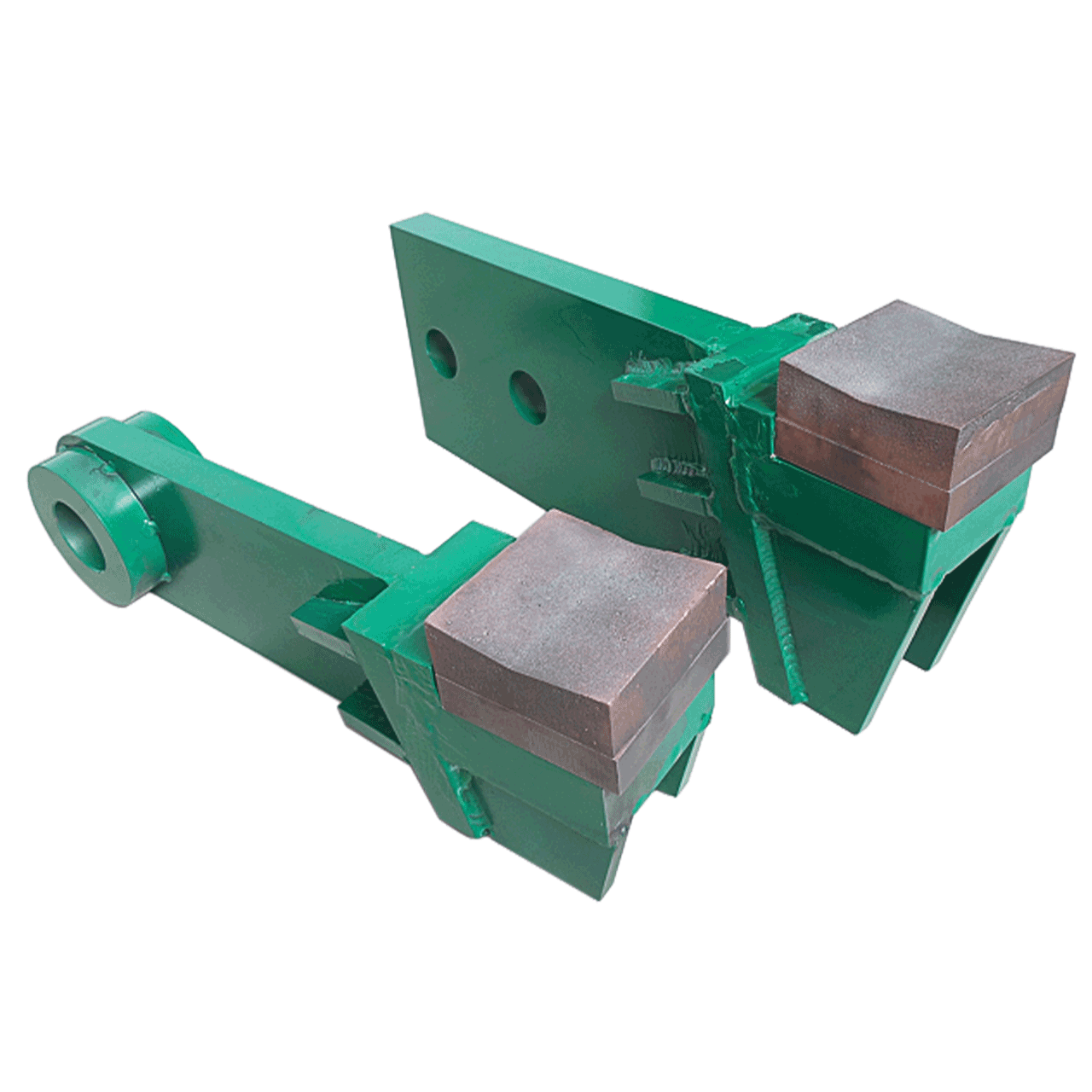

Wood Hog/Shredder Hammer

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

The hammer head is one of the core components of the hammer crusher, arranged on the hammer shaft of the crusher rotor. The hammer head directly hits the material when the crusher is running at high speed, and finally crushes into a suitable material size. The main object of work is granite, pebbles, limestone and other relatively hard materials, which are formed into powder or fine particles through the continuous blow, crushing and grinding of the hammer head running at high speed. Widely used in major sand plants, cement plants, mines, road construction sites and other construction sites. According to the material, it can be divided into: high manganese steel hammer head (Mn13M, Mn13Cr2, Mn18Cr2), double alloy hammer head, high chromium alloy hammer head, etc.

Performance characteristics:

1. The impact force on the material increases and the crushing effect is improved.

2. High wear resistance and long service life.

3. It has good mechanical shock resistance and thermal shock resistance.

4. Improve the grinding effect and reduce the production cost of raw materials.

Moretec crusher wearing parts provide you:

Custom configuration to ensure consistent production

The durable manganese steel increases the normal operation time of the crusher.

Reduce equipment wear

• Inventory-rich patterns (covering all major brands and models), and based only on original drawings

All patterns of paper production ensure fast delivery and perfect match with crusher.

· Based on our more than 15 years of experience in this field, we can make adjustments according to special requirements.

Perfect management, covering your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm orders), delivery (clear photos and test reports are ready for customer confirmation), after-sales (after-sales inspection after the goods arrive at the work site, size matching, service life inspection, etc.). Make sure there is no doubt about each purchase)

Abundant production capacity: about 10000 tons per year to ensure supply capacity to customers

Performance characteristics:

1. The impact force on the material increases and the crushing effect is improved.

2. High wear resistance and long service life.

3. It has good mechanical shock resistance and thermal shock resistance.

4. Improve the grinding effect and reduce the production cost of raw materials.

Moretec crusher wearing parts provide you:

Custom configuration to ensure consistent production

The durable manganese steel increases the normal operation time of the crusher.

Reduce equipment wear

• Inventory-rich patterns (covering all major brands and models), and based only on original drawings

All patterns of paper production ensure fast delivery and perfect match with crusher.

· Based on our more than 15 years of experience in this field, we can make adjustments according to special requirements.

Perfect management, covering your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm orders), delivery (clear photos and test reports are ready for customer confirmation), after-sales (after-sales inspection after the goods arrive at the work site, size matching, service life inspection, etc.). Make sure there is no doubt about each purchase)

Abundant production capacity: about 10000 tons per year to ensure supply capacity to customers

Parts List