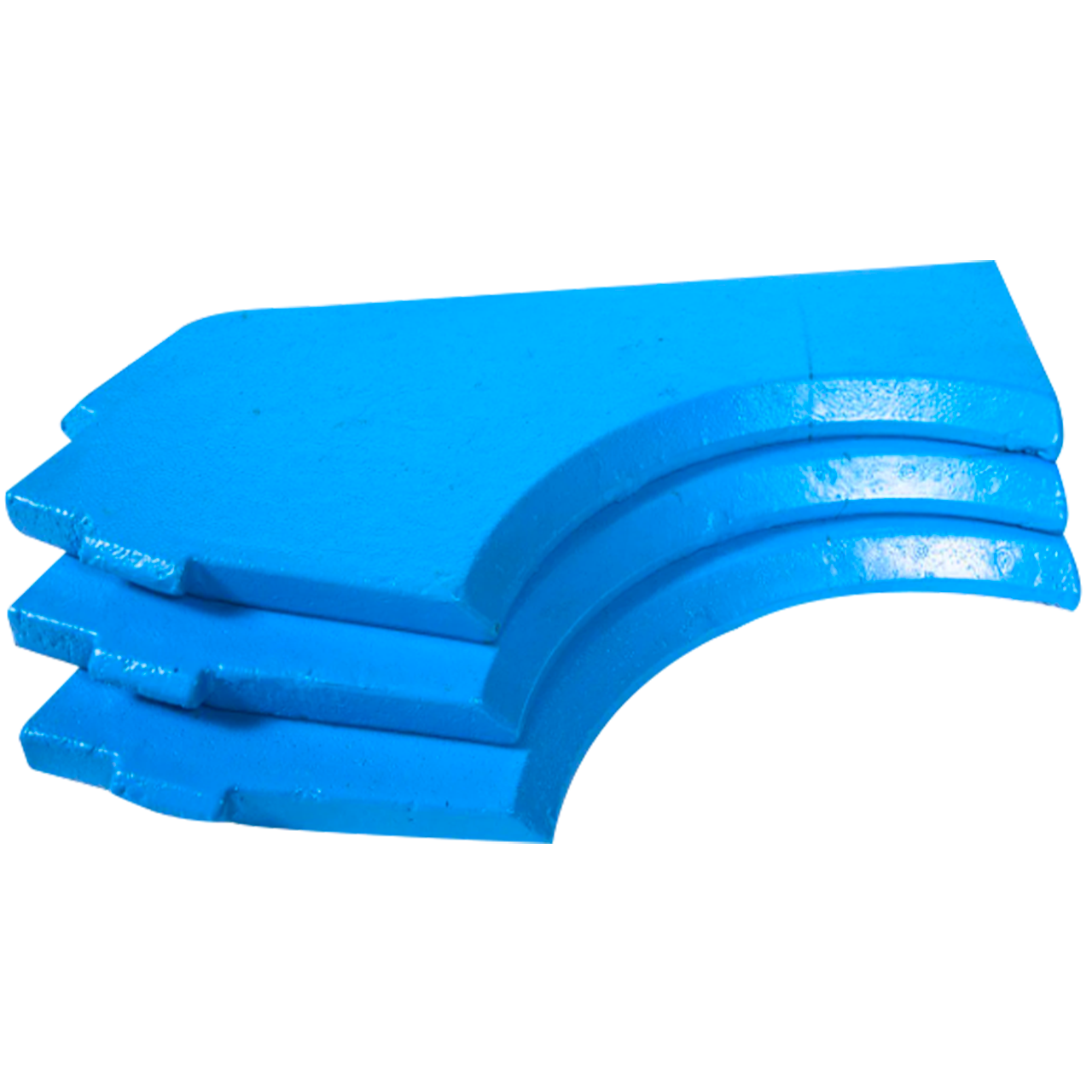

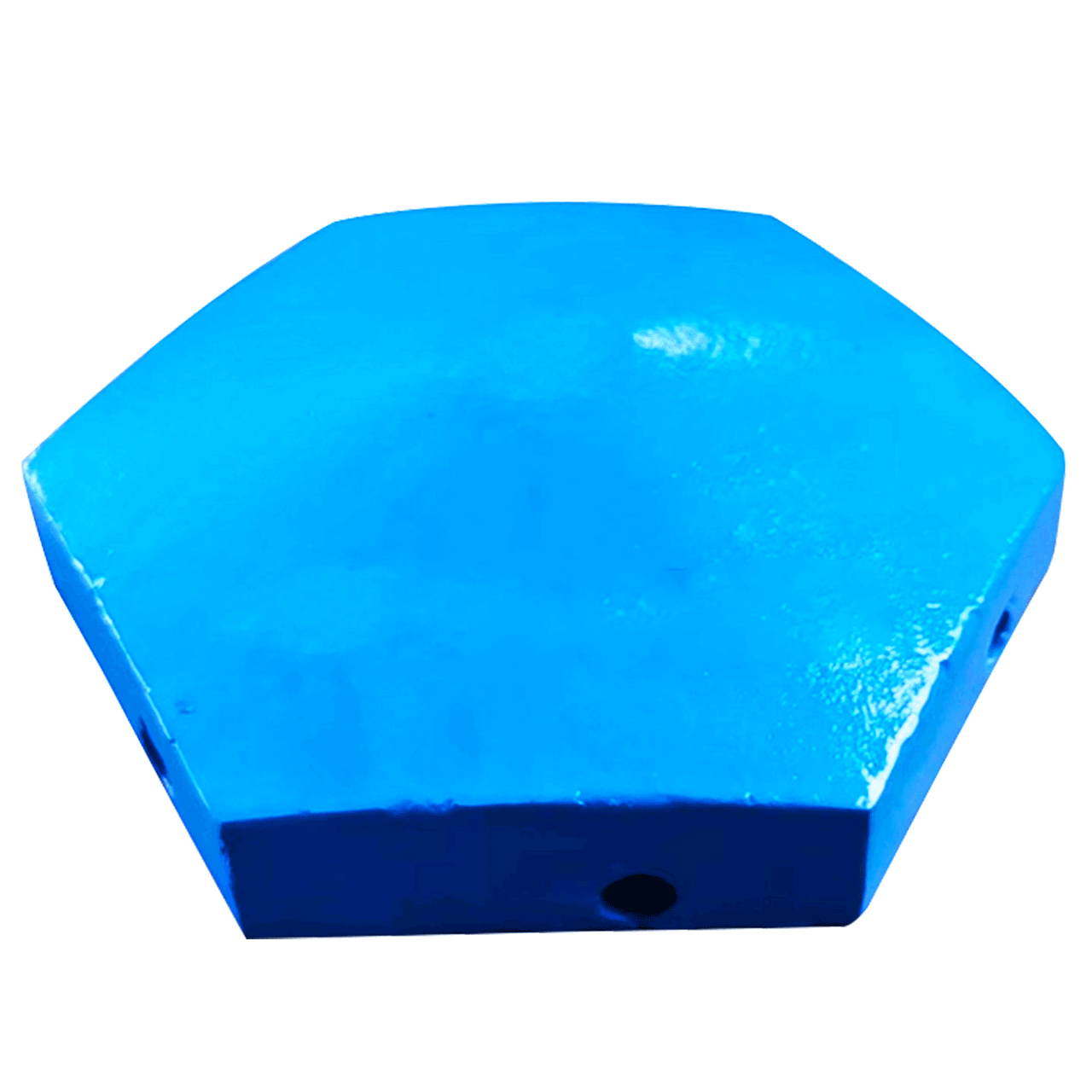

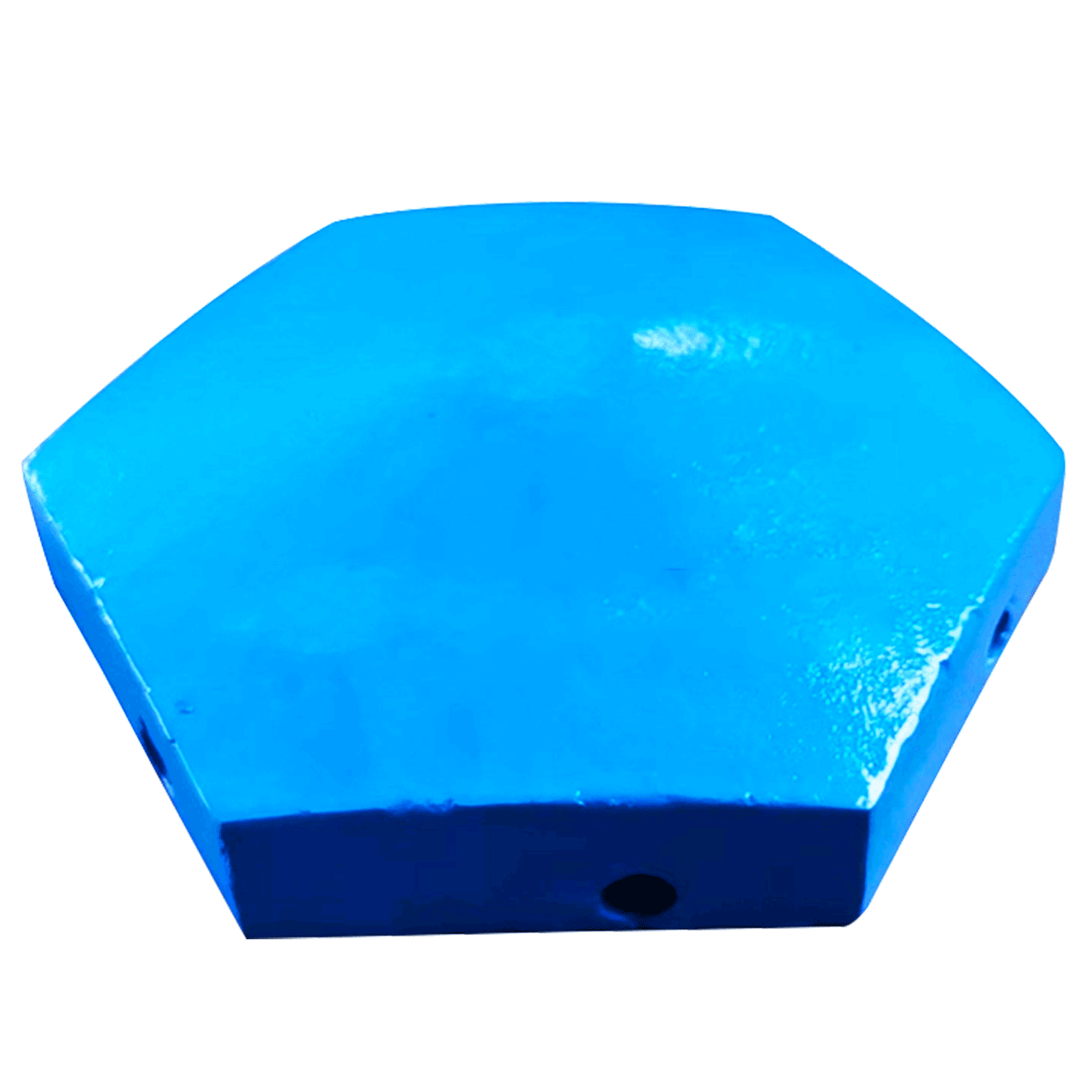

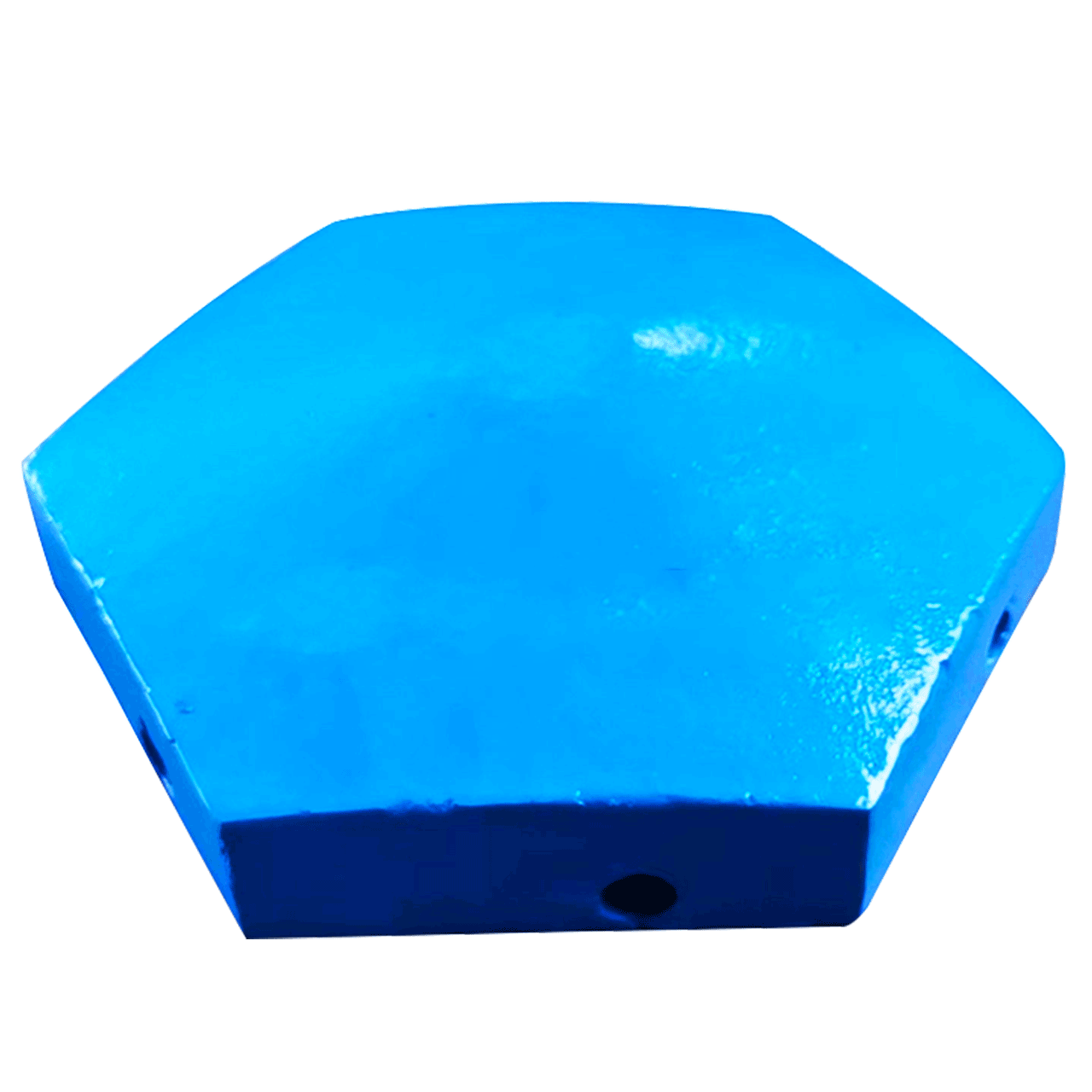

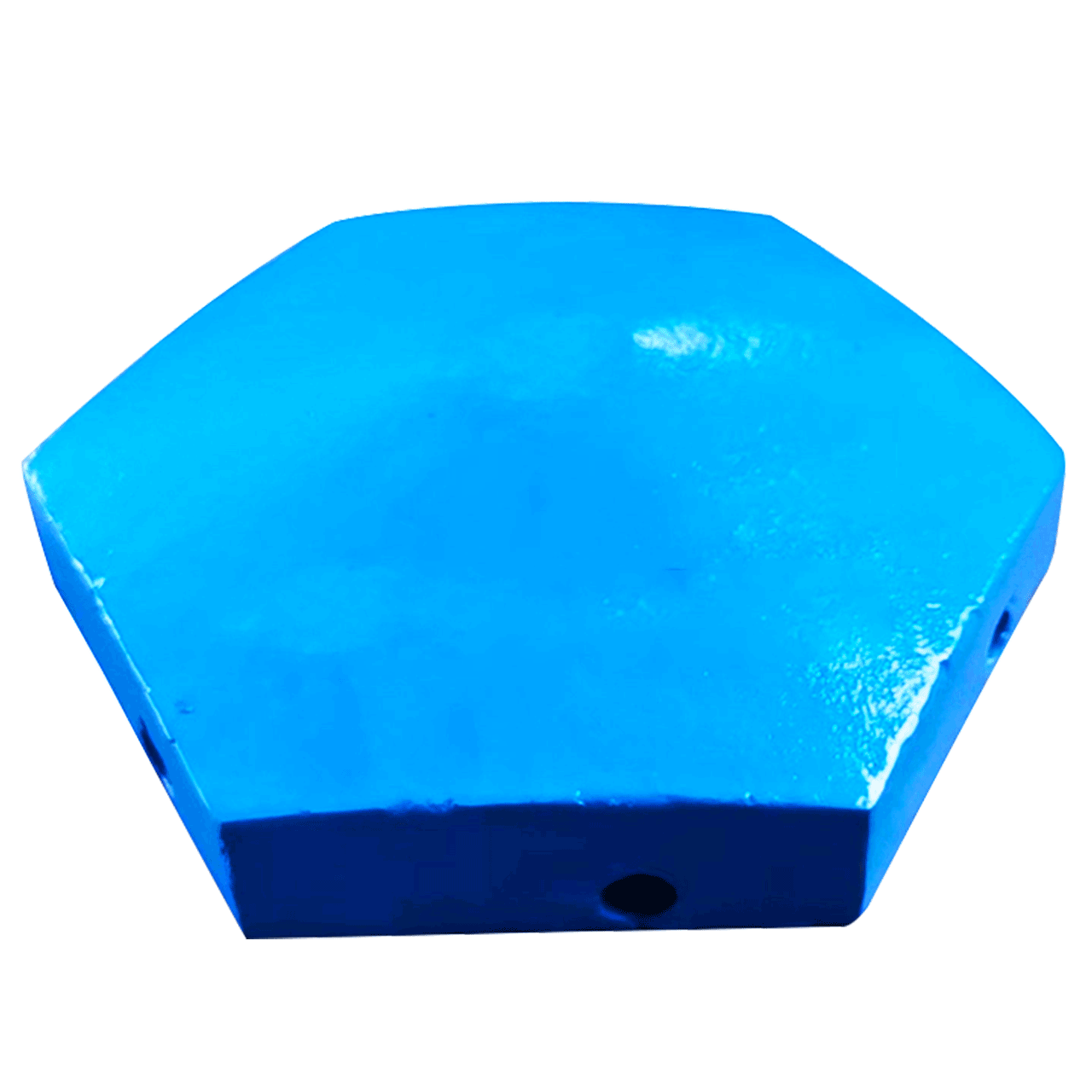

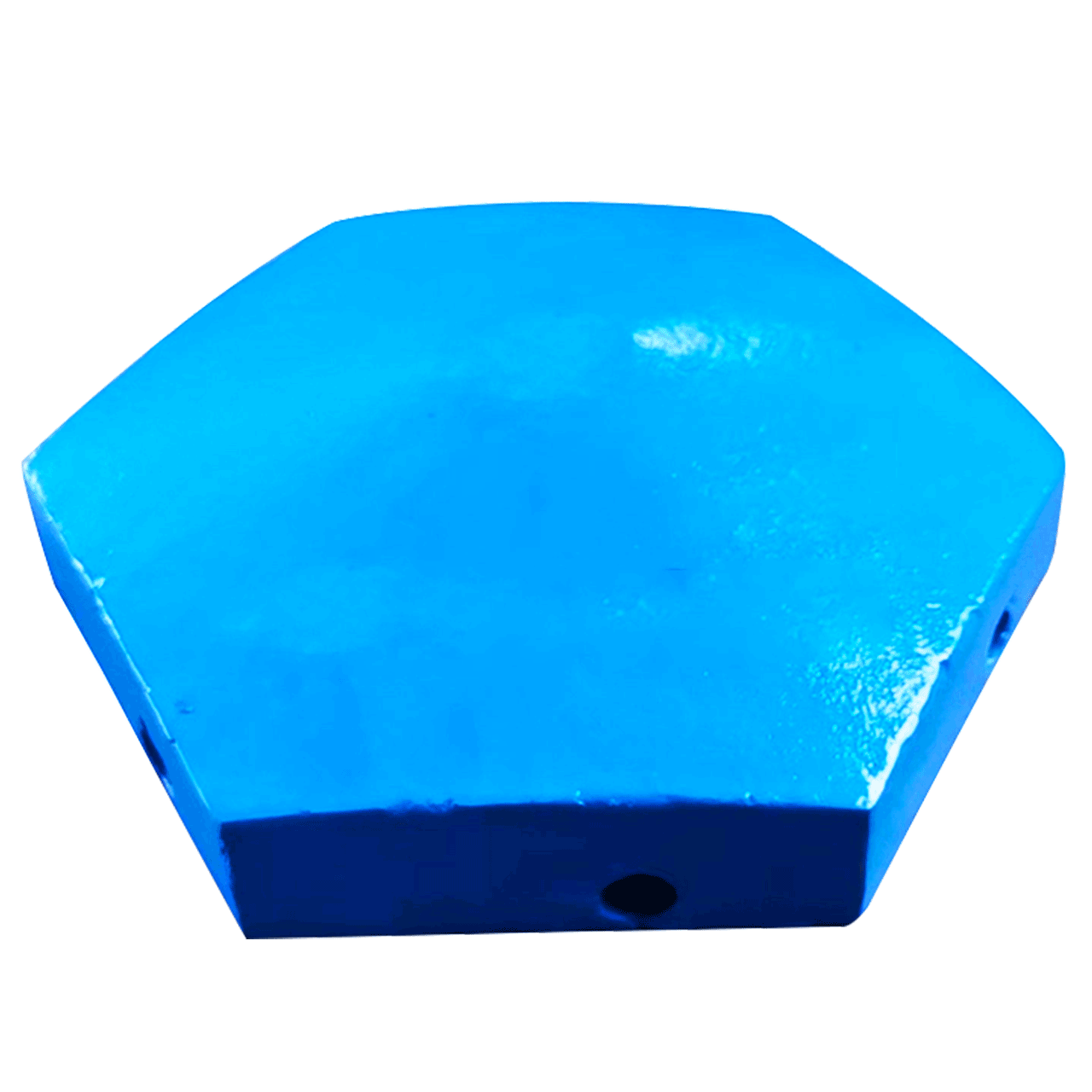

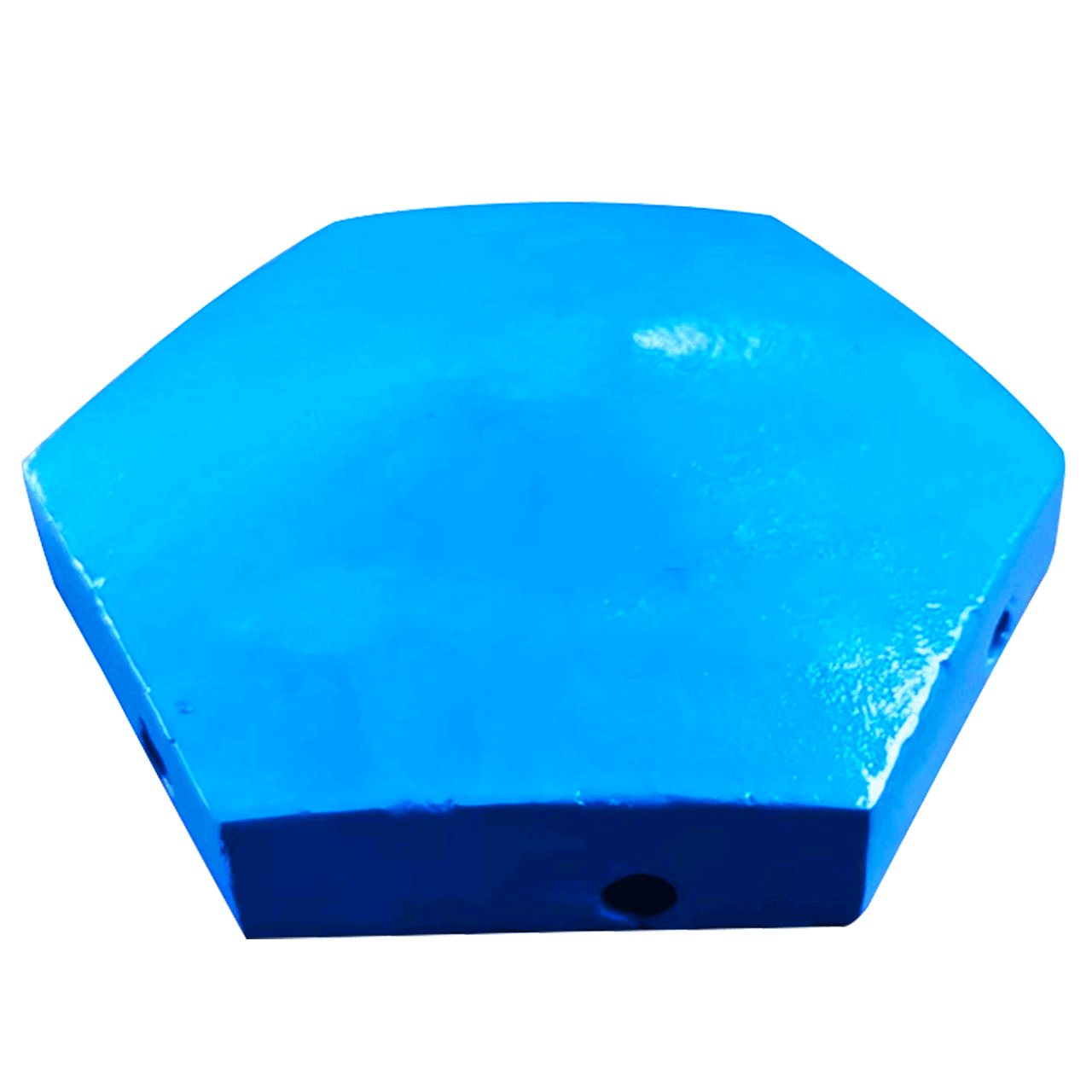

B9100 VSI Crusher Rotor Assembly

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

The rotor of the impact crusher is the "heart" of the crusher, and it is also a strict part of the impact crusher acceptance, which plays a vital role in the work. Therefore, the company has developed and produced a strong