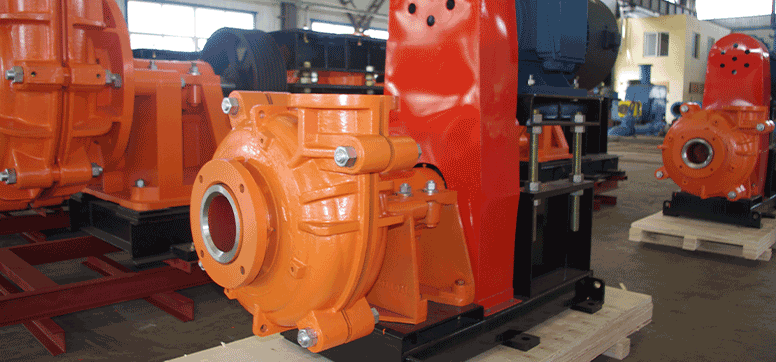

Although the essence of a mud pump is to pump mud with solid particles, there is no problem using this pump to pump clean water. However, using a mud pump for a long time to pump clean water is very inappropriate, as each pump is designed for its specific purpose. Therefore, for long-term pumping of clean water, it is recommended to use a clean water pump.

Most people believe that the effluent efficiency of slurry pumps and sewage pumps is high. Some even approach the efficiency of cleaning water pumps. However, by comparing the clean water efficiency of slurry pumps and sewage pumps, this is not the case. The clean water efficiency of the slurry pump and sewage pump is as follows:

1) The design of ordinary clean water pumps is to achieve maximum efficiency. That is to say, the hydraulic structural parameters of the clean water pump are the best combination to achieve the highest efficiency. The efficiency of pumps with special requirements such as slurry pumps and sewage pumps cannot exceed the efficiency of clean water pumps in the same period. This comparison refers to the advanced level of contemporaries, rather than someone's design level.

2) With the continuous improvement of theoretical research and the deepening and accumulation of experimental conclusions. The application of two-phase flow theory will inevitably improve the efficiency of sewage pumps and slurry pumps.

3) The widening of the mud pump channel is mainly to reduce the flow rate of two-phase flow in the channel and reduce wear. Therefore, the efficiency of highly abrasive slurry pumps is usually lower than that of soft slurry pumps.

4) To prevent blockage, the channel of the sewage pump has been widened, so the efficiency of the original sewage pump is usually lower than that of the secondary sewage pump.

according to φ/ Statistical results of sewage pump efficiency with ds=0.6-0.8 and q<600m3/h.

The efficiency formula under this condition was obtained.

[1] The concentration of ETA=0.78- (6.74q) -0.32-0.29 (0.32-lg 0.013ns) in Q-flow rate is 0.32 to 0.29 φ- The allowable diameter of the pump.

5) It is recommended to provide the efficiency of the sewage pump and slurry pump, while also providing the minimum diameter. Facilitate comparison of pump design levels. Suggest establishing through experimentation η= F (q, ns, φ) The relationship between sewage pump and slurry pump.

6) The main reason why the efficiency of sewage pumps and slurry pumps is lower than that of clean water pumps is due to their widened flow channels. The decrease in efficiency is mainly related to the degree of widening. So, if there is no capacity limit.

It is meaningless to compare the efficiency of two different sewage pumps and slurry pumps (with the same q, h, and n).