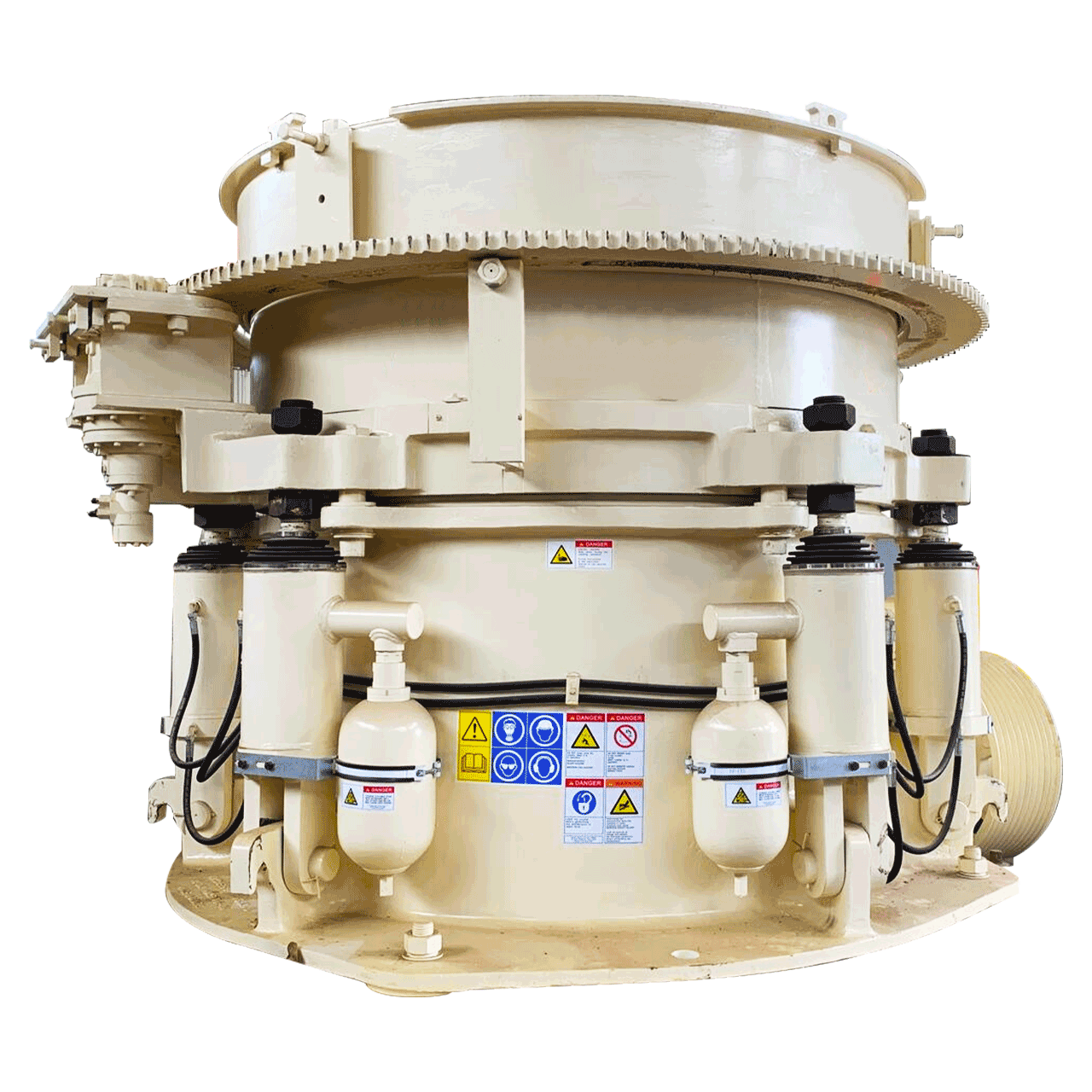

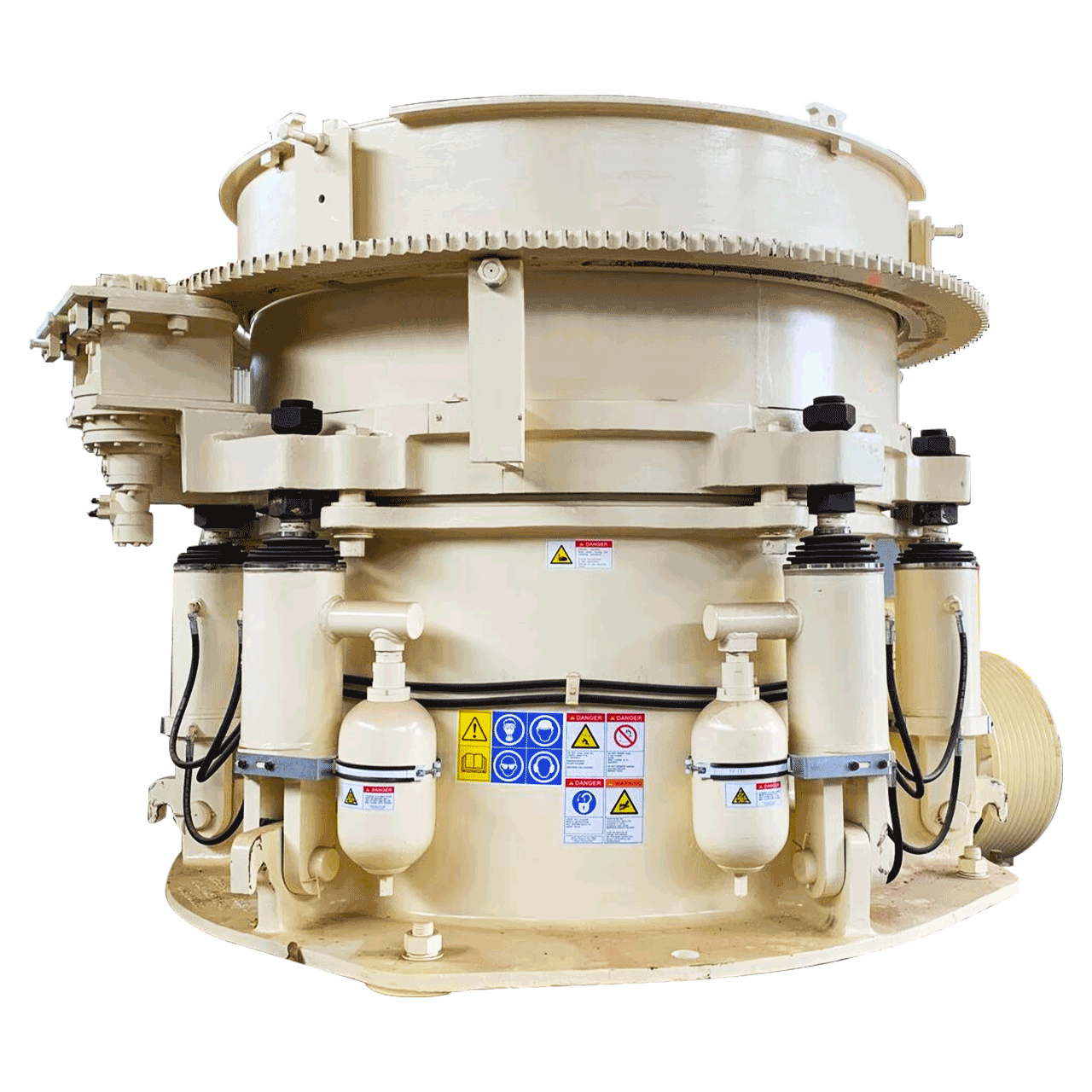

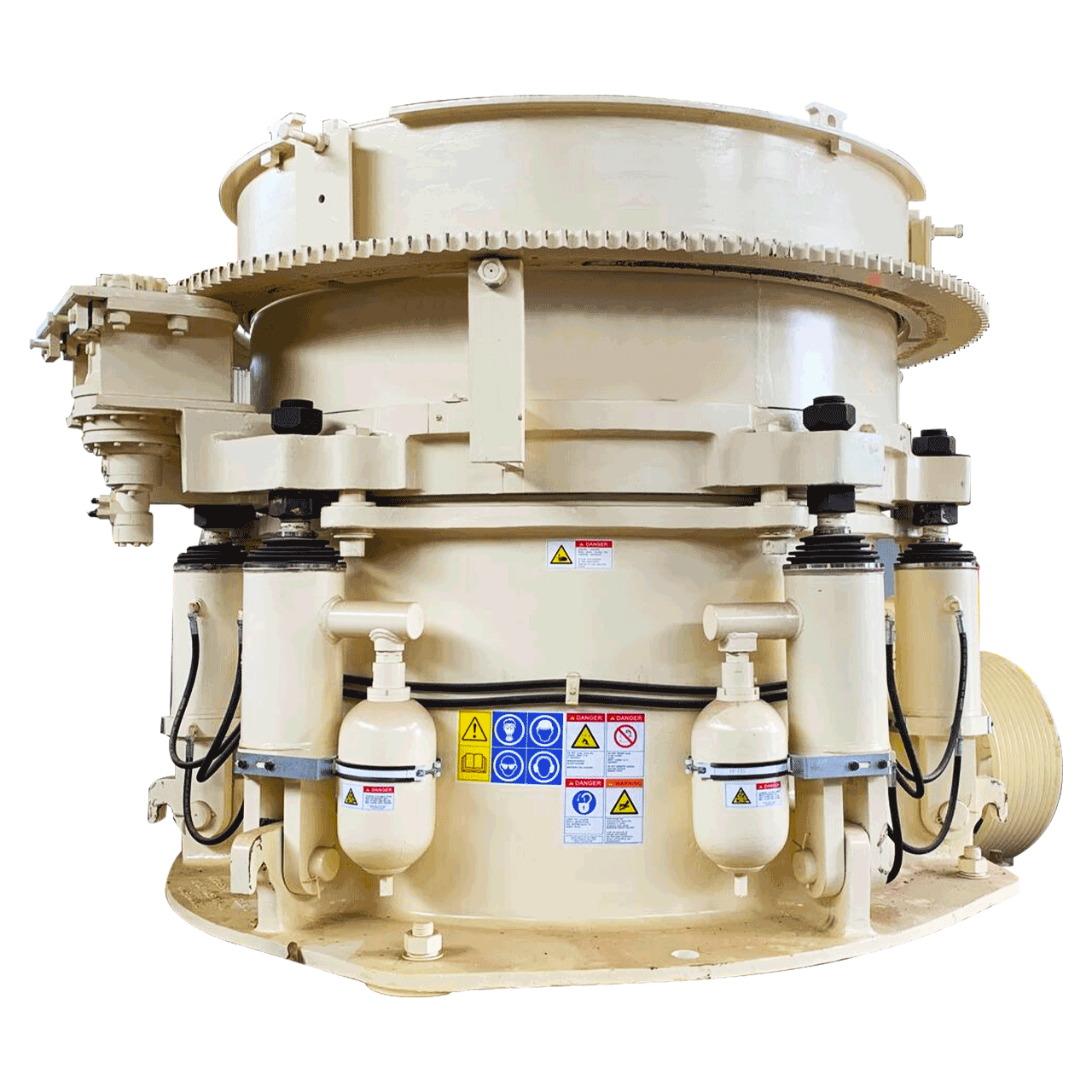

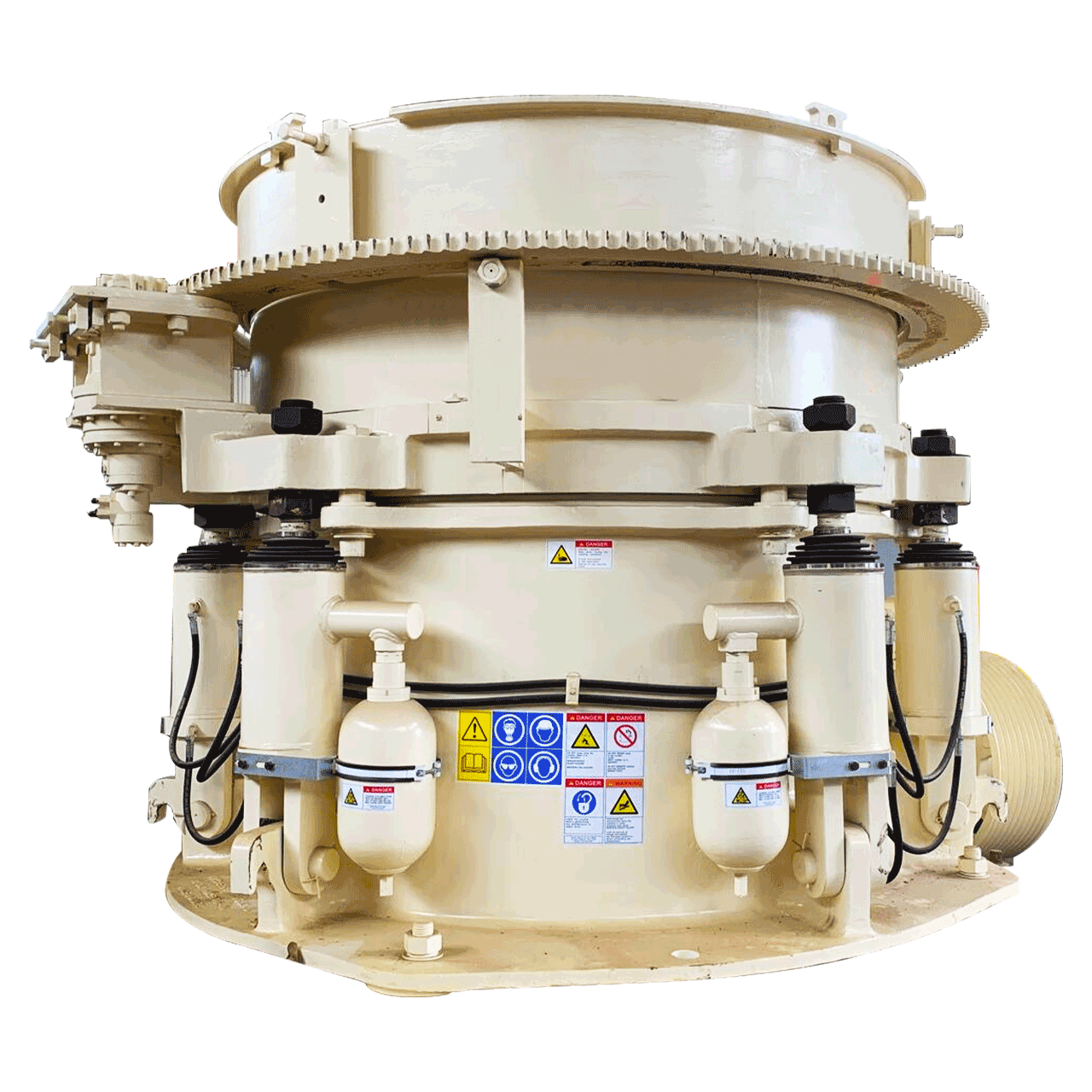

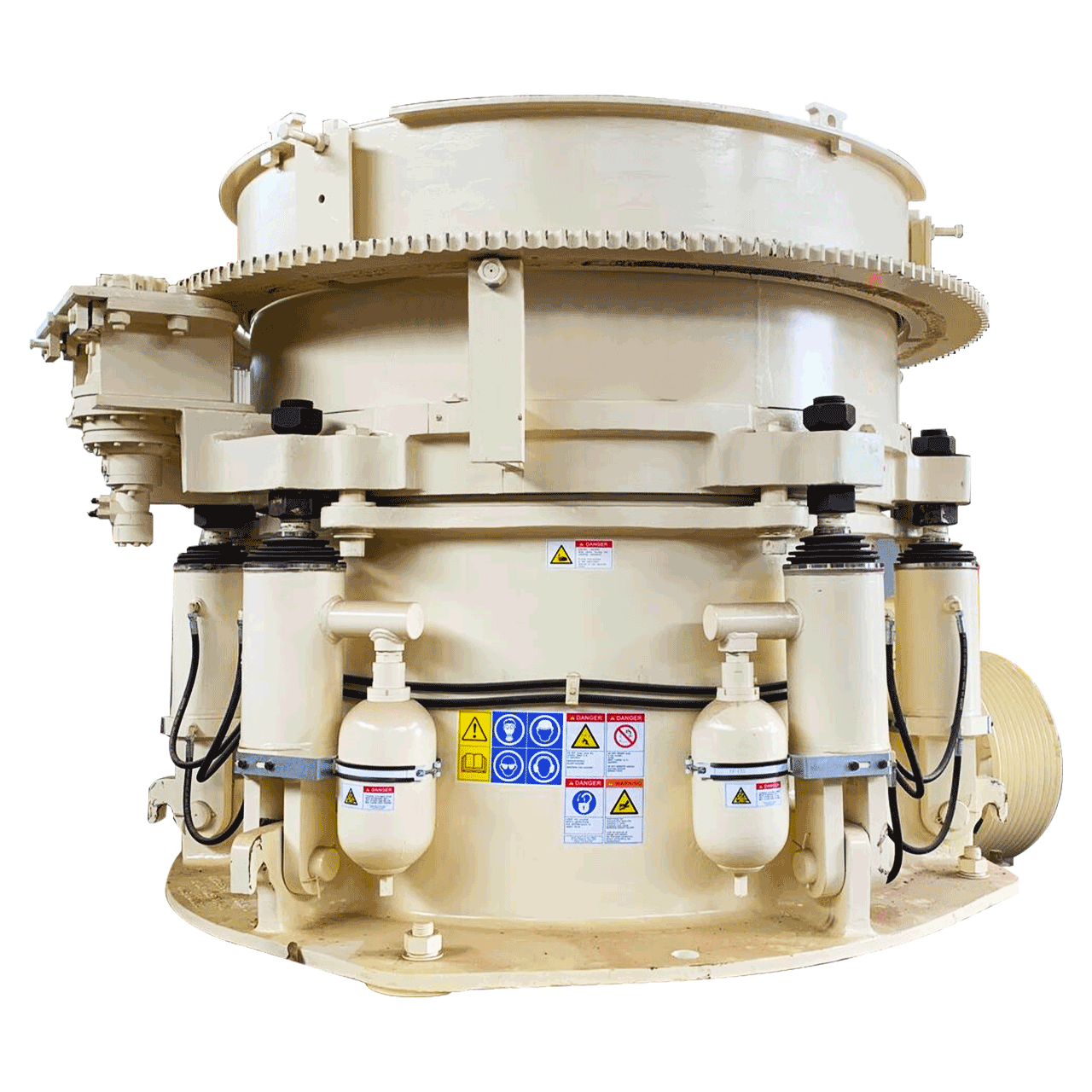

MH3 MH series multi-cylinder hydraulic cone crusher

Manufacturer : MORETEC

Part number : MH3

OEM Compatibility :

Category :Crusher / Cone crusher

Description

Description

MORETEC is a professional mine crushing and screening equipment manufacturer and service provider.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

MH series multi-cylinder hydraulic cone crusher

When the MH series multi-cylinder hydraulic cone crusher is working, the motor drives the pulley or the coupling, and the drive