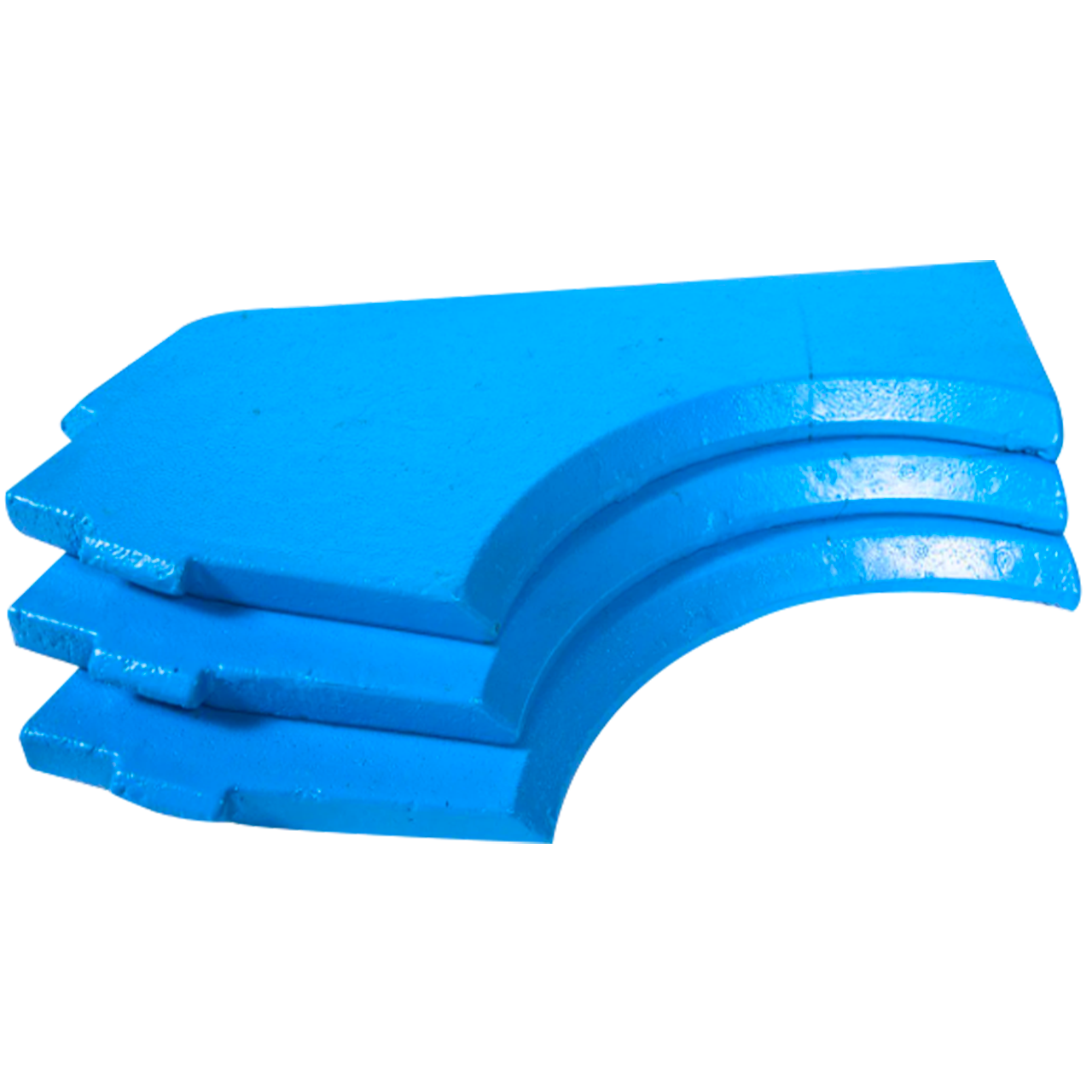

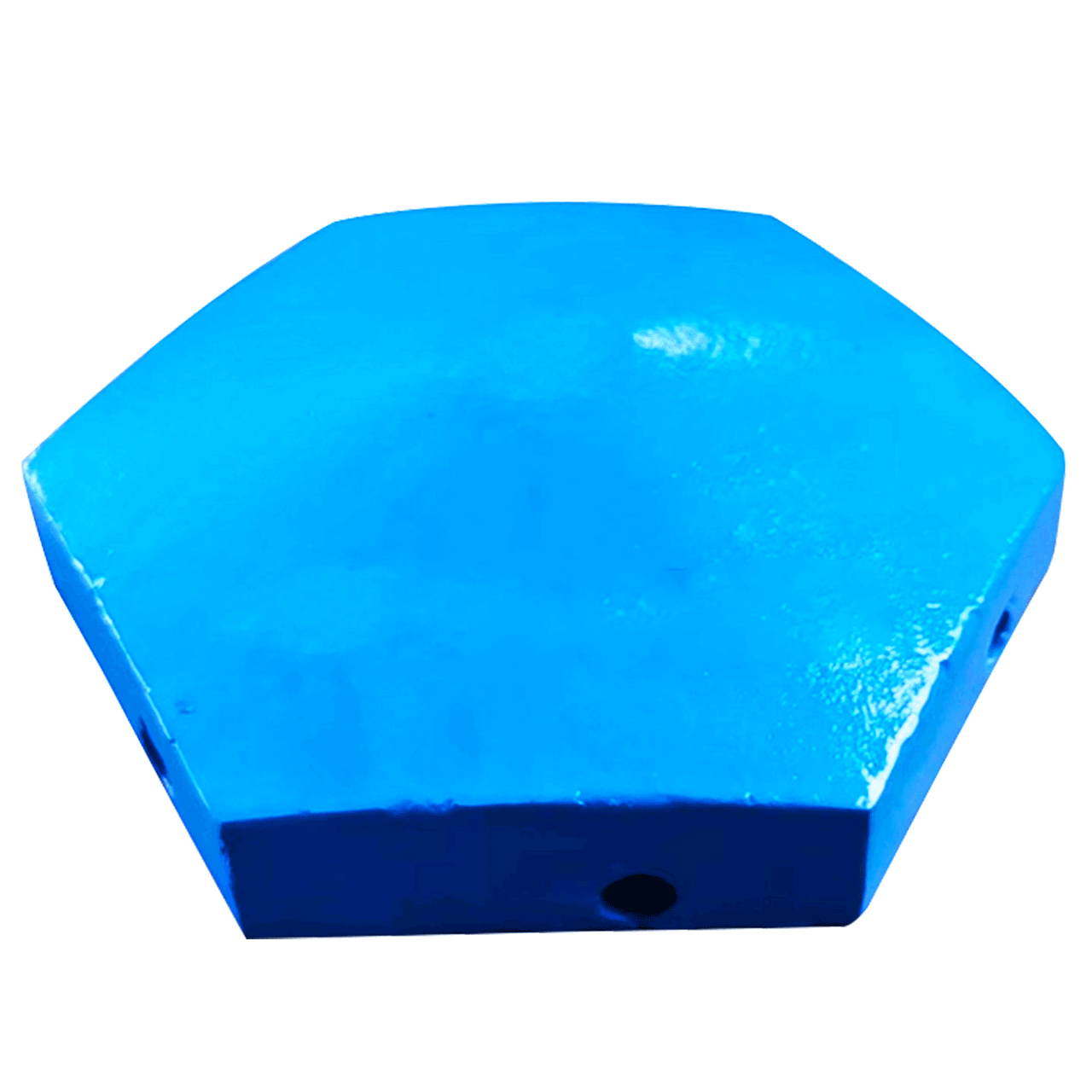

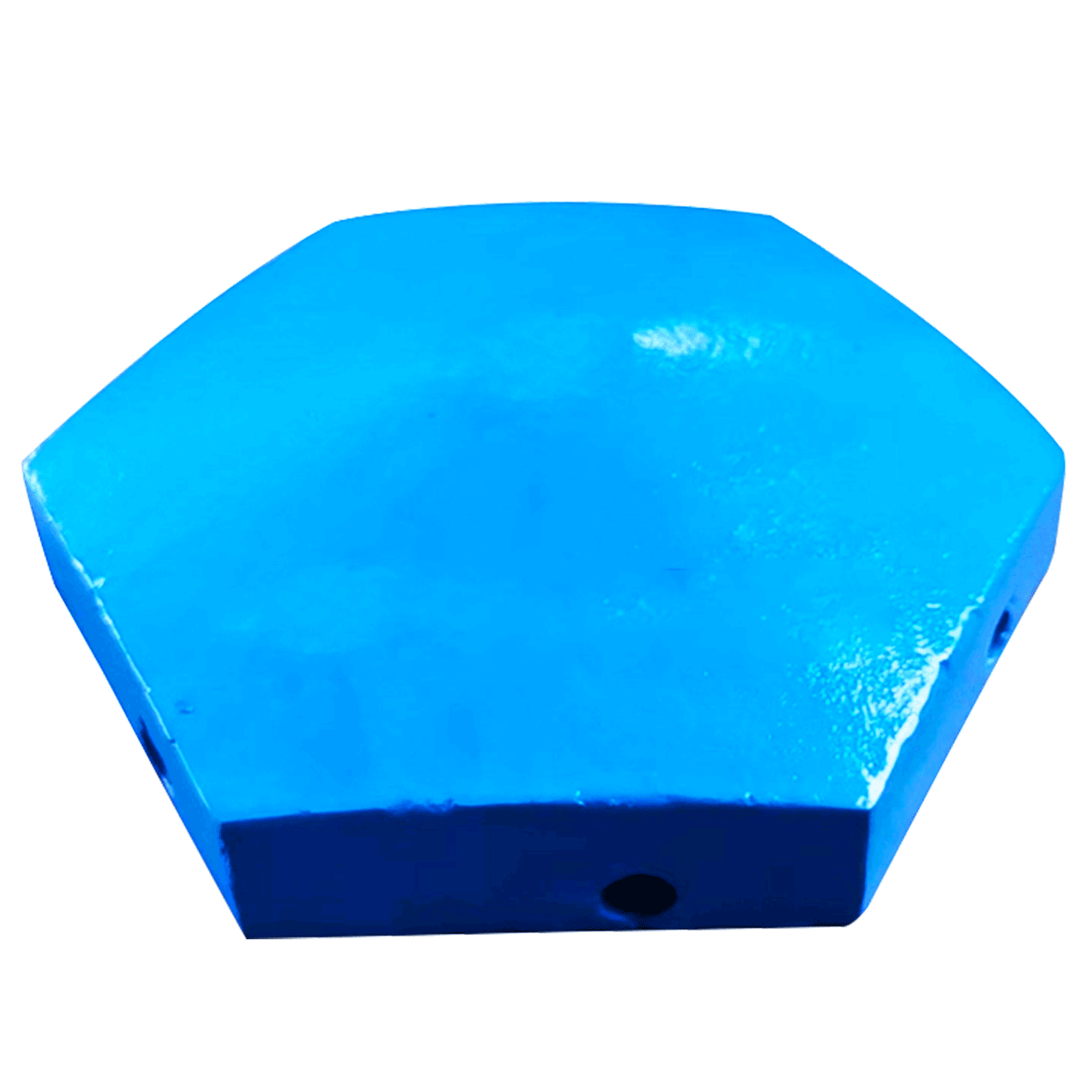

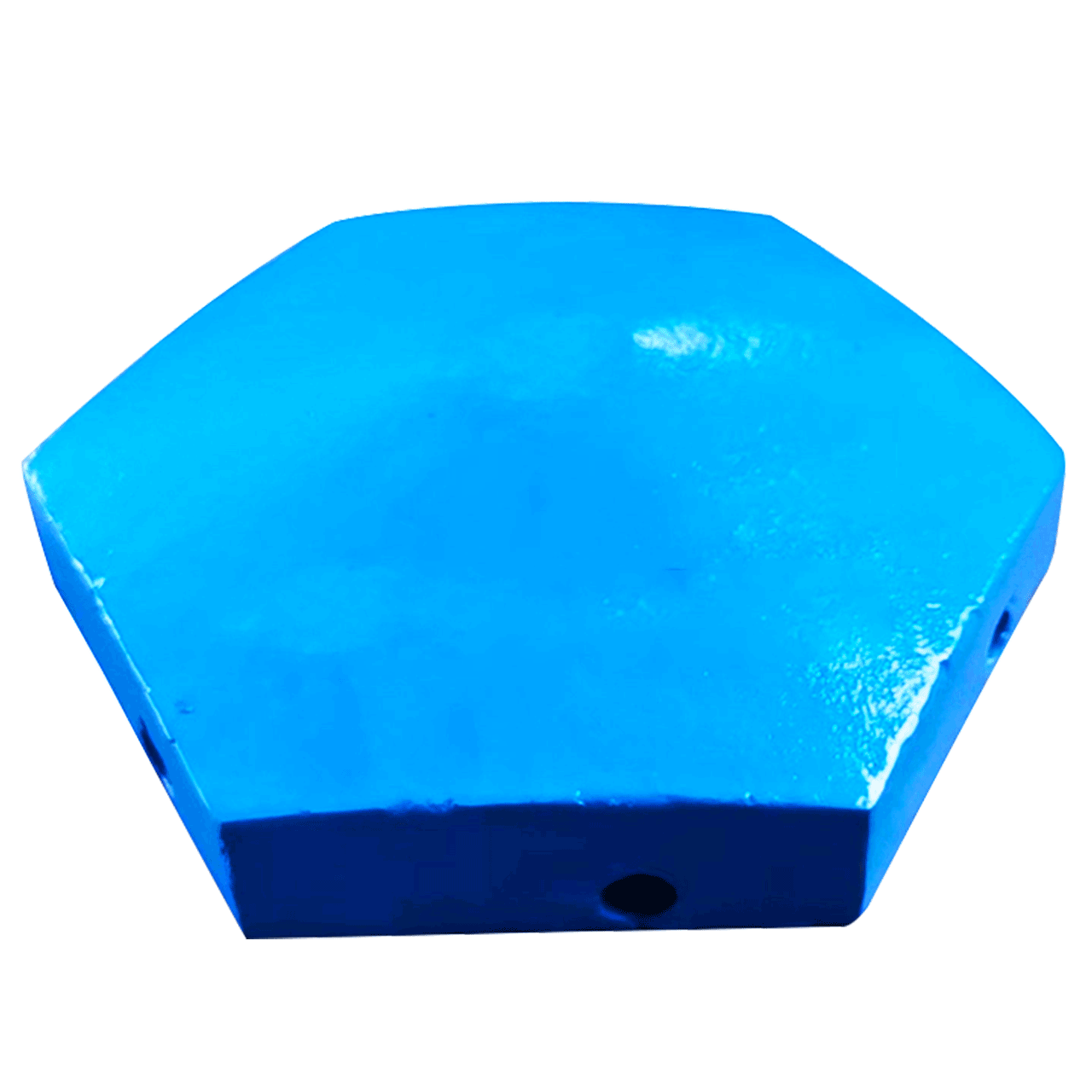

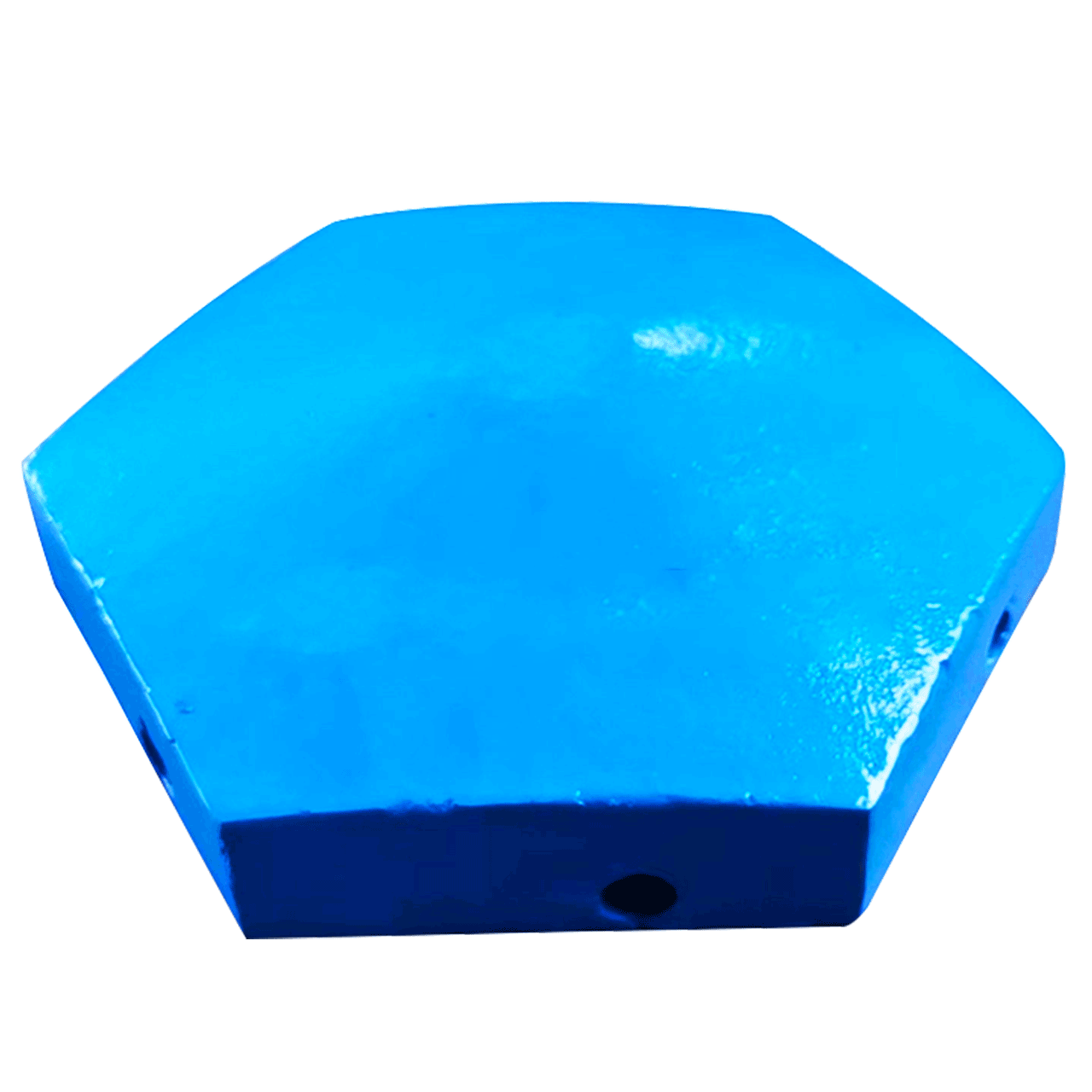

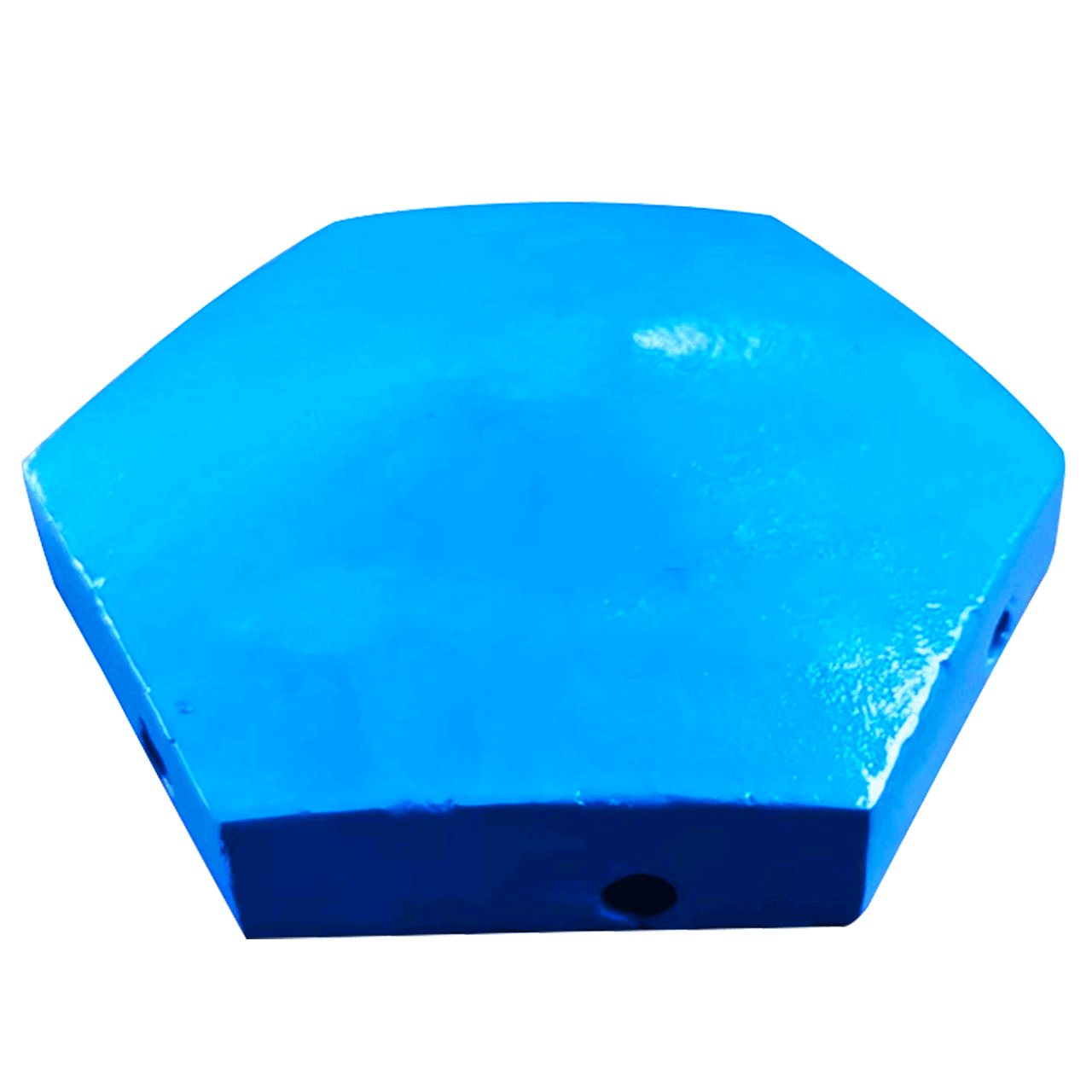

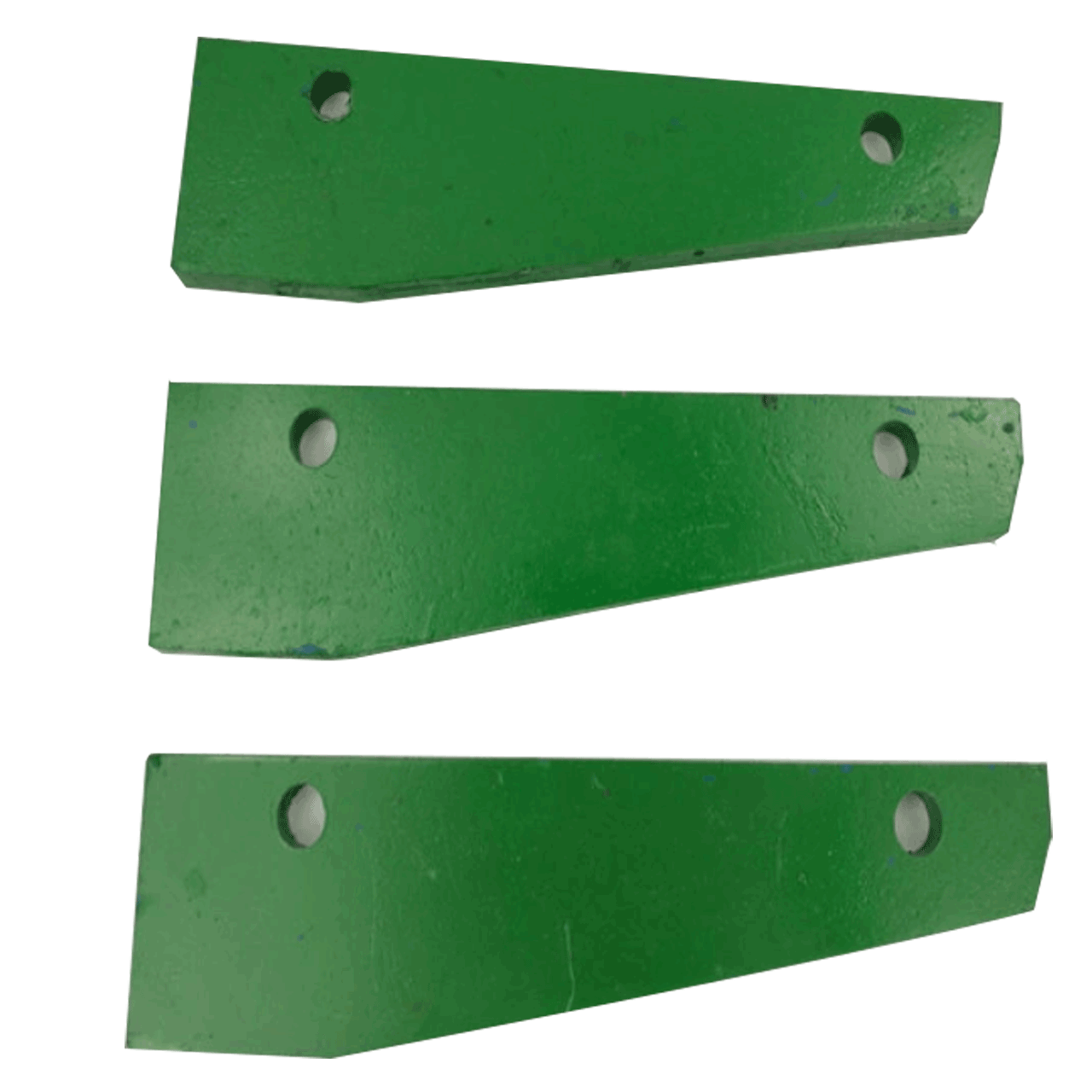

VSI Crusher Rotor Assembly Suit

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

The crusher rotor is one of the important components of the crusher. Its main function is to send materials into the crushing chamber and accelerate them. At the same time, under high-speed rotation, the material is broken into small particles by centrifugal force, thereby achieving the purpose of material processing.

