The application market of MUD PUMP is very broad, there are mines, paper, printing and dyeing, environmental protection, graphite, gold, ceramics, oil refining, petroleum, chemical industry, farms, salt farms, iodine farms, dyeing and chemical industry, brewing, fertilizer, coking and chemical processing plant, construction, gold mine, mud, quicksand, mud ponds, sewage ponds, sewage sending and sucking of thick slurry and thick liquids, loaded and suspended material sewage operations, but also can be used as a coal mine drainage and containing mud block of the fluids.

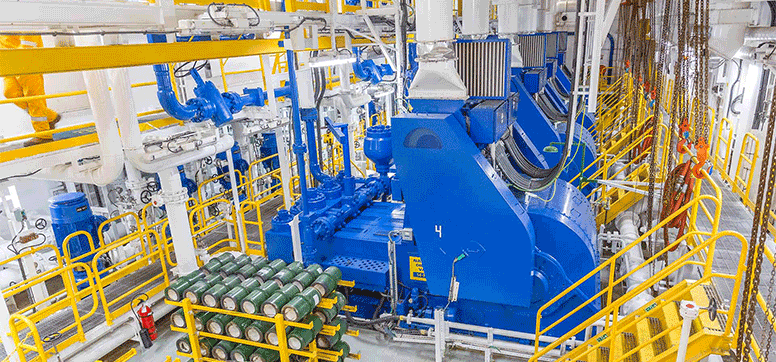

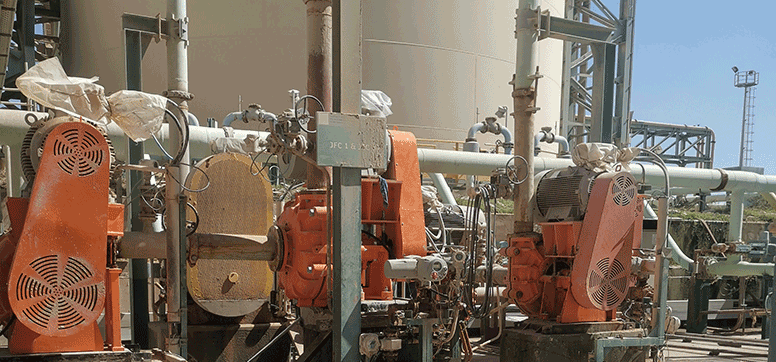

Mud pump is the main equipment of hydraulic dredging project ship, its main use of water movement to complete the purpose of dredging

This kind of water-powered dredger is mainly divided into rake suction type, winch suction type, bucket wheel type, suction cup type, blowing (suction) mud type, jet type and so on.

Currently used in the dredger mud pumps are centrifugal, single-stage, single-suction suspended (a few old mud pumps for the seat) mud pump, its working principle is similar to the centrifugal water pump.

Types of mud pumps

(A) according to the head classification

Dredger mud pump according to its head or discharge of mud distance can be divided into low-pressure high-flow mud pump, its head is generally 16 ~ 35m water column; medium-pressure mud pump, its head is 35 ~ 55m water column; and high-pressure mud pump, its head is 55 ~ 70m water column

(B) according to the impeller type

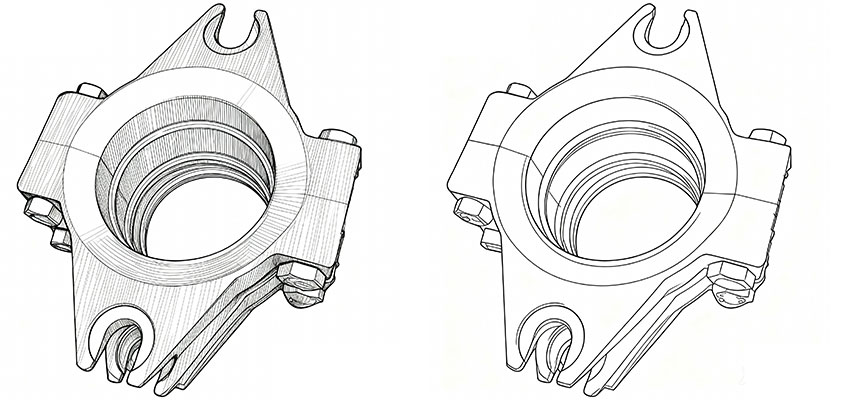

1、Impeller type can be divided into two types: separate type and closed type.

