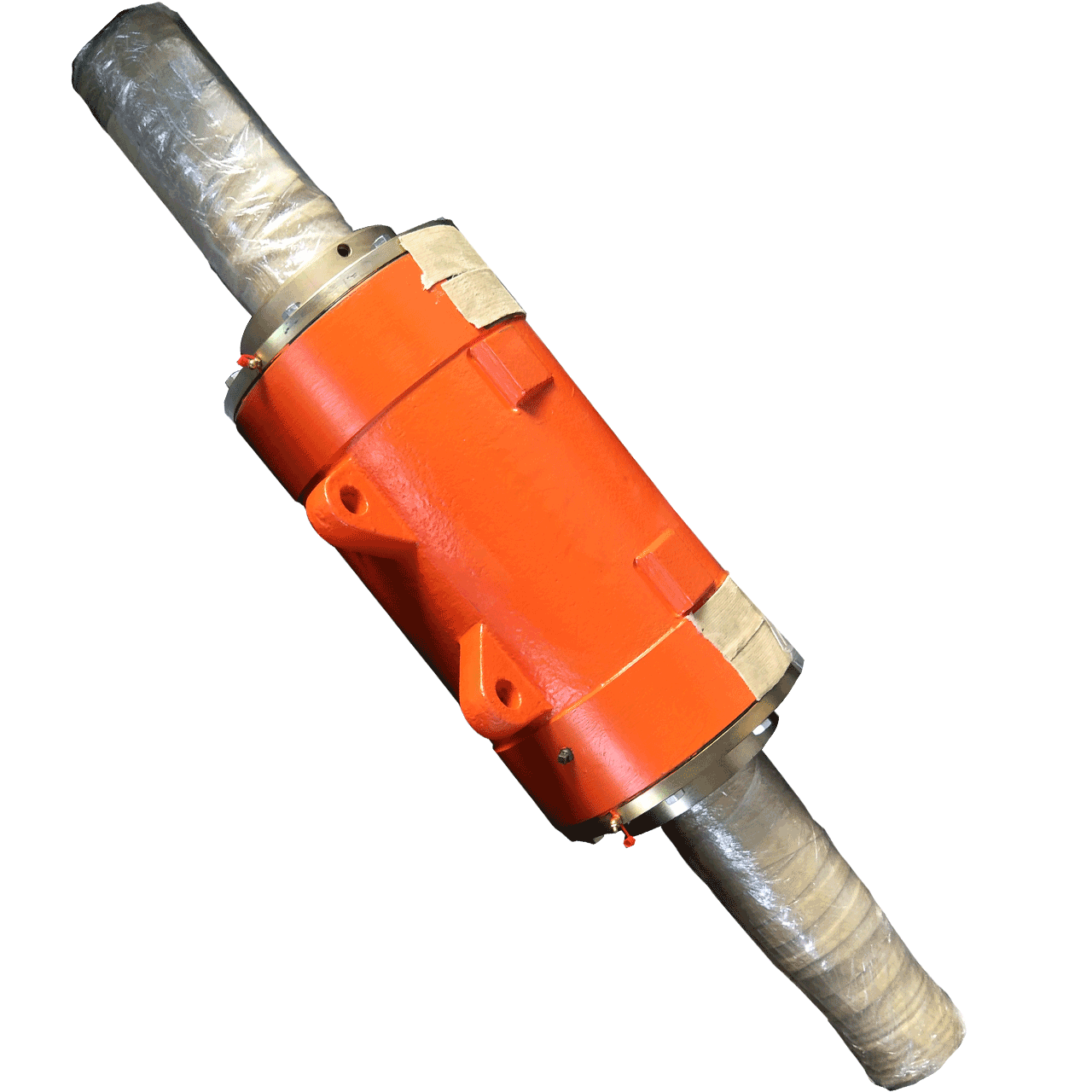

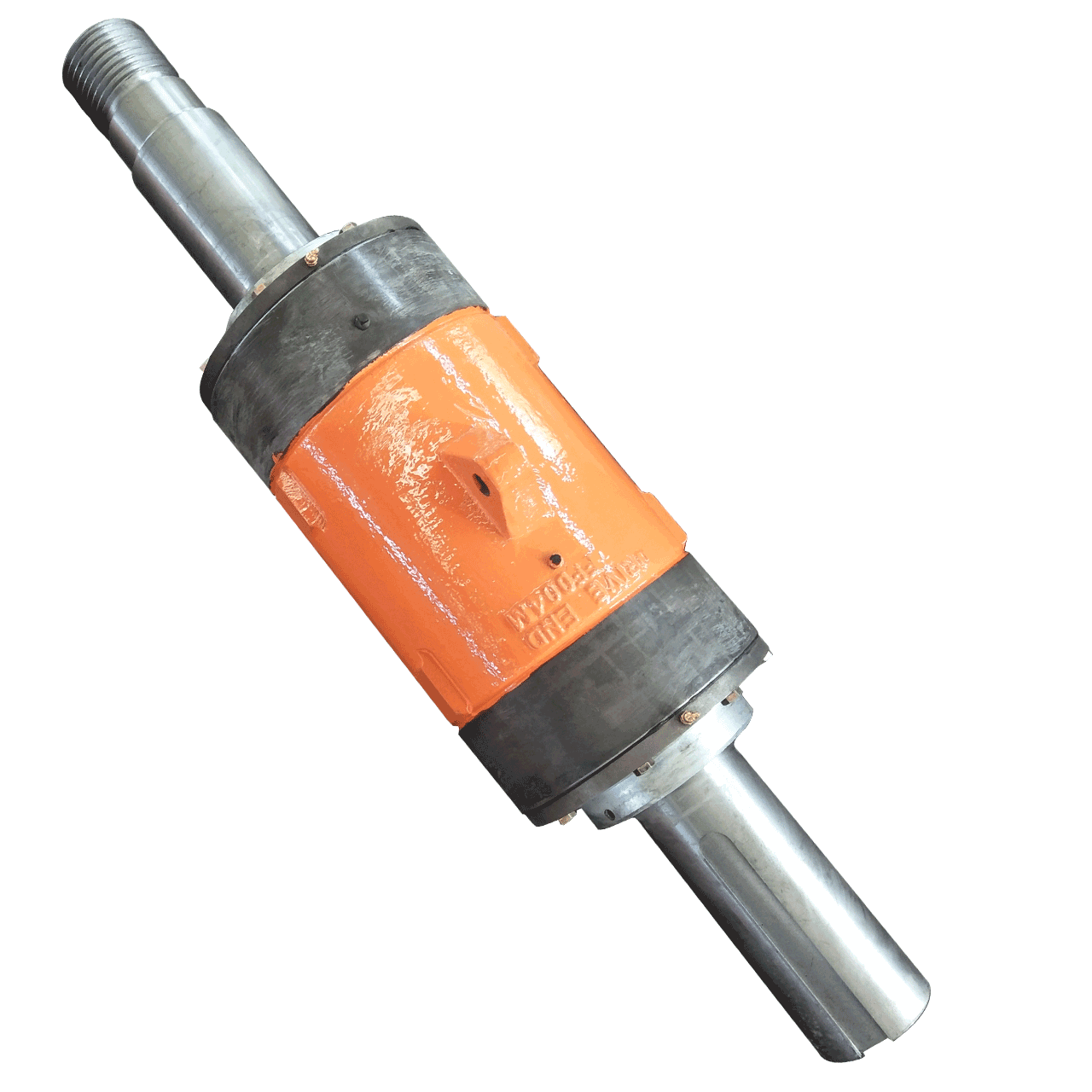

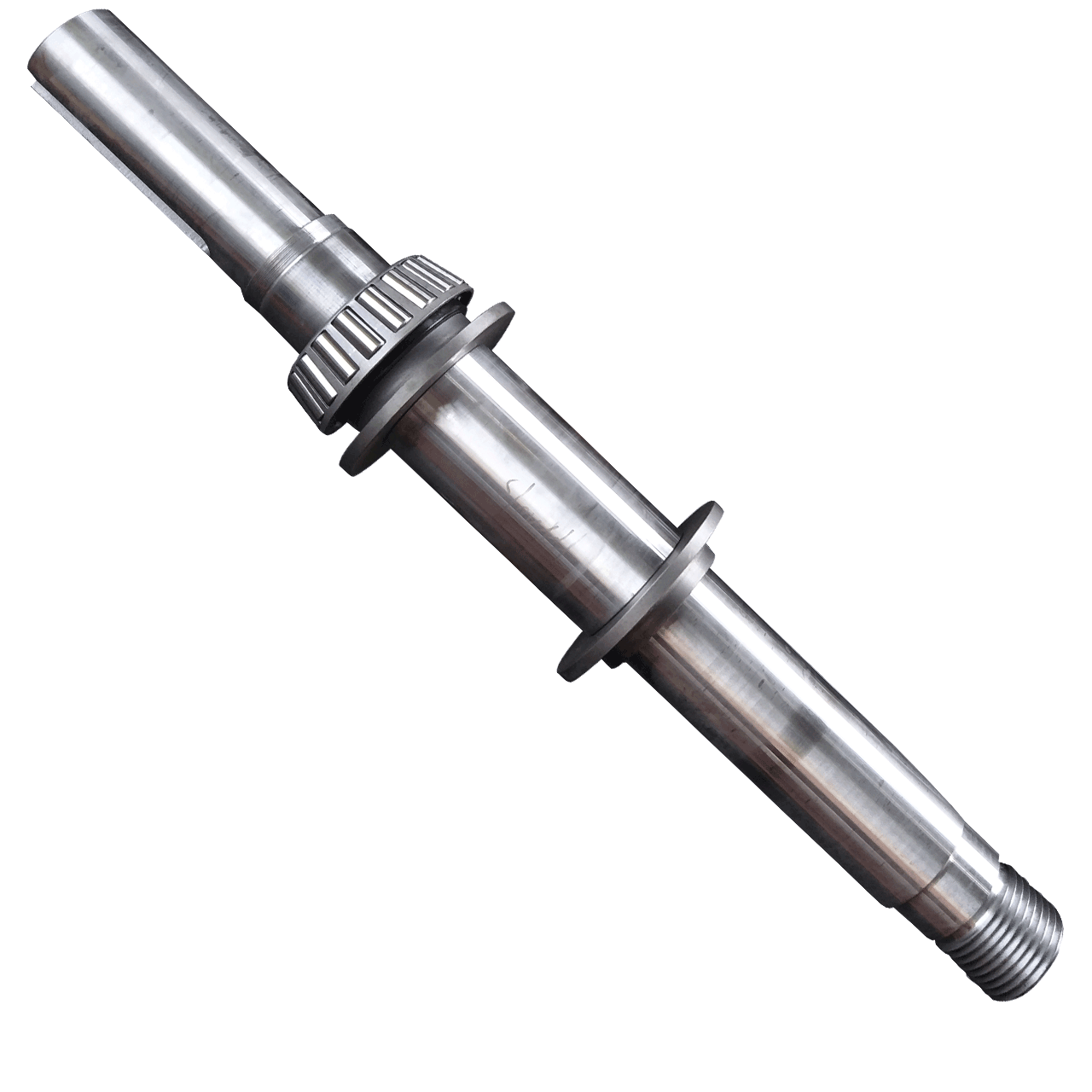

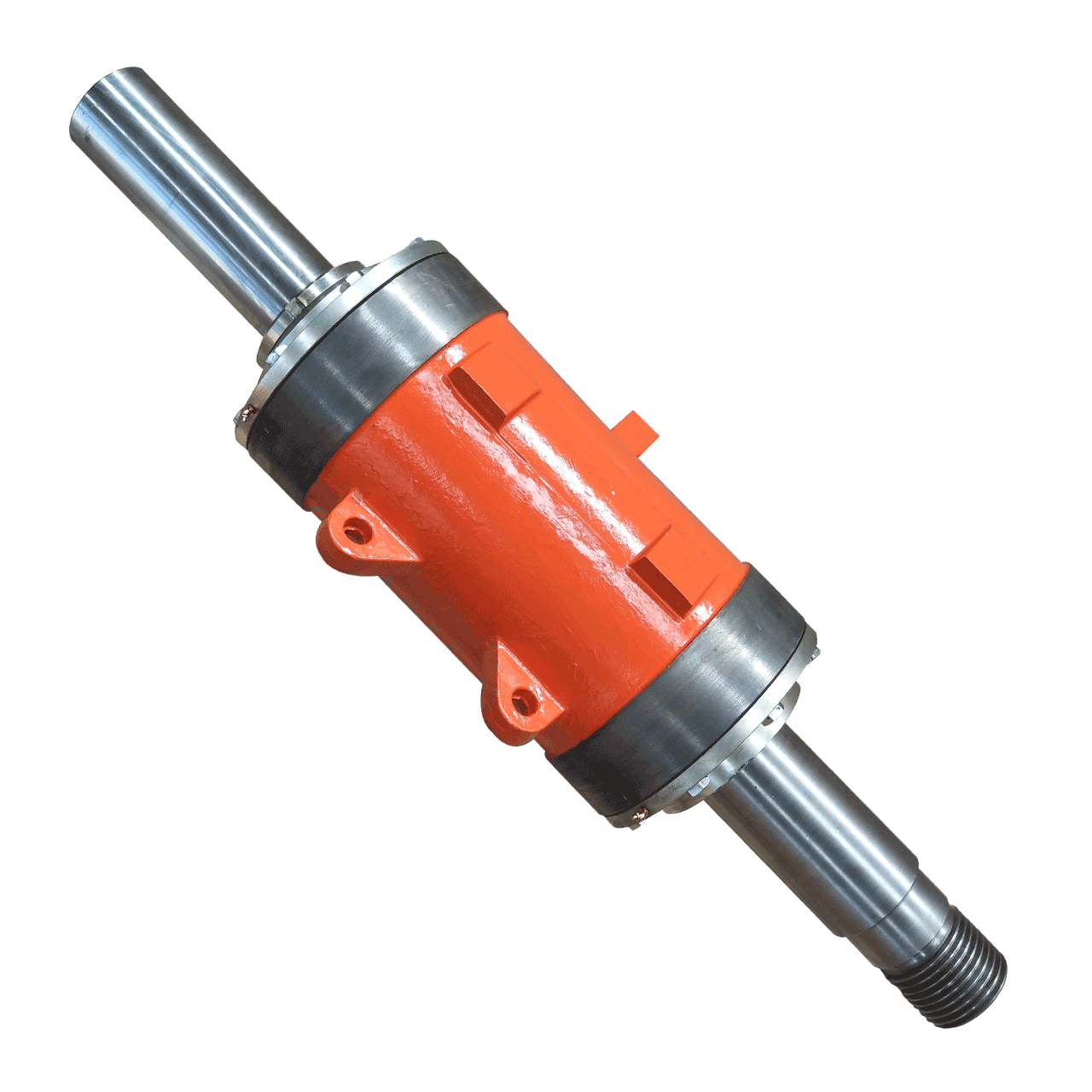

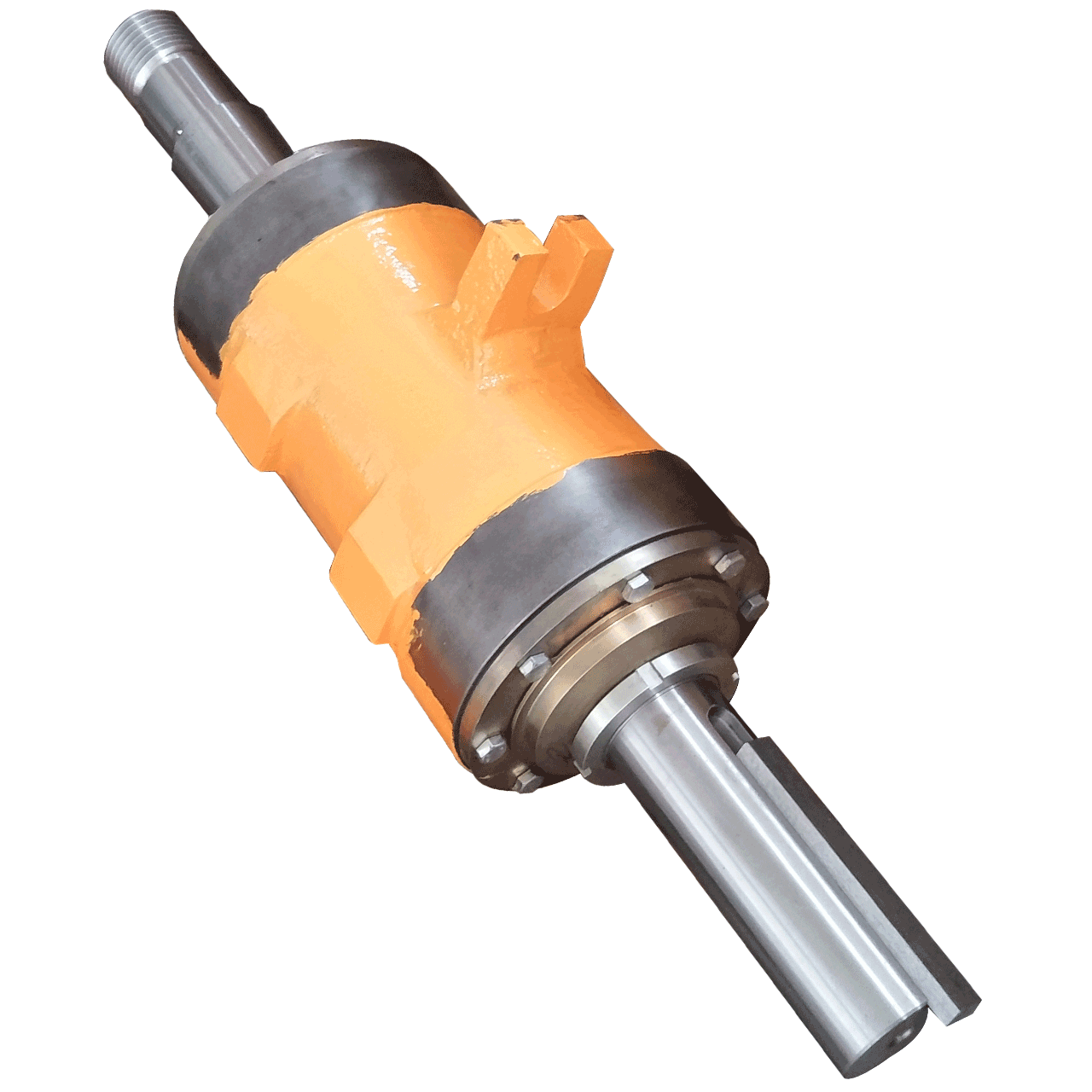

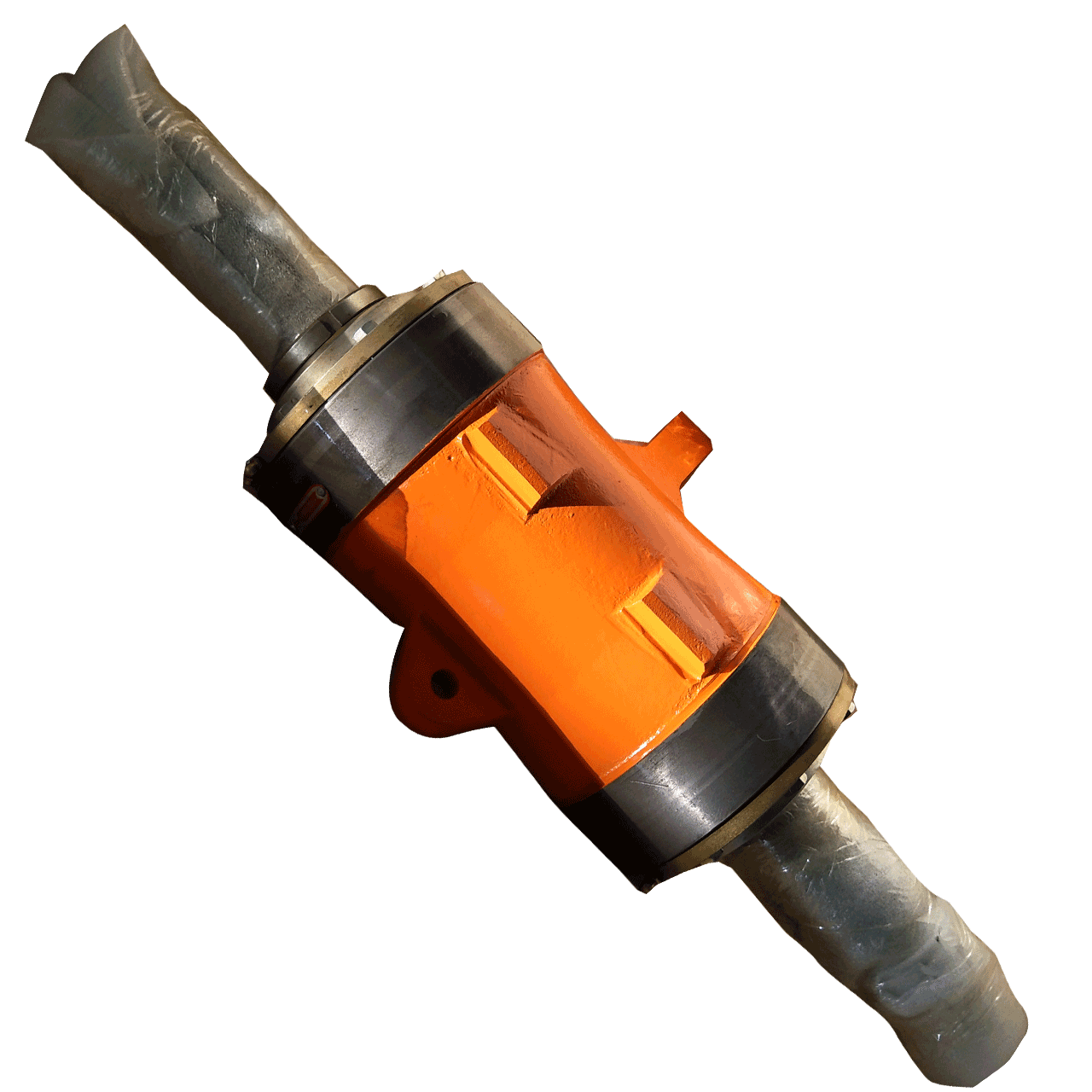

D3058 Pump metal fitting impeller

Manufacturer : MORETEC

Part number : D3058

OEM Compatibility :

Description

Description

Product overview:

MORETEC impellers are available in a variety of materials and designs to meet your specific application. MORETEC provide fully interchangeable equipment and parts for the mineral processing and mining industries. We use FARO 3D reverse engineering, wear and corrosion material forming technology to provide our real customers with equipment and parts with longer wear life.

Classification and Function of Slurry Pump Impeller:

1. Slurry pump impellers are divided into closed impellers according to mechanical structure: they are composed of blades and front and rear cover plates. The closed impeller has high efficiency and is difficult to manufacture, and is mostly used in centrifugal pumps. Suitable for conveying clean liquids with low viscosity and no particles, such as clear water and solutions; Semi-closed impeller: Semi-closed impeller is suitable for conveying materials that are easy to precipitate or contain trace particles, and the efficiency is lower than that of closed impeller; Open impeller impeller: an impeller with only blades and no complete cover is called an open impeller. The open impeller is suitable for conveying materials containing more suspended solids, with low efficiency and low liquid pressure.

