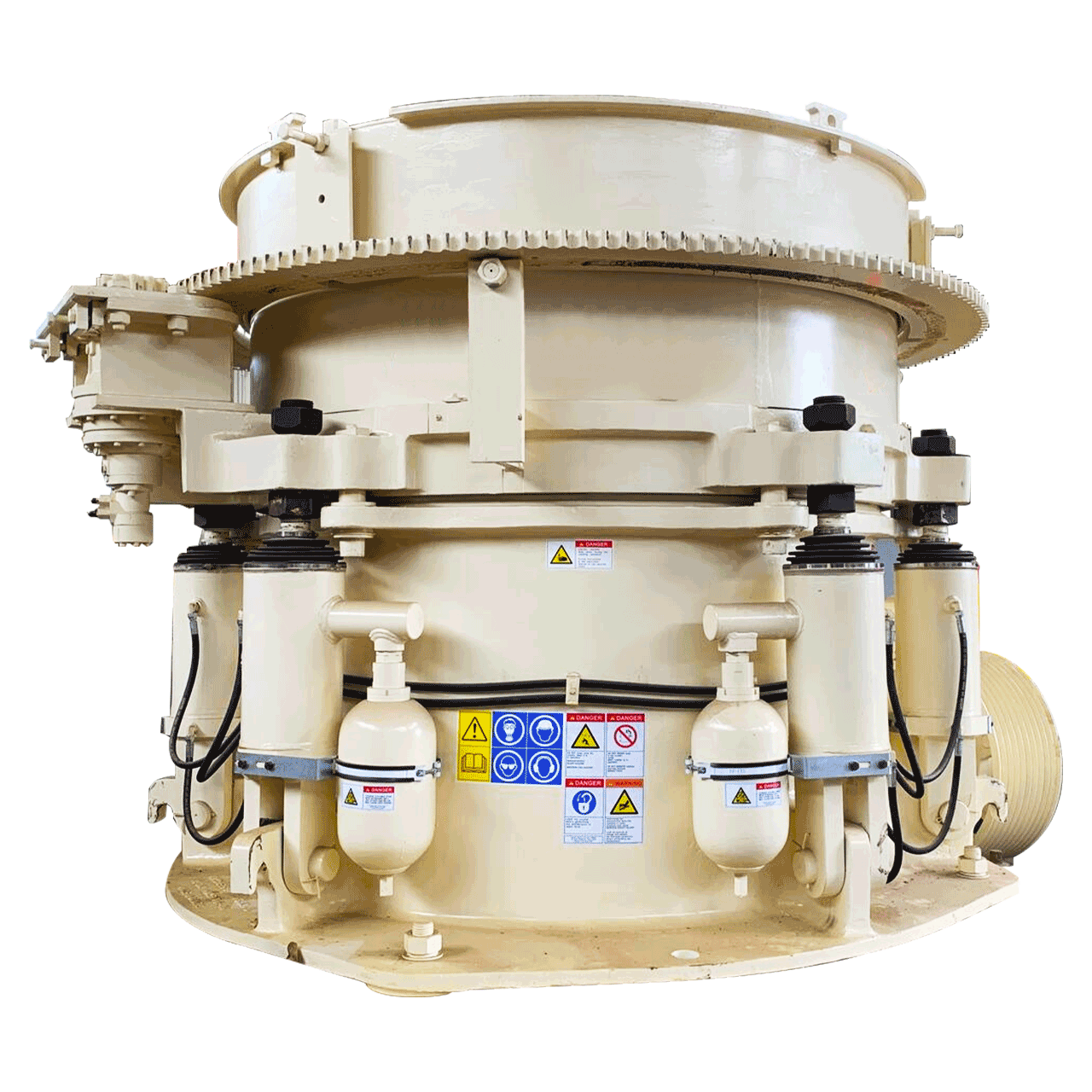

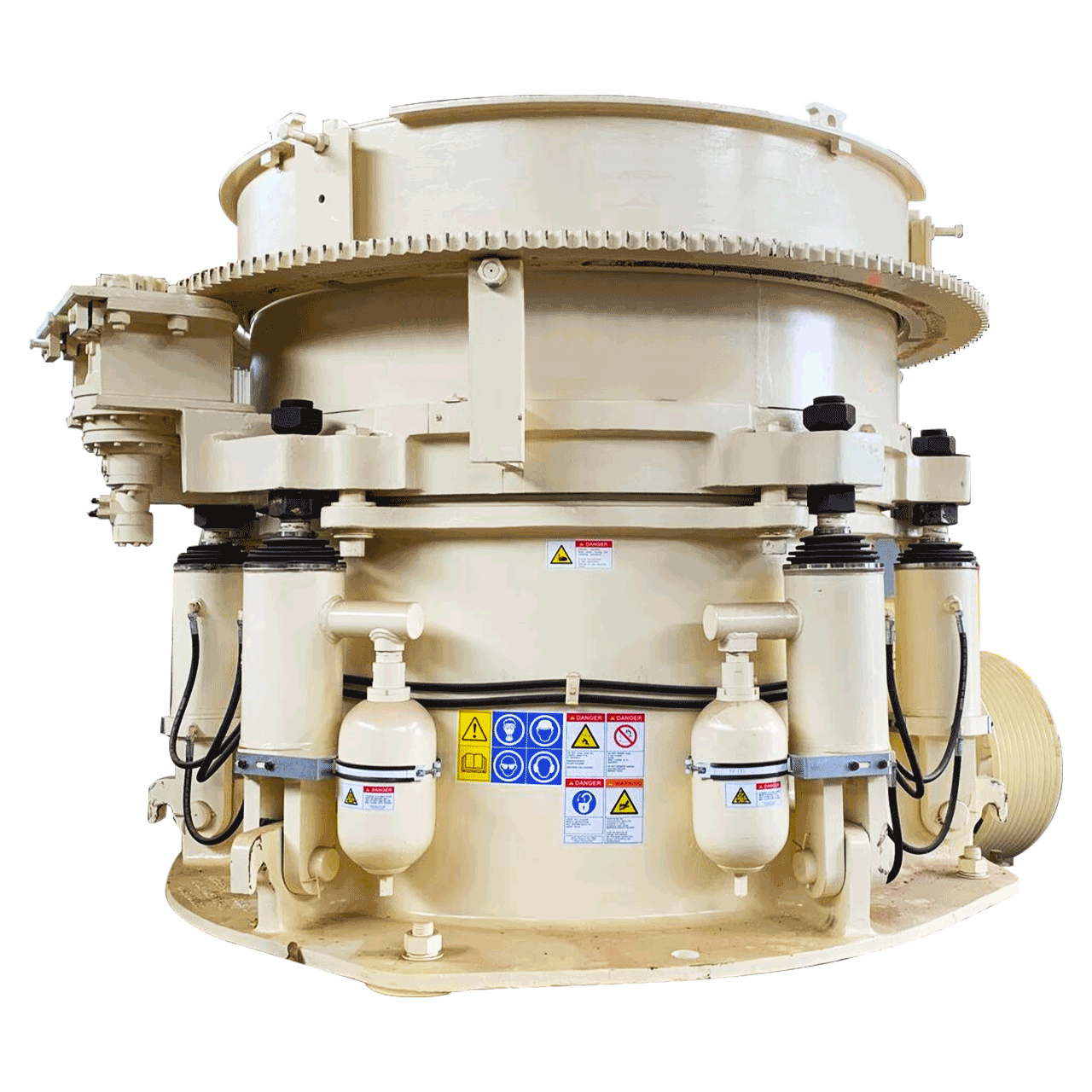

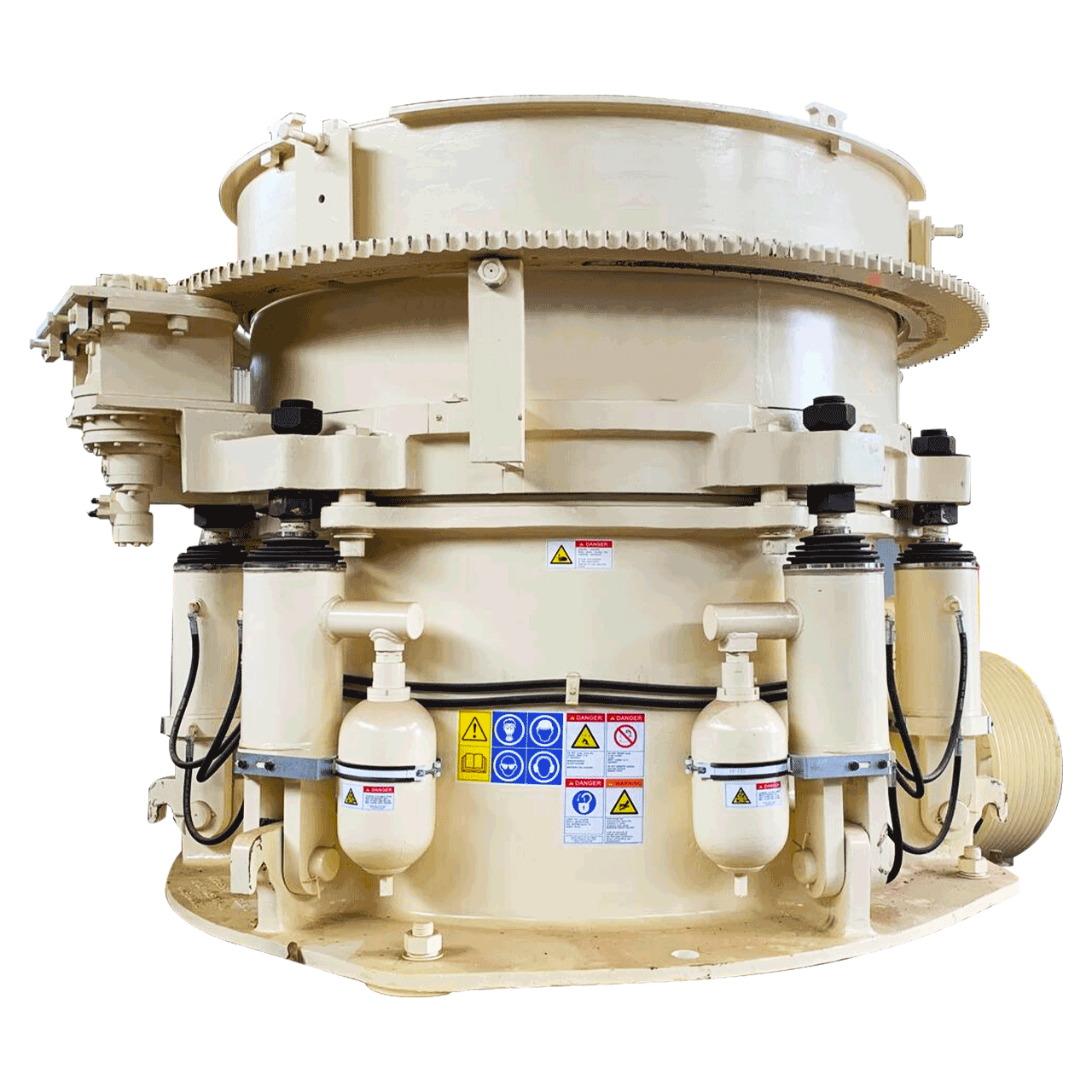

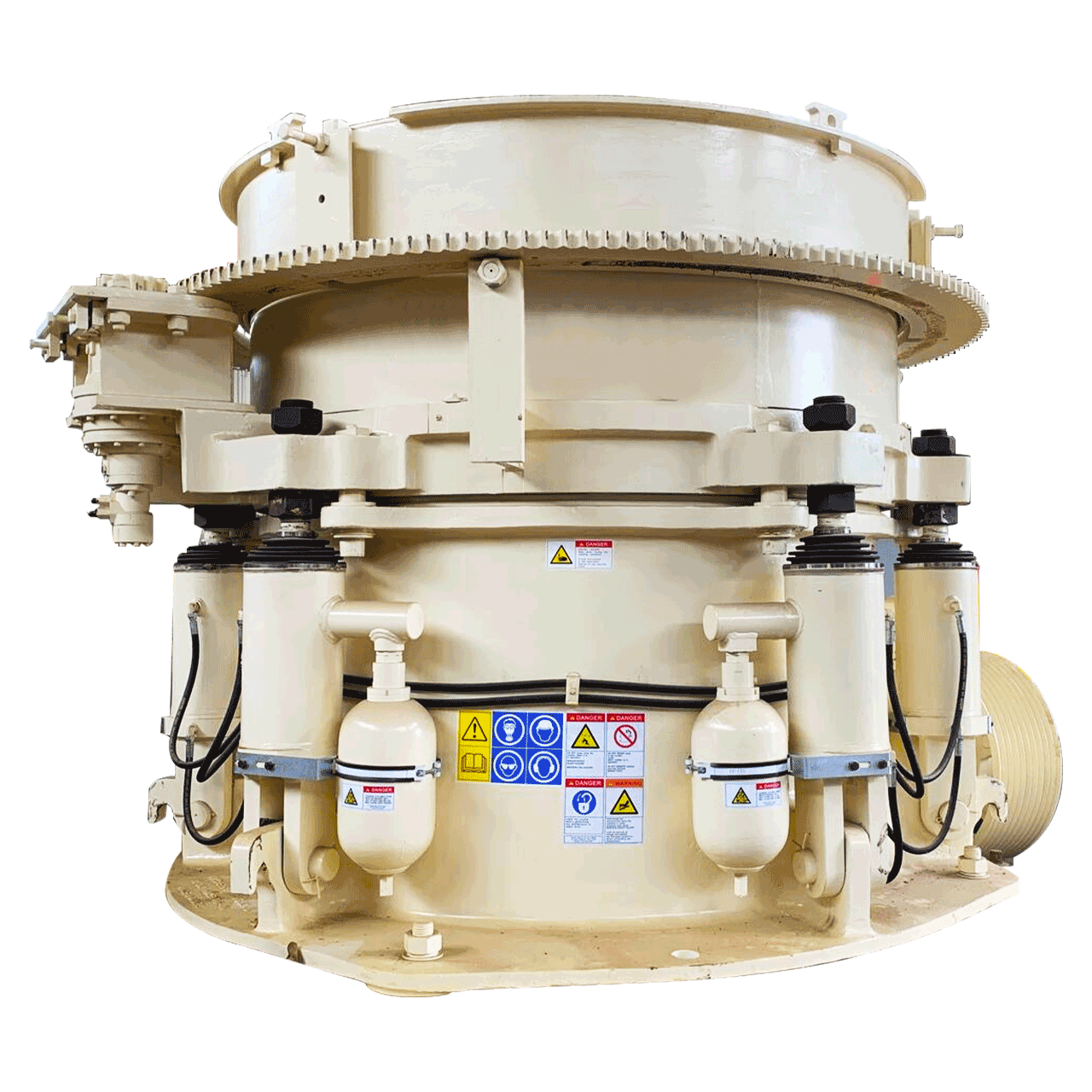

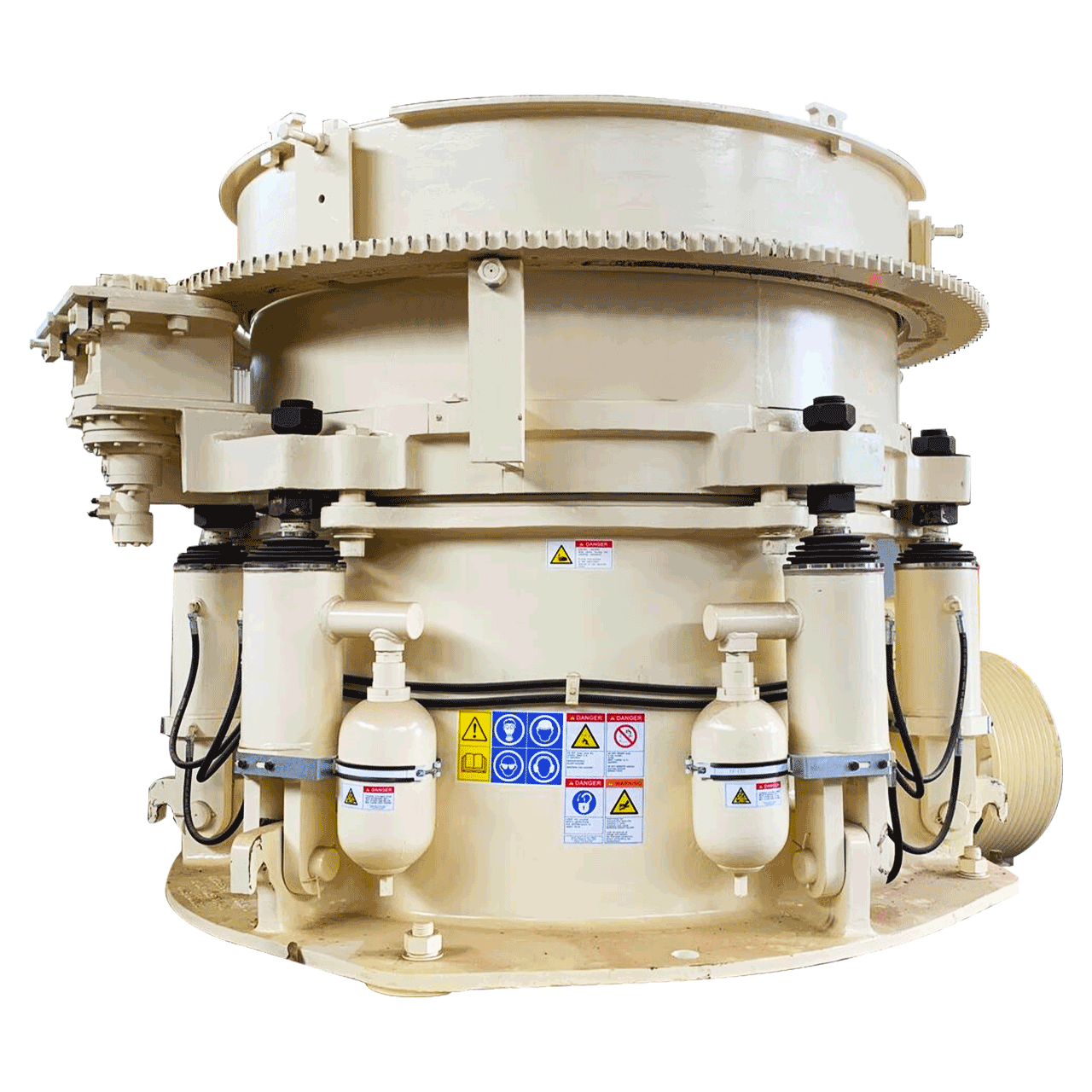

MG220 MG Series Single Cylinder Hydraulic Cone Crusher

Manufacturer : MORETEC

Part number : MG220

OEM Compatibility :

Category :Crusher / Cone crusher

Description

Description

MORETEC is a professional mine crushing and screening equipment manufacturer and service provider.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

MG Series Single Cylinder Hydraulic Cone Crusher

MG series hydraulic cone crushers are designed for heavy-duty conditions, and can be used for medium and fine crushing in various sizes of mines and stone industries. The constant crushing chamber design keeps the feed rate and production rate constant during the liner wear cycle, resulting in a significant reduction in operating costs.