2, the impeller can also be divided into single-side inhalation and double-side inhalation two types. In single suction type, mud water enters from one side, while double suction type, water is inhaled from both ends. Modern mud pumps are generally single suction type.

3, the impeller can also be divided into two types of runoff type and axial flow type. Mud pump impeller outer diameter and inner diameter of the ratio with the increase in speed and decrease. Runoff impeller ratio of the largest, axial flow impeller ratio of 1. Most mud pumps for the runoff type.

(C) according to the pump shell type

1, constant speed worm shell type: pump casing around the impeller cross-sectional area is incremental, in order to make each cross-section of the discharge velocity is constant, about half the speed of the outer edge of the impeller. With a diffusion cone tube can be converted to this high-speed pressure head. Diffusion cone tube conversion efficiency can be as high as 90%.

2、Variable speed worm shell type: the increase rate of the channel area is larger than that required for constant speed worm shell type, thus the flow rate of the liquid in the worm shell is constantly high and can be as low as 40%.

3、Diffusion vane pump casing:

A guide vane is fitted around the impeller to provide a diffusion channel to reduce the discharge rate. This increases the conversion efficiency by 10-20%, producing a total efficiency of up to 70%.

Comprehensive analysis of the above, consider obtaining its maximum efficiency, modern mud pumps are constant speed worm shell type.

(D) according to the mud pump impeller blade number classification

According to the mud pump impeller blade number can be divided into three blades, four blades, five blades mud pump, theoretically speaking, generally speaking, three impeller mud pump its channel is larger, less likely to be clogged by debris or stones. For this reason, the general small mud pump in order to facilitate the dredging of debris through the three impellers, of course, small mud pump impeller width than the theoretical calculation of the width is slightly larger.

(E) according to the mud pump impeller shape to points

Can be divided into circular vane type, logarithmic spiral vane and involute vane type.

Troubleshooting

Water pump vibration

▲Cause: pump shaft and diesel engine (or motor) is not concentric, impeller imbalance, bearing damage;

▲Solution: adjust the concentricity, impeller for balance test, replace the bearing.

Pump water is slow

▲Reason: the gap between the front liner and the impeller is large, the outlet pipe can not seal the air, emptying full;

▲Solution: adjust the gap, adjust the outlet pipe, install vacuum device.

Pump does not suck water

▲Reason: not enough filling priming water, air can not be discharged from the pump, suction pipe leakage, large gap between the front liner and impeller;

▲Original solution: continue to fill the priming water, check the pipeline for air leakage, adjust the clearance between the impeller and the front liner.

Water discharge pressure

Small pressure, small flow rate

▲Reason: there is air in the pump, the clearance between the impeller and the front liner is large, the clutch is not closed tightly, the impeller or the liner is worn;

▲Solution: Empty the gas in the pump, adjust the gap to adjust the clutch friction plate clearance, replace the impeller or liner.

Pump wear fast

▲Reason: poor construction environment (large particles), long conveying distance, long inlet pipe line;

▲Solution: replace the sand field, add a booster unit, shorten the length of the inlet pipe to reduce cavitation.

Impeller journal wear fast

▲Reason: low head of high pressure water pump, misalignment of packing, pump shaft and back cover are not concentric;

▲Solution: replace the high pressure pump higher than the mud pump head, replace the packing, adjust the concentricity.

Translated with www.DeepL.com/Translator (free version)