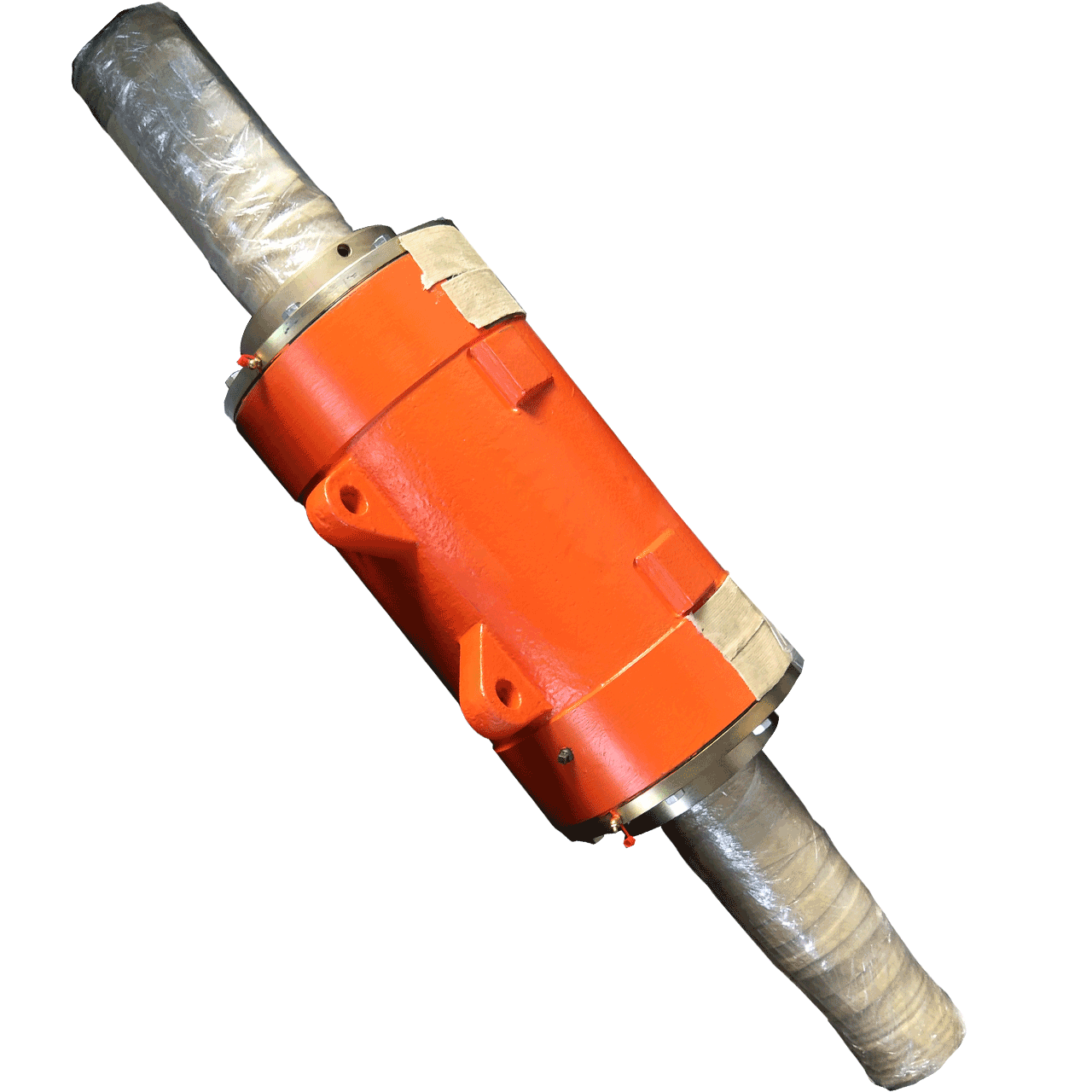

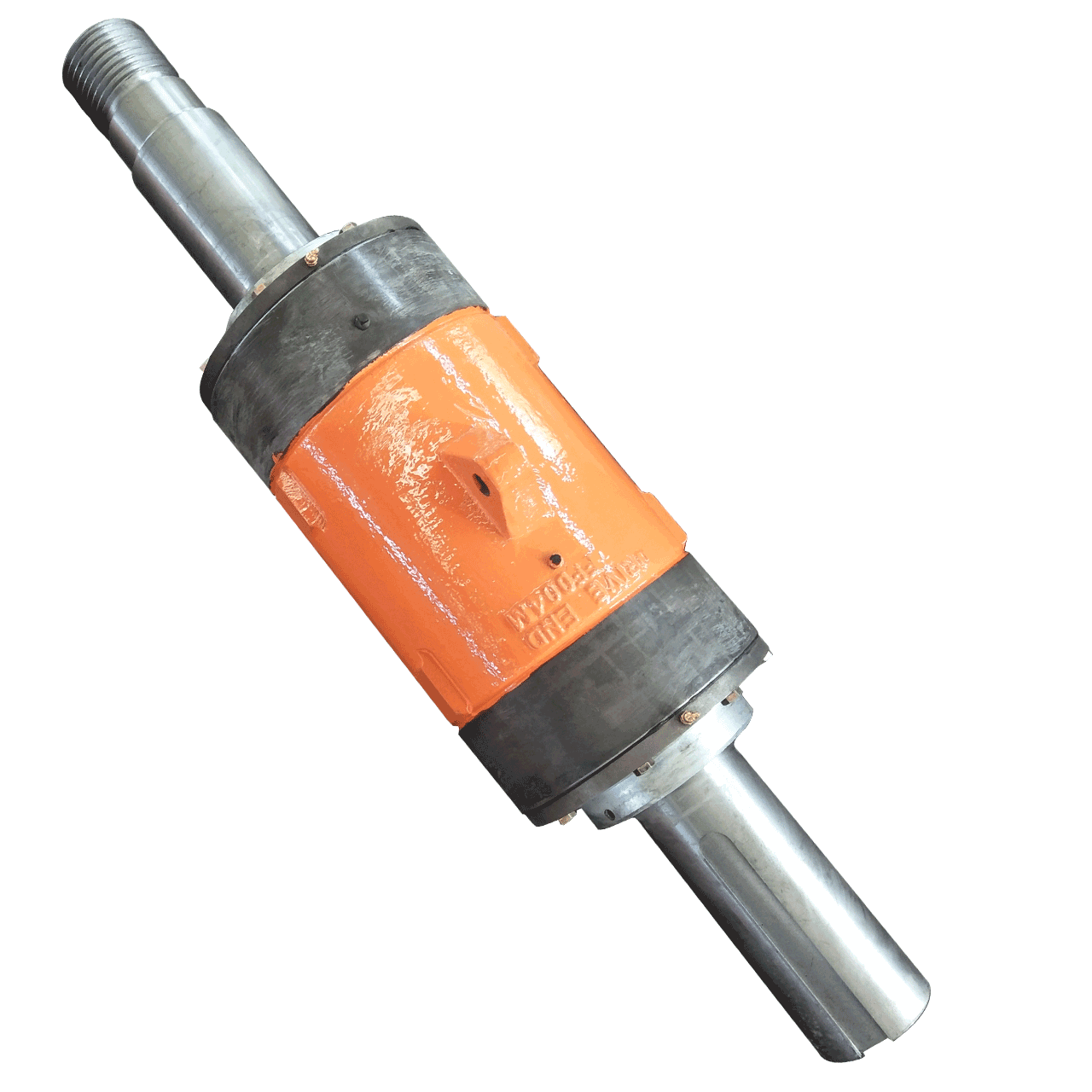

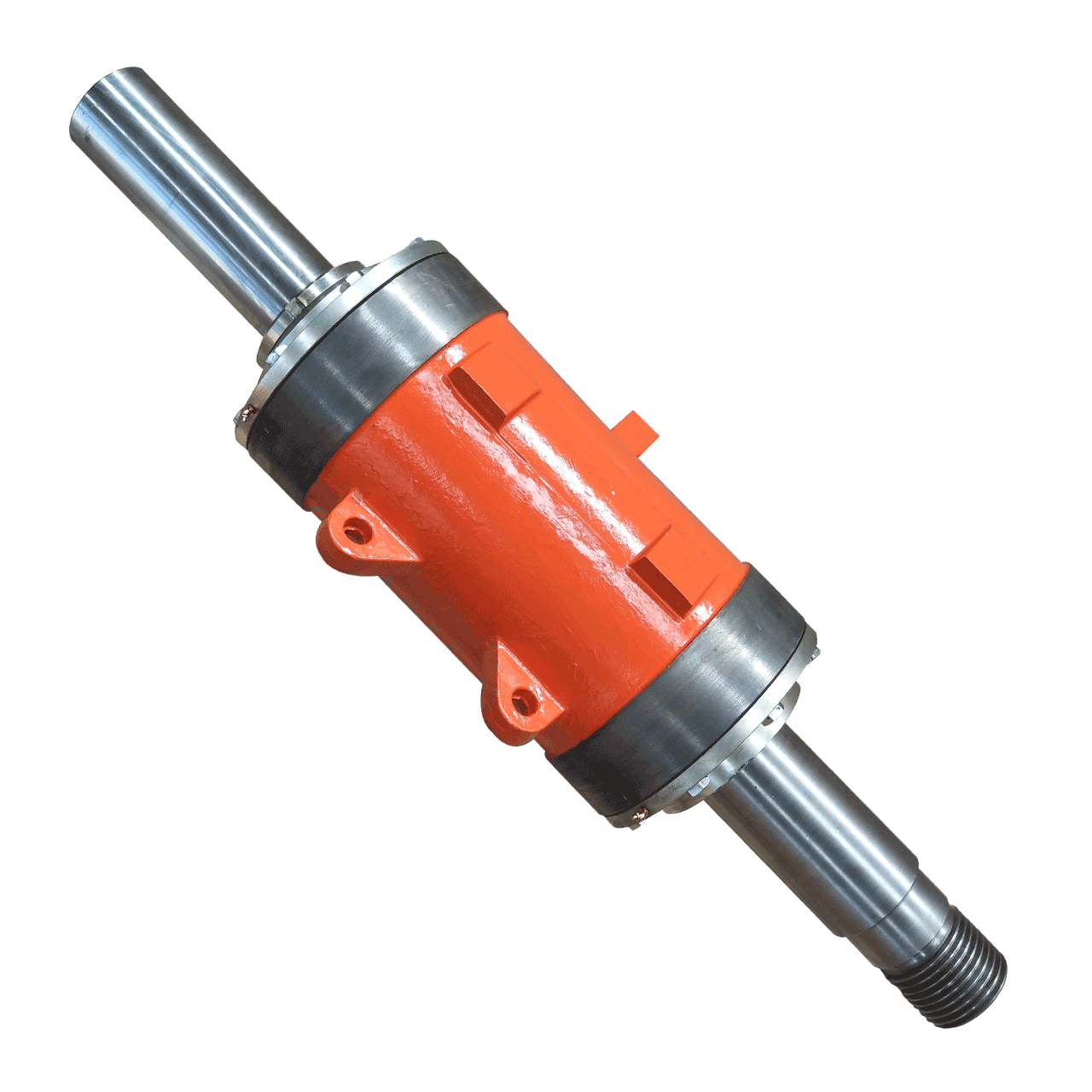

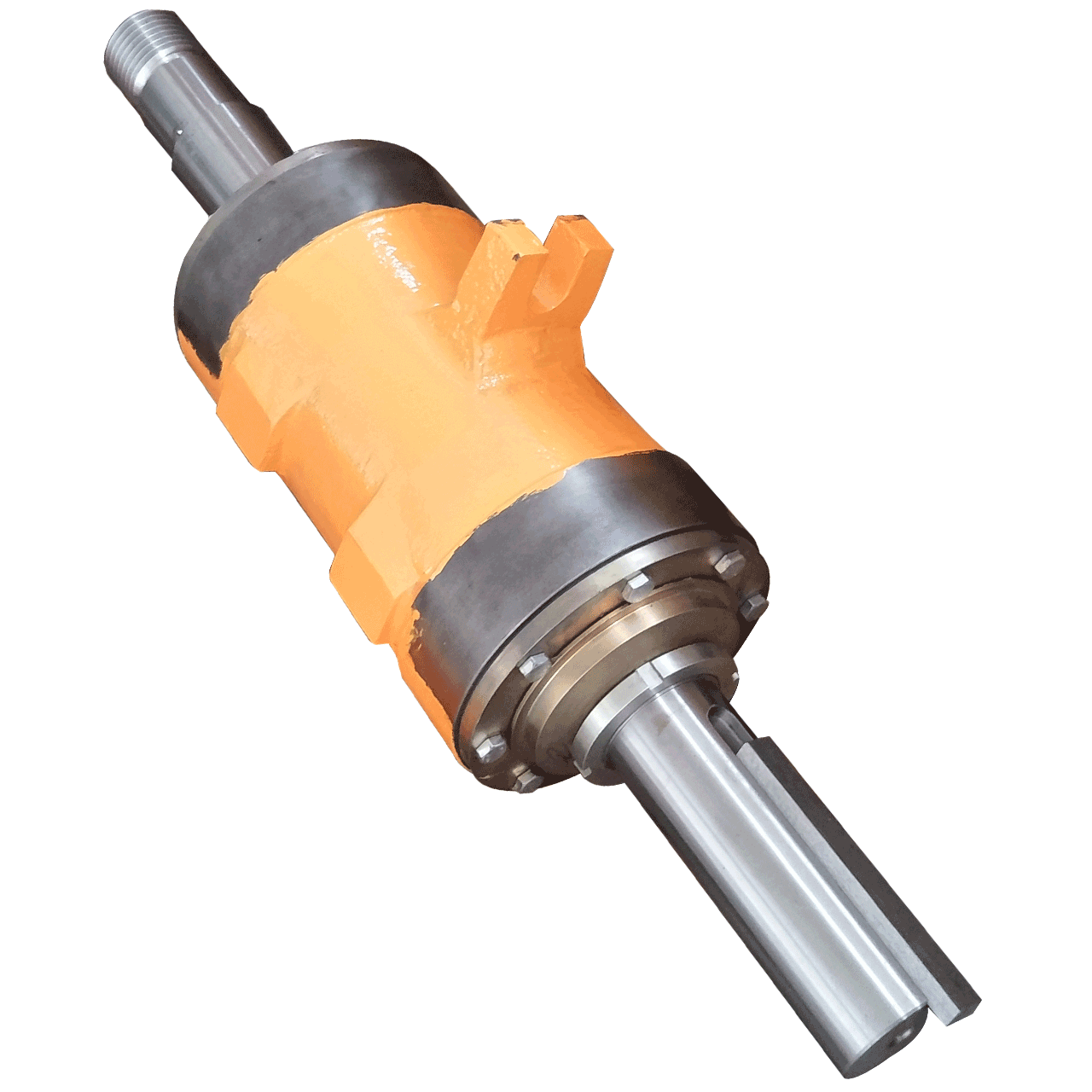

C029HS1 Pump Metal Fittings Decompression Cover

Manufacturer : MORETEC

Part number : C029HS1

OEM Compatibility : Warman® 029

Description

Description

Product summary:

MORETEC pressure relief covers are available in a variety of materials and designs to meet your specific application. MORETEC provide absolutely interchangeable equipment and parts for mineral processing and mining. We use FARO 3D reverse engineering design, wear and corrosion material forming technology to provide our real customers with equipment and parts with longer wear life.