The working principle of the single-cylinder hydraulic cone crusher is to drive the coupling through the rotation of the motor, and the rotating shaft and the cone part make the eccentric shaft do periodic swing motion under the axis line. After the material enters the crushing cavity from the feeding port, it is squeezed, ground and rubbed by the eccentric shaft and the rolling mortar wall to achieve the purpose of continuous crushing.

MG Features

· Reasonable structure, advanced crushing principle and technical parameters, reliable operation and low operating cost.

· Reasonable coordination of eccentricity, cavity type and motion parameters greatly improves production capacity and work efficiency.

· Adopt layer compression crushing principle design, so that crushing occurs between material and material, with high crushing efficiency and excellent particle shape.

· Constant output setting ensures constant output output.

· The special crushing wall and rolling mortar wall design make the utilization rate of wearing parts higher, and greatly reduce the user's investment in spare parts.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

MG Series Single Cylinder Hydraulic Cone Crusher

MG series hydraulic cone crushers are designed for heavy-duty conditions, and can be used for medium and fine crushing in various sizes of mines and stone industries. The constant crushing chamber design keeps the feed rate and production rate constant during the liner wear cycle, resulting in a significant reduction in operating costs.

The working principle of the single-cylinder hydraulic cone crusher is to drive the coupling through the rotation of the motor, and the rotating shaft and the cone part make the eccentric shaft do periodic swing motion under the axis line. After the material enters the crushing cavity from the feeding port, it is squeezed, ground and rubbed by the eccentric shaft and the rolling mortar wall to achieve the purpose of continuous crushing.

MG Features

· Reasonable structure, advanced crushing principle and technical parameters, reliable operation and low operating cost.

· Reasonable coordination of eccentricity, cavity type and motion parameters greatly improves production capacity and work efficiency.

· Adopt layer compression crushing principle design, so that crushing occurs between material and material, with high crushing efficiency and excellent particle shape.

· Constant output setting ensures constant output output.

· The special crushing wall and rolling mortar wall design make the utilization rate of wearing parts higher, and greatly reduce the user's investment in spare parts.

| Weight | 10.2 ton |

| Max Feeding size | 215 mm |

| Capacity | 70-315t/h |

| Discharge Range | 8-35mm |

| Power | 132-220kw |

Parts List

Parts List

No accessories information

People who seen this item also look

Ratings and Reviews

|

This is the first time that I have not purchased a crusher product in China before. Of course, I consulted with many parties before purchasing. Through comparison, I finally chose moretec in terms of service and product technology. After receiving the goods, I was really satisfied. The price was very favorable, and I was very satisfied in all aspects.

Emmanuel, Dec 13 2022

|