structure of the heavy rotor to obtain a higher moment of inertia. High wear-resistant materials and crushing cavity, making the performance of the crusher outstanding. The bearing seat adopts integral cast steel structure and unique plate hammer fixing device, which makes the plate hammer more reliable. The improved adjustment device reduces the time of shutdown and maintenance. The self-contained top opening device can quickly complete the replacement of vulnerable parts such as hammers. Selection of bearing specifications, higher carrying capacity. The rotor is analyzed to ensure stability and reliability.

Working principle

Impact crusher is a kind of crushing machinery that uses impact energy to crush materials. When the material enters the action area of the plate hammer, it is broken by the high-speed impact of the plate hammer, and is thrown to the counterattack device installed above the rotor to be broken again, and then bounces back to the action area of the plate hammer from the counterattack liner to be broken again. This process is repeated until the material is crushed to the required particle size and discharged from the lower part of the machine. Adjusting the gap between the counterattack frame and the rotor frame can achieve the purpose of changing the particle size and shape of the material. The machine adopts spring safety device behind the counterattack plate. When the non-broken materials enter the crushing chamber, the front and rear counterattack frames retreat and the non-broken materials are discharged from the machine.

Counterattack construction waste crusher energy-saving mine crushing equipment crushing industry

Scope of application

Impact crushers are widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries for medium and fine crushing materials. Its discharge size can be adjusted, crushing specifications diversification.

It is a kind of crushing machinery that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at high speed. When the material enters the action area of the plate hammer, it collides with the plate hammer on the rotor and is then thrown to the counterattack device to be broken again, and then bounces back to the action area of the plate hammer from the counterattack liner to be broken again. This process is repeated. The material enters the three counterattack cavities of the 1. 2. from large to small to be broken until the required size, discharge from the discharge port. Adjusting the gap between the counter-attack frame and the rotor can achieve the purpose of changing the material discharge particle size and material shape. The stone directly falls into the high-speed rotating turntable from the upper part of the machine. Under the action of high-speed centrifugal force, high-speed collision and high-density crushing will occur with the flying stones distributed around the turntable in an umbrella-shaped manner. After hitting each other, the stone will form eddy current motion between the turntable and the casing, causing multiple mutual blows, friction and crushing, and will be discharged through the lower part. Form a closed circuit for many times, controlled by the screening equipment to achieve the required particle size.

Large impact crusher strictly control quality

Counterattack crusher is widely used in artificial sand making, crushing and other industries. Its discharge size can be adjusted. Counterattack crusher has a unique structure, equipped with high-chromium plate hammer and counterattack liner, and can be used for crushing hard rock. The shape of the product after crushing is cubic and can be crushed selectively.

