How to choose a slurry pump? How to choose a slurry pump that is suitable for working conditions?

1. Firstly, confirm whether to use a horizontal slurry pump or a vertical slurry pump. The criterion for judgment is whether there is pressure at the pump inlet. If the slurry can naturally flow into the pump chamber, a horizontal slurry pump can be used. If the slurry is in the water tank, a vertical slurry pump is required.

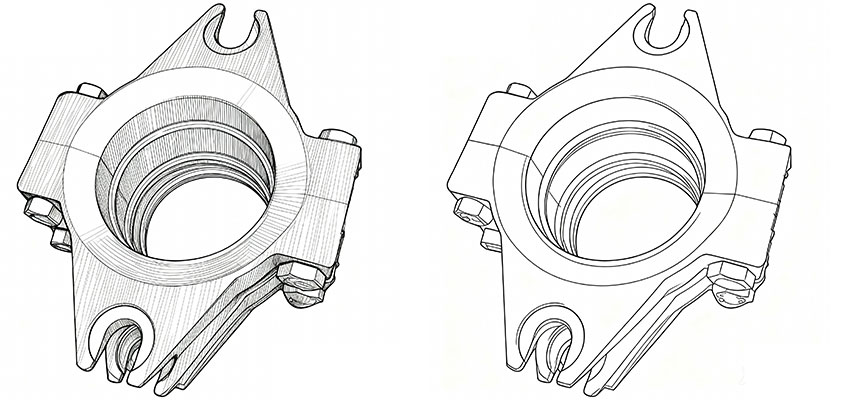

2. Select the material of the slurry pump based on the acidity and alkalinity of the slurry. Acid resistant and wear-resistant materials include: natural rubber material, A49 material, A33 material. Wear resistant materials include A05 material and A07 material.

3. To determine the material, it is necessary to determine the pump type. Horizontal pump types include AH series slurry pumps, ZJ series slurry pumps, and ZGB series slurry pumps. Vertical pumps include SP series and ZJL series. When encountering special working conditions, there are ZJQ series. The ZJQ series is used for diving conditions. AF series foam pump is used to transport the pulp containing foam gas, which is more used in paper mills.

4. To determine the pump type, it is necessary to confirm the sealing method, including packing seal, pressure reducing cover auxiliary impeller seal, and mechanical seal. The mechanical seal and packing seal must be sealed with cooling water. And the cost of mechanical seals is high, with no leakage at all.

5. Choose a suitable pump and calculate the motor power used based on the efficiency of the flow head pump and the specific gravity of the slurry.

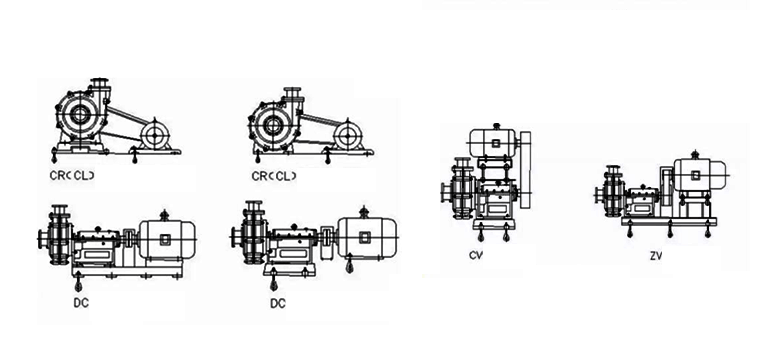

6. The next step is to determine the placement of the slurry pump and motor, also known as the slurry pump transmission mode, which includes CRZ transmission, ZVZ transmission, CV transmission, DCZ transmission, etc.