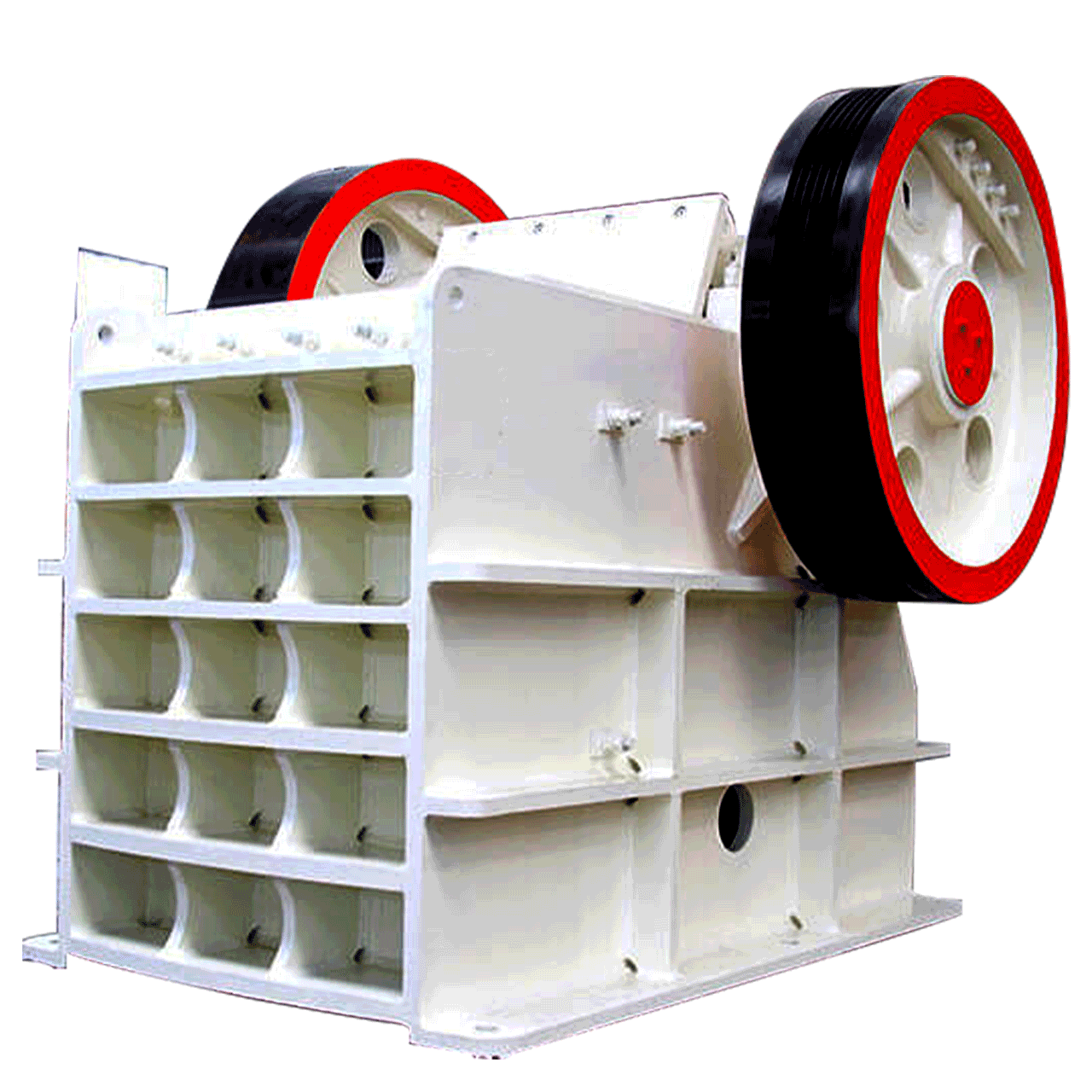

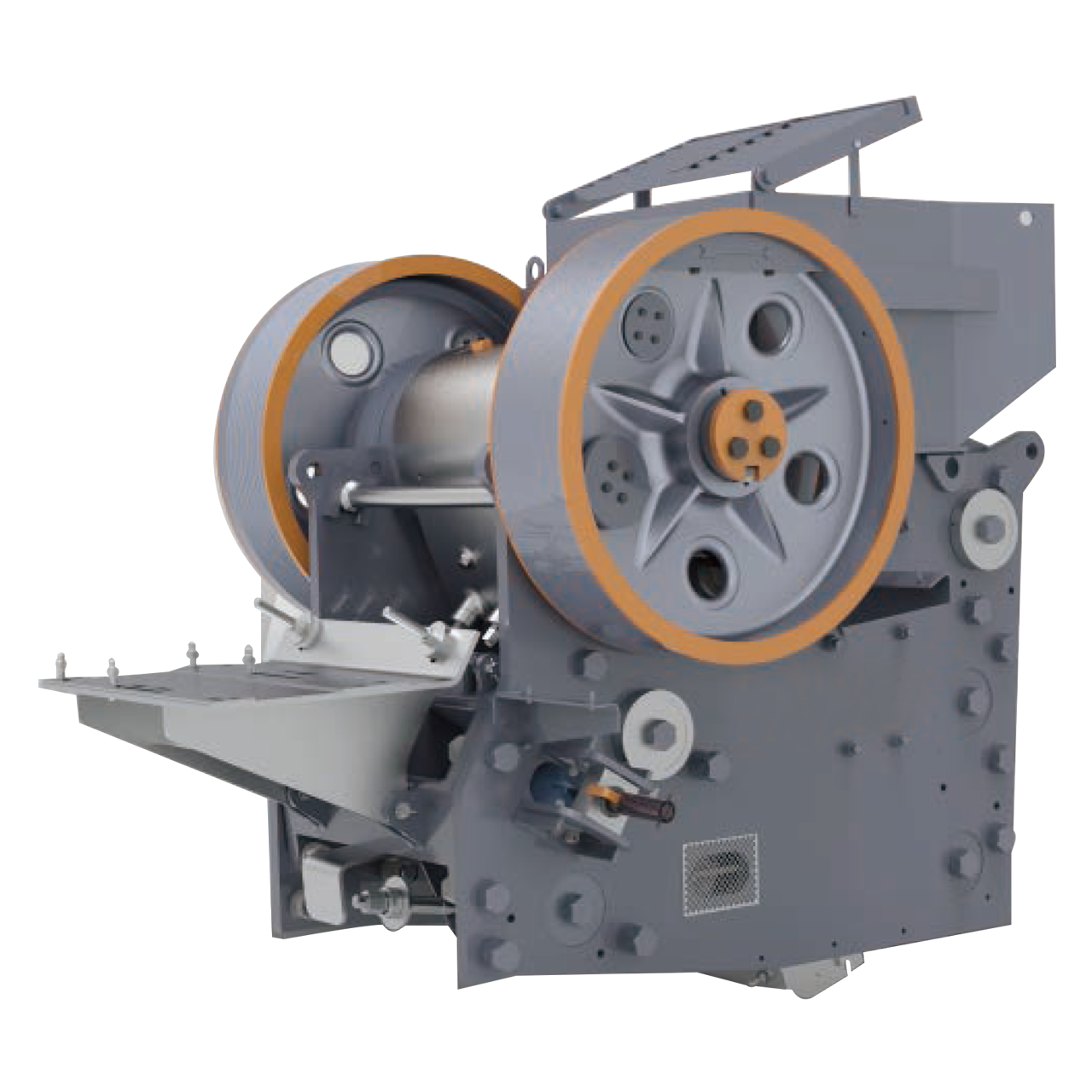

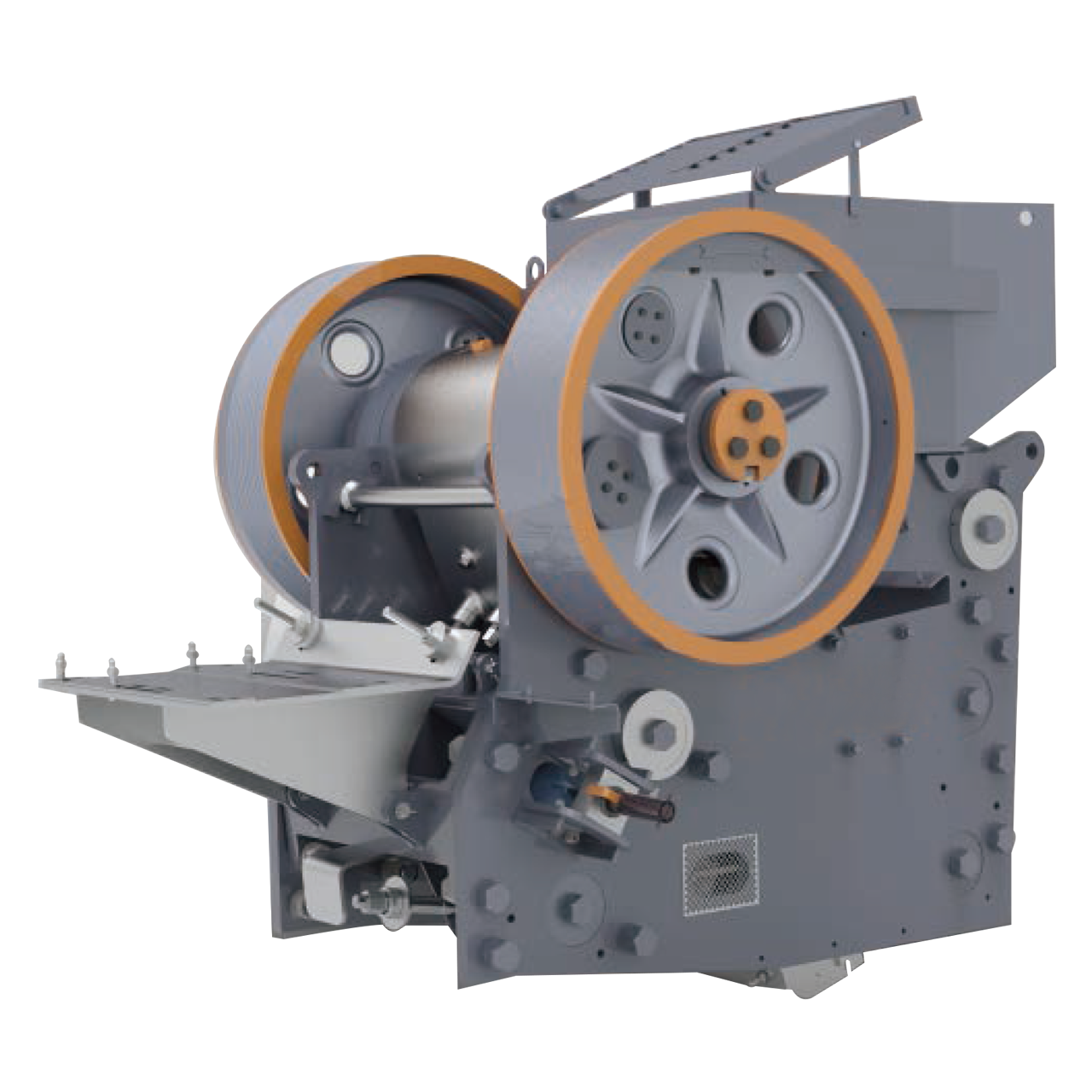

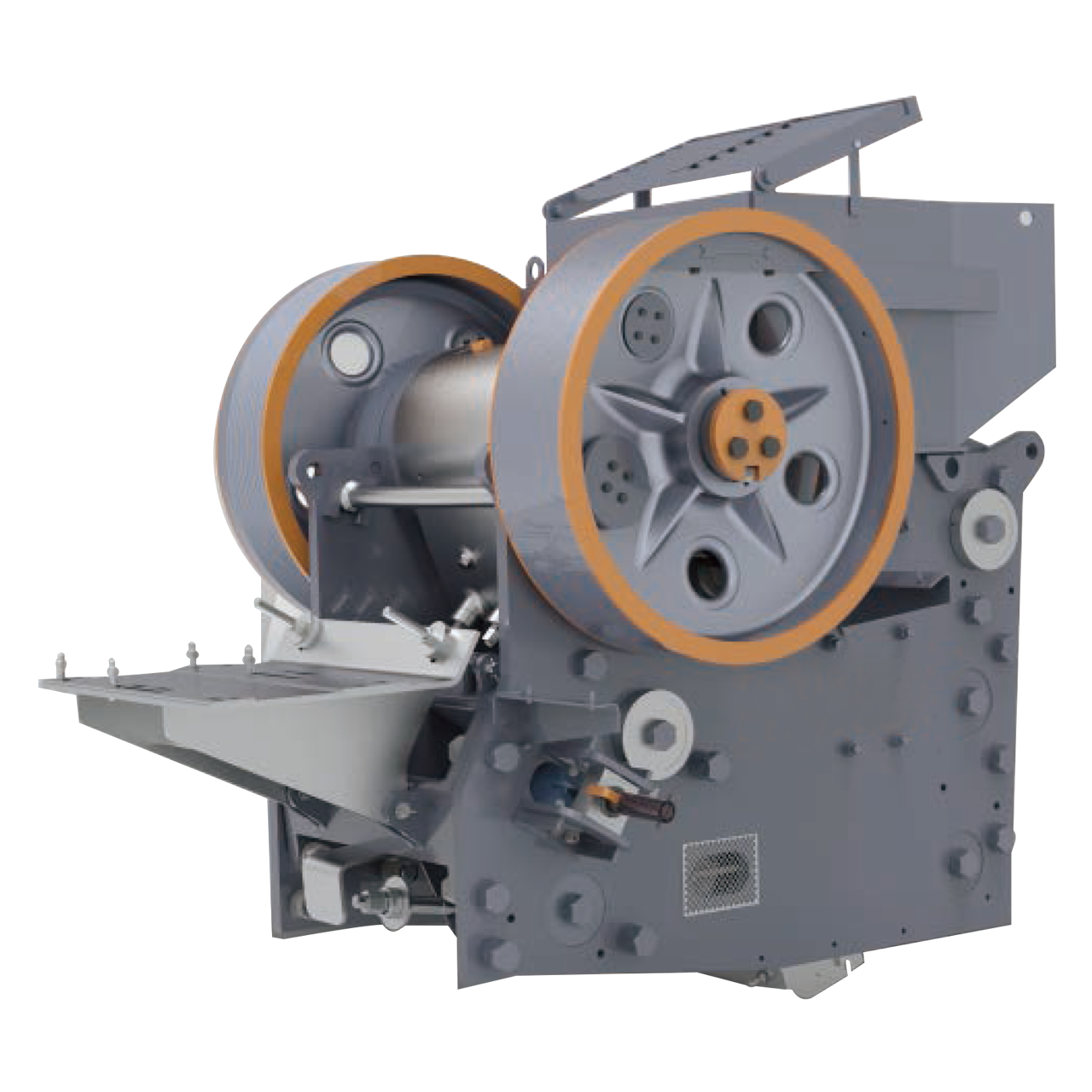

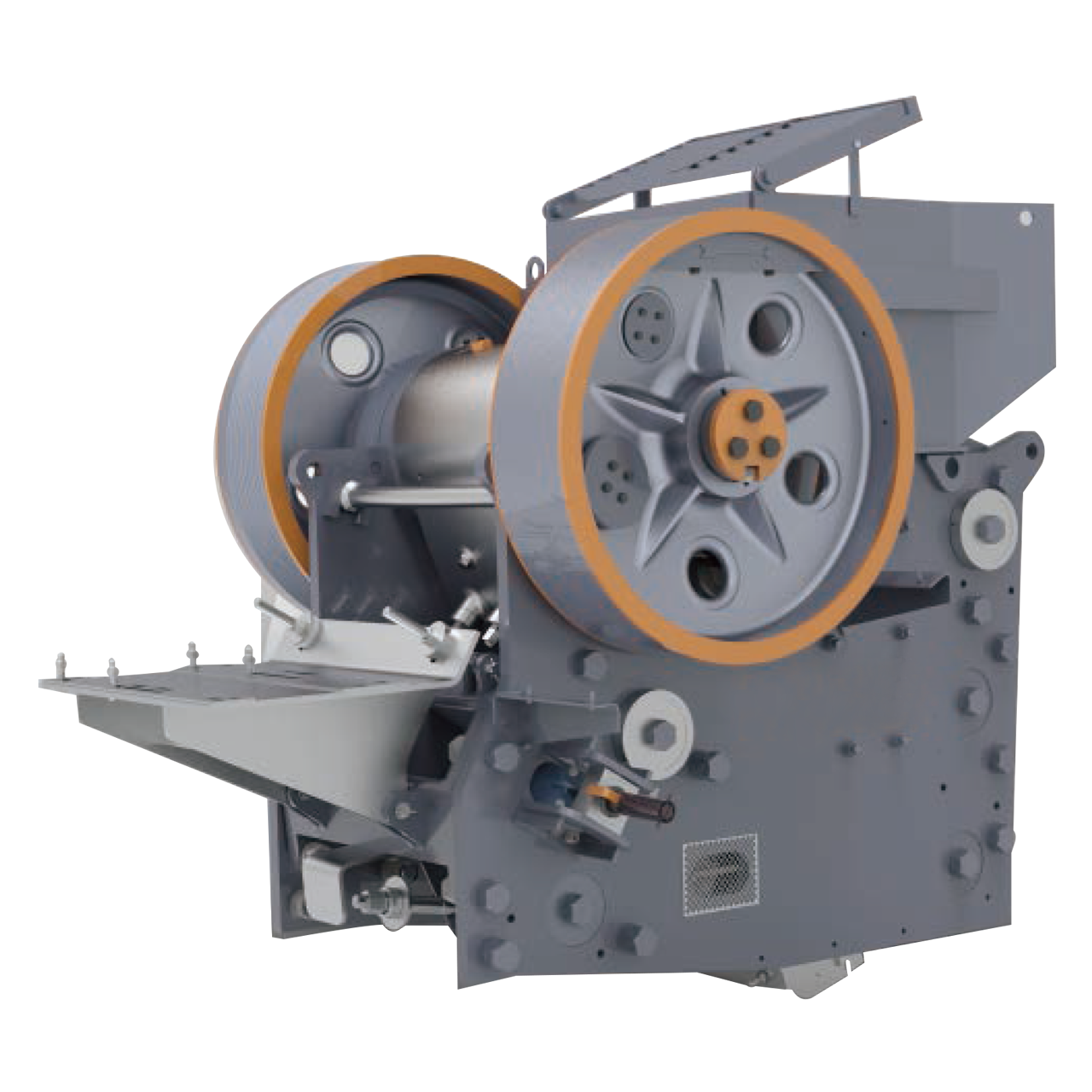

PE200x350 PE Series 200x350 Jaw Crusher

Manufacturer : MORETEC

Part number : PE200x350

OEM Compatibility :

Category :Crusher / Jaw crusher

Description

Description

PE series Eshi crusher

MORETEC is a heavy mining machinery manufacturing company specializing in the production of crushers, sand making machines, mills, mobile crushing stations, and mineral processing equipment.