2. According to its suction method, it can be divided into: single suction type has a simple structure and only sucks liquid from one side; The double suction type structure is more complicated, and the liquid is sucked from both sides, and the liquid absorption capacity is large.

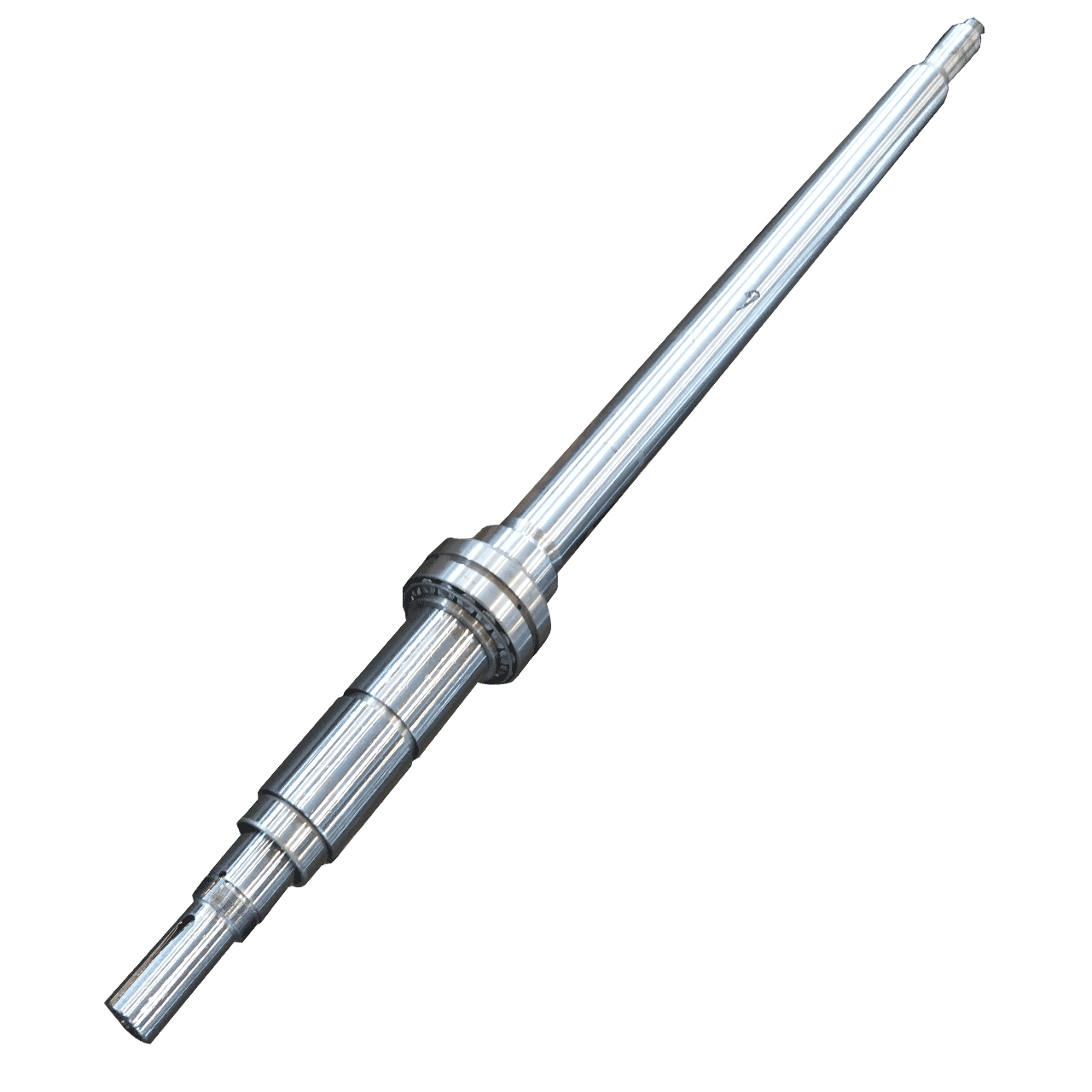

The impeller is the rotor and rotating part of the centrifugal pump. The front and rear shields have pump-out vanes to reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. No insert or nut is required for casting the impeller thread. It can also provide high efficiency and high lift design. It increases or decreases the pressure and flow of the fluid. When the slurry pump handles the solid mixture, the most worn component is the impeller.

Rubber wet parts have good wear resistance and corrosion resistance, and are usually used in acidic conditions. Such as mining tailings, small particles, and raw pulp. The entire displacement part includes cover plate gasket, throat bushing, frame plate gasket, frame plate gasket insert. Rubber spare parts are made of natural rubber, code-named SR26 and SR55.

The size of the rubber impeller is the same as that of the high chromium alloy impeller. We can also provide rubber mud pumps with metal impellers. Impeller is the most important spare part of centrifugal slurry pump. Centrifugal pumps require the impeller to generate centrifugal force to treat the slurry. The impeller generates centrifugal force when it runs to a certain speed.

Disclaimer:

MORETEC provide complete new pumps and replacement parts (including components). Any use of competitor names, trademarks, models or part numbers is for reference only.

MORETEC impellers are available in a variety of materials and designs to meet your specific application. MORETEC provide fully interchangeable equipment and parts for the mineral processing and mining industries. We use FARO 3D reverse engineering, wear and corrosion material forming technology to provide our real customers with equipment and parts with longer wear life.

Classification and Function of Slurry Pump Impeller:

1. Slurry pump impellers are divided into closed impellers according to mechanical structure: they are composed of blades and front and rear cover plates. The closed impeller has high efficiency and is difficult to manufacture, and is mostly used in centrifugal pumps. Suitable for conveying clean liquids with low viscosity and no particles, such as clear water and solutions; Semi-closed