Crusher rotor materials mainly include cast steel, forged steel, alloy steel, etc.

1. Cast steel material: Cast steel is suitable for non-metallic minerals, coal, building materials and other fields. It has high strength and toughness, so it has advantages in processing some materials that are difficult to break. However, it has a short working life and is susceptible to wear and fatigue.

2. Forged steel material: Forged steel is more wear-resistant and stable than cast steel, and it also has better toughness and strength. The strength of forged steel materials can be increased to more than twice that of cast steel, making it suitable for handling harder materials.

3. Alloy steel material: Alloy steel has excellent anti-wear properties and corrosion resistance, so it is suitable for processing hard materials containing impurities such as silicon and phosphorus. The working life of alloy steel is longer than that of cast steel and forged steel, and it is currently one of the mainstream materials for crusher rotors.

When selecting crusher rotor materials, you need to consider the following factors:

1. Hardness and size of material

2. The working environment of the rotor 3. The price of the crusher rotor

Moretec's crusher wearing parts provide you with:

· Customized configurations ensure consistent production;

· Long-lasting manganese steel increases crusher uptime;

· Reduce equipment wear and tear;

· Extensive stock of patterns (covering all major makes and models), as well as all patterns produced only from original drawings, ensuring fast delivery and a perfect match to the crusher;

· Based on our more than 15 years of experience in this field, we can adjust according to special requirements;

· Perfect management covering your entire purchasing process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm order), delivery (clear photos and test reports are ready for customer confirmation) , After-sales (after-sales inspection, size matching, service life inspection, etc. after the goods arrive at the work site). Ensure every purchase without question);

· Abundant production capacity: about 10,000 tons per year to ensure supply capacity to customers.