Jaw crusher is the traditional crushing equipment, many models, large output. PE jaw crusher is mainly used for primary crushing of various ores and raw materials, and can also be used for coarse crushing and fine crushing.

There are many models of PE jaw crusher, among which the most popular models are PE-750 × 1060, PE-600 × 900, PE-150 × 250, etc. In order to meet the strict requirements of customers, the crusher has been extended to PEX jaw crusher, also known as fine crusher, under the continuous innovation of engineers.

PE series jaw crusher is one of the mainstream crushing equipment with large sales volume and high production efficiency in the mining equipment industry. MORETEC jaw breaking is used in the first process of crushing various ore rocks. It can process various ores with compressive strength not higher than 320MPa to medium particle size at one time. It often forms a complete set of sand and gravel production line together with cone crusher, impact crusher and sand making machine.

What industries is PE jaw crusher suitable?

The crusher has been widely used in mining, building materials, highway, railway, water conservancy, chemical industry, chemical industry, cement, construction, refractory materials and ceramics and other industries, as well as crushing various soft and hard ores with compressive strength of 350MPa and diameter of 500-1800mm. Pebble, granite, basalt, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand and other metal ores. The crushing efficiency of the PE jaw crusher is remarkable, the crushing ratio is large, and the output is high, which is favored by the majority of users.

ore beneficiation

This crusher is used in almost all mineral and mining industries. Whether it is processing metal ore or non-metal ore, we can provide you with size reduction solutions, because our series of products can be used for crushing, downsizing, and beneficiation, with reliable design and versatility, suitable for you Application. The PE jaw crusher can process 1-2000 tons of ore per hour, so in Africa, many gold mines choose our jaw crusher as the primary crushing of their entire beneficiation line.

