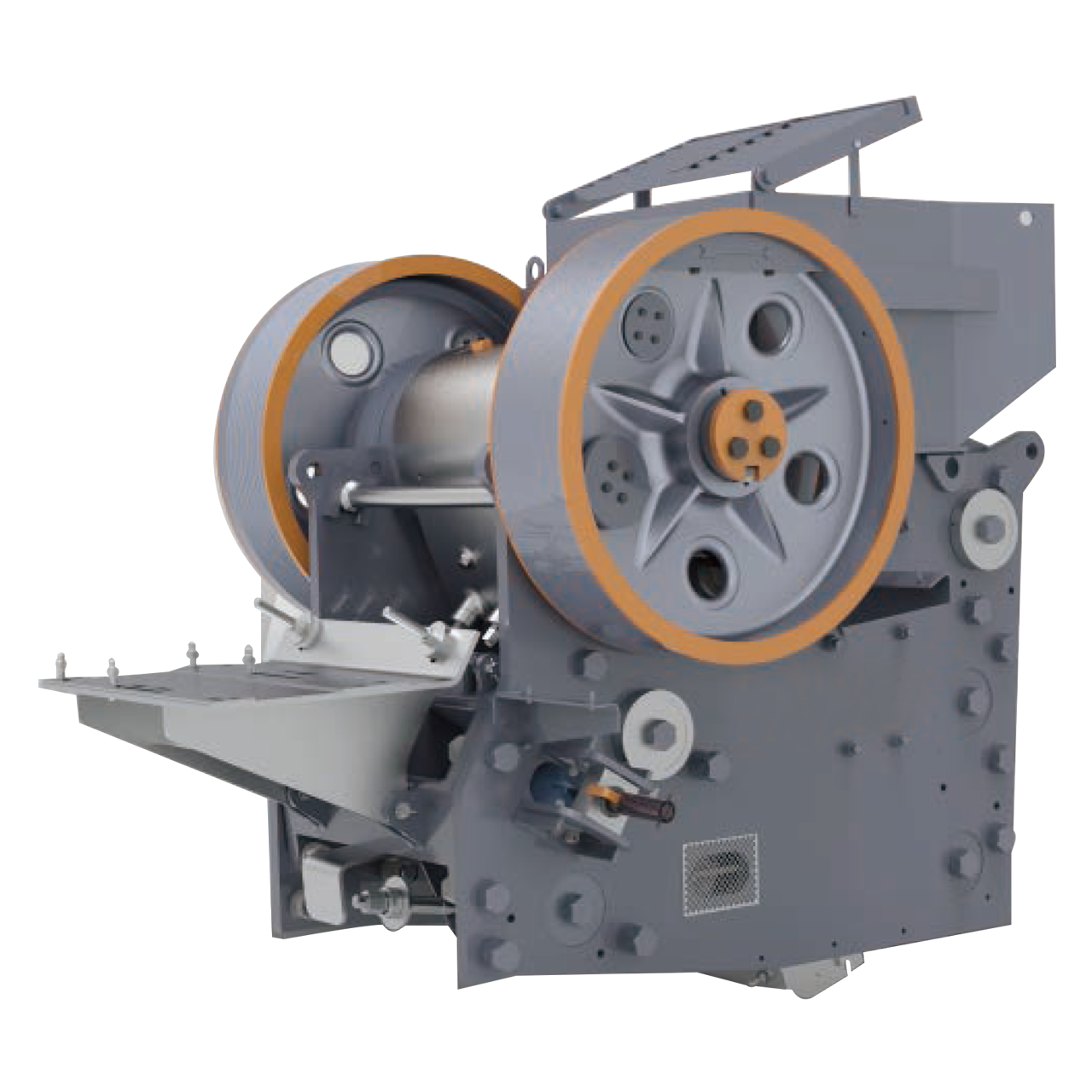

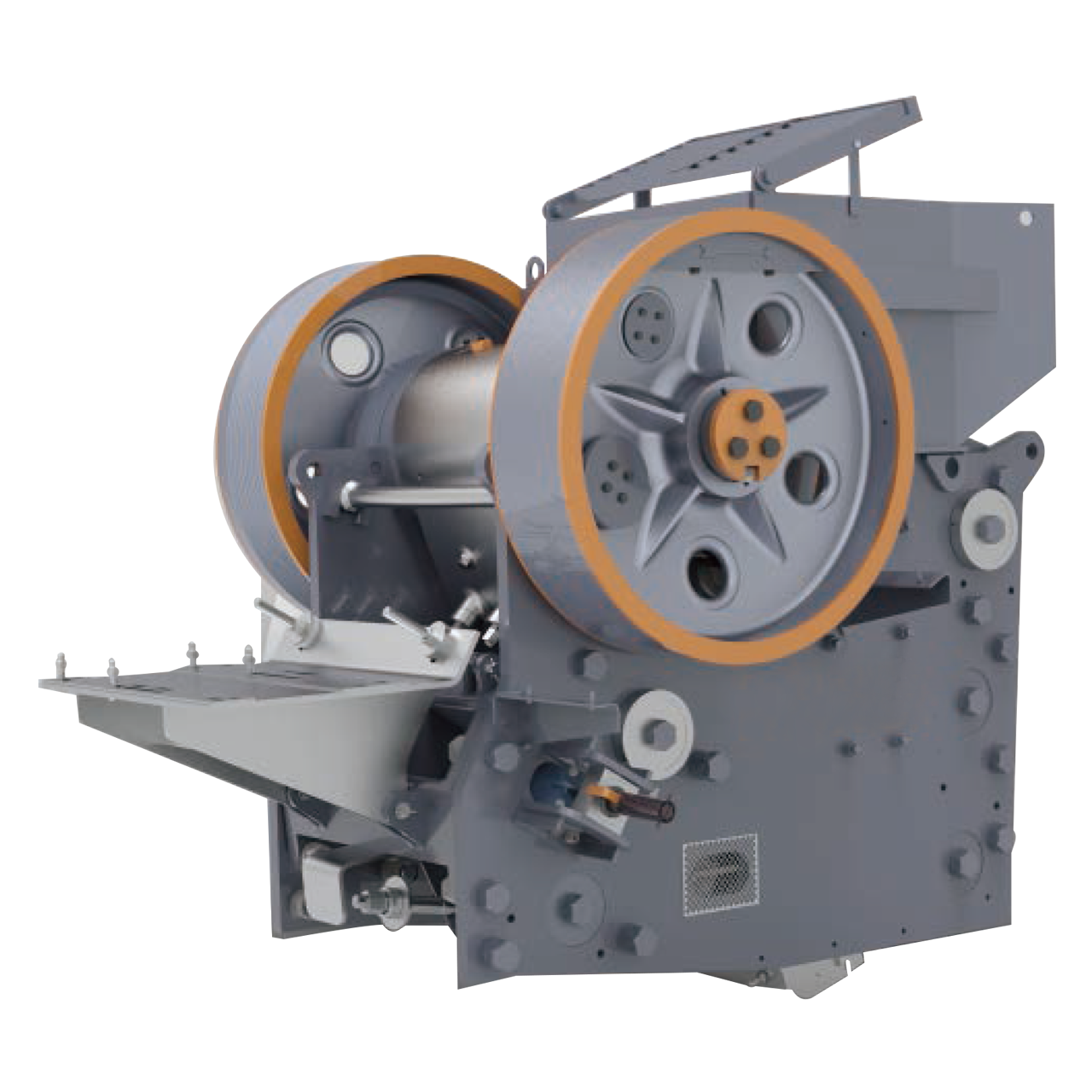

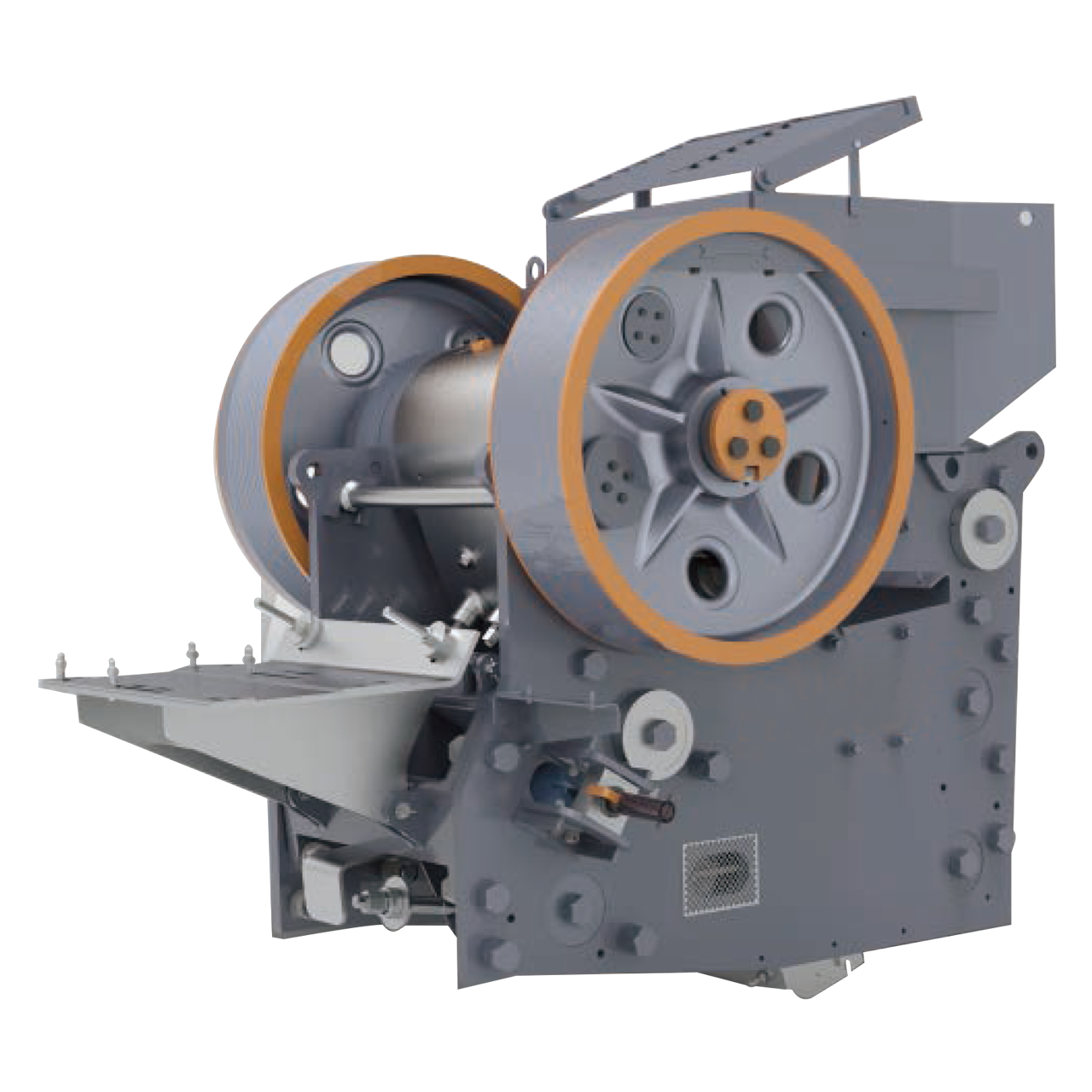

