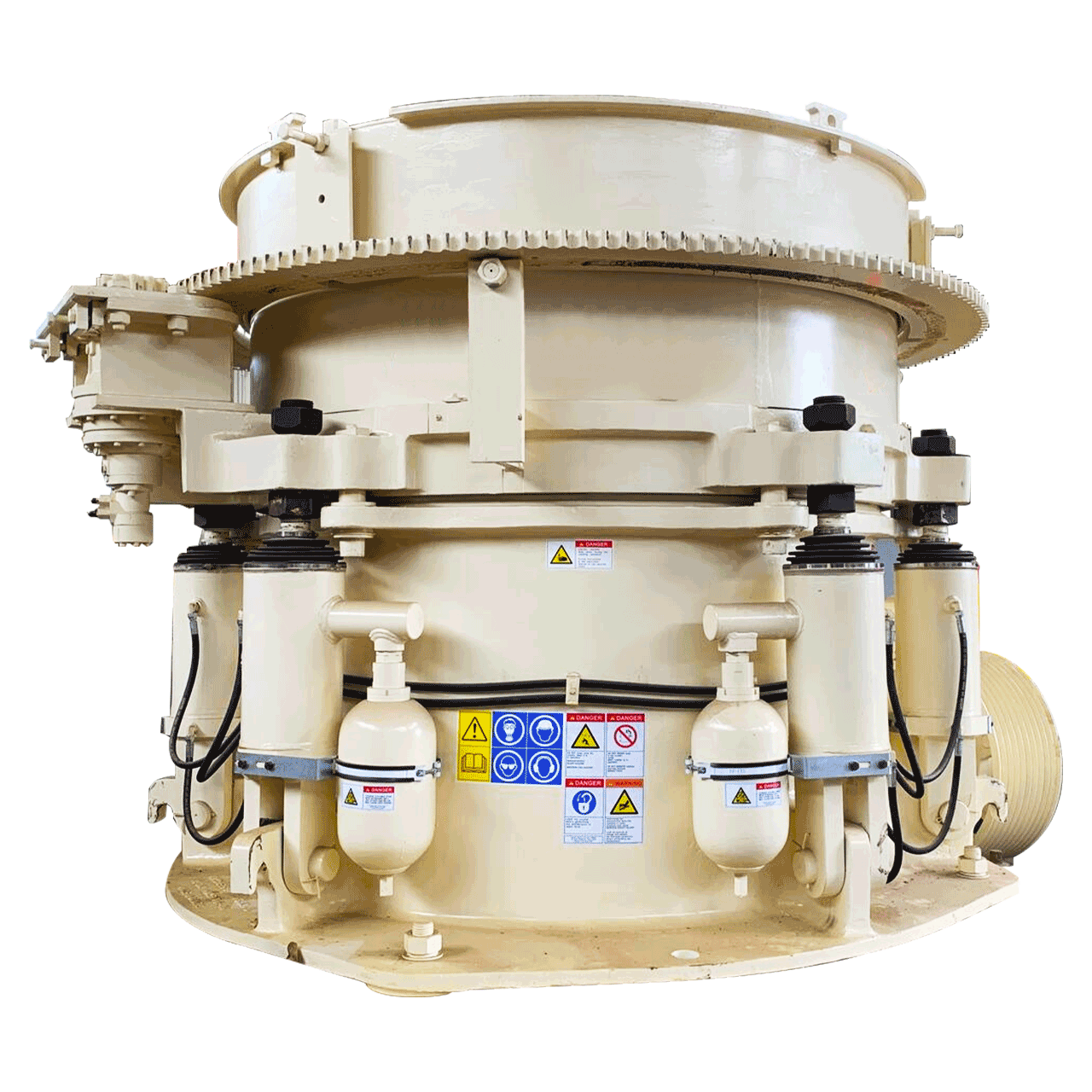

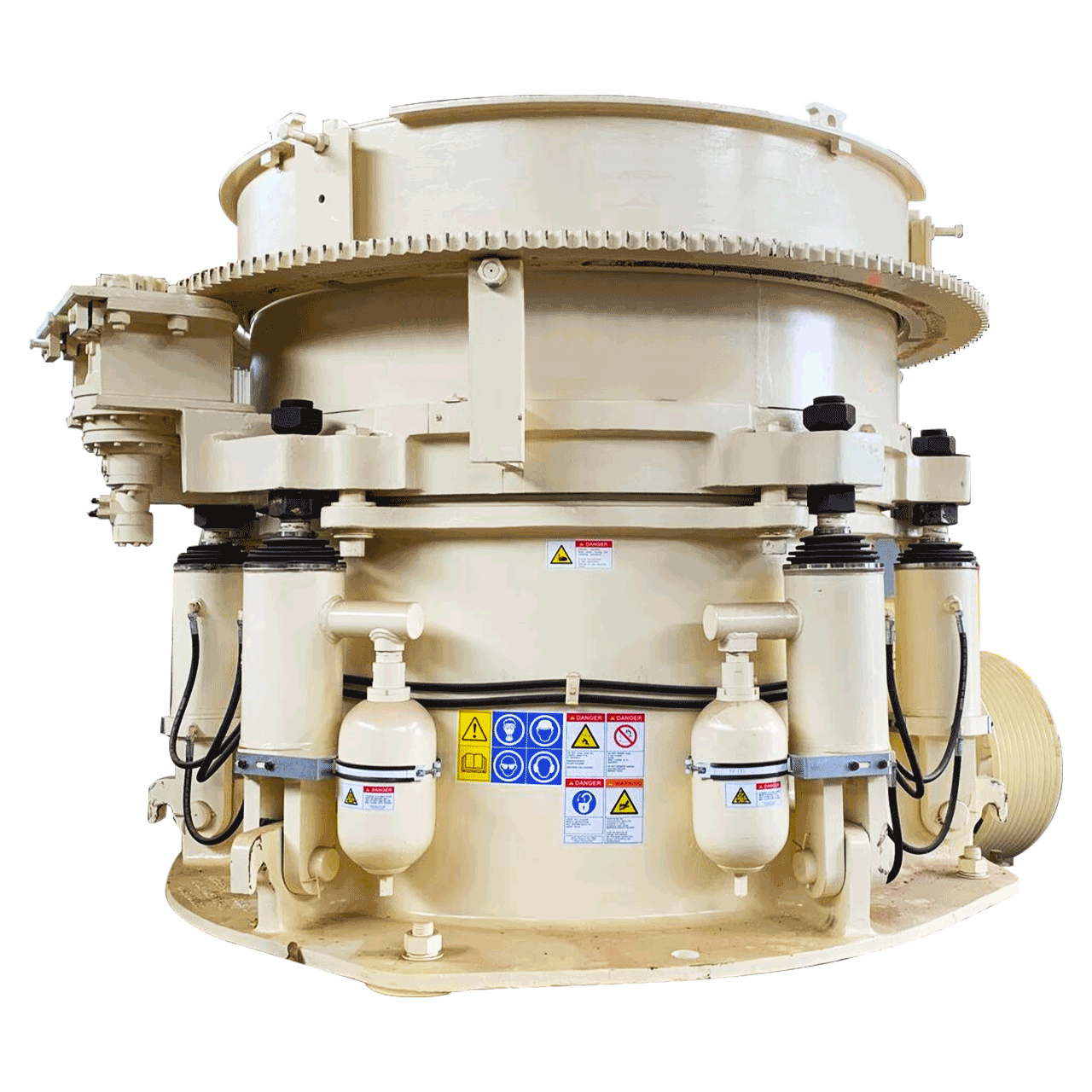

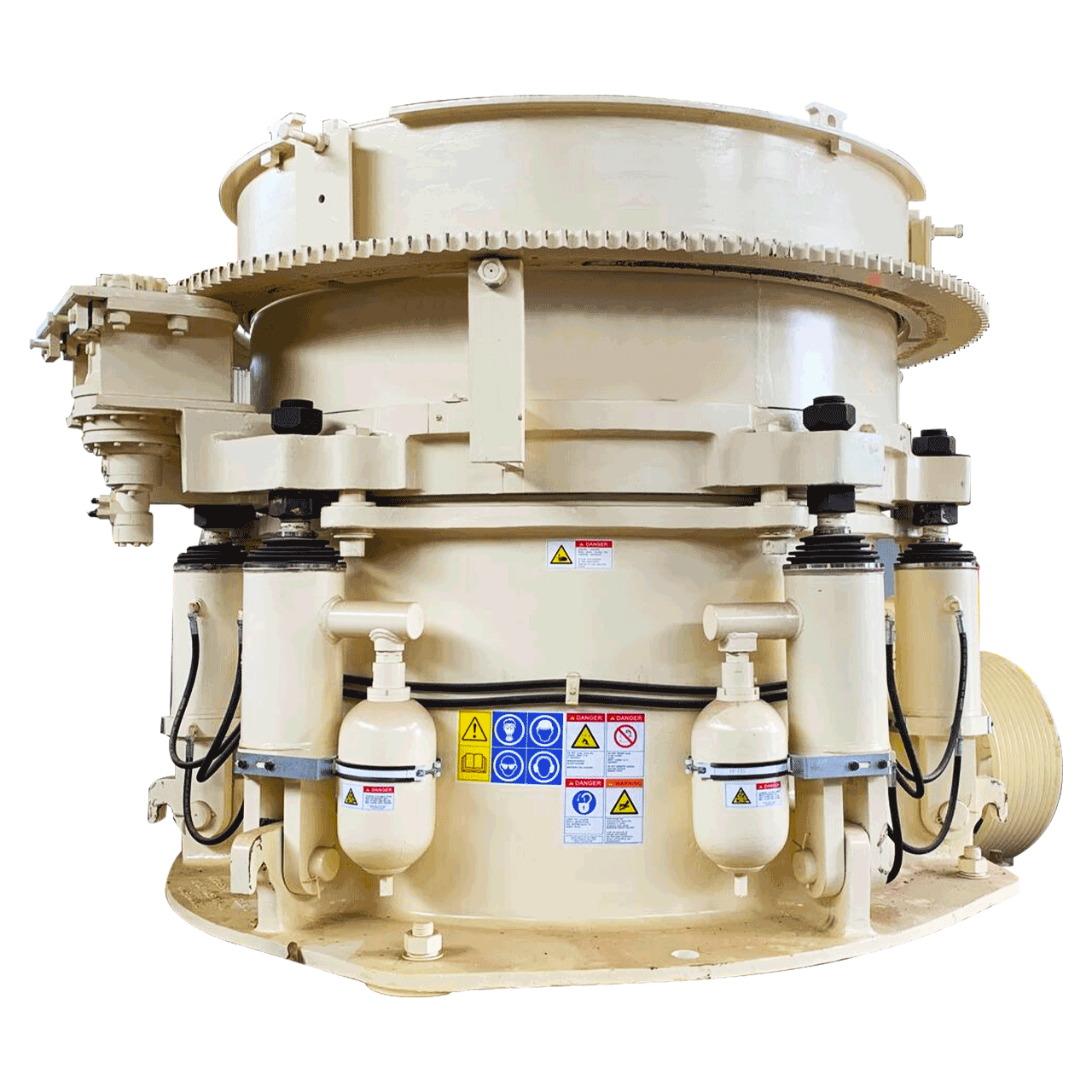

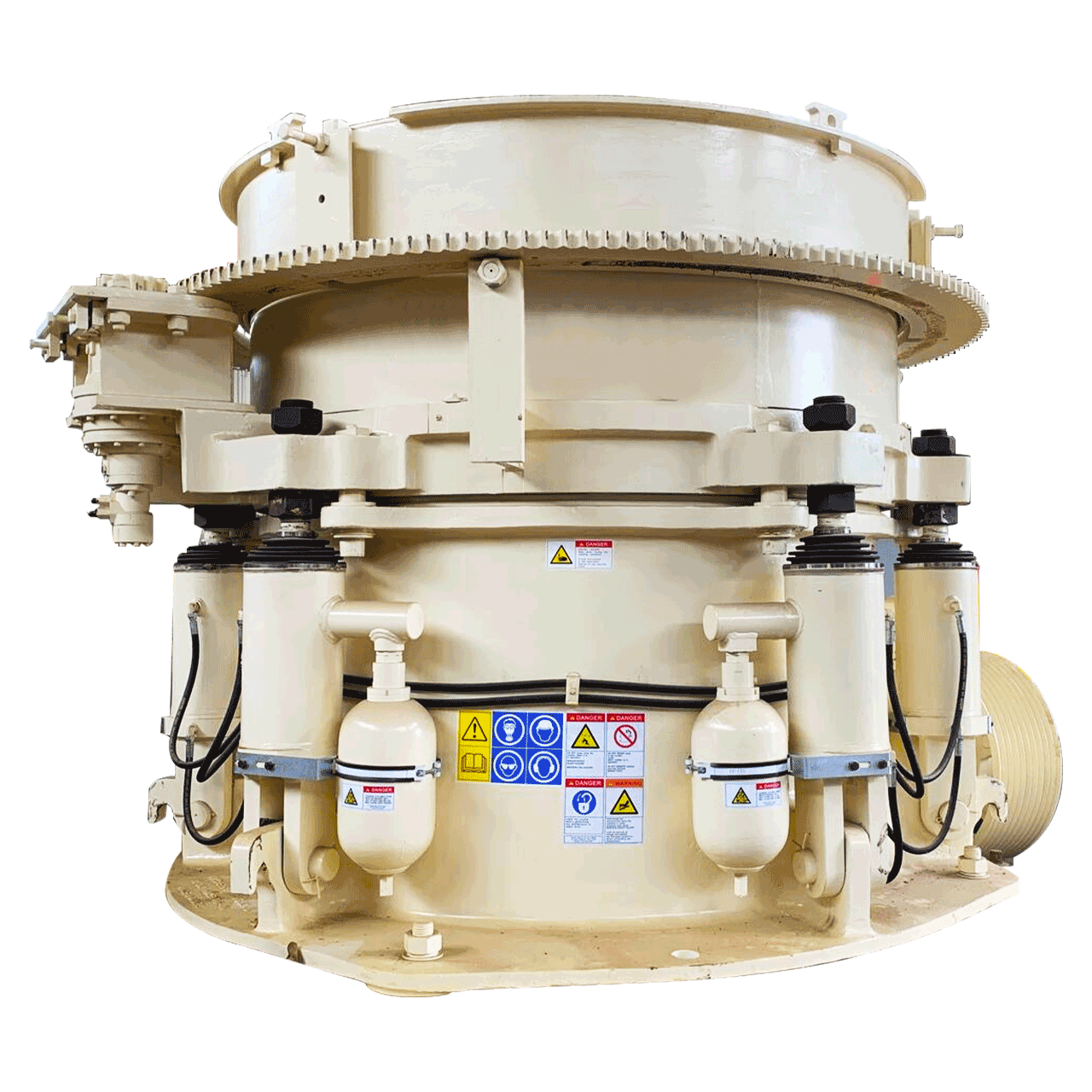

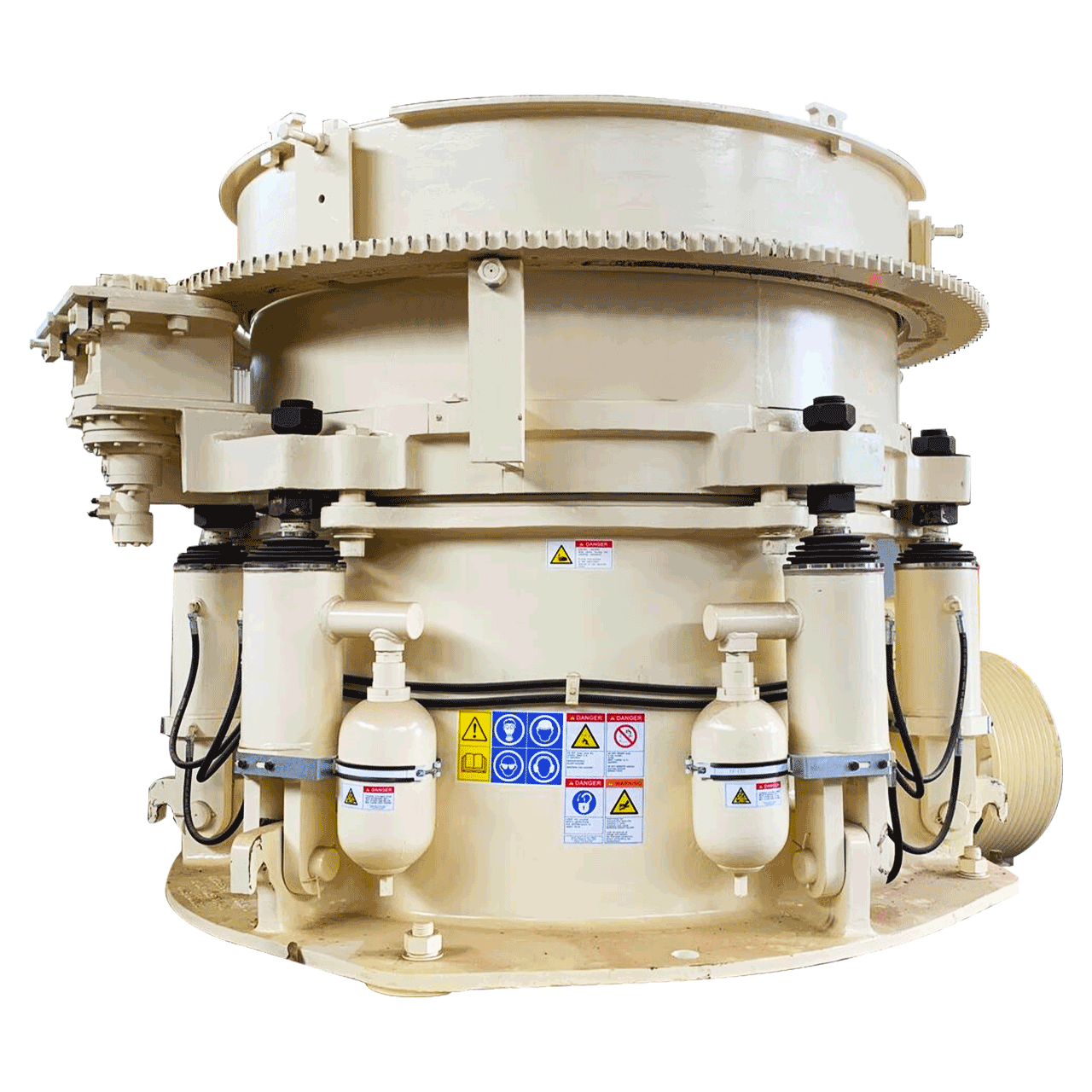

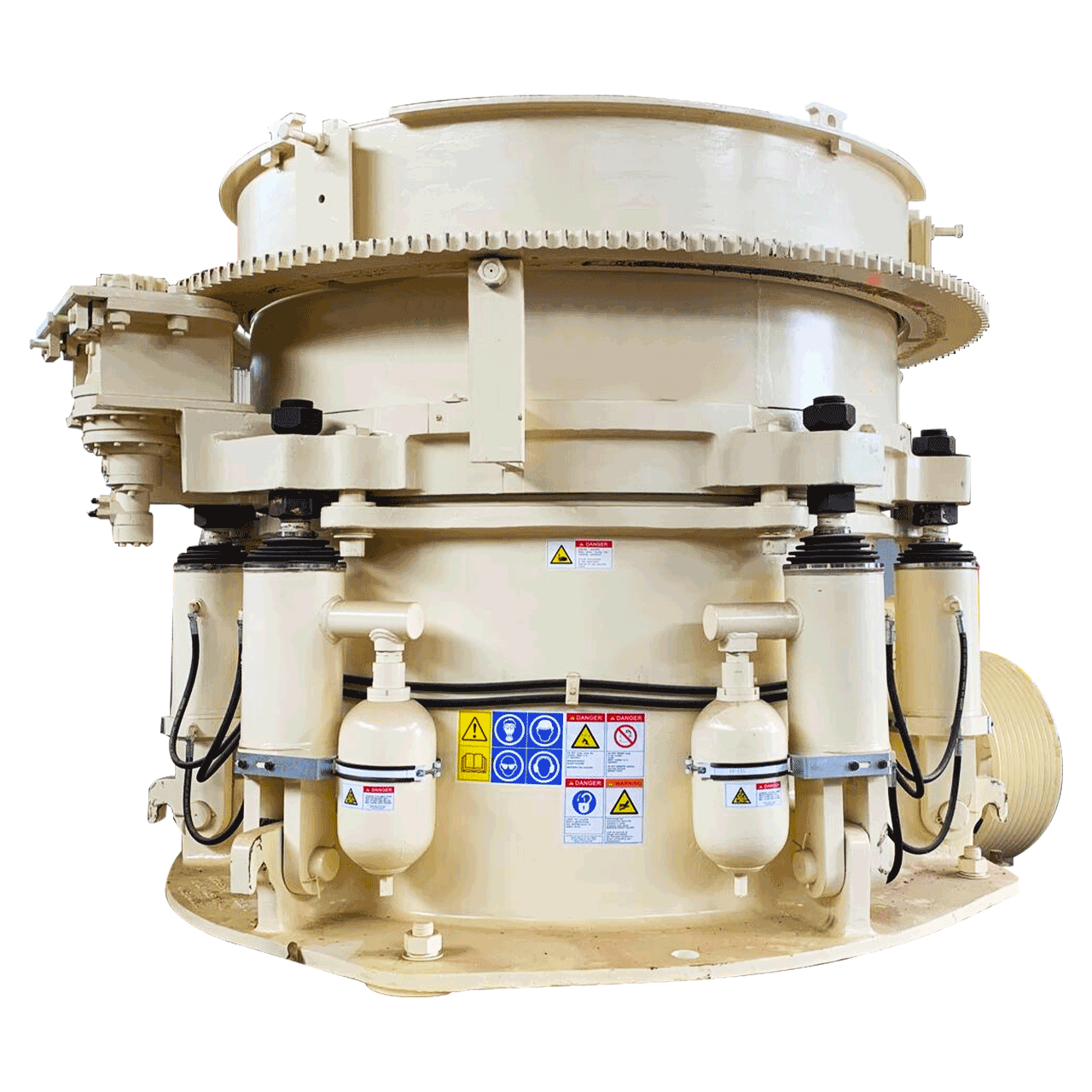

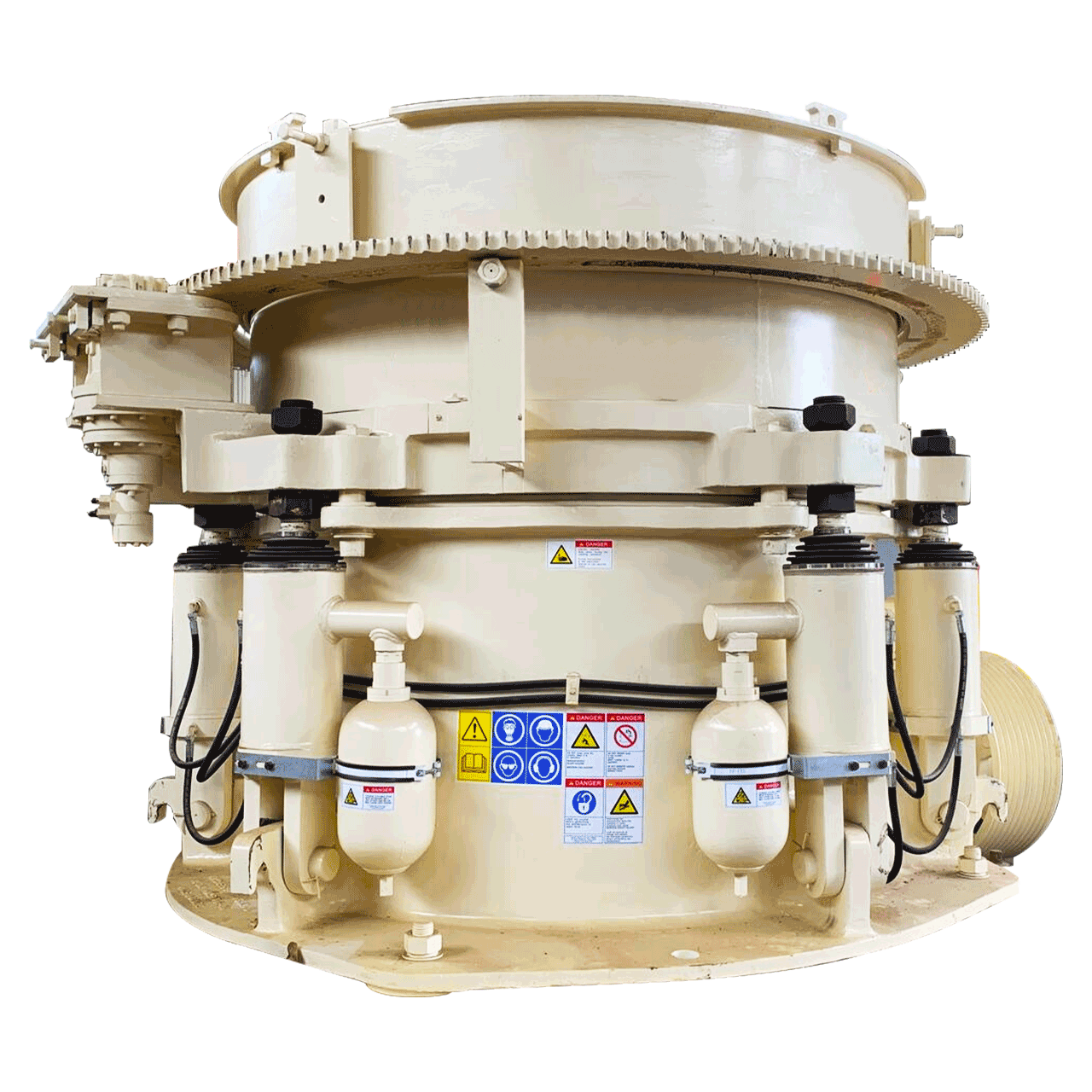

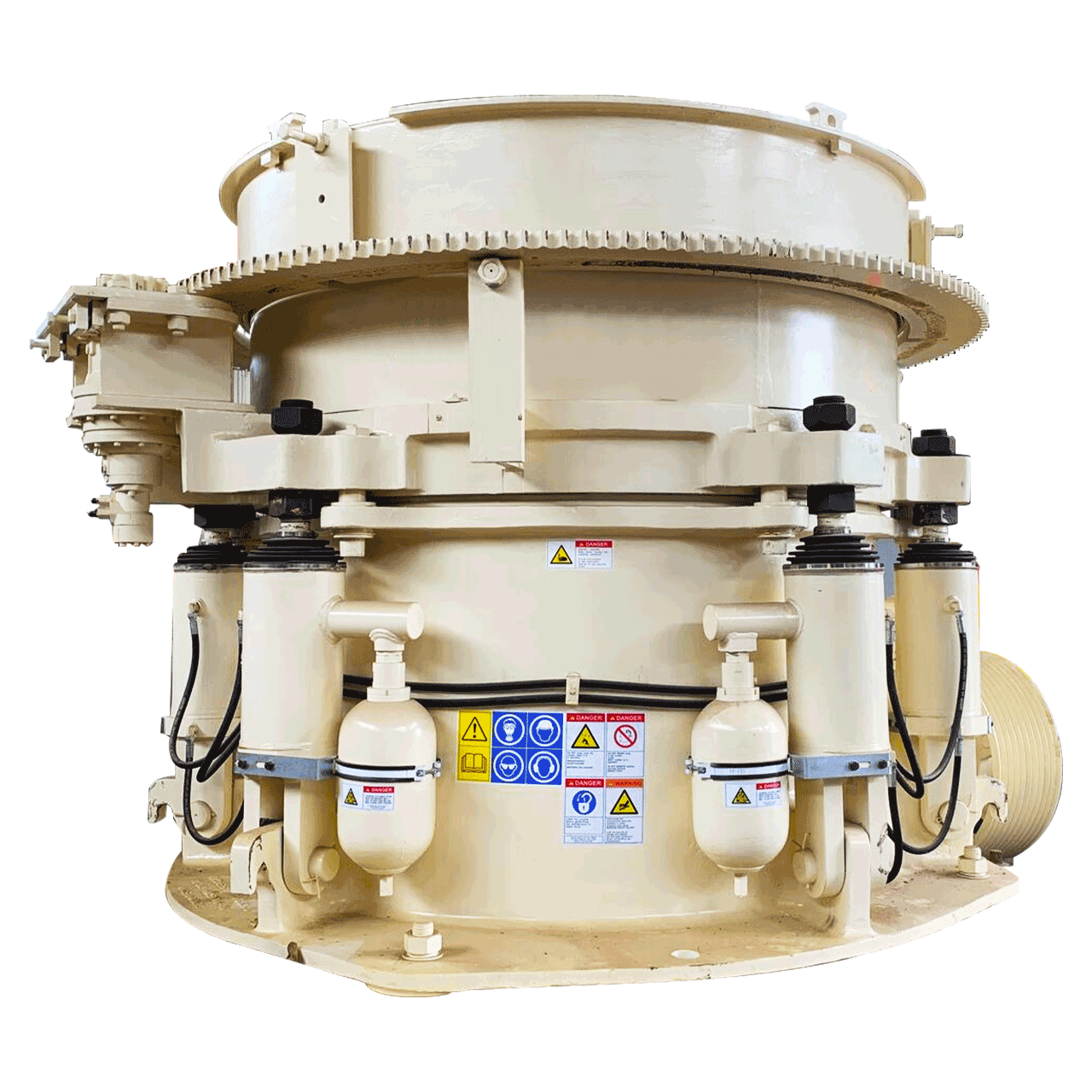

SH440 SH Series Single Cylinder HydraulicCone Crusher

Manufacturer : MORETEC

Part number : SH440

OEM Compatibility :

Category :Crusher / Cone crusher

Description

Description