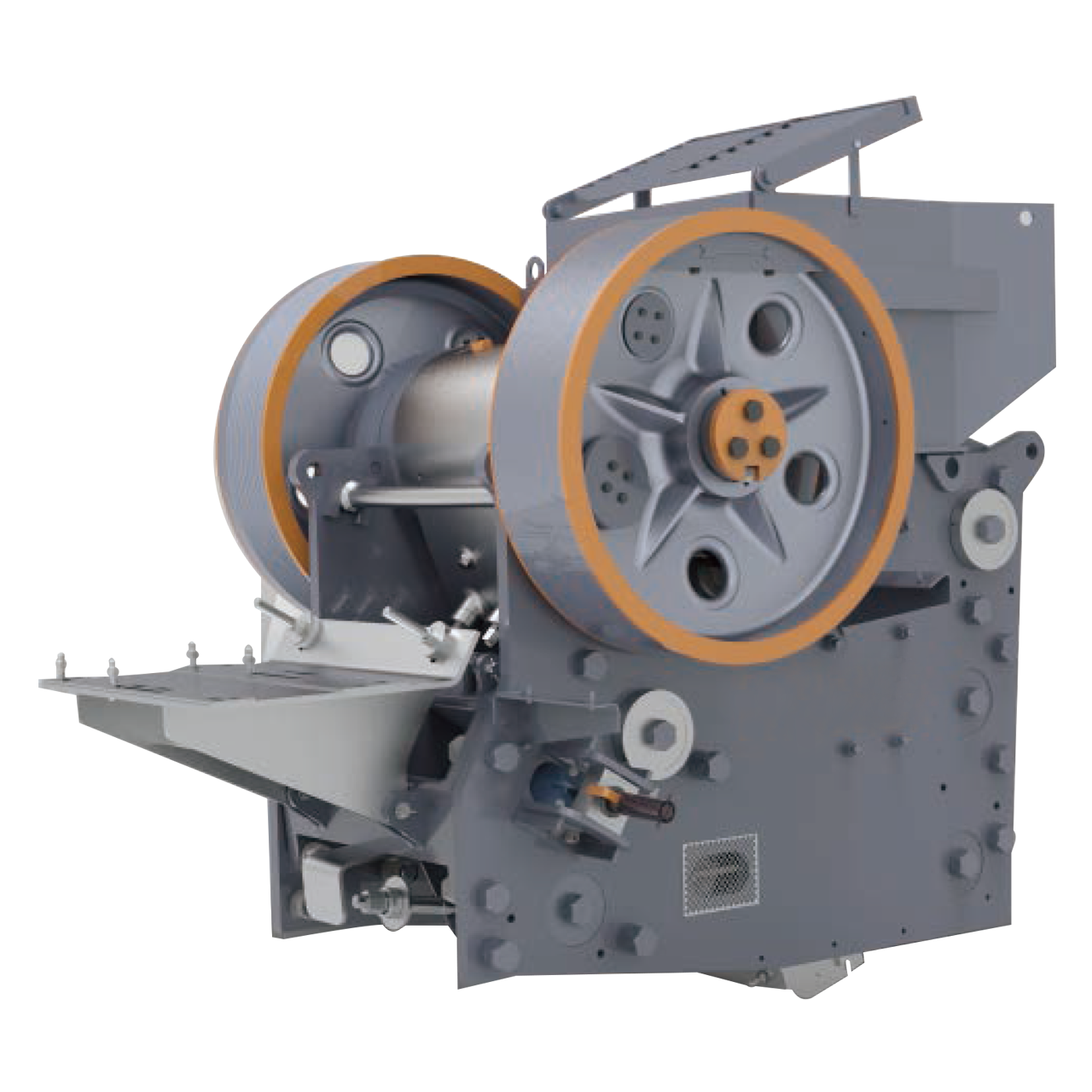

Working principle

The motor drives the belt and pulley to move the moving jaw up and down through the eccentric shaft. When the moving jaw rises, the angle between the toggle plate and the moving jaw becomes larger, thereby pushing the moving jaw plate to approach the fixed jaw plate. At this time, the crushed material is squeezed, Rubbing, grinding and other multiple forces are crushed. When the moving jaw goes down, the included angle between the toggle plate and the moving jaw becomes smaller, and the distance between the moving jaw plate and the fixed jaw plate is increased under the action of the pull rod and spring. At this time, the crushed material is discharged from the shaking mouth of the crushing cavity. With the continuous operation of the eccentric shaft, the moving jaw makes periodic reciprocating motion, and the material entering the crushing cavity is continuously crushed and discharged to realize continuous production.

