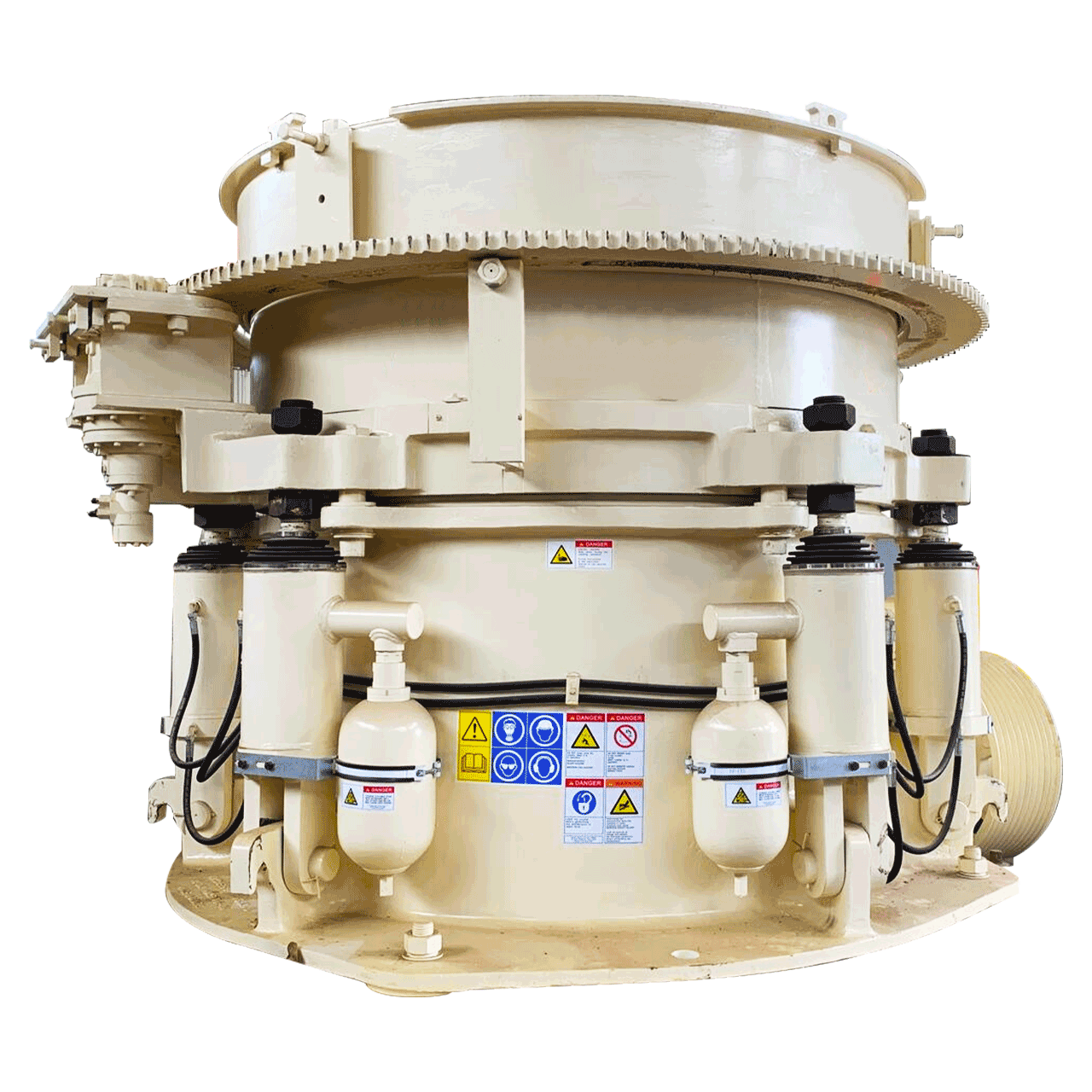

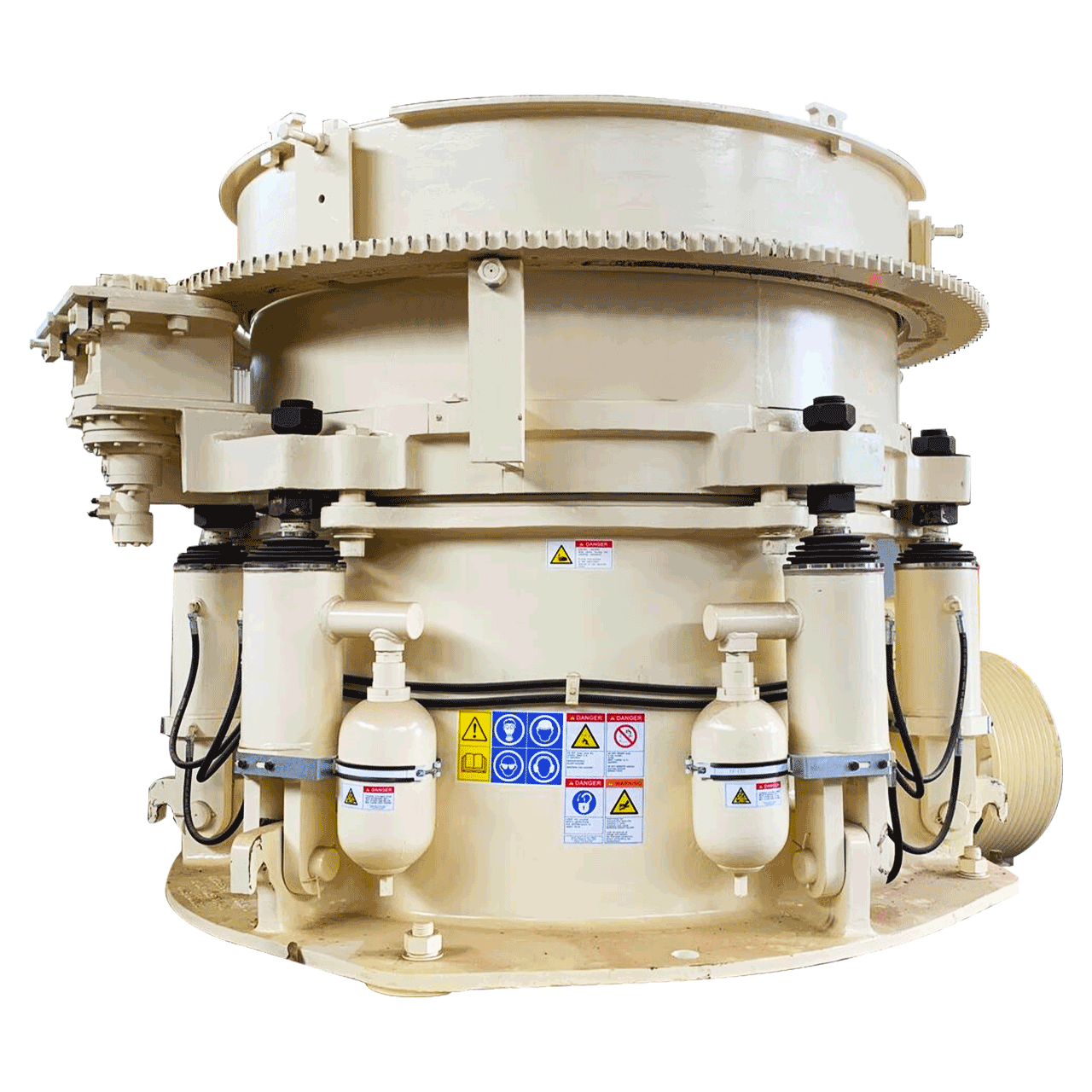

MH200 MH Series Multi Cylinders Hydraulic Cone Crusher

Manufacturer : MORETEC

Part number : MH200

OEM Compatibility :

Category :Crusher / Cone crusher

Description

Description

MORETEC is a professional mine crushing and screening equipment manufacturer and service provider.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

MH Series Multi Cylinders Hydraulic Cone Crusher

The MH series multi-cylinder hydraulic cone crusher is designed for heavy-duty working conditions, with extra high stability, an extremely huge production capacity, and crushing efficiency. It is equipped with an advanced mainframe combined with large eccentricity, high speed, and also with an intelligent automatic control system, so that it produces an excellent crushing performance during the crushing operation. Compared to other cone crushers, it has a higher main shaft speed and bigger crushing force; that’s why the fine-grained content of the discharge is higher, and is mainly used in mines and aggregate industry middle level crushing.

MH Features

· The combination of high-performance crushing cavity type and high crushing frequency greatly improves the processing capacity of the machine. At the same time, the principle of lamination crushing is adopted, and the needle-like particle size of the crushed products is greatly reduced;

· With a unique flat hammer locking device, combined with the fixed position of the wedge, on the rotor, a larger tightening torque is generated;

· The hammer is fixed on the rotor by a mechanical process, eliminating the gap between the rotors and ensuring a firm fixation;

· It adopts full hydraulic operation, so it is easy to use, has strong iron passing ability, and is easy to realize automation;