MORETEC is a professional mine crushing and screening equipment manufacturer and service provider.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

SH Series Single Cylinder Hydraulic Cone Crusher

SH series hydraulic cone crushers are designed for heavy-duty conditions and can be used for fine crushing in mining and stone industries of various sizes. Constant crushing chamber design allows feed and production rates to remain constant over the liner wear cycle, resulting in significantly lower operating costs.

SH · Features

· EHD (extra-heavy duty) design.

· The main shaft has two points to support the weight, which can withstand more crushing force and more stroke.

· The overload capacity is very high, improving the rate of operation.

· Gear clearance can be adjusted from the outside.

· The eccentric distance of the eccentric bushing is adjustable, making the machine more adaptive to a variety of working conditions.

· The production can be carried out under a constant discharge port, avoiding the change of the discharge port during production.

· Due to the small dynamic cone angle, there is inter particle breakage and the product is of higher quantity.

· The specially designed crushing cavity adopts the principle of high-energy lamination, which has larger input capacity, higher output, less wear of wearing parts, and the particle shape of the product tends to be cubic, and the content of needle flakes is less.

Factors that might affect the crusher’s production capacity

· The feeding material has viscosity or the humidity of feeding material is greater than or equal to 3%.

· The amount of feeding material surpasses the crusher’s processing capacity by 10%.

· A segregation occurs in the feeding material or mal distribution inside of the crushing cavity .

