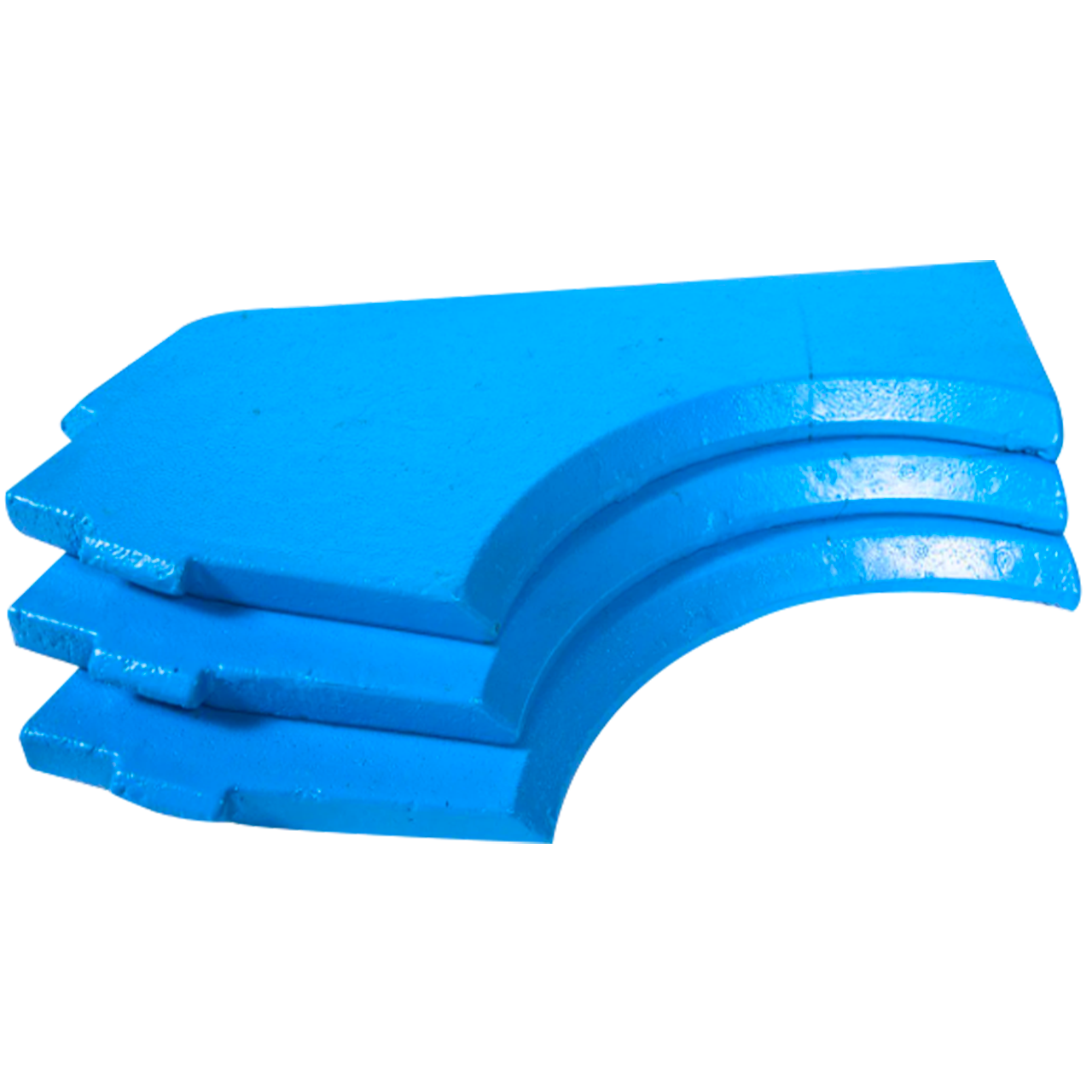

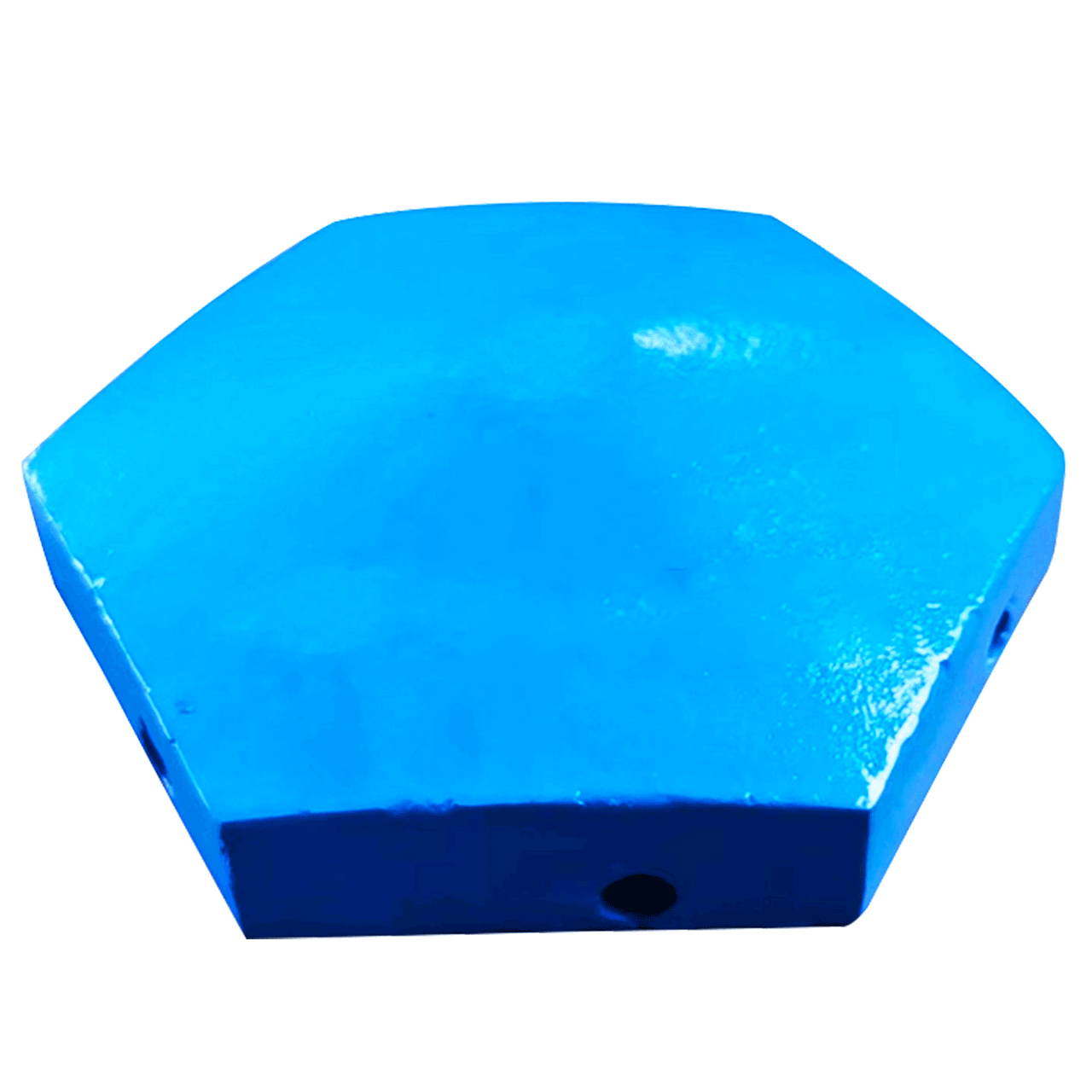

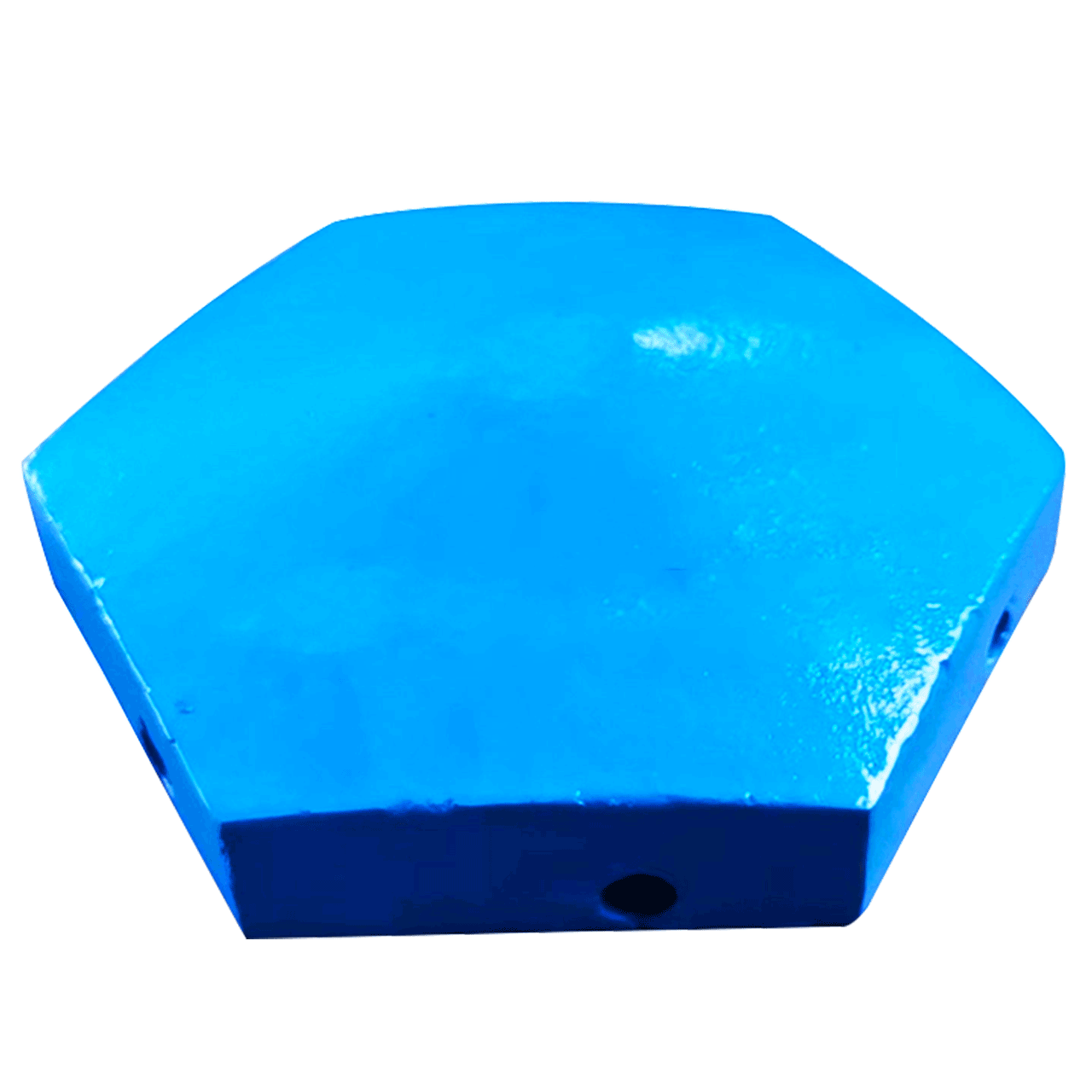