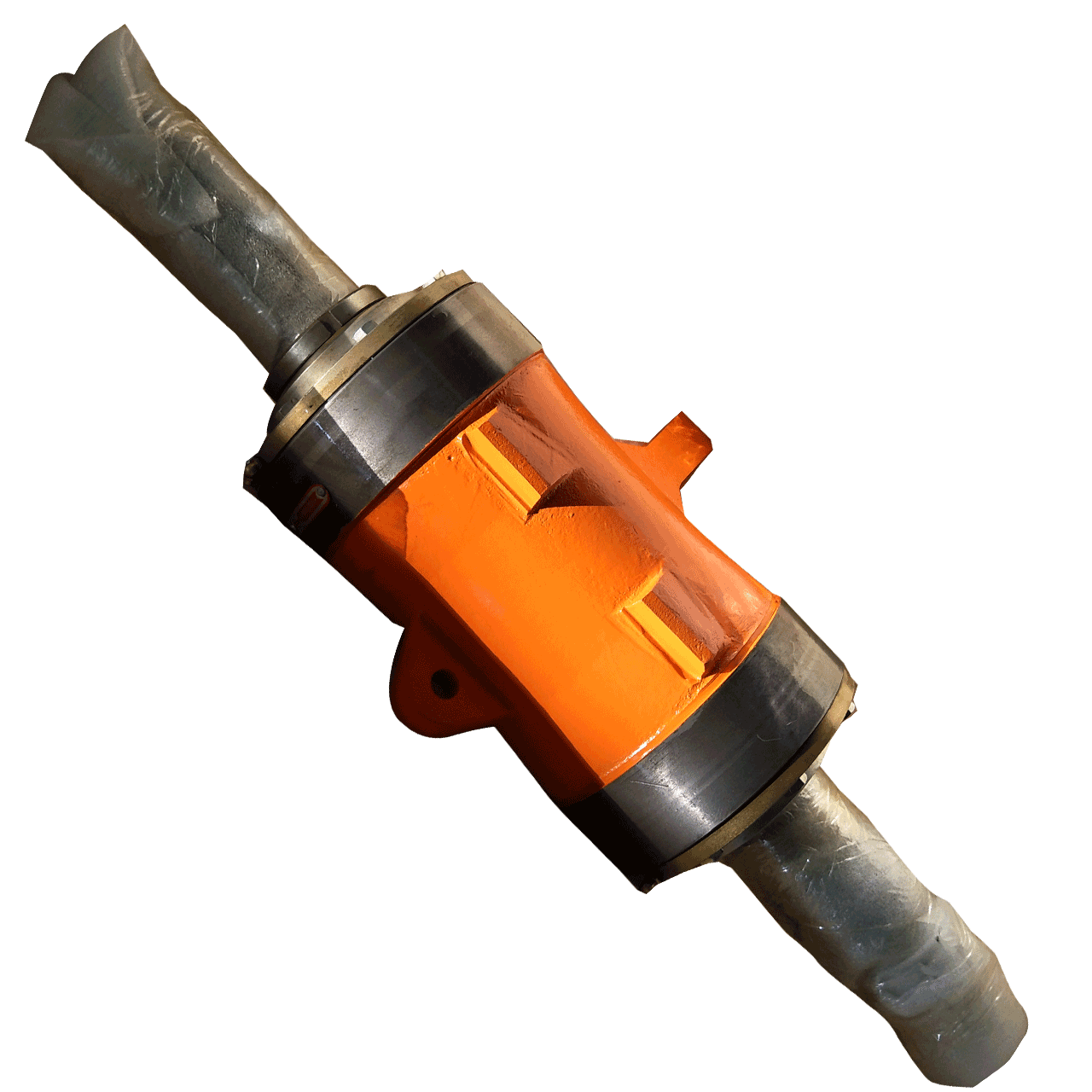

Slurry pump pressure relief cover seal is also called dynamic seal, mainly with the auxiliary impeller, in the pump operation to play a sealing role. Generally, slurry pumps are used to transport various abrasive and corrosive materials. The materials contain solid particles of a certain particle size and some acid-base ions. During the material transportation process, the slurry pump pressure reducing cover and flow parts will be subject to wear, Cavitation, corrosion and other methods are damaged. Among them, the slurry pump pressure reducing cover is the central part of the slurry pump, which will cause serious abrasion, corrosion, cavitation and other problems.

