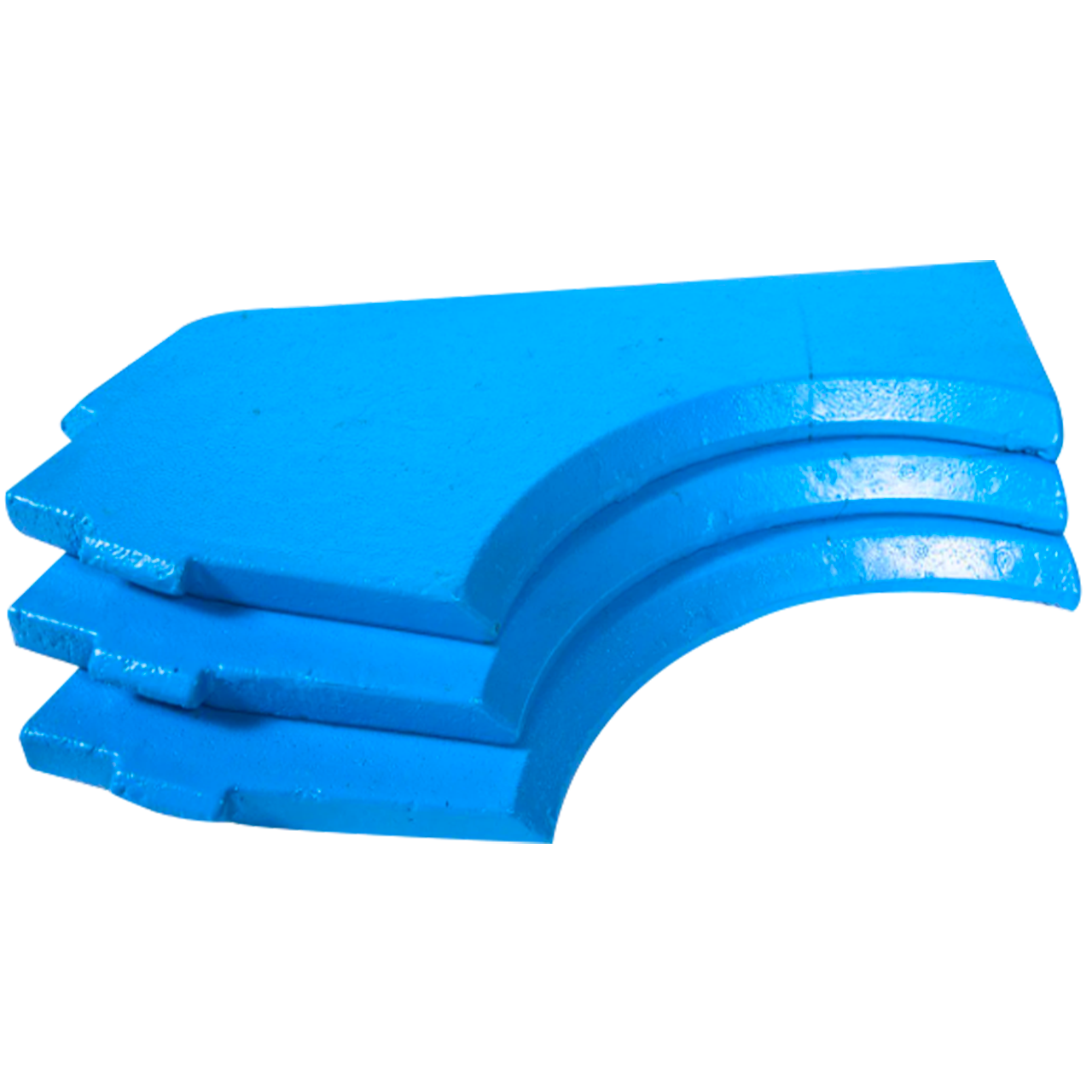

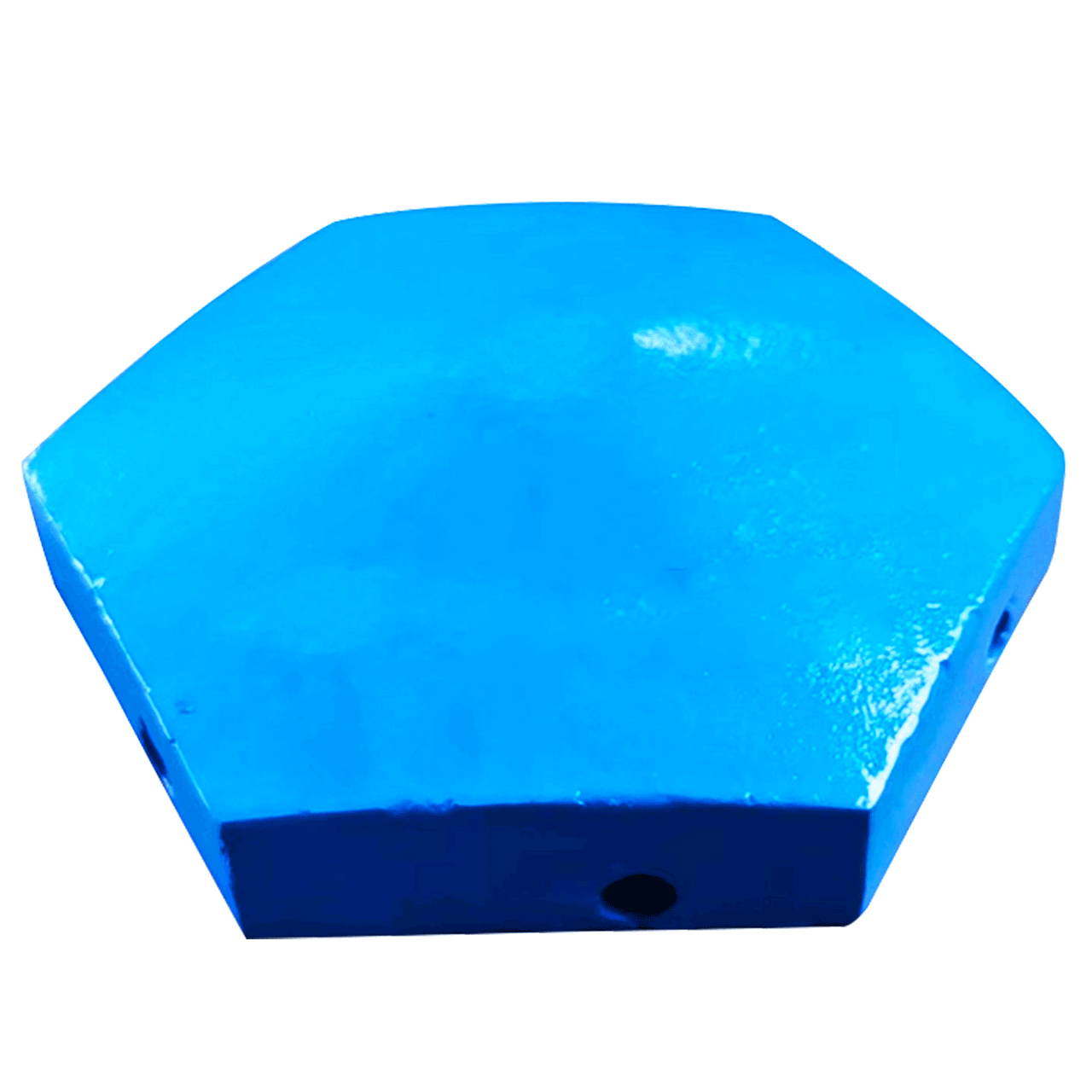

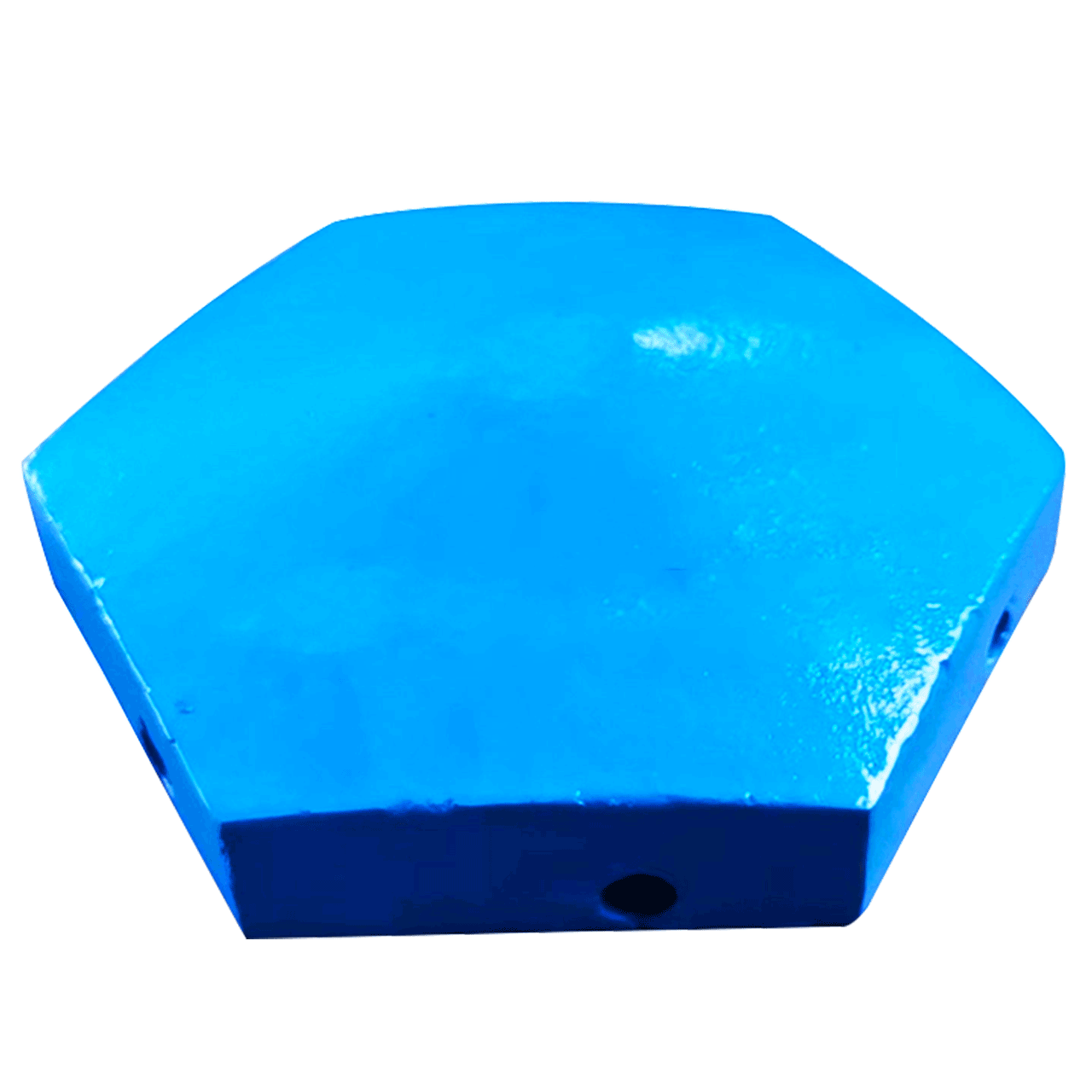

Cavity Wear Plate VSI Crusher B6150se

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

Vertical shaft impact (VSI) crushers are designed for secondary, tertiary or quaternary crushing. Different from other types of impact crushers, the vertical shaft impact crusher (VSI) is designed with a unique rock-to-rock crushing principle. It can be hit with a fast-moving blowing rod (carbide rotor) or thrown into a stationary anvil. In the anvil, it breaks during impact.

The cavity wear plate is designed to protect the outer edge of the rotor from excited particles in the crushing chamber. As the rotor rotates, it hits particles that have bounced from the chamber accumulation after initially leaving the rotor. Since the TCWPs are the wear parts furthest from the center and are located on the front face of the rotor, they are most susceptible to this type of wear. These parts are in two locations

