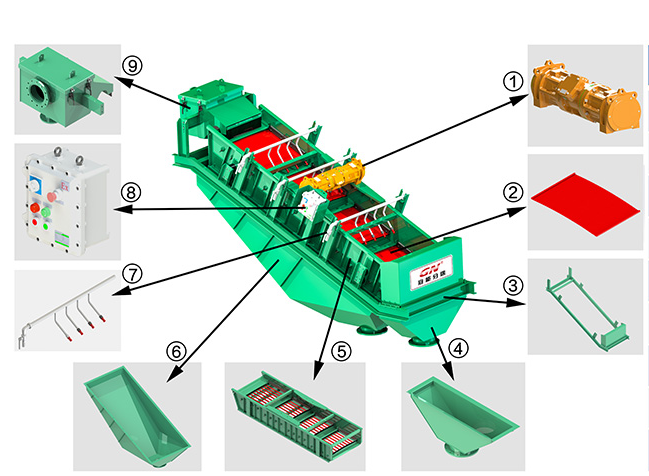

Parts List