· Use of high wear-resistant and compressive raw materials, the equipment loss during operation is small, the failure rate is low, and the service life of the whole machine is greatly improved.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

MH Series Multi Cylinders Hydraulic Cone Crusher

The MH series multi-cylinder hydraulic cone crusher is designed for heavy-duty working conditions, with extra high stability, an extremely huge production capacity, and crushing efficiency. It is equipped with an advanced mainframe combined with large eccentricity, high speed, and also with an intelligent automatic control system, so that it produces an excellent crushing performance during the crushing operation. Compared to other cone crushers, it has a higher main shaft speed and bigger crushing force; that’s why the fine-grained content of the discharge is higher, and is mainly used in mines and aggregate industry middle level crushing.

MH Features

· The combination of high-performance crushing cavity type and high crushing frequency greatly improves the processing capacity of the machine. At the same time, the principle of lamination crushing is adopted, and the needle-like particle size of the crushed products is greatly reduced;

· With a unique flat hammer locking device, combined with the fixed position of the wedge, on the rotor, a larger tightening torque is generated;

· The hammer is fixed on the rotor by a mechanical process, eliminating the gap between the rotors and ensuring a firm fixation;

· It adopts full hydraulic operation, so it is easy to use, has strong iron passing ability, and is easy to realize automation;

· Use of high wear-resistant and compressive raw materials, the equipment loss during operation is small, the failure rate is low, and the service life of the whole machine is greatly improved.

| Power | 132 kW |

| Weight | 12.2 ton |

| Max Feeding size | 185 mm |

| Capacity | 90-250t/h |

| Discharge Range | 10-38mm |

Parts List