The selection process is as follows: raw materials and bulk materials-vibrating feeder-jaw crusher (primary crushing)-belt conveyor-cone crusher (secondary crushing)-belt conveyor-vibrating screen (finished products of different sizes). Different granularity can meet the requirements of different specifications of customers.

Features of jaw crusher

1. Crush ore and rock at a pressure lower than 320 MP;

2. Easy to maintain;

3. Used in mining, construction, chemical industry;

4. Crusher with shorter machine stop time;

5. low cost;

6. Long service life;

7, a broken, simple structure;

8. Great construction intensity;

9. High crushing rate;

10. Easy to maintain;

11. Stable performance;

12. Uniform jaw extrusion of the final product

MORETEC is a heavy mining machinery manufacturing company specializing in the production of crushers, sand making machines, mills, mobile crushing stations, and mineral processing equipment.

Jaw crusher is the traditional crushing equipment, many models, large output. PE jaw crusher is mainly used for primary crushing of various ores and raw materials, and can also be used for coarse crushing and fine crushing.

There are many models of PE jaw crusher, among which the most popular models are PE-750 × 1060, PE-600 × 900, PE-150 × 250, etc. In order to meet the strict requirements of customers, the crusher has been extended to PEX jaw crusher, also known as fine crusher, under the continuous innovation of engineers.

PE series jaw crusher is one of the mainstream crushing equipment with large sales volume and high production efficiency in the mining equipment industry. MORETEC jaw breaking is used in the first process of crushing various ore rocks. It can process various ores with compressive strength not higher than 320MPa to medium particle size at one time. It often forms a complete set of sand and gravel production line together with cone crusher, impact crusher and sand making machine.

What industries is PE jaw crusher suitable?

The crusher has been widely used in mining, building materials, highway, railway, water conservancy, chemical industry, chemical industry, cement, construction, refractory materials and ceramics and other industries, as well as crushing various soft and hard ores with compressive strength of 350MPa and diameter of 500-1800mm. Pebble, granite, basalt, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand and other metal ores. The crushing efficiency of the PE jaw crusher is remarkable, the crushing ratio is large, and the output is high, which is favored by the majority of users.

ore beneficiation

This crusher is used in almost all mineral and mining industries. Whether it is processing metal ore or non-metal ore, we can provide you with size reduction solutions, because our series of products can be used for crushing, downsizing, and beneficiation, with reliable design and versatility, suitable for you Application. The PE jaw crusher can process 1-2000 tons of ore per hour, so in Africa, many gold mines choose our jaw crusher as the primary crushing of their entire beneficiation line.

Working principle

The motor drives the belt and pulley to move the moving jaw up and down through the eccentric shaft. When the moving jaw rises, the angle between the toggle plate and the moving jaw becomes larger, thereby pushing the moving jaw plate to approach the fixed jaw plate. At this time, the crushed material is squeezed, Rubbing, grinding and other multiple forces are crushed. When the moving jaw goes down, the included angle between the toggle plate and the moving jaw becomes smaller, and the distance between the moving jaw plate and the fixed jaw plate is increased under the action of the pull rod and spring. At this time, the crushed material is discharged from the shaking mouth of the crushing cavity. With the continuous operation of the eccentric shaft, the moving jaw makes periodic reciprocating motion, and the material entering the crushing cavity is continuously crushed and discharged to realize continuous production.

The selection process is as follows: raw materials and bulk materials-vibrating feeder-jaw crusher (primary crushing)-belt conveyor-cone crusher (secondary crushing)-belt conveyor-vibrating screen (finished products of different sizes). Different granularity can meet the requirements of different specifications of customers.

Features of jaw crusher

1. Crush ore and rock at a pressure lower than 320 MP;

2. Easy to maintain;

3. Used in mining, construction, chemical industry;

4. Crusher with shorter machine stop time;

5. low cost;

6. Long service life;

7, a broken, simple structure;

8. Great construction intensity;

9. High crushing rate;

10. Easy to maintain;

11. Stable performance;

12. Uniform jaw extrusion of the final product

Parts List