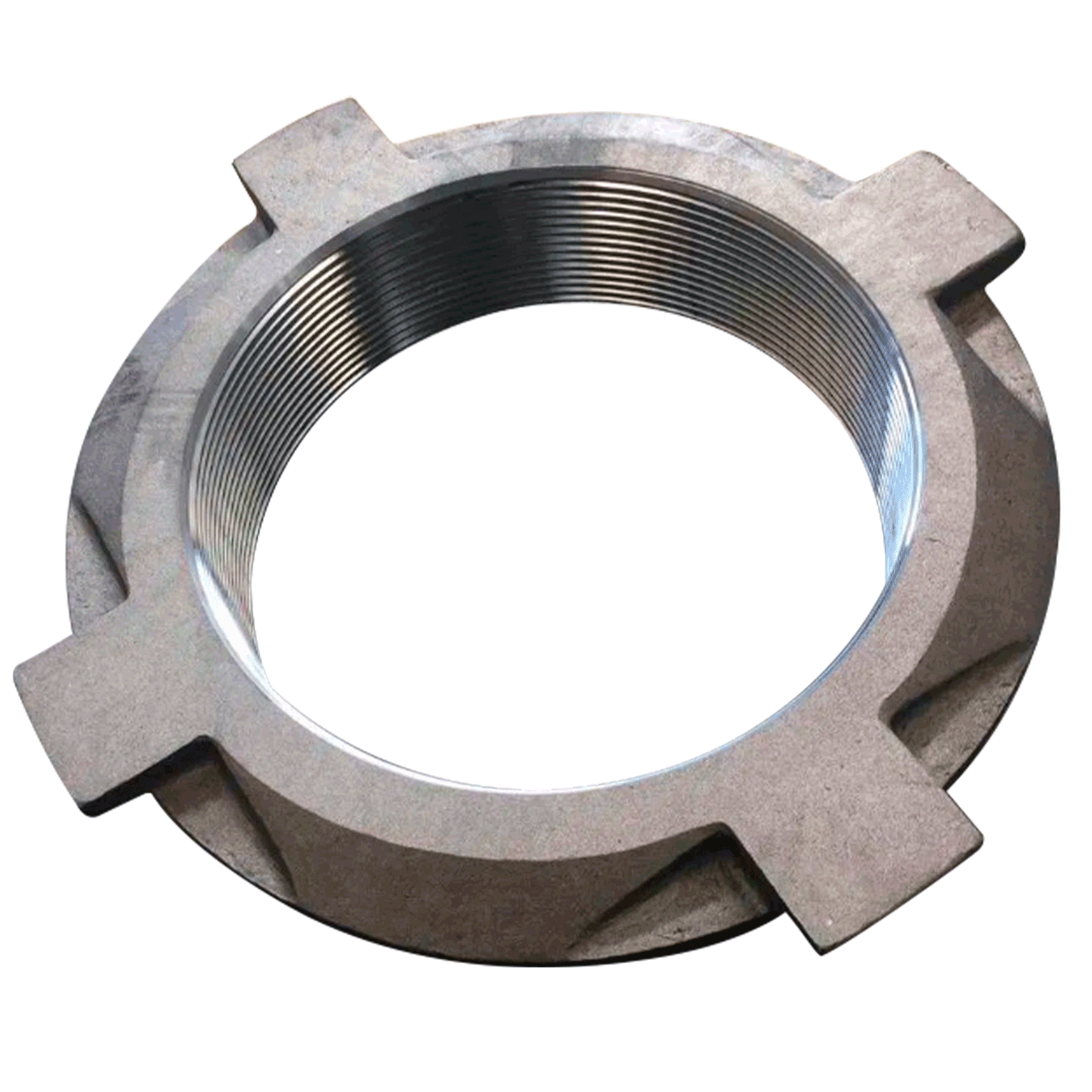

Eccentric shafts

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

The shaft is a cylindrical object that passes through the middle of the bearing or the middle of the wheel or the middle of the gear, but a few are square. A shaft is a mechanical part that supports a rotating part and rotates with it to transmit movement, torque or bending moment. Generally, it is a metal round rod shape, and each section can have different diameters. The rotating parts of the machine are mounted on the shaft.

Common shafts can be divided into crankshaft, straight shaft, flexible shaft, solid shaft, hollow shaft, rigid shaft, and flexible shaft (flexible shaft) according to the structural shape of the shaft.