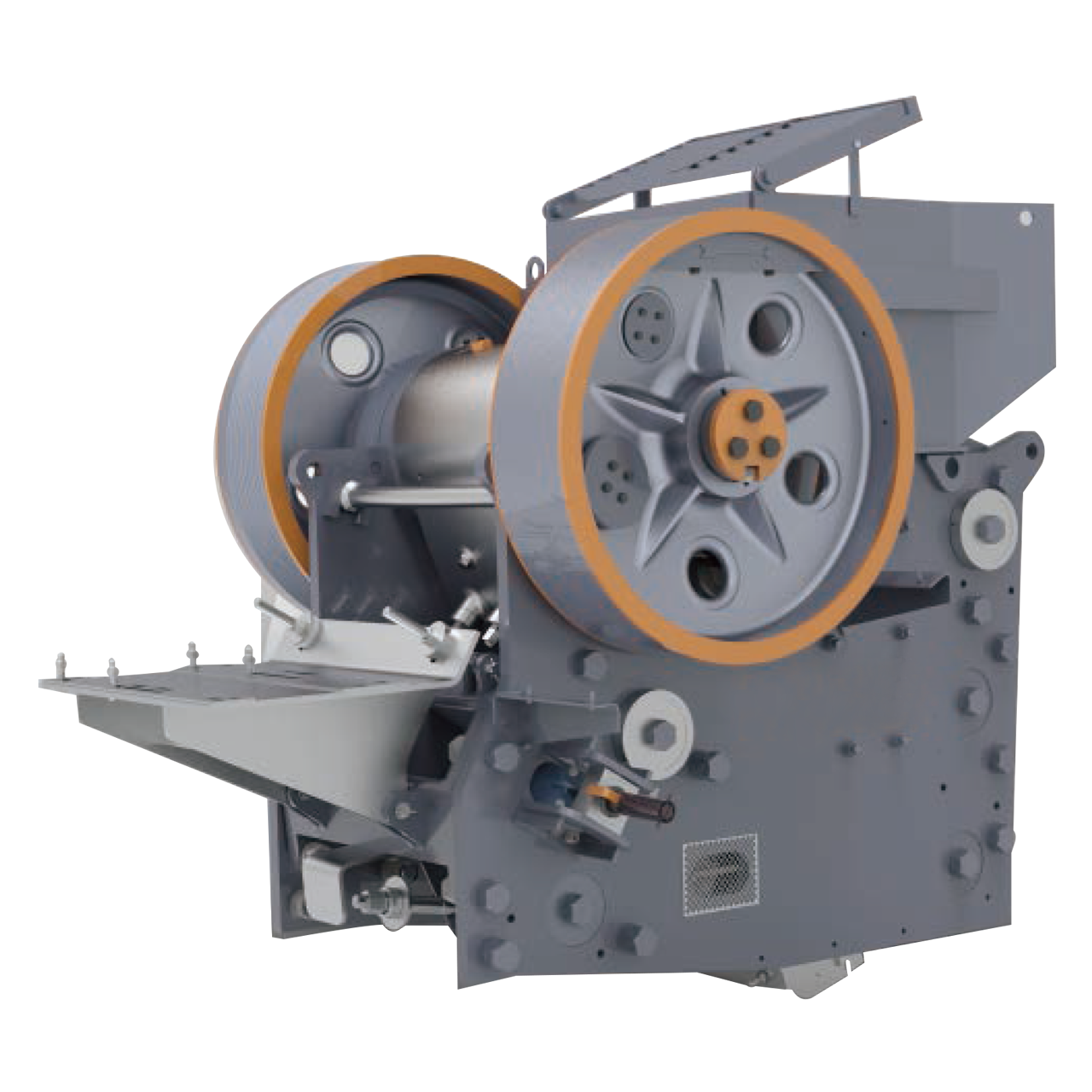

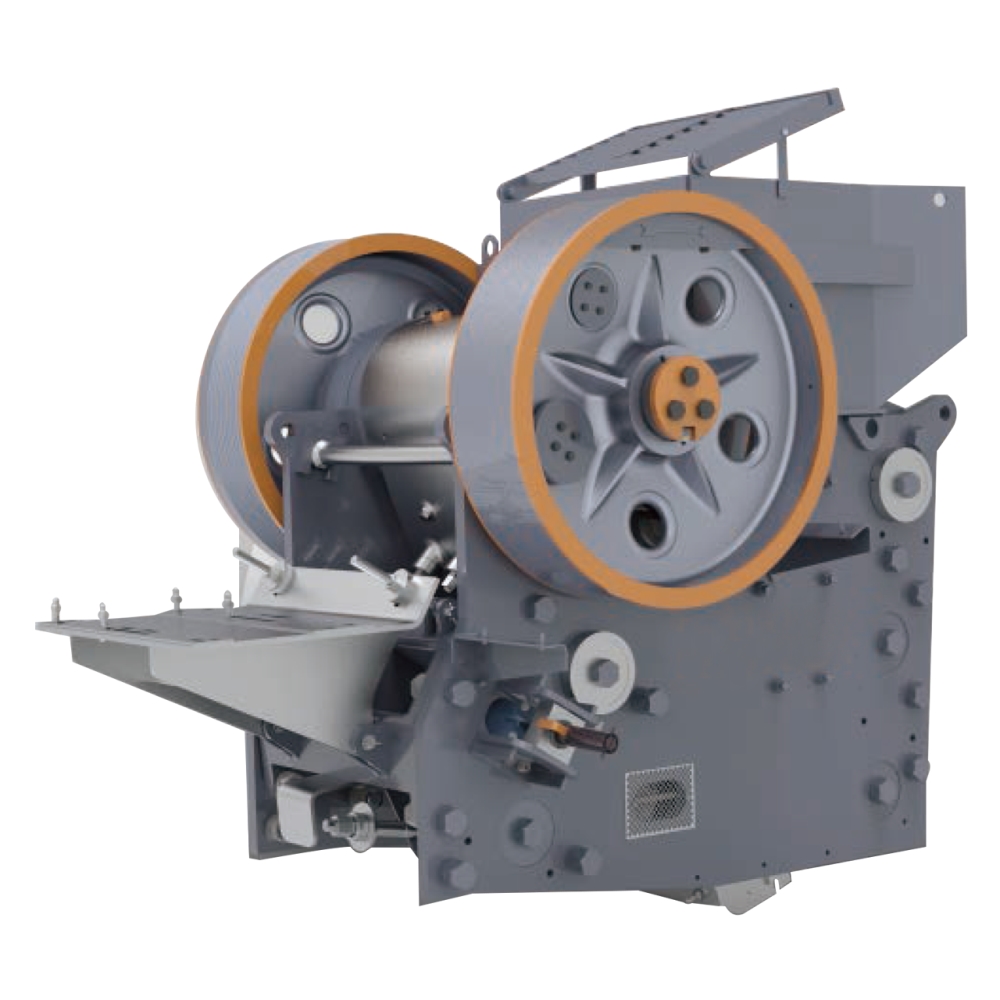

ME200 ME Series Jaw Crusher

Manufacturer : MORETEC

Part number : ME200

OEM Compatibility :

Category :Crusher / Jaw crusher

Description

Description

MORETEC is a professional mine crushing and screening equipment manufacturer and service provider.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