impeller: Semi-closed impeller is suitable for conveying materials that are easy to precipitate or contain trace particles, and the efficiency is lower than that of closed impeller; Open impeller impeller: an impeller with only blades and no complete cover is called an open impeller. The open impeller is suitable for conveying materials containing more suspended solids, with low efficiency and low liquid pressure.

2. According to its suction method, it can be divided into: single suction type has a simple structure and only sucks liquid from one side; The double suction type structure is more complicated, and the liquid is sucked from both sides, and the liquid absorption capacity is large.

The impeller is the rotor and rotating part of the centrifugal pump. The front and rear shields have pump-out vanes to reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. No insert or nut is required for casting the impeller thread. It can also provide high efficiency and high lift design. It increases or decreases the pressure and flow of the fluid. When the slurry pump handles the solid mixture, the most worn component is the impeller.

Rubber wet parts have good wear resistance and corrosion resistance, and are usually used in acidic conditions. Such as mining tailings, small particles, and raw pulp. The entire displacement part includes cover plate gasket, throat bushing, frame plate gasket, frame plate gasket insert. Rubber spare parts are made of natural rubber, code-named SR26 and SR55.

The size of the rubber impeller is the same as that of the high chromium alloy impeller. We can also provide rubber mud pumps with metal impellers. Impeller is the most important spare part of centrifugal slurry pump. Centrifugal pumps require the impeller to generate centrifugal force to treat the slurry. The impeller generates centrifugal force when it runs to a certain speed.

Disclaimer:

MORETEC provide complete new pumps and replacement parts (including components). Any use of competitor names, trademarks, models or part numbers is for reference only.

Parts List

Parts List

No accessories information

People who seen this item also look

Ratings and Reviews

|

The product received, first of all, from the appearance is very satisfied, because the purchase before the purchase and moretec business staff in detail, so whether from the product material or external size are particularly suitable for our current needs, if you need to buy, you can also choose his home

Tom, Dec 17 2022

|