The structural design of the shaft is an important step to determine the reasonable shape and all structural dimensions of the shaft and to design the shaft. It consists of the type, size and position of the parts installed on the shaft, the fixing method of the parts, the nature, direction, size and distribution of the load, the type and size of the bearing, the blank of the shaft, the manufacturing and assembly process, the installation and transportation, The deformation of the shaft and other factors are related.

Moretec crusher wearing parts provide you:

Custom configuration ensures consistent production

Durable manganese steel increases the normal operation time of the crusher

Reduce equipment wear

The well-stocked patterns (covering all major brands and models), as well as all patterns produced only according to the original drawings, ensure fast delivery and perfect match with the crusher.

Based on our more than 15 years of experience in this field, we can make adjustments according to special requirements.

Perfect management covers your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm orders), delivery (clear photos and test reports are ready for customer confirmation), After-sales (after-sales inspection after the shipment arrives at the work site, size matching, service life inspection, etc.). Make sure there is no doubt about each purchase)

Abundant production capacity: about 10000 tons per year to ensure supply capacity to customers.

Common shafts can be divided into crankshaft, straight shaft, flexible shaft, solid shaft, hollow shaft, rigid shaft, and flexible shaft (flexible shaft) according to the structural shape of the shaft.

The structural design of the shaft is an important step to determine the reasonable shape and all structural dimensions of the shaft and to design the shaft. It consists of the type, size and position of the parts installed on the shaft, the fixing method of the parts, the nature, direction, size and distribution of the load, the type and size of the bearing, the blank of the shaft, the manufacturing and assembly process, the installation and transportation, The deformation of the shaft and other factors are related.

Moretec crusher wearing parts provide you:

Custom configuration ensures consistent production

Durable manganese steel increases the normal operation time of the crusher

Reduce equipment wear

The well-stocked patterns (covering all major brands and models), as well as all patterns produced only according to the original drawings, ensure fast delivery and perfect match with the crusher.

Based on our more than 15 years of experience in this field, we can make adjustments according to special requirements.

Perfect management covers your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm orders), delivery (clear photos and test reports are ready for customer confirmation), After-sales (after-sales inspection after the shipment arrives at the work site, size matching, service life inspection, etc.). Make sure there is no doubt about each purchase)

Abundant production capacity: about 10000 tons per year to ensure supply capacity to customers.

