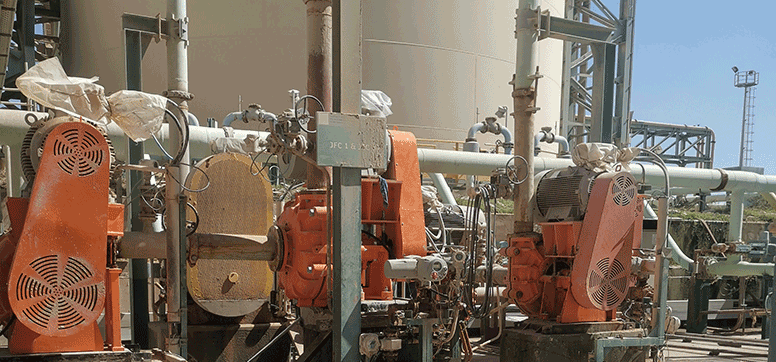

Key Considerations for Choosing the Right Mud Pump for Your Industrial Application

Key Considerations for Choosing the Right Mud Pump for Your Industrial Application

Selecting the right mud pump for your industrial application is key to ensuring operational efficiency, reducing maintenance costs and extending equipment life. Here is a list of key considerations for selecting a mud pump

1. Mud pump type selection

Centrifugal pumps:

For low viscosity slurries

For applications with high flow requirements

Plunger Pumps:

Used for high viscosity slurries or in scenarios where high pressure is required

For applications where accurate flow control is required

Piston Pumps:

Powerful pumping of high viscosity slurries

Often used for high flow rates and high pressure requirements

Screw pumps:

Smoothly conveys viscous slurries

Suitable for irregular particle slurry

2. Properties of slurries

Viscosity:

Pump selection needs to be based on the viscosity of the slurry, viscous slurries require more powerful pumping equipment.

Particle size:

Pumps need to be designed to accommodate the size of the particles in the slurry, oversized particles may lead to clogging.

Chemical composition:

Pump material selection needs to consider the chemicals in the slurry to avoid corrosion.

Temperature:

The operating temperature range of the pump needs to match the temperature of the slurry to avoid high or low temperatures affecting performance.

3. Flow and pressure requirements

Required flow rate:

Determine the flow range of the mud pump according to the needs of industrial applications to ensure that the pumping capacity meets the production requirements.

Working pressure:

The pump needs to have enough pressure to push the slurry through the pipeline to prevent underpowered conditions.

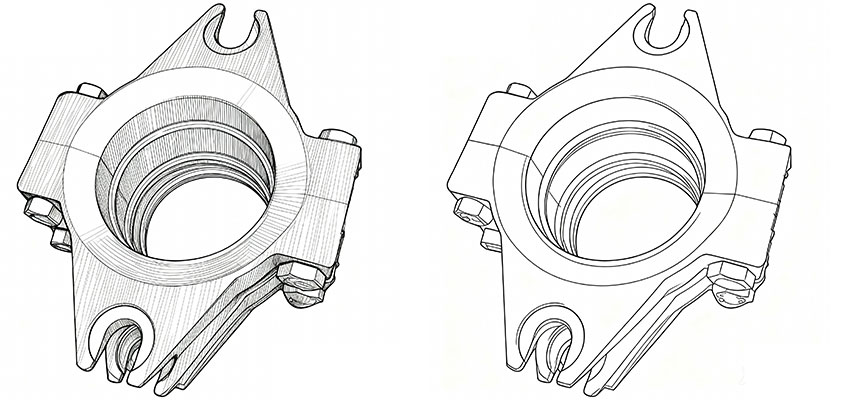

4. Pump material and durability

Corrosion resistance:

The pump body and important parts should be made of corrosion-resistant materials to ensure that long-time operation is not affected.

Abrasion resistance:

The pump liner, impeller and other parts need to have high abrasion resistance to cope with the impact of harder particles in the slurry.

5. Energy efficiency and operating costs

Energy efficiency considerations:

Choose a high-efficiency pump to reduce energy consumption and operating costs.

Maintenance costs:

Evaluate the maintenance cycle and repair cost of the pump, choose the pump that is easy to maintain and the parts can be replaced.

6. Operating environment and installation conditions

Installation location:

Ensure that the pump is installed in a suitable location to avoid the pump being affected by environmental factors (such as vibration, temperature changes, etc.).

Space requirements:

Ensure that the volume and weight of the pump is suitable for the installation space to avoid the equipment exceeding the available installation area.

7. Pump efficiency and reliability

Long-term stability:

Select those slurry pumps that can maintain stable performance over a long period of operation.

Pump failure rate:

Select mud pump brands and models with high reliability and low failure rates based on historical data.

8. Pump maintenance and service

Maintainability:

Whether the pump is easy to disassemble, clean and maintain, and whether regular maintenance is simple.

Spare parts availability:

Whether the spare parts of the pump are easy to obtain, and whether the supplier provides timely technical support.

9. Environmental considerations

Emission control:

The pump should comply with environmental regulations to ensure that the slurry is handled without causing secondary pollution to the environment.

Noise control:

Whether the operating noise of the pump meets industrial standards to reduce the impact on the working environment.

10. Cost and budget

Initial investment:

What is the purchase cost of the pump? Does it meet the budget?

Life cycle costs:

In addition to the initial investment, the long-term operating and maintenance costs of the equipment need to be considered.

Summarize:

When selecting the right slurry pump for an industrial application, a number of factors need to be considered, including the nature of the slurry, the flow and pressure requirements, the material and durability of the pump, the energy efficiency, the operating environment, and the maintenance requirements. By thoroughly evaluating these key factors, the most suitable mud pump can be selected to ensure the stability and efficiency of the production process.