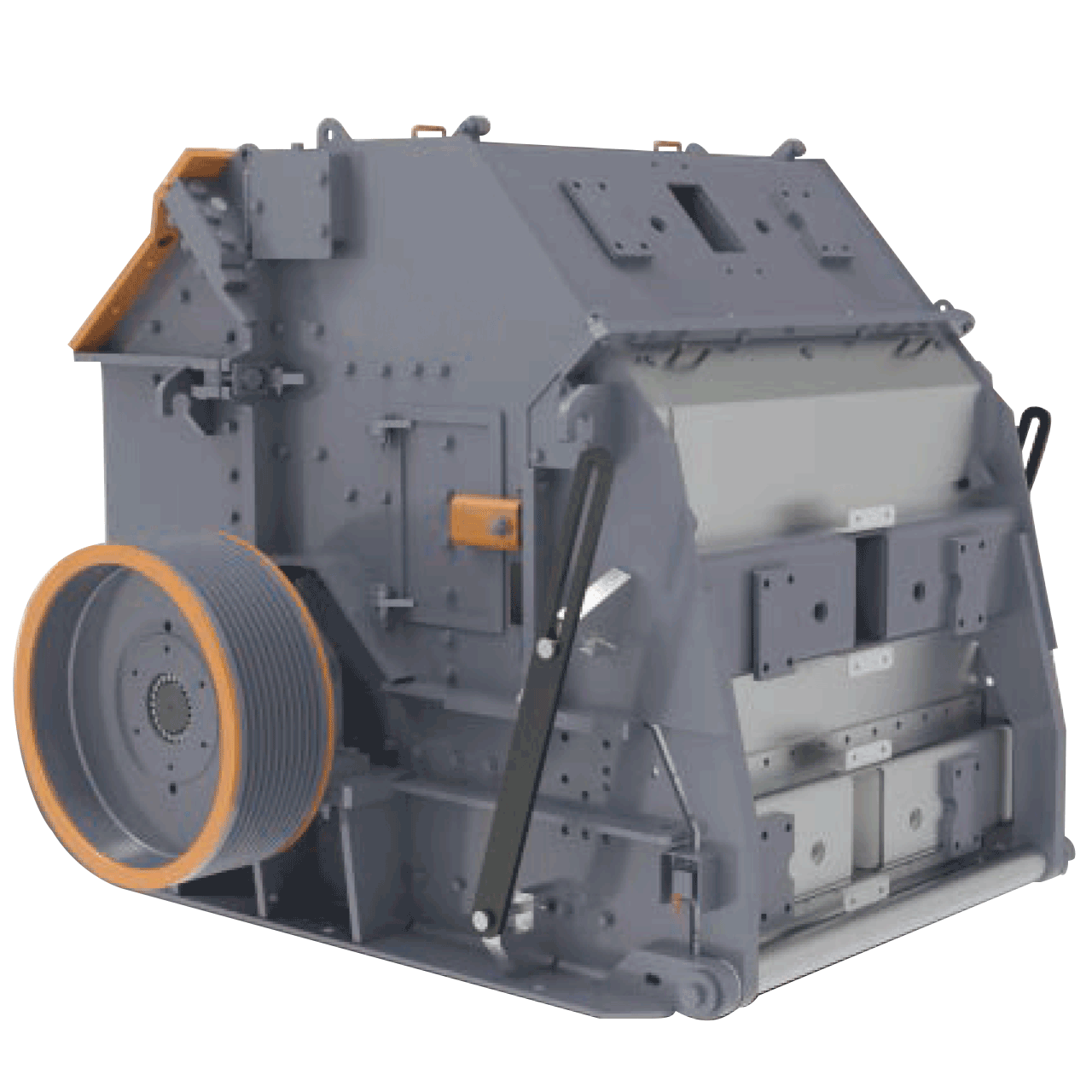

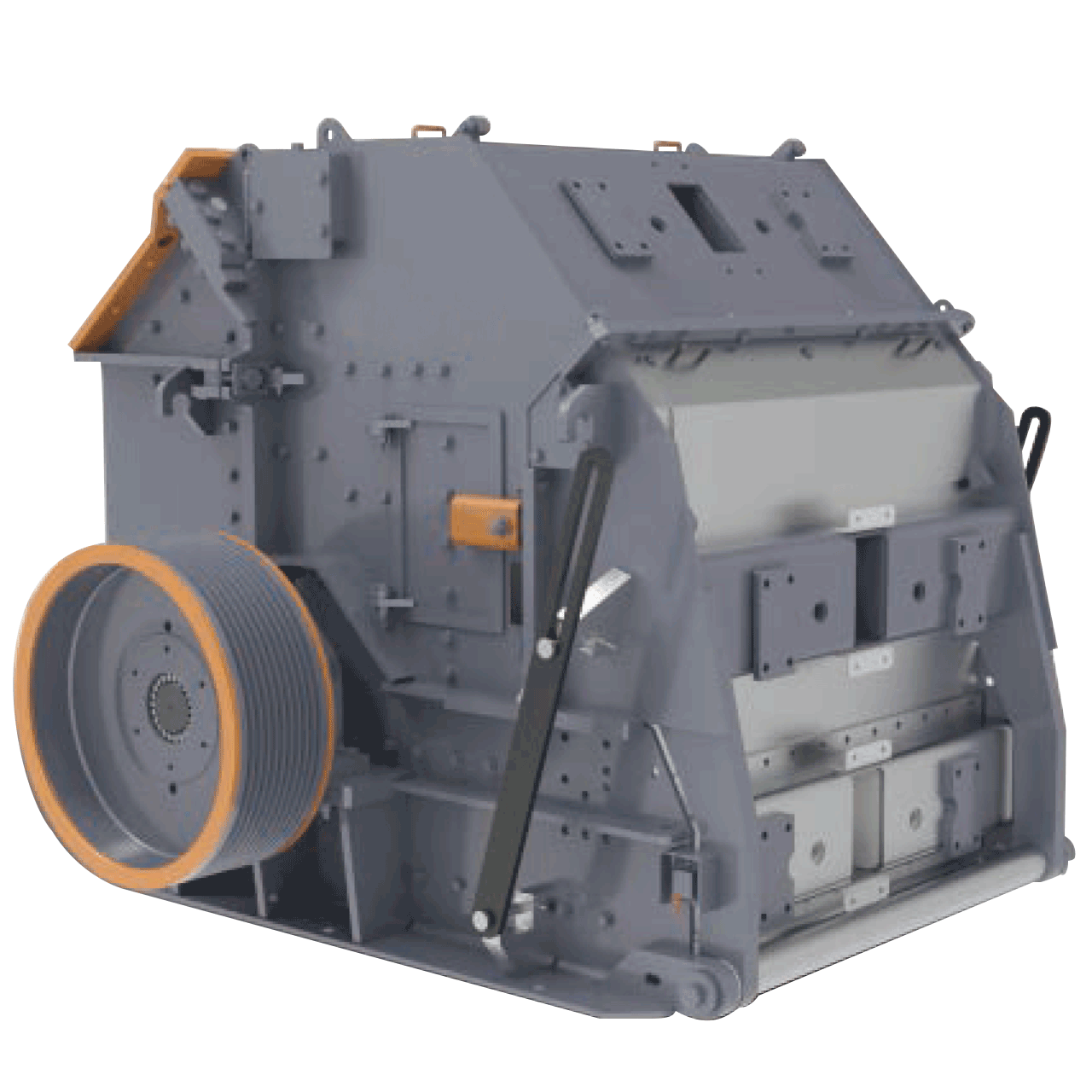

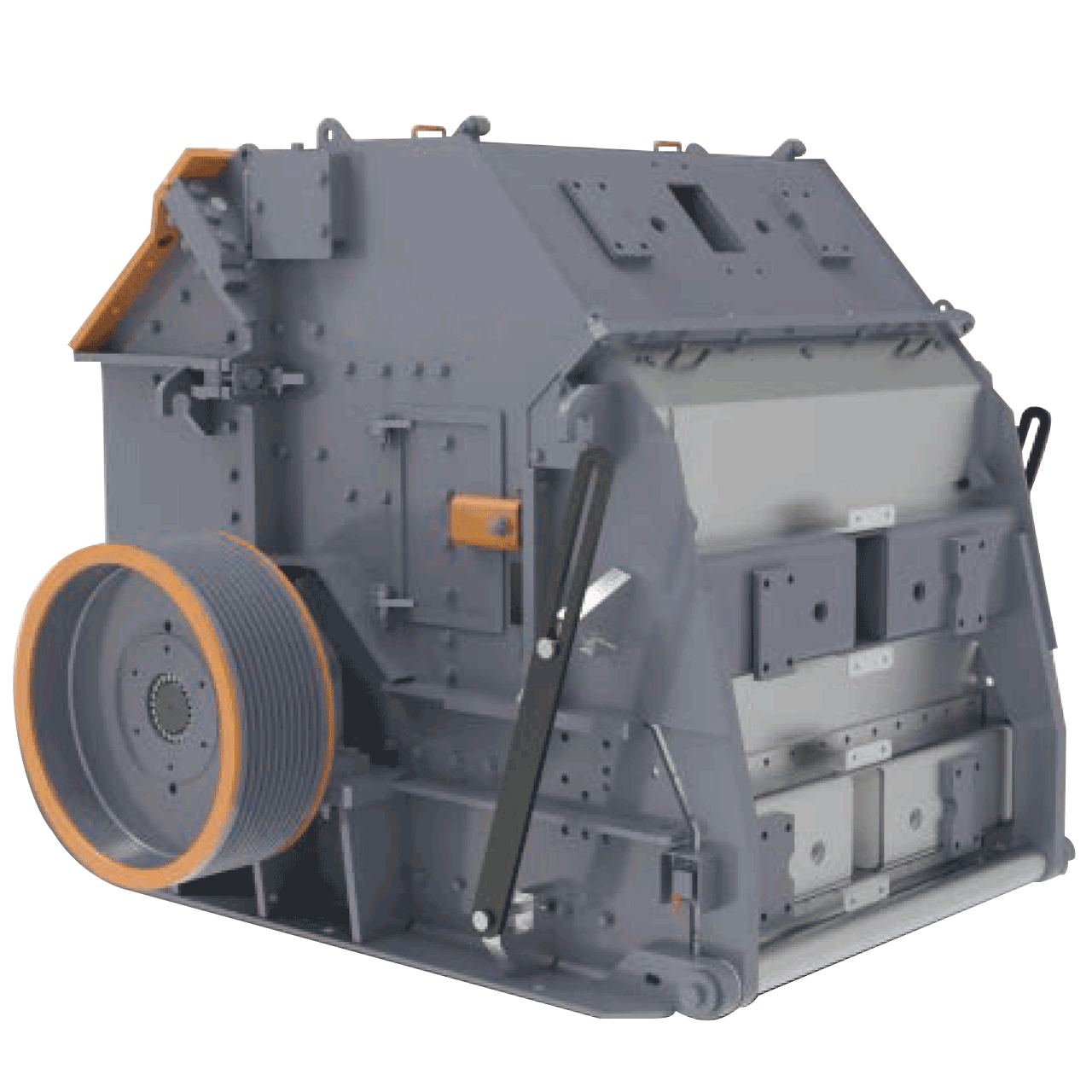

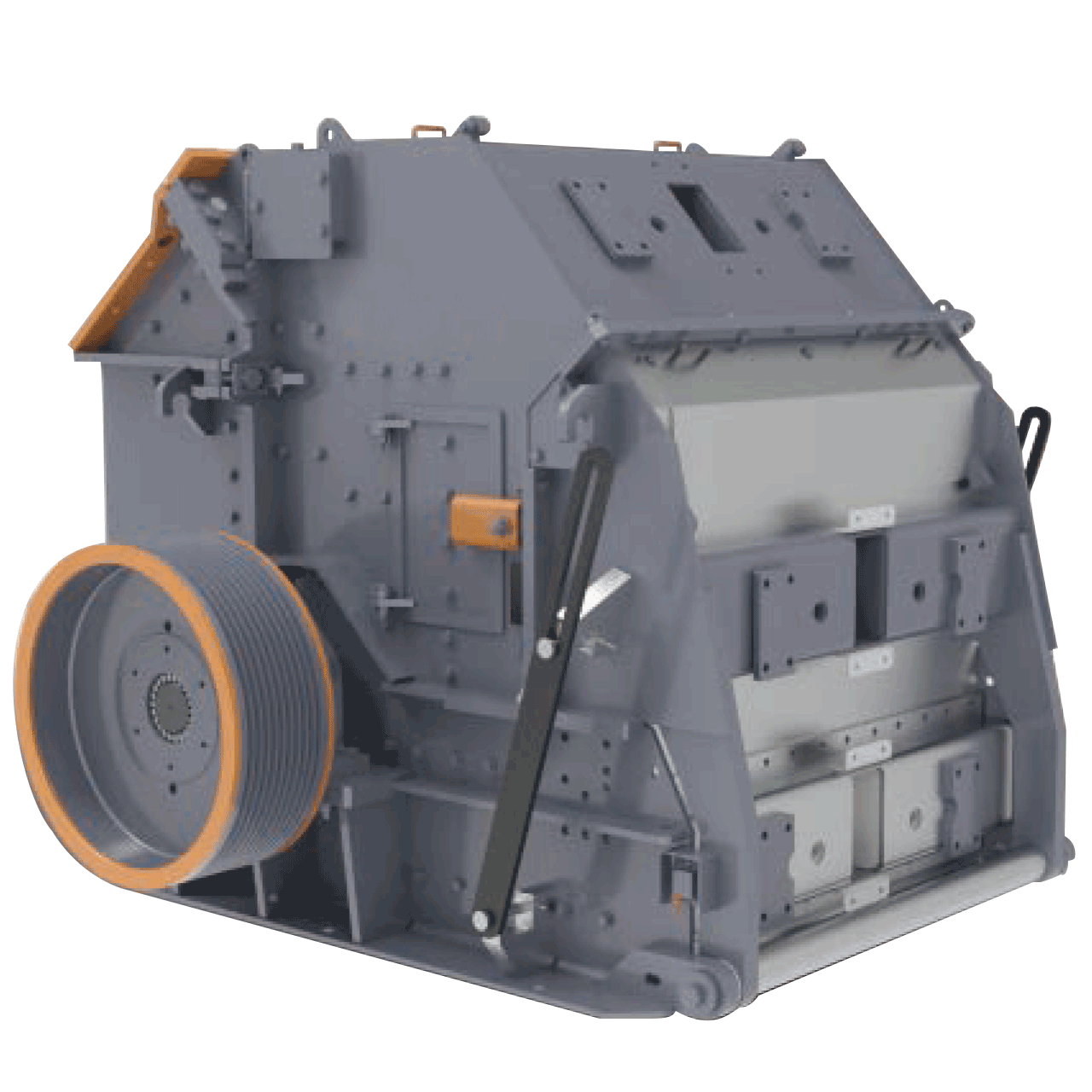

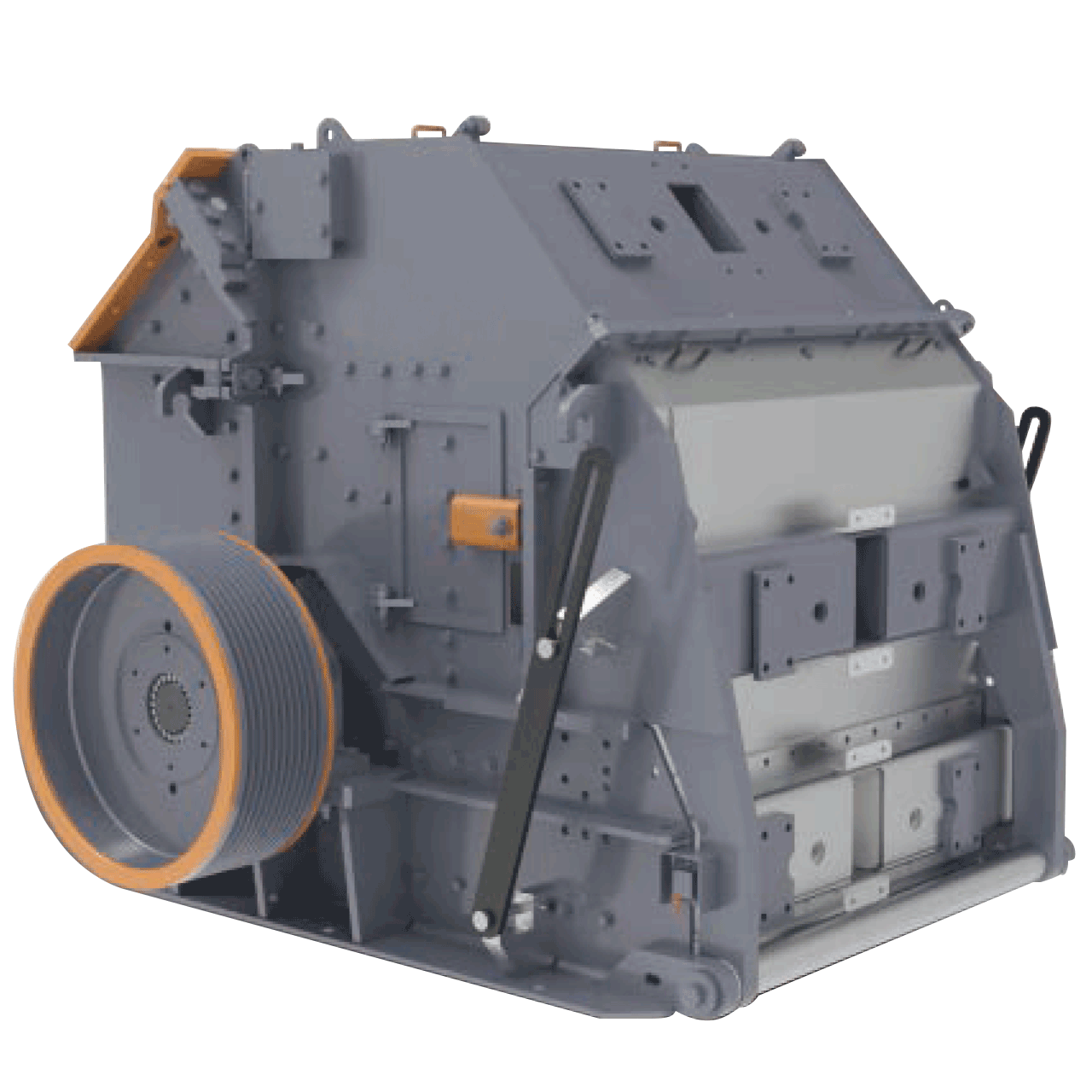

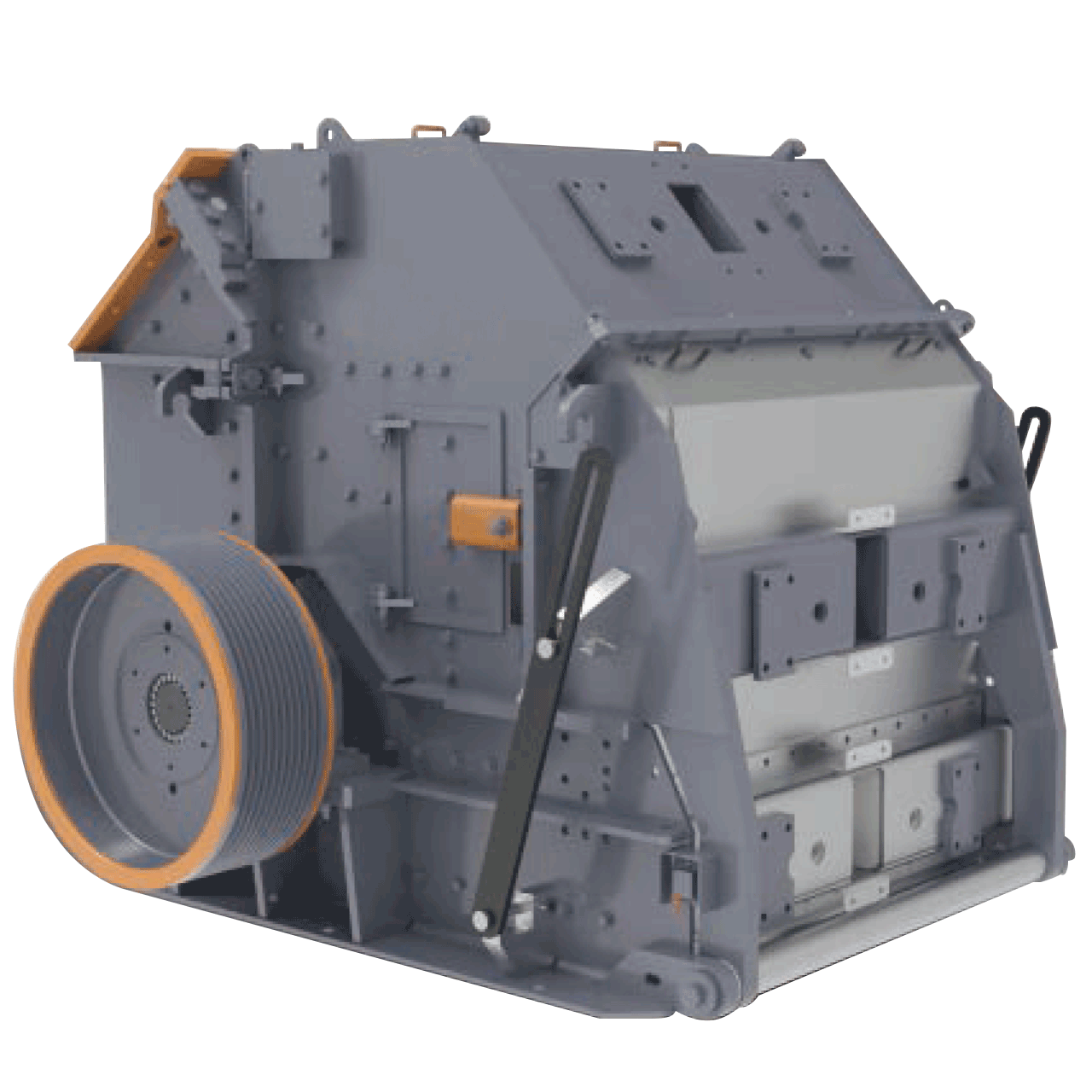

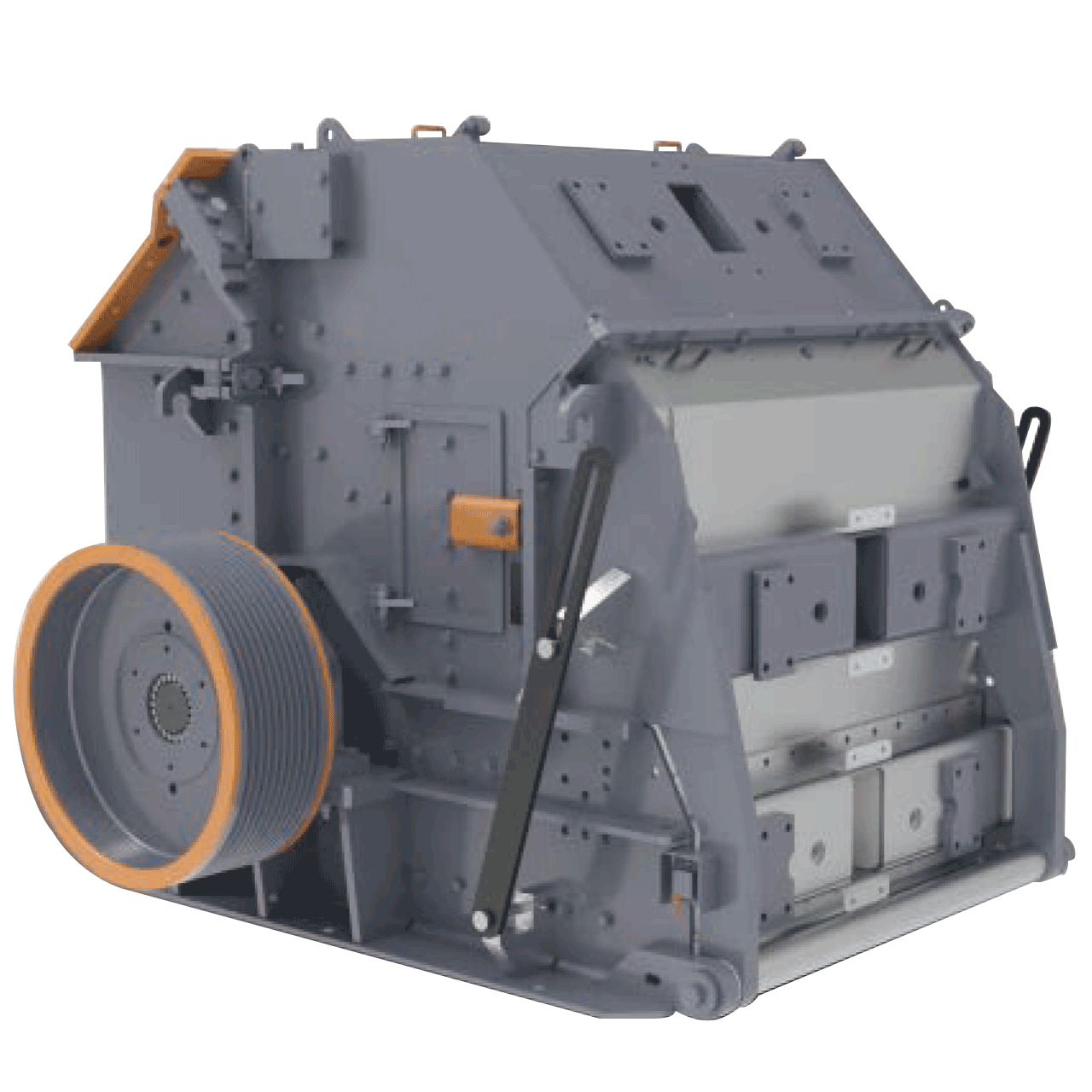

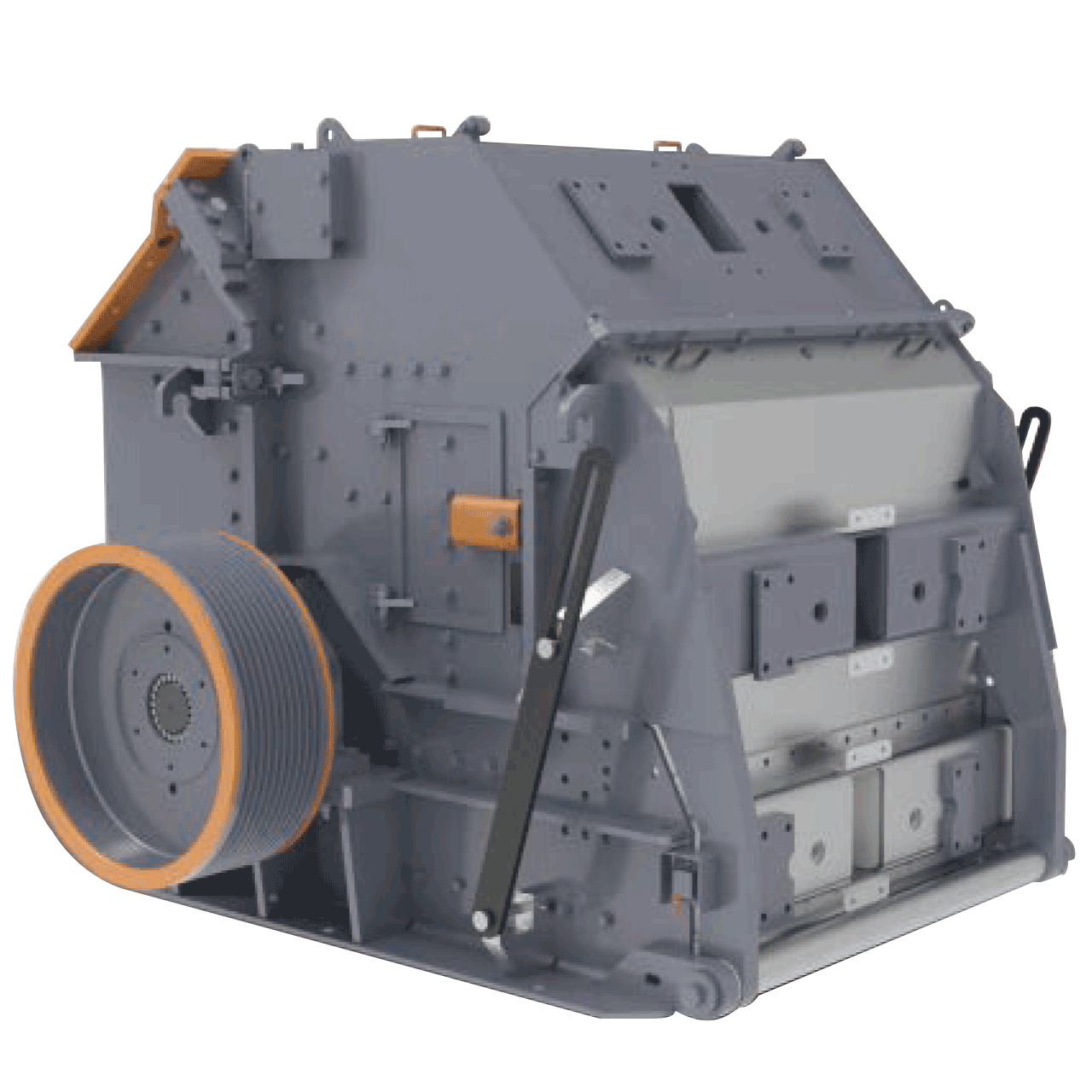

MNP1520 HFJ Series Impact Crusher

Manufacturer : MORETEC

Part number : MNP1520

OEM Compatibility :