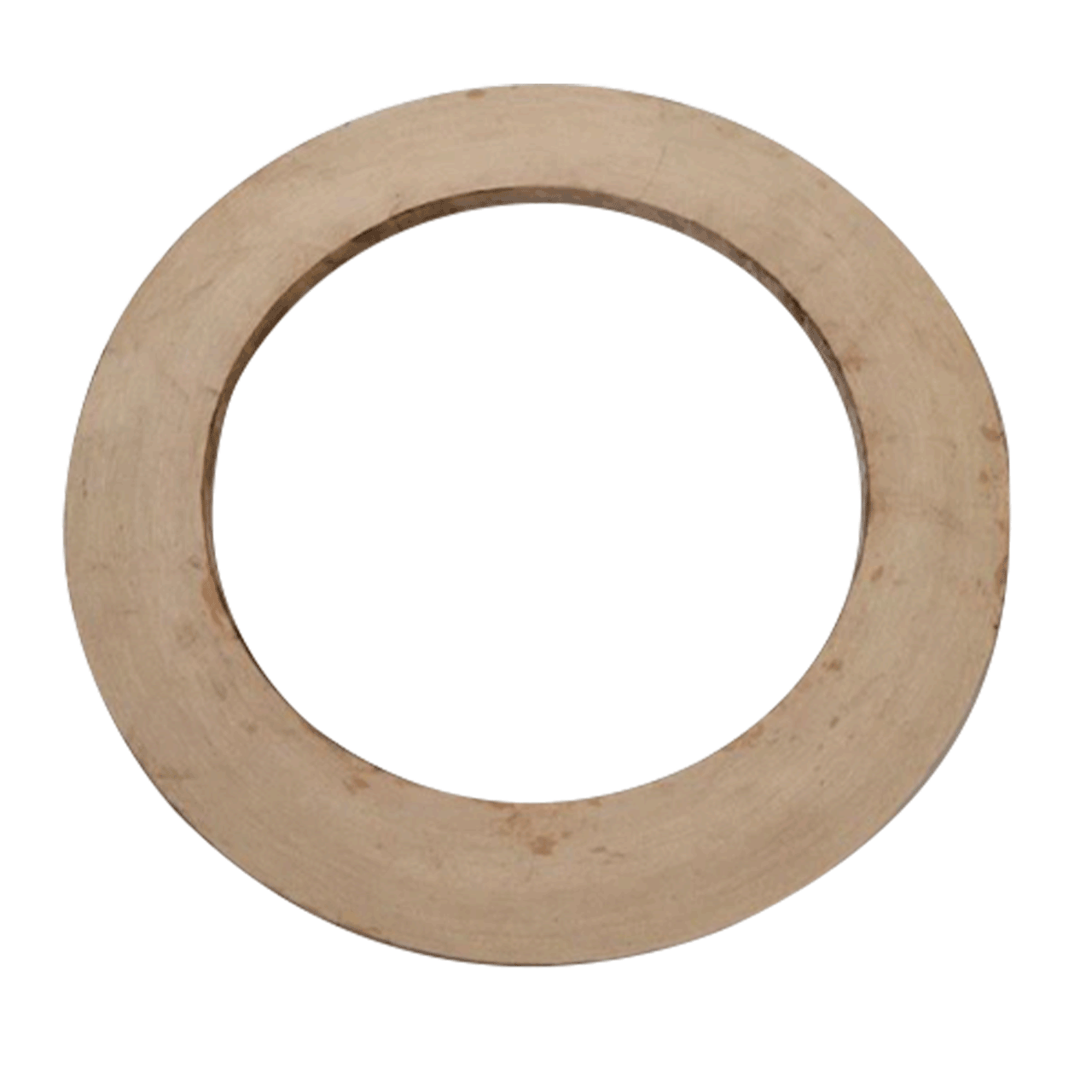

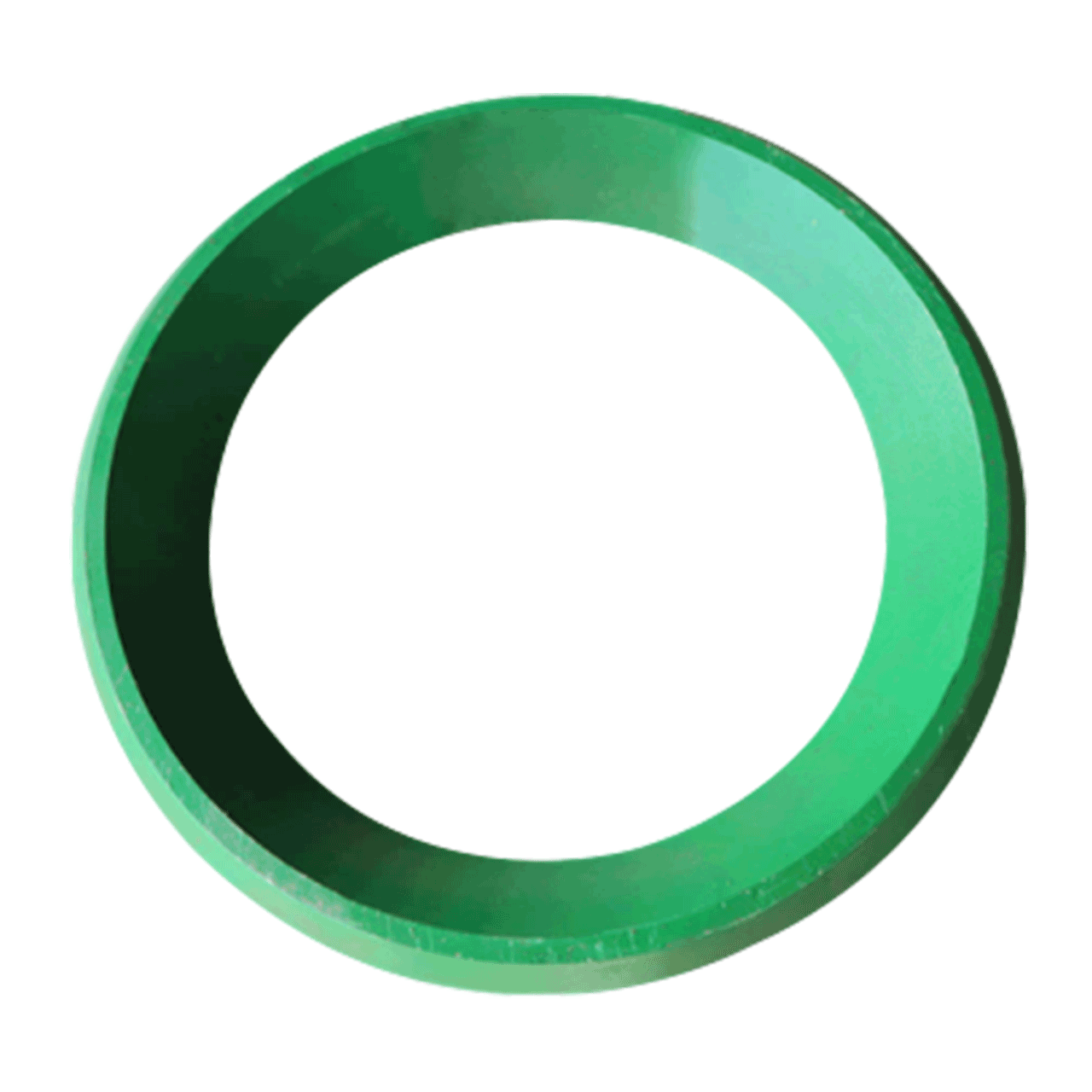