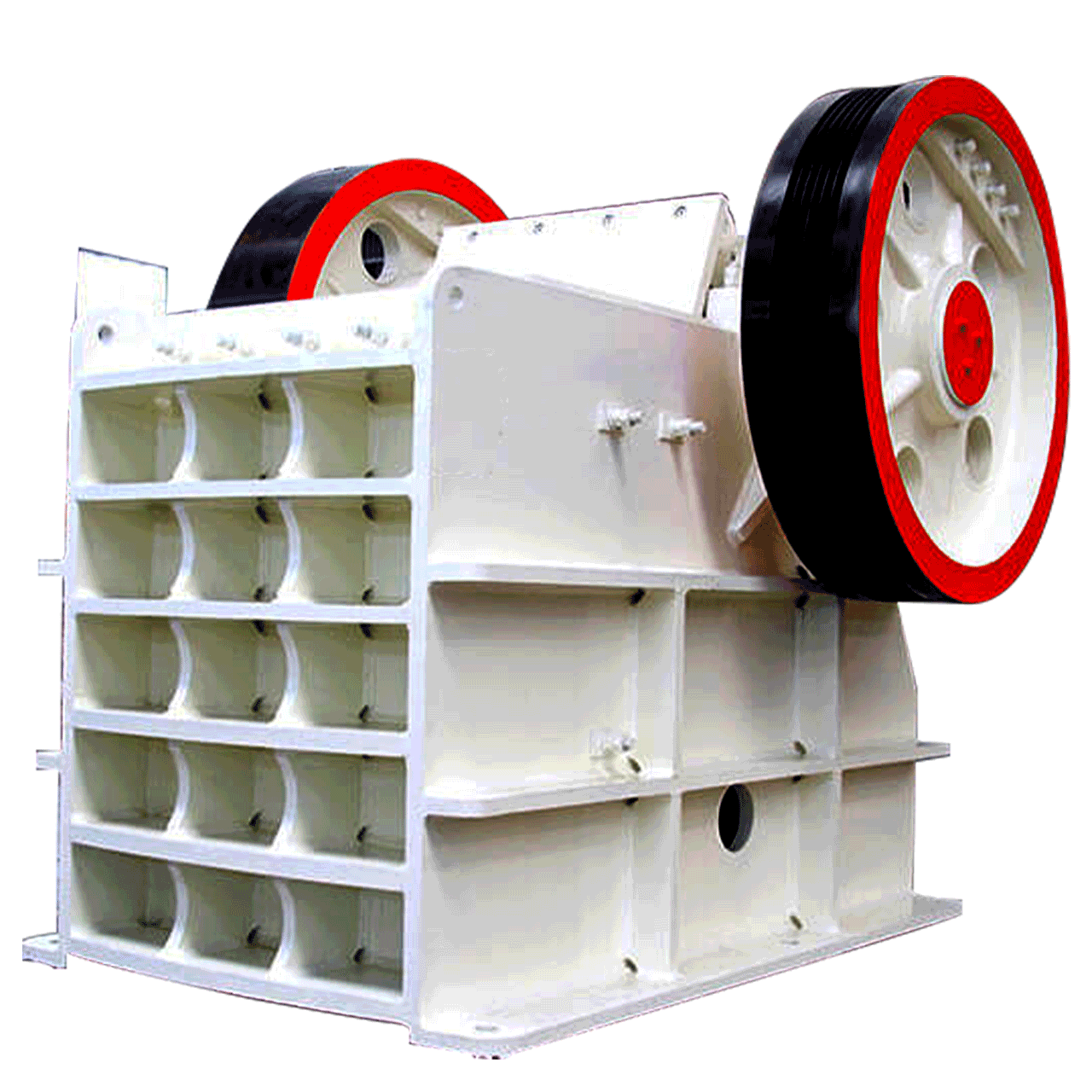

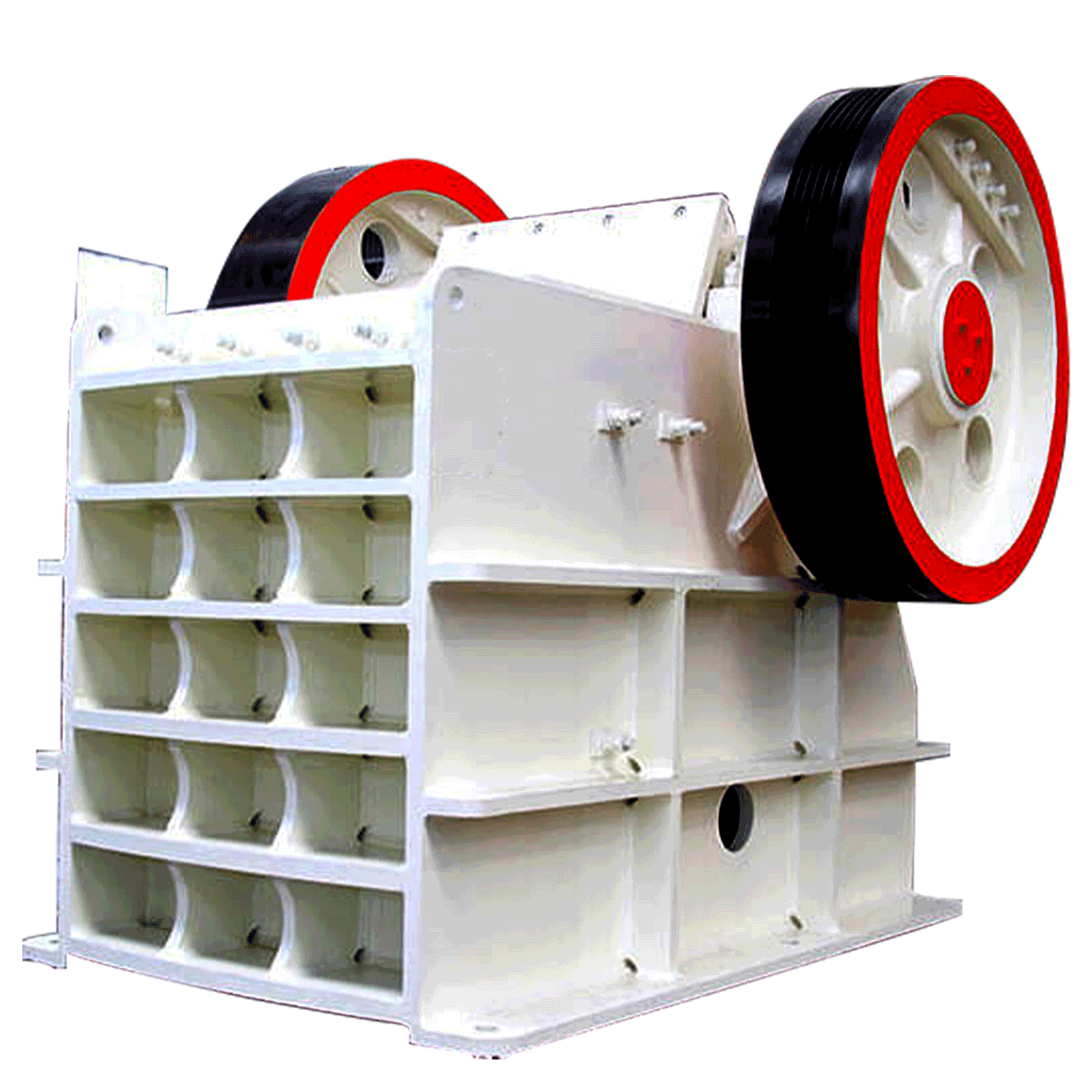

ME Series Jaw Crusher

ME series jaw crushers are mainly applied to coarse crushing in mine and aggregate industries, with the processing capacity ranging from 60 - 1500t/h,which can meet the requirements of small and middle-large size coarse crushing in most cases.

When the jaw crusher is working, the motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate to approach the fixed jaw plate, and at the same time, the material is crushed, crushed, and crushed multiple times. When the movable jaw goes down, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod spring. At this time, the crushed material is discharged from the lower opening of the crushing cavity, and the crushing motor is continuously rotated with the motor. The jaws are used for periodic crushing and discharging to realize mass production.

ME · Features

· Deep cavity crushing ratio, optimized cavity design, high crushing efficiency.

· Long service life, low maintenance rate and low operating cost. Robust frame design and large diameter forged spindle with no threads and sharp corners to minimize stress concentrations.

· Strong bearing capacity and high stability. Larger forging blanks process heavy eccentric shaft, high manganese steel jaw plate and high-grade cast steel movable jaw assembly, which has stronger equipment carrying capacity and higher stability.

· Integrated motor base design, so that the overall equipment is more compact, the utility rate of space is higher and the installation is easier.

· Gasket-type discharge port adjustment device is reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment, the lubrication system is safe and reliable, the component replacement is convenient, and the maintenance workload is small.

· The double-block hydraulic adjustment system is equipped, the mechanical type or the hydraulic wedge type can be optional, and there is no need to add gaskets manually.

Note:

The above table capacity is only an approximate value for the performance of crusher. The corresponding conditions are open-circuit crushing and dry blasting granite with a material bulk density of 1600kg/m³, whose maximum size meets the maximum feed size allowed by the crusher. The minimum tight-side discharge opening that the crusher can operate normally depends on the particle size distribution of feeding, the crushability of the material (Wi), the content of contaminants of feeding, the type of jaw plate installed and the type of raw material.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. With customers all over the world, MORETEC has carried out all-round cooperation with many well-known state-owned and private enterprises in terms of spare parts sales, equipment transformation, and technology.