Category :Crusher / Impact Crusher

Description

Description

MORETEC is a professional mine crushing and screening equipment manufacturer and service provider.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

HFJ series impact crusher

HFJ series impact crushers are widely used in processing operations for primary and secondary ore crushing. It is a crusher equipment that uses impact energy to crush brittle materials below medium hardness. When working, driven by the motor of the crusher, the rotor rotates at high speed, and the ore obtains huge kinetic energy from the impact process. After being broken again, the ore bounced back by the counterattack plate is again impacted by the hammer head, and the above-mentioned crushing process continues to be repeated. Sometimes primary crushing is sufficient to obtain the final product.

HFJ Features

· HFJ series MNP1520 model, the size of the feeding port can reach 2040×995mm, the maximum feeding size can reach 700mm, and the crushing efficiency is high;

· Heavy-duty rotor design and unique crushing cavity design not only ensure the stability, but also make the final product score higher during the operation of the equipment;

· Wedges are used to fix the blow bars, the gap between the counterattack plate and the blow bars can be easily adjusted, the discharge particle size can be effectively controlled, and the particle shape is good;

· The crescent-shaped plate hammer can ensure the vertical impact of the material, the impact force is large, and the crushing efficiency is high.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

HFJ series impact crusher

HFJ series impact crushers are widely used in processing operations for primary and secondary ore crushing. It is a crusher equipment that uses impact energy to crush brittle materials below medium hardness. When working, driven by the motor of the crusher, the rotor rotates at high speed, and the ore obtains huge kinetic energy from the impact process. After being broken again, the ore bounced back by the counterattack plate is again impacted by the hammer head, and the above-mentioned crushing process continues to be repeated. Sometimes primary crushing is sufficient to obtain the final product.

HFJ Features

· HFJ series MNP1520 model, the size of the feeding port can reach 2040×995mm, the maximum feeding size can reach 700mm, and the crushing efficiency is high;

· Heavy-duty rotor design and unique crushing cavity design not only ensure the stability, but also make the final product score higher during the operation of the equipment;

· Wedges are used to fix the blow bars, the gap between the counterattack plate and the blow bars can be easily adjusted, the discharge particle size can be effectively controlled, and the particle shape is good;

· The crescent-shaped plate hammer can ensure the vertical impact of the material, the impact force is large, and the crushing efficiency is high.

| Max feeding size | 700 mm |

| Weight | 27.1 ton |

| kw | 400kw |

| Feed Opening | 2040×995mm |

Parts List