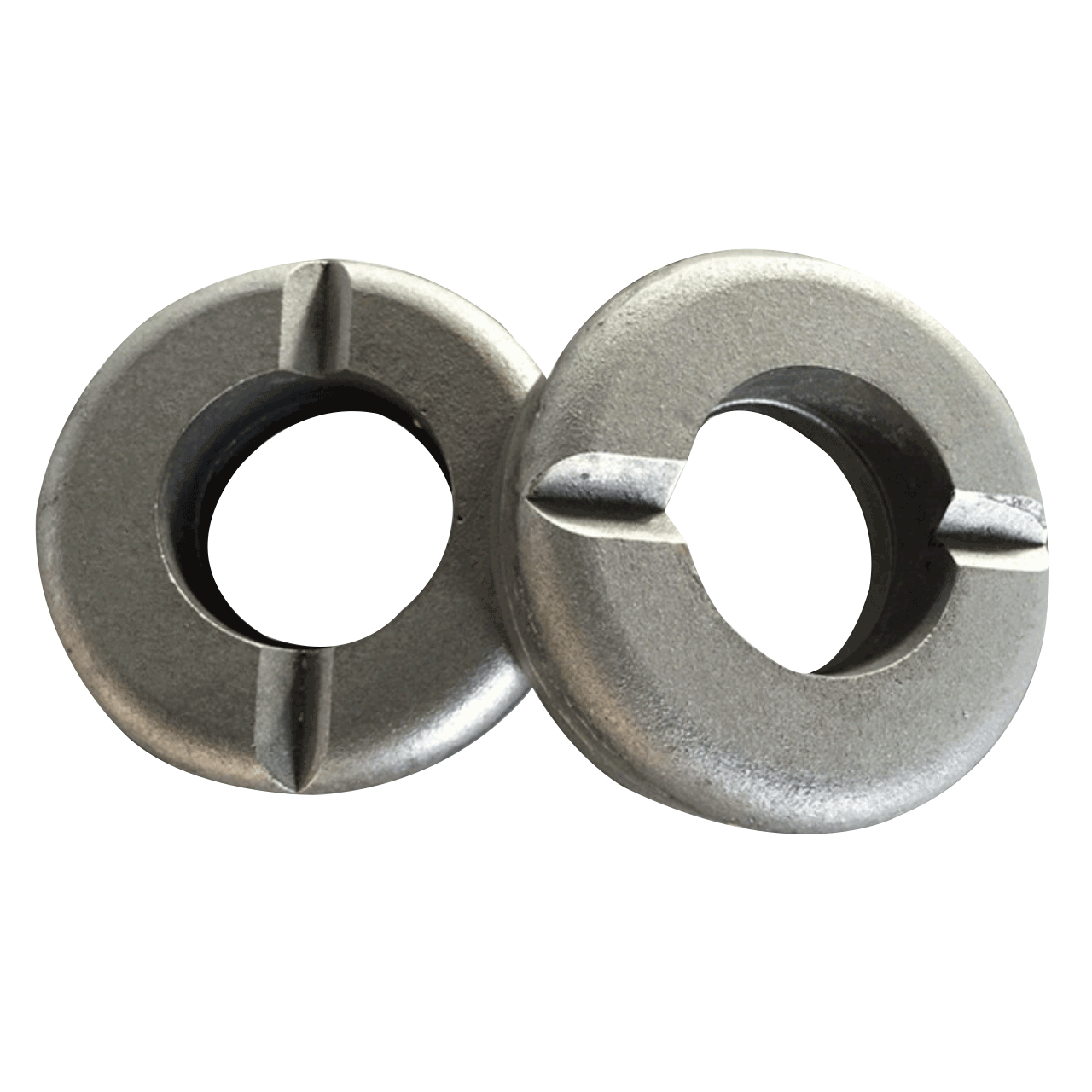

Parts List