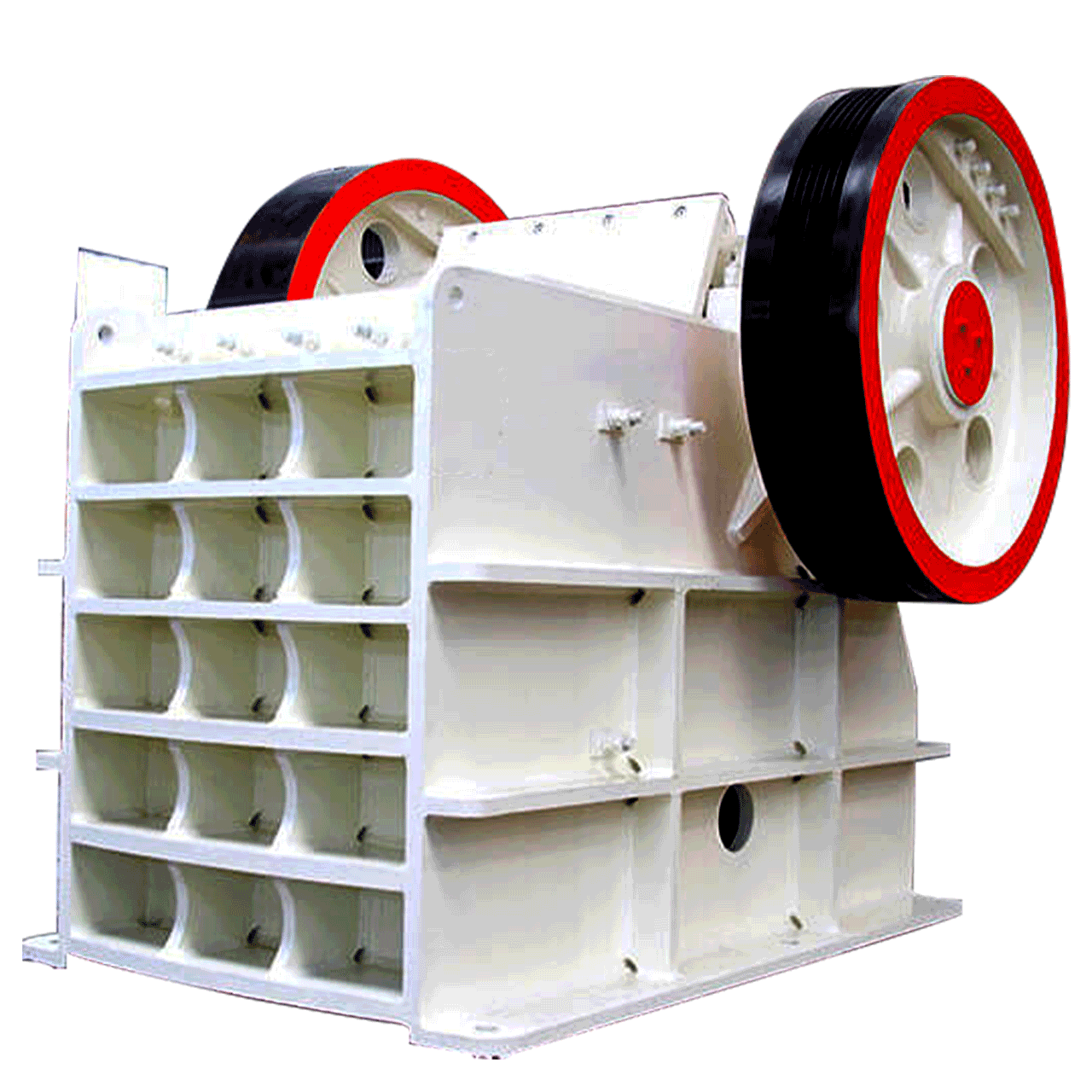

ME Series Jaw Crusher

ME series jaw crushers are mainly applied to coarse crushing in mine and aggregate industries, with the processing capacity ranging from 60 - 1500t/h,which can meet the requirements of small and middle-large size coarse crushing in most cases.

When the jaw crusher is working, the motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate to approach the fixed jaw plate, and at the same time, the material is crushed, crushed, and crushed multiple times. When the movable jaw goes down, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod spring. At this time, the crushed material is discharged from the lower opening of the crushing cavity, and the crushing motor is continuously rotated with the motor. The jaws are used for periodic crushing and discharging to realize mass production.

ME · Features

· Deep cavity crushing ratio, optimized cavity design, high crushing efficiency.

· Long service life, low maintenance rate and low operating cost. Robust frame design and large diameter forged spindle with no threads and sharp corners to minimize stress concentrations.

· Strong bearing capacity and high stability. Larger forging blanks process heavy eccentric shaft, high manganese steel jaw plate and high-grade cast steel movable jaw assembly, which has stronger equipment carrying capacity and higher stability.

· Integrated motor base design, so that the overall equipment is more compact, the utility rate of space is higher and the installation is easier.

