Slurry pumps common failures and solutions, the main slurry pumps often encountered during the use of the problem is summarized, and the corresponding solution against, greatly facilitating the user against the query slurry pumps common failures and solutions.

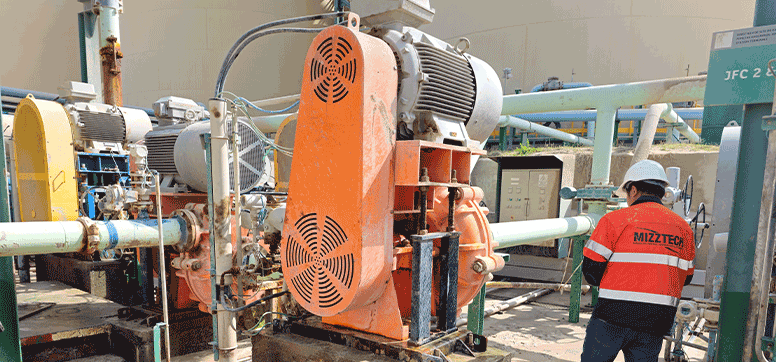

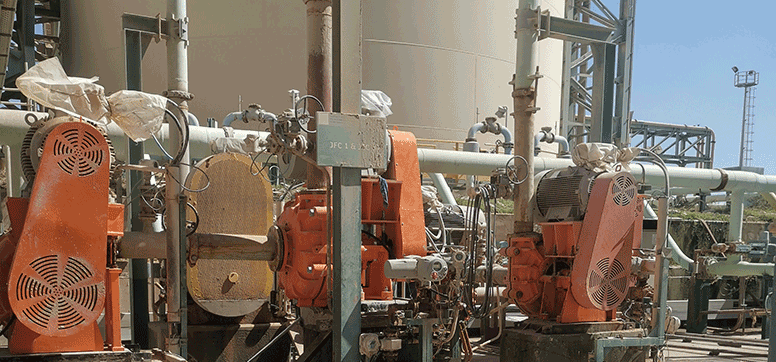

Find slurry pump manufacturer on MIZZTECH, real professional slurry pump research and production enterprises, slurry pump model complete, welcome to inquire procurement!

Now summarized as follows:

First, the slurry pump does not suck water

Occurrence of reasons:

1. suction pipe or packing leakage

2. Steering is not right or impeller damage

3. Suction pipe blockage

Solution:

1. Plug the air leakage part

2. Check the steering and replace the impeller with a new one.

3. Exclude the blockage

Second, the slurry pump shaft power is too large

Occurrence causes:

1. packing gland is too tight, packing heat

2. Pump friction

3. Bearing damage

4. Drive device belt is too tight

5. Pump flow is large

6. High speed and high ratio

7. Motor shaft and pump shaft are not centered or not parallel

Solution:

1. Loosen packing gland bolts

2. Eliminate friction

3. Replace the bearing

4. Adjust the belt

5. Adjust the operating conditions of the pump

6. Adjust the speed

7. Adjust the motor shaft and pump shaft

Third, the pump bearing overheating

Causes:

1. Bearing grease (oil), too much or too little

2. Grease (oil) has debris

3. Bearing damage

Solution:

1. Adjust the grease (oil), to be appropriate

2. Change new grease (oil)

3. Change new bearings

Fourth, the pump bearing life is short

Generate causes:

1. Motor shaft and pump shaft is not centered, or not parallel

2. Shaft bending

3. Friction in the pump or impeller out of balance

4. The bearing enters the foreign matter or the grease quantity is not proper.

5. Bearing assembly is not reasonable

Solution:

1. Adjust the motor shaft and pump shaft

2. Change the shaft

3. Eliminate friction, change new impeller

4. Clean the bearings

5. Reassemble the bearings

Five, the pump packing at the serious leakage

Causes

1. Serious packing wear

2. Serious wear of shaft sleeve

3. Seal water is not clean

Solution:

1. Change new packing

2. Replace the shaft sleeve

3. Clean sealing water

Six, the pump vibration noise

Causes:

1. Bearing damage

2. Impeller imbalance

3. Suction pipe air intake, clogging

4. Uneven flow, pump pumping

Solution:

1. Replace the new bearing

2. Replace the new impeller

3. Eliminate air intake, clean up the blockage

4. Improve the pump feed