On the rotor, first place them on the top of the rotor tip to protect the fragile area of the parts, and second on the other side of the rotor port to protect the leading edge from wear and damage

Rotor efficiency.

Moretec crusher wearing parts provide you:

• Custom configurations ensure consistent production;

· Durable manganese steel increases the uptime of the crusher;

Reduce equipment wear;

· Extensive inventory of patterns (covering all major brands and models), as well as all patterns produced only according to the original drawings, ensuring fast delivery and perfect matching with the crusher;

· Based on our more than 15 years of experience in this field, we can adjust according to special requirements;

· Perfect management, covering your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirmation of all necessary information, confirmation of orders), delivery (clear photos and test reports are ready for customer confirmation), After-sales (after-sales inspection, size matching, service life inspection, etc. after the shipment arrives at the work site). ensure that there is no doubt about each purchase);

· Abundant production capacity: about 10000 tons per year to ensure supply capacity to customers.

The cavity wear plate is designed to protect the outer edge of the rotor from excited particles in the crushing chamber. As the rotor rotates, it hits particles that have bounced from the chamber accumulation after initially leaving the rotor. Since the TCWPs are the wear parts furthest from the center and are located on the front face of the rotor, they are most susceptible to this type of wear. These parts are in two locations

On the rotor, first place them on the top of the rotor tip to protect the fragile area of the parts, and second on the other side of the rotor port to protect the leading edge from wear and damage

Rotor efficiency.