Performance characteristics of impact crusher

Crushing ratio, high crushing efficiency, convenient maintenance and other characteristics, the product is a cube, is the ideal processing equipment for road surface and hydropower construction with aggregates. High chromium plate hammer, wear-resistant counterattack liner; Unique tooth-type counterattack liner; Especially suitable for hard rock crushing, high efficiency and energy saving; The shape of the product is cubic, the size of the discharge is adjustable, simplifying the crushing process.

working principle of impact crusher:

Impact crusher is a kind of crushing machinery that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at high speed. When the material enters the hammer action area, it collides with the hammer on the rotor and is crushed again. Then it is thrown to the counterattack device to be crushed again, and then it bounces back to the hammer action area from the counterattack liner to be crushed again. This process is repeated. The material enters the counterattack cavity of the 1. 2. from large to small and is repeatedly crushed until the required size, discharge from the discharge port. Adjusting the gap between the counter-attack frame and the rotor can achieve the purpose of changing the material discharge particle size and material shape.

Impact crusher is a crushing equipment widely used in the market at present. The equipment is mainly used for intermediate crushing operation of crushed materials. It is very targeted for crushing materials. It is widely used in building materials, mining, metallurgy, chemical industry, water conservancy, hydropower, highway, railway and other fields, and is favored by the majority of users.

Working principle of impact crusher

First, the impact crusher motor drives the rotor to rotate through the triangular belt. At this time, the plate hammer on the rotor is in a radioactive state under the action of centrifugal force. When the material enters the rotation range of the plate hammer from the material inlet, it is impacted by the high-speed operation plate hammer and thrown to the impact plate along the tangential direction of the plate hammer rotation. Then, it returns from the counter plate to the rotation space of the plate hammer and enters the impact zone of the second counter plate. The material is subjected to the repeated impact of the plate hammer, the counterattack plate and the impact in the crushing cavity, which continuously produces cracks along the joint surface of the joint itself, and the internal organization is damaged, loosened and fragmented. Particles smaller than the crushing requirements are discharged out of the machine along the gap between the hammer and the counterattack plate, which becomes the crushed product.

The main products of the Moretec are various types of dental plate, frame, jaw type stone breaker, roller machine, hammer head, roller skin, side guard plate, vibrating screen, hammer crusher. (production and processing) Main: high manganese steel roller skin, dental plate, hammer head, high hardness, all kinds of mine crushing equipment. All kinds of ball mill accessories, rotary kiln accessories, counterattack parts, dryer accessories, large ring gear, small gear, plate hammer, jaw plate, roller, tug, roller belt, roller ring, coupling, eight hole pad, liner, crusher and other accessories.

Installation of impact crusher

1. Before installing the impact crusher, carefully check the size of the equipment bolt hole and the foundation bolt, as well as whether the center position of the equipment and the motor and its height difference are consistent with the actual object;

2. During installation, the equipment level of the impact crusher should be strictly found, and the horizontal tolerance of the shaft should not exceed 2 mm/m;

3. According to the crushing size requirements of the impact crusher, the gap between the impact plate and the outer edge of the rotor is correctly adjusted through the nut of the spring device.

Empty load test run inspection of impact crusher

1. Open the inspection hole of the impact crusher and check the fixing and connection of each impact plate;

2. Whether the clearance between the impact plate and the outer edge of the rotor meets the requirements;

3, single test motor rotation direction, whether the thread head is reversed;

4. Check the oil quality and quantity of each lubrication point;

5. Fastening condition of each fixing piece.

After the above inspection, it is sure that there is no problem, the impact crusher can be tested in empty load.

Main use

The impact crusher can handle materials with a side length of 100-500mm or less, has a compressive strength of up to 350 MPa, and has the advantages of large crushing ratio, cube particles after crushing, etc. Widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries for medium and fine materials. Its discharge size can be adjusted, crushing specifications diversification.

Advantages

(1) The clearance between the counterattack plate and the plate hammer can be easily adjusted, the discharge particle size can be effectively controlled, and the particle shape is good;

(2) The ore is broken along the joint surface, so the power consumption is low and the efficiency is high;

(3) No key connection, convenient maintenance, economical and reliable;

(4) full crushing function, high productivity, small parts wear, high comprehensive benefits;