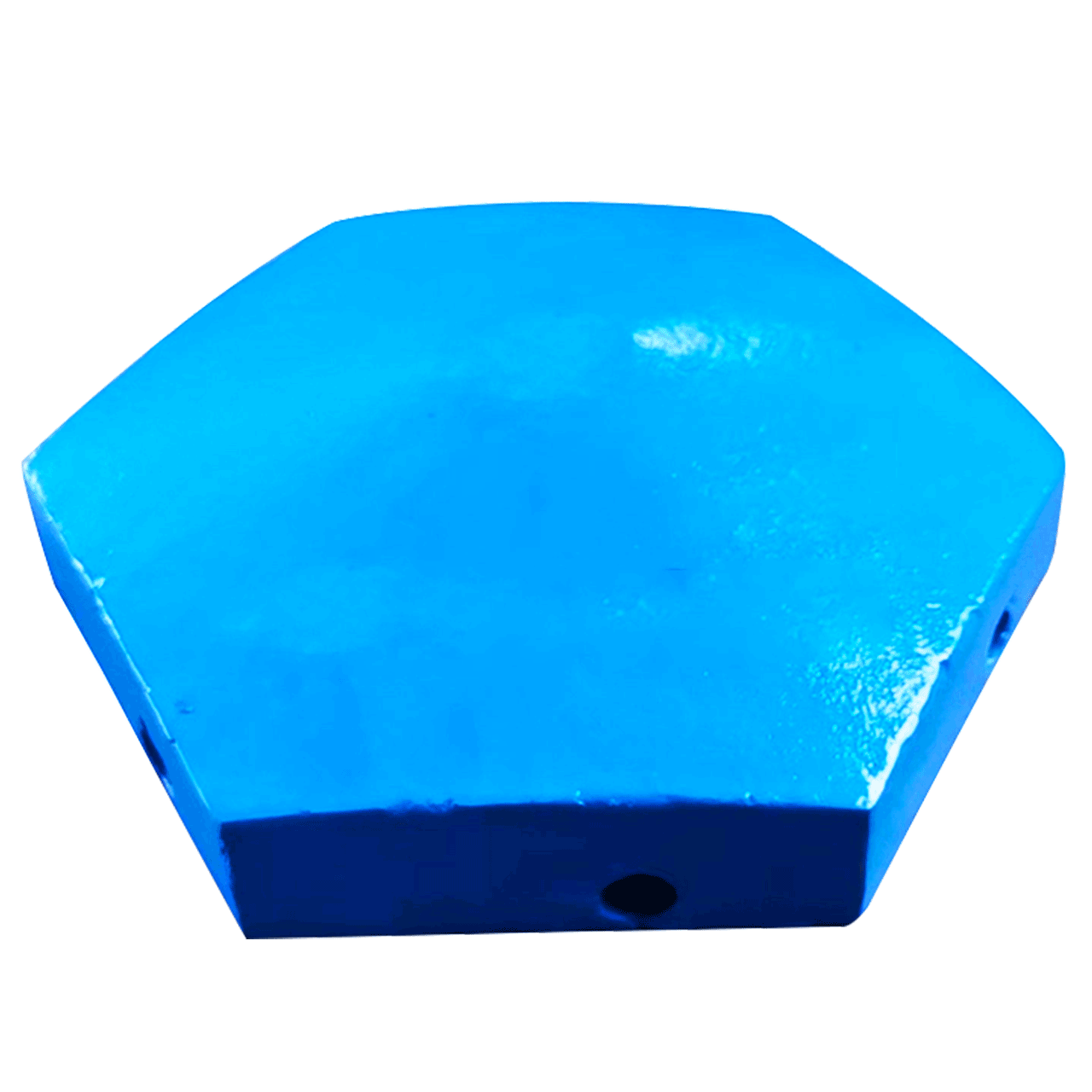

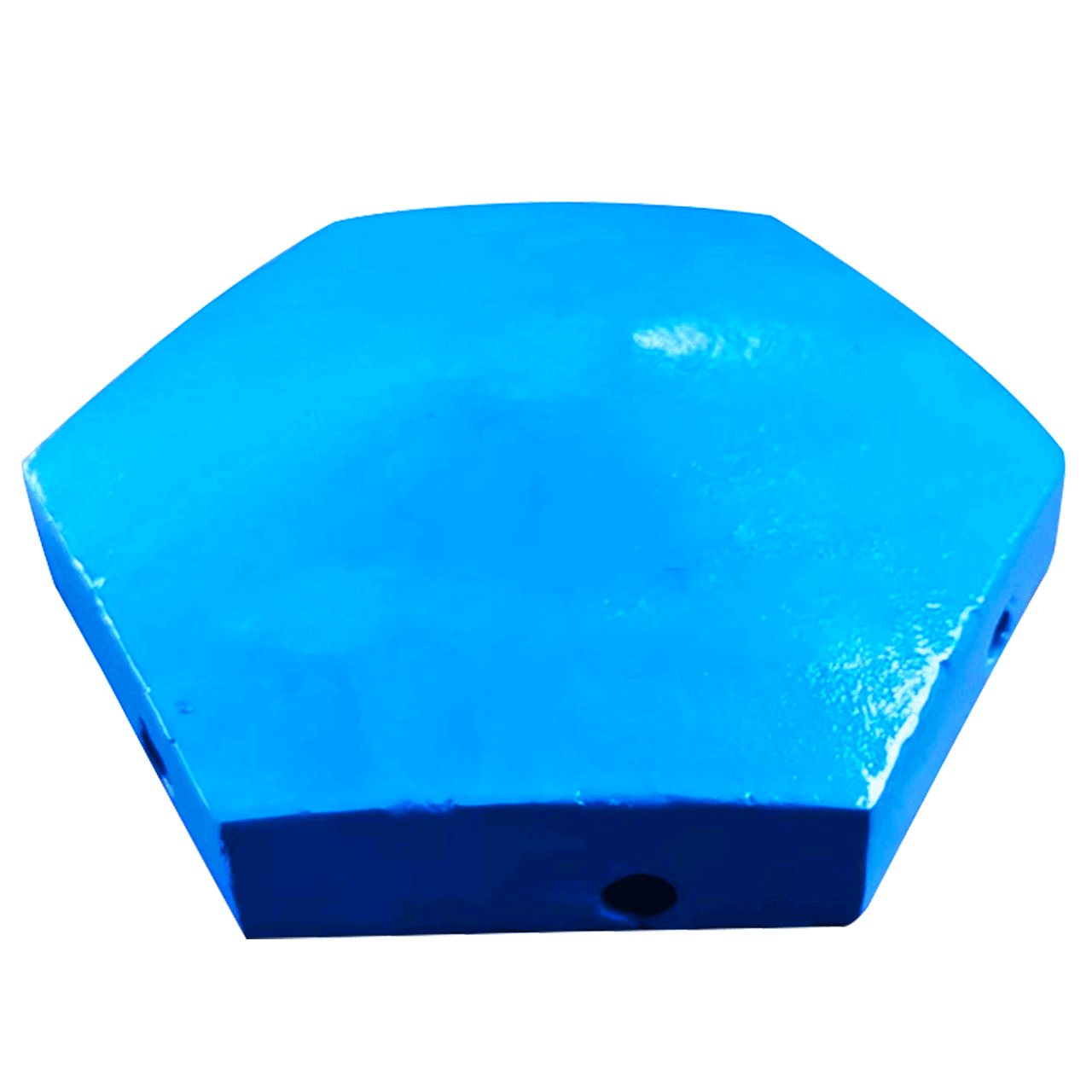

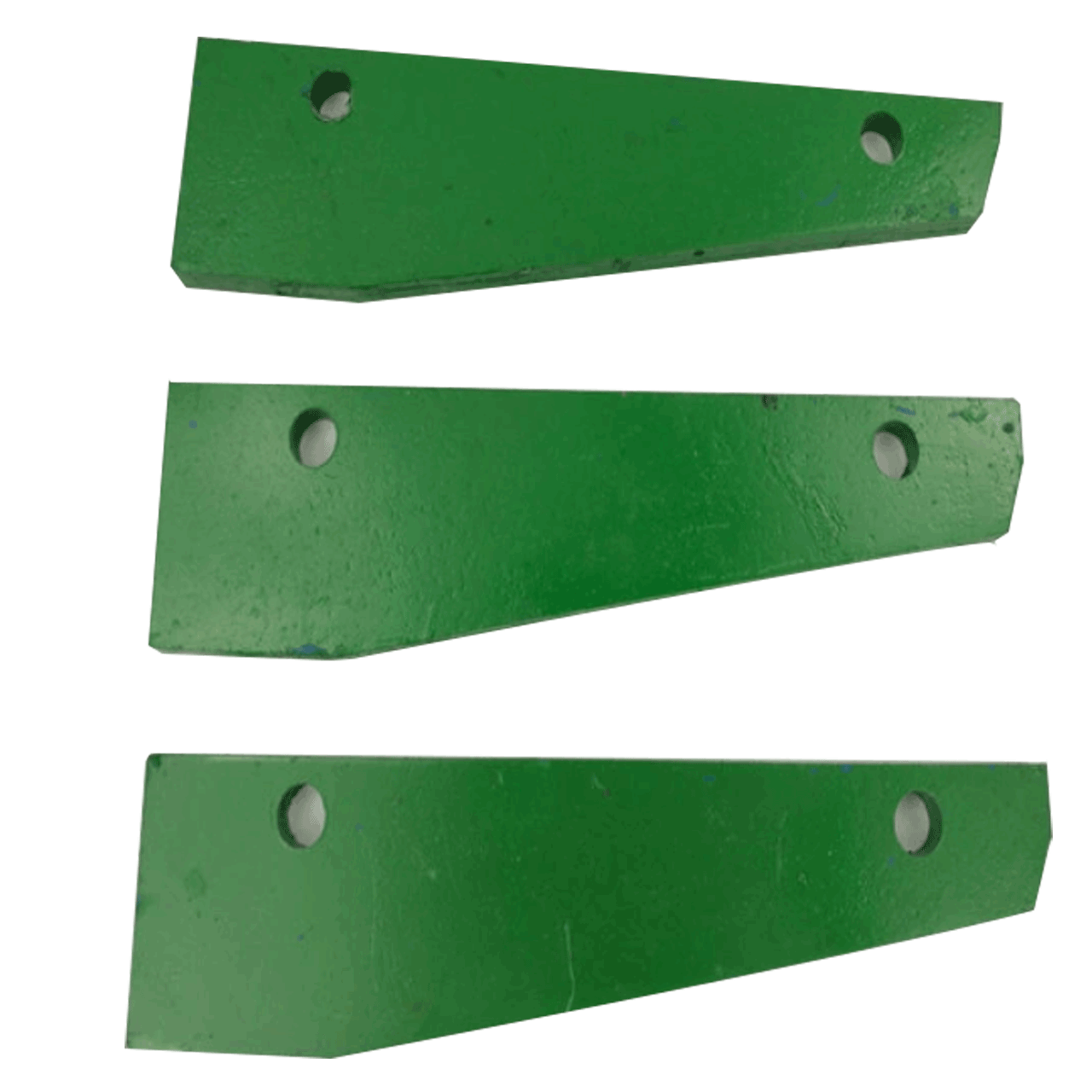

B7150se Rotor VSI Crusher Rotor Tip B963940490

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

Solution to rotor imbalance 1) Balance test of rotor before production; 2) Feeding should be uniform to avoid uneven force on rotor; 3) When replacing the hammer head, it is best to replace it completely or symmetrically, and install it according to the correct method. 4. Precautions for rotor maintenance The impact crusher has aggravated the wear of the rotor bearing due to long-term work under harsh conditions.