Crusher rotor materials mainly include cast steel, forged steel, alloy steel, etc.

1. Cast steel material: Cast steel is suitable for non-metallic minerals, coal, building materials and other fields. It has high strength and toughness, so it has advantages in processing some materials that are difficult to break. However, it has a short working life and is susceptible to wear and fatigue.

2. Forged steel material: Forged steel is more wear-resistant and stable than cast steel, and it also has better toughness and strength. The strength of forged steel materials can be increased to more than twice that of cast steel, making it suitable for handling harder materials.

3. Alloy steel material: Alloy steel has excellent anti-wear properties and corrosion resistance, so it is suitable for processing hard materials containing impurities such as silicon and phosphorus. The working life of alloy steel is longer than that of cast steel and forged steel, and it is currently one of the mainstream materials for crusher rotors.

When selecting crusher rotor materials, you need to consider the following factors:

1. Hardness and size of material

2. The working environment of the rotor 3. The price of the crusher rotor

Moretec's crusher wearing parts provide you with:

· Customized configurations ensure consistent production;

· Long-lasting manganese steel increases crusher uptime;

· Reduce equipment wear and tear;

· Extensive stock of patterns (covering all major makes and models), as well as all patterns produced only from original drawings, ensuring fast delivery and a perfect match to the crusher;

· Based on our more than 15 years of experience in this field, we can adjust according to special requirements;

· Perfect management covering your entire purchasing process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm order), delivery (clear photos and test reports are ready for customer confirmation) , After-sales (after-sales inspection, size matching, service life inspection, etc. after the goods arrive at the work site). Ensure every purchase without question);

· Abundant production capacity: about 10,000 tons per year to ensure supply capacity to customers.

Parts List