Analysis of wear resistance of slurry pump ceramic/coating/alloy materials

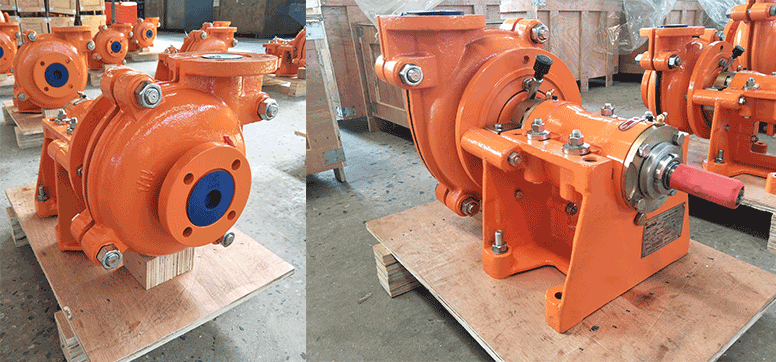

Let’s talk about the ceramic/coating/alloy materials of slurry pumps. In recent years, various domestic industries have been constantly exploring and developing, and the field of slurry pumps is no exception. Slurry pumps are a type of vulnerable pumps. Wear-resistant materials are undoubtedly the key factor of slurry pumps. Continuous research and development to explore the wear resistance of materials has become the key to industry research.

1. Common traditional materials for slurry pumps

1. High chromium wear-resistant alloy material (slurry pump, dredging pump)

High chromium wear-resistant alloy material is a material with a large market share in common applications of slurry pumps.

Generally called: A05, Cr26, Chromium 26, KmTBCr26

This material is currently widely used

The main factor that determines the quality of the material is the Cr content, which according to standards is between 25-27

Therefore, in order to boast that their materials are excellent, many manufacturers generally say that the Cr content reaches 27-29

But chromium is an important metal element, but it is not decisive.

Otherwise, the material of the slurry pump is easy to study. Just increase the Cr content.

2. Ceramic accessories for slurry pumps

In recent years, ceramic slurry pumps have continued to appear in market applications.

Many customers are very interested in ceramic accessories

Moretec Pump Industry has also done a lot of research on ceramic accessories for slurry pumps

Ceramic accessories are not a new product in recent years. Slurry pumps made of such materials have been available at home and abroad many years ago.

However, the market application is not very large

There are many main reasons. I think the main ones are as follows:

First of all, ceramic accessories have high requirements on working conditions, and the slurry they transport must be uniform and fine particles.

Because lumpy objects in the conveyed slurry will produce a large impact force, they will be damaged and cause the accessories to break.

However, the slurry transported by the slurry pump often contains uneven particles.

Once again, the production process of ceramic slurry pump accessories is subject to certain restrictions, and its machinability is poor. In other words, it is possible to mold it in one go during production.

Post-processing is difficult and the plasticity is poor

In addition, ceramic slurry pump accessories are difficult to recycle after replacement, which will lead to the existence of a large amount of garbage, especially in the new era of increasing environmental pressure, which is difficult to adapt to.