· The feeding material is too tough or durable.

· Prescreening or the closed-circuit screening capacity is not enough or there is a low level of screening efficiency.

· The crusher’s under load or the crusher’s set up is below the performance number.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

SH Series Single Cylinder Hydraulic Cone Crusher

SH series hydraulic cone crushers are designed for heavy-duty conditions and can be used for fine crushing in mining and stone industries of various sizes. Constant crushing chamber design allows feed and production rates to remain constant over the liner wear cycle, resulting in significantly lower operating costs.

SH · Features

· EHD (extra-heavy duty) design.

· The main shaft has two points to support the weight, which can withstand more crushing force and more stroke.

· The overload capacity is very high, improving the rate of operation.

· Gear clearance can be adjusted from the outside.

· The eccentric distance of the eccentric bushing is adjustable, making the machine more adaptive to a variety of working conditions.

· The production can be carried out under a constant discharge port, avoiding the change of the discharge port during production.

· Due to the small dynamic cone angle, there is inter particle breakage and the product is of higher quantity.

· The specially designed crushing cavity adopts the principle of high-energy lamination, which has larger input capacity, higher output, less wear of wearing parts, and the particle shape of the product tends to be cubic, and the content of needle flakes is less.

Factors that might affect the crusher’s production capacity

· The feeding material has viscosity or the humidity of feeding material is greater than or equal to 3%.

· The amount of feeding material surpasses the crusher’s processing capacity by 10%.

· A segregation occurs in the feeding material or mal distribution inside of the crushing cavity .

· The feeding material is too tough or durable.

· Prescreening or the closed-circuit screening capacity is not enough or there is a low level of screening efficiency.

· The crusher’s under load or the crusher’s set up is below the performance number.

| Weight | 14.3 ton |

| Max Feeding size | 215 mm |

| Capacity | 66-412t/h |

| Discharge Range | 6-44mm |

| Power | 250kw |

Parts List