Slurry pump shaft seal type selection

There is a pressure difference between the fluid inside the pump and the atmospheric pressure outside the pump, the liquid leaks outward along the gap between the shaft and the casing, for which a sealing device needs to be set up, which is called a shaft seal.

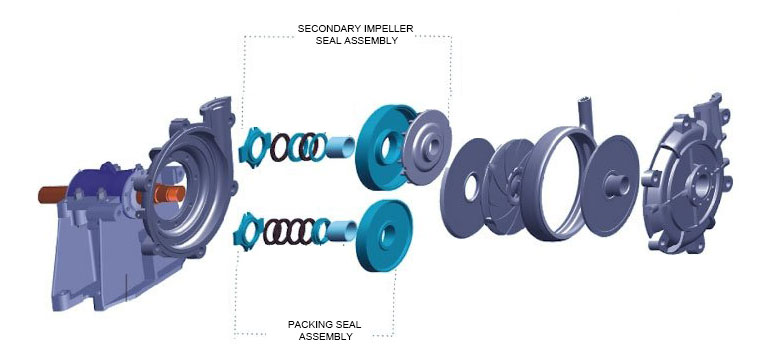

At present, the slurry pump commonly used shaft seal type has three kinds, namely the impeller power seal, packing seal and mechanical seal.

Second, select the basis and conditions

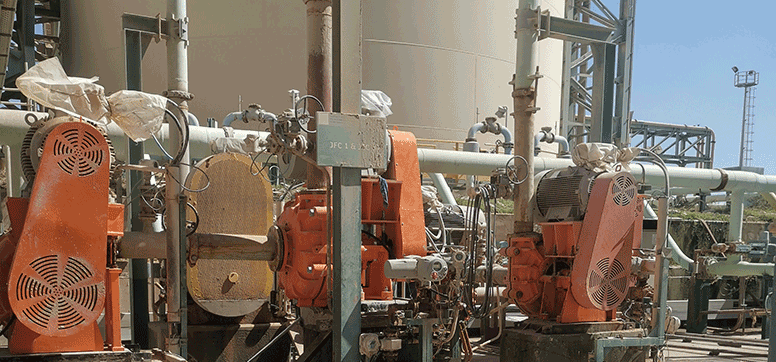

In the site water volume, water pressure can reach the slurry pump shaft seal water requirements, it is recommended that the preferred vice impeller power seal.

This shaft seal type due to low cost, easy maintenance and other advantages, in the coal washing system is widely used.

In the field water shortage or water pressure is not stable and can not reach the slurry pump shaft seal water requirements, can choose grease lubrication vice impeller power seal.

At this time, it should be noted that in the operation of the regular addition of grease one or two times a day, to ensure that the packing is in a good lubrication state, in order to improve the reliability of the operation, the packing can be selected from carbon fiber impregnated with tetrafluoroethylene packing.

Packing seal form is mainly used in the second stage and above of the tandem pump.

In the coal industry, heavy media coal processing system, slurry pump pipeline is shorter, the head is generally not more than 80m.

The use of single-stage pumps that can meet the actual needs.

Will not appear in the form of a series so generally do not choose the packing seal form of shaft sealing.

Coal washing system, such as qualified media pumps, some do not allow the dilution of slurry (or water) process section is recommended to prioritize the use of mechanical seals.

In order to improve the environmental quality of the site to achieve a long operating cycle, no leakage on site.

The above situations (sufficient water, shortage, do not allow water to dilute the slurry) can be selected mechanical seals, can be combined with the concentration of slurry, temperature and feed pressure and other conditions to choose the appropriate mechanical seal structure and friction vice material.

The only disadvantage of using mechanical seals is to increase the investment cost of equipment.

Slurry pump shaft seal type selection, slurry pumps are mainly packing seal, vice impeller seal and mechanical seal three types. About the slurry pump shaft seal form of introduction can click the link to view.

Vice impeller seal is generally used in the backflow work, the backflow pressure should be less than 10% of the pump outlet pressure, this type of shaft seal does not need to add shaft sealing water, but there is a power loss, generally about 5%

Packing seal need to add shaft sealing water and should ensure sufficient water pressure and water volume, shaft sealing water pressure is equal to the pump outlet pressure plus 35kPa

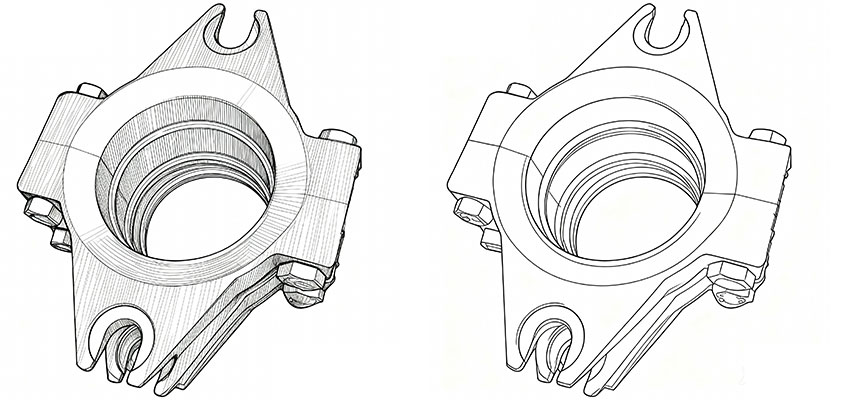

Our company will mechanical seal applied to slurry pump, with its no leakage, reliable operation and other superiority to obtain user praise, widely promoted!

And solve the multi-stage tandem slurry pump leakage problem, speed up the pace of slurry pump tandem application