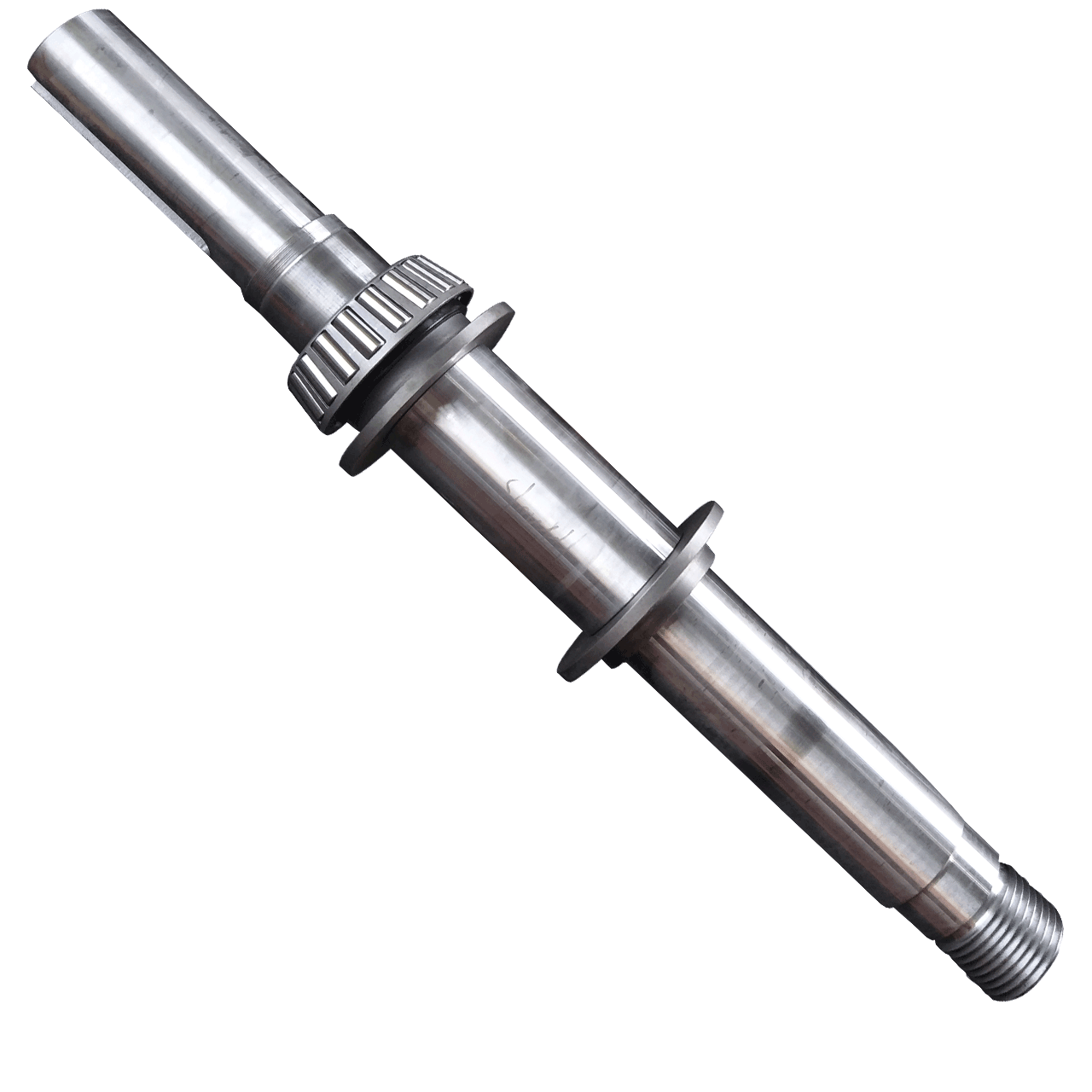

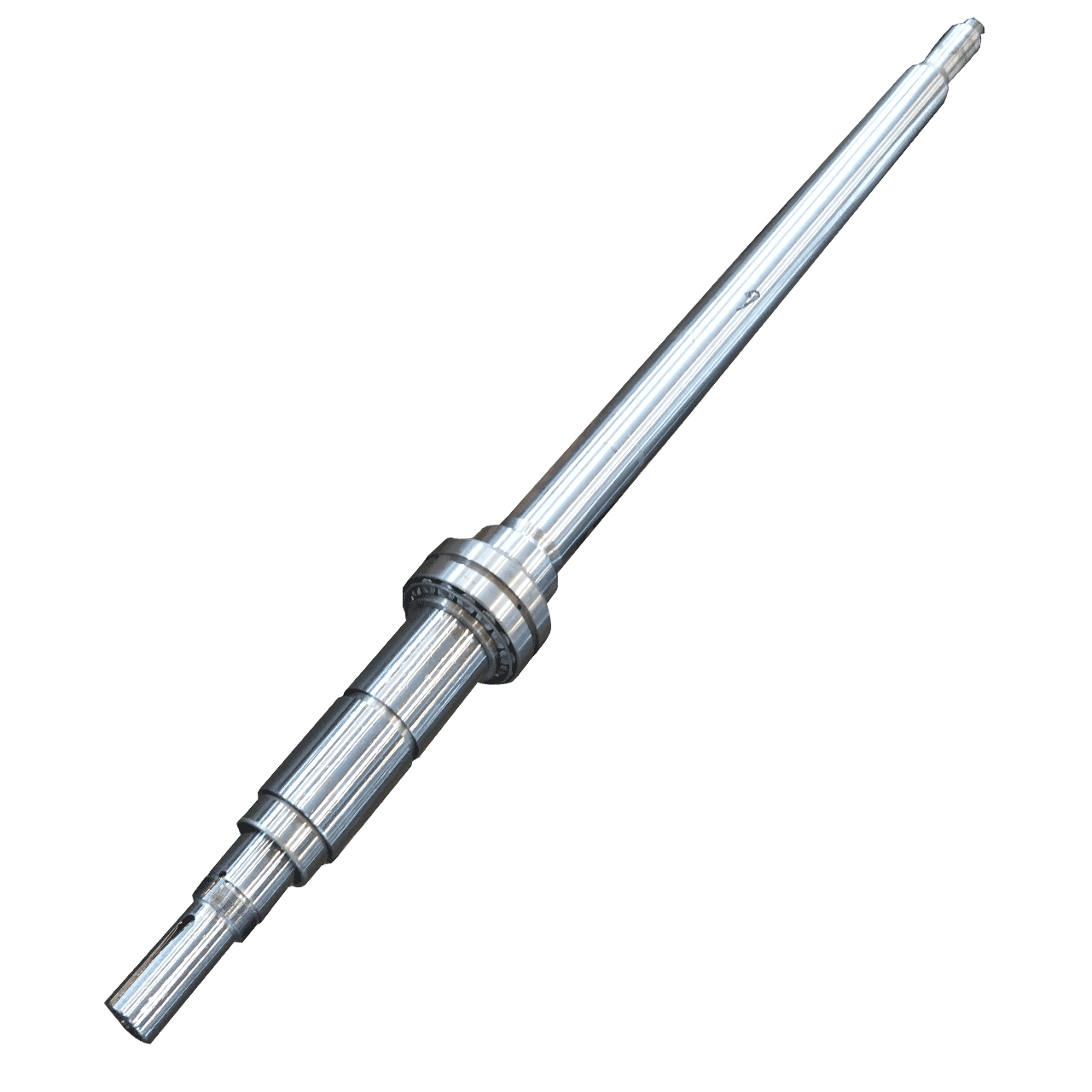

Slurry pump spare parts, I .e. pump parts, are directly connected to the slurry, which are crucial to the service life of the slurry pump. The fluid receiving components include impellers, linings, throat sleeves, frame plate lining inserts, housings, etc. These components are very easy to wear because they work under the long-term impact of high-speed abrasive and corrosive slurry. For the long service life of pump parts, materials play an important role here.

MORETEC provide a variety of pump accessories, suitable for any application and use case, made of a variety of materials, including chromium white iron (a variety of metallurgical changes), natural rubber, polyurethane, etc. We also provide expert advice on determining the correct metal composition for your specific application, which is especially important when pumping slurry with extremely high or low pH. Other factors include the running speed of the pump, particle size and hardness-all of which will affect the choice of impeller. Impeller is the core of any pumping application. Achieving efficiency in your process requires proper impeller selection. This cannot be overemphasized, so please contact us directly to discuss your requirements.

When you need them most. Contact MORETEC immediately to find out how quickly we can transport replacement parts from the warehouse to your work site.