Gap adjustment of the rotor and the counter-attack liner: When the rotor of the impact crusher is running, the gap between the rotor and the counter-attack liner cannot be adjusted. If the material in blocks is stranded between the counterattack plate and the plate shell, it is recommended to slightly lift the counterattack frame between the re-adjustment gap, so that the block feed will become loose and the counterattack frame is easy to adjust. If the counterattack frame is not sufficient, you can tap it on the loose tie rod (protected by a wooden board). The clearance between the rotor and the counterattack liner is completed by the adjustment device of the machine. First, loosen the bolt sleeve.

The following describes the use of impact crusher rotor matters needing attention: 1 reasonable adjustment of the relationship between each other. The impact-broken rotor bearing is mainly subjected to impact load when working. The size of the load on the rolling element is different. The rolling element under the combined force of the impact load has the greatest force, and the inner and outer ring raceway is also here. The force is the greatest when the rolling element is in contact.

Reasonably adjust the matching relationship between the rotor bearings. The counterattack broken rotor bearing is mainly subjected to impact load when working. The size of the load on the rolling element is different. The rolling element under the combined force of the impact load has the greatest force, and the inner and outer ring raceway is also here. The force is the greatest when the rolling element is in contact.

Moretec crusher wearing parts provide you:

Custom configuration ensures consistent production

Durable manganese steel increases the uptime of the crusher

Reduce equipment wear

The abundant inventory of patterns (covering all major brands and models), as well as all patterns produced only according to the original drawings, ensure fast delivery and a perfect match with the crusher.

Based on our more than 15 years of experience in this field, we can adjust it according to special requirements.

Perfect management, covering your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm the order), delivery (clear photos and test reports are ready for customer confirmation), After-sales (after-sales inspection, size matching, service life inspection, etc. after the goods arrive at the work site). Make sure there is no doubt about each purchase)

Abundant production capacity: about 10000 tons per year to ensure the supply capacity to customers.

Gap adjustment of the rotor and the counter-attack liner: When the rotor of the impact crusher is running, the gap between the rotor and the counter-attack liner cannot be adjusted. If the material in blocks is stranded between the counterattack plate and the plate shell, it is recommended to slightly lift the counterattack frame between the re-adjustment gap, so that the block feed will become loose and the counterattack frame is easy to adjust. If the counterattack frame is not sufficient, you can tap it on the loose tie rod (protected by a wooden board). The clearance between the rotor and the counterattack liner is completed by the adjustment device of the machine. First, loosen the bolt sleeve.

The following describes the use of impact crusher rotor matters needing attention: 1 reasonable adjustment of the relationship between each other. The impact-broken rotor bearing is mainly subjected to impact load when working. The size of the load on the rolling element is different. The rolling element under the combined force of the impact load has the greatest force, and the inner and outer ring raceway is also here. The force is the greatest when the rolling element is in contact.

Reasonably adjust the matching relationship between the rotor bearings. The counterattack broken rotor bearing is mainly subjected to impact load when working. The size of the load on the rolling element is different. The rolling element under the combined force of the impact load has the greatest force, and the inner and outer ring raceway is also here. The force is the greatest when the rolling element is in contact.

Moretec crusher wearing parts provide you:

Custom configuration ensures consistent production

Durable manganese steel increases the uptime of the crusher

Reduce equipment wear

The abundant inventory of patterns (covering all major brands and models), as well as all patterns produced only according to the original drawings, ensure fast delivery and a perfect match with the crusher.

Based on our more than 15 years of experience in this field, we can adjust it according to special requirements.

Perfect management, covering your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm the order), delivery (clear photos and test reports are ready for customer confirmation), After-sales (after-sales inspection, size matching, service life inspection, etc. after the goods arrive at the work site). Make sure there is no doubt about each purchase)

Abundant production capacity: about 10000 tons per year to ensure the supply capacity to customers.

Parts List