Moretec crusher wearing parts provide you:

• Custom configurations ensure consistent production;

· Durable manganese steel increases the uptime of the crusher;

Reduce equipment wear;

· Extensive inventory of patterns (covering all major brands and models), as well as all patterns produced only according to the original drawings, ensuring fast delivery and perfect matching with the crusher;

· Based on our more than 15 years of experience in this field, we can adjust according to special requirements;

· Perfect management, covering your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirmation of all necessary information, confirmation of orders), delivery (clear photos and test reports are ready for customer confirmation), After-sales (after-sales inspection, size matching, service life inspection, etc. after the shipment arrives at the work site). ensure that there is no doubt about each purchase);

· Abundant production capacity: about 10000 tons per year to ensure supply capacity to customers.

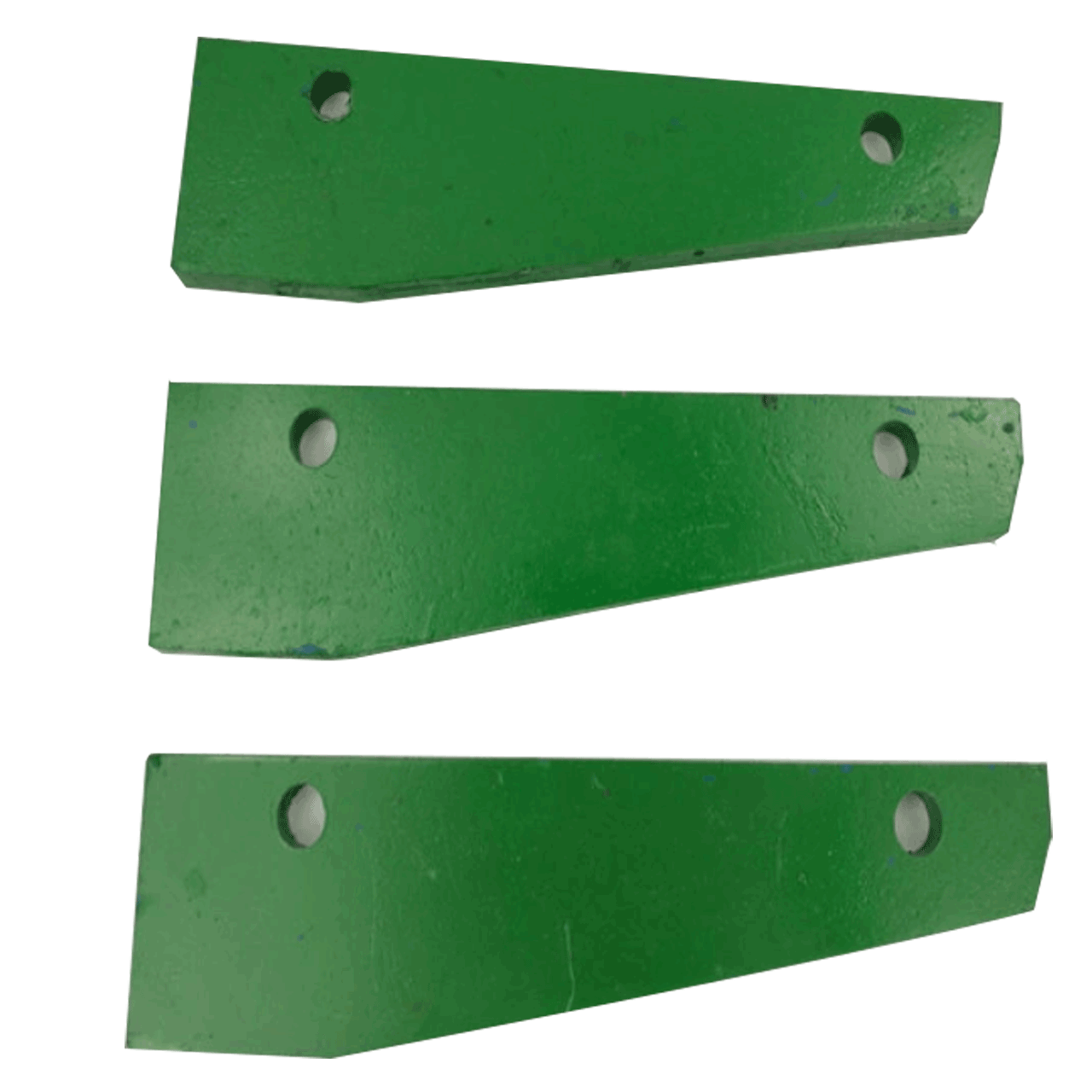

Parts List