shaft and the cone part make the eccentric shaft do periodic swing motion under the axis line. After the material enters the crushing cavity from the feeding port, it is crushed by the mutual impact extrusion, grinding and rubbing of the eccentric shaft and the rolling mortar wall. The material crushed to the required particle size falls under the action of its own gravity and is discharged from the bottom. The hydraulic insurance system can hydraulically lift the support sleeve and the fixed cone to remove the faulty objects when the equipment has an iron failure or a boring phenomenon. production efficiency.

MH Features

· Crushing occurs between materials and the liner life is extended. The discharge particle size is more uniform, which is beneficial to the construction sand making operation;

· Hydraulic adjustment of the discharge port and overload protection greatly improve the operation level of the cone crusher, making maintenance simpler, more convenient operation, shorter downtime and saving manpower and material resources;

· Use of high wear-resistant and compressive raw materials, the equipment loss during operation is small, the failure rate is low, and the service life of the whole machine is greatly improved.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

MH series multi-cylinder hydraulic cone crusher

When the MH series multi-cylinder hydraulic cone crusher is working, the motor drives the pulley or the coupling, and the drive shaft and the cone part make the eccentric shaft do periodic swing motion under the axis line. After the material enters the crushing cavity from the feeding port, it is crushed by the mutual impact extrusion, grinding and rubbing of the eccentric shaft and the rolling mortar wall. The material crushed to the required particle size falls under the action of its own gravity and is discharged from the bottom. The hydraulic insurance system can hydraulically lift the support sleeve and the fixed cone to remove the faulty objects when the equipment has an iron failure or a boring phenomenon. production efficiency.

MH Features

· Crushing occurs between materials and the liner life is extended. The discharge particle size is more uniform, which is beneficial to the construction sand making operation;

· Hydraulic adjustment of the discharge port and overload protection greatly improve the operation level of the cone crusher, making maintenance simpler, more convenient operation, shorter downtime and saving manpower and material resources;

· Use of high wear-resistant and compressive raw materials, the equipment loss during operation is small, the failure rate is low, and the service life of the whole machine is greatly improved.

| Power | 250 kW |

| Weight | 16.1 ton |

| Max Feeding size | 220 mm |

| Capacity | 95-390t/h |

| Discharge Range | 8-45mm |

Parts List