· Gasket-type discharge port adjustment device is reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment, the lubrication system is safe and reliable, the component replacement is convenient, and the maintenance workload is small.

· The double-block hydraulic adjustment system is equipped, the mechanical type or the hydraulic wedge type can be optional, and there is no need to add gaskets manually.

Note:

The above table capacity is only an approximate value for the performance of crusher. The corresponding conditions are open-circuit crushing and dry blasting granite with a material bulk density of 1600kg/m³, whose maximum size meets the maximum feed size allowed by the crusher. The minimum tight-side discharge opening that the crusher can operate normally depends on the particle size distribution of feeding, the crushability of the material (Wi), the content of contaminants of feeding, the type of jaw plate installed and the type of raw material.

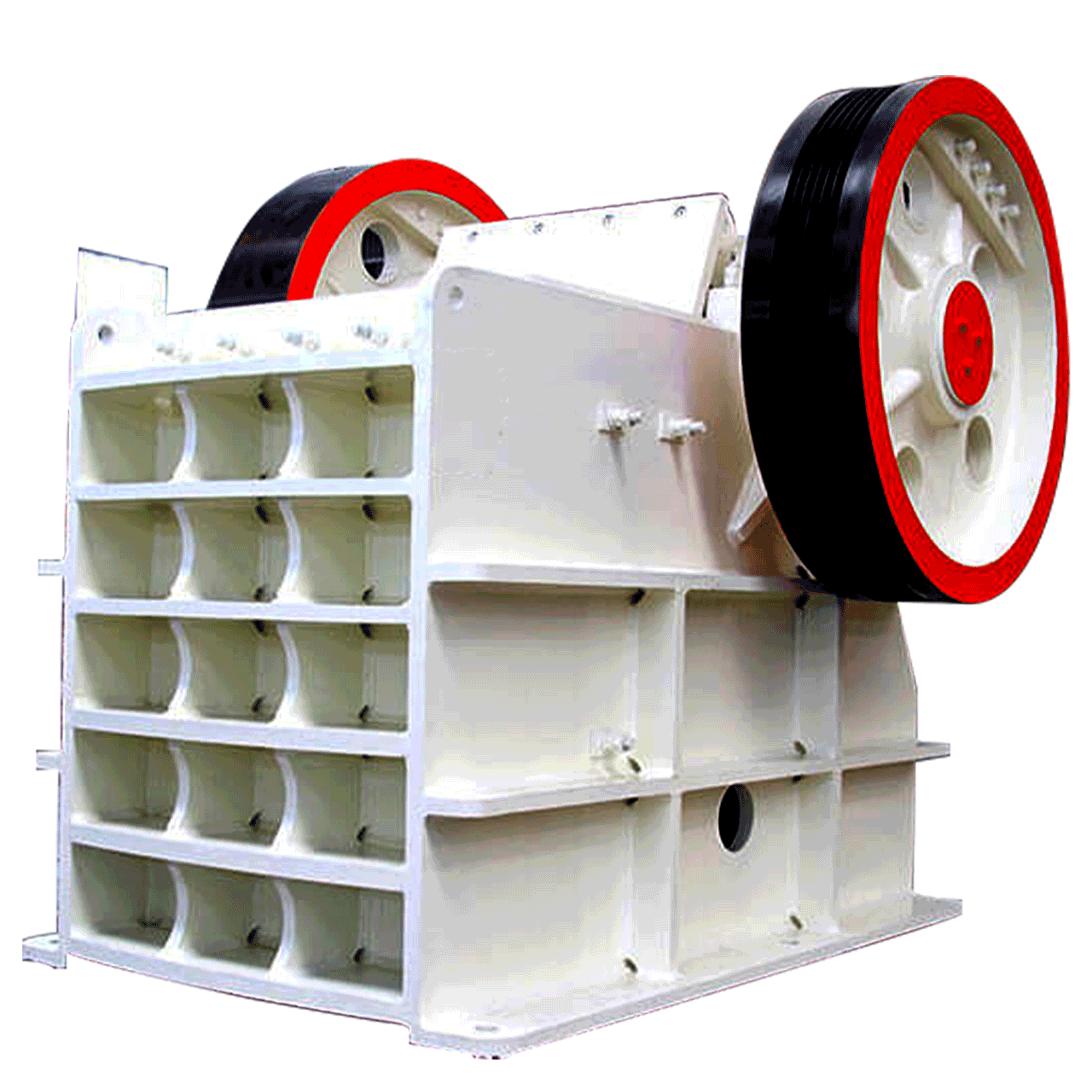

| Crusher weight | 137 ton |

| Crusher power | 400 kW |

| Feeding size | 2000×1500mm |

| Discharge Range | 175-300mm |

| Capacity | 625-1570t/h |

Parts List