Disclaimer:

MORETEC provide complete new pumps and replacement parts (including components), and any use of competitor names, trademarks, models or part numbers is for reference only.

MORETEC pressure relief covers are available in a variety of materials and designs to meet your specific application. MORETEC provide absolutely interchangeable equipment and parts for mineral processing and mining. We use FARO 3D reverse engineering design, wear and corrosion material forming technology to provide our real customers with equipment and parts with longer wear life.

Slurry pump pressure relief cover seal is also called dynamic seal, mainly with the auxiliary impeller, in the pump operation to play a sealing role. Generally, slurry pumps are used to transport various abrasive and corrosive materials. The materials contain solid particles of a certain particle size and some acid-base ions. During the material transportation process, the slurry pump pressure reducing cover and flow parts will be subject to wear, Cavitation, corrosion and other methods are damaged. Among them, the slurry pump pressure reducing cover is the central part of the slurry pump, which will cause serious abrasion, corrosion, cavitation and other problems.

Slurry pump spare parts, I .e. pump parts, are directly connected to the slurry, which are crucial to the service life of the slurry pump. The fluid receiving components include impellers, linings, throat sleeves, frame plate lining inserts, housings, etc. These components are very easy to wear because they work under the long-term impact of high-speed abrasive and corrosive slurry. For the long service life of pump parts, materials play an important role here.

MORETEC provide a variety of pump accessories, suitable for any application and use case, made of a variety of materials, including chromium white iron (a variety of metallurgical changes), natural rubber, polyurethane, etc. We also provide expert advice on determining the correct metal composition for your specific application, which is especially important when pumping slurry with extremely high or low pH. Other factors include the running speed of the pump, particle size and hardness-all of which will affect the choice of impeller. Impeller is the core of any pumping application. Achieving efficiency in your process requires proper impeller selection. This cannot be overemphasized, so please contact us directly to discuss your requirements.

When you need them most. Contact MORETEC immediately to find out how quickly we can transport replacement parts from the warehouse to your work site.

Disclaimer:

MORETEC provide complete new pumps and replacement parts (including components), and any use of competitor names, trademarks, models or part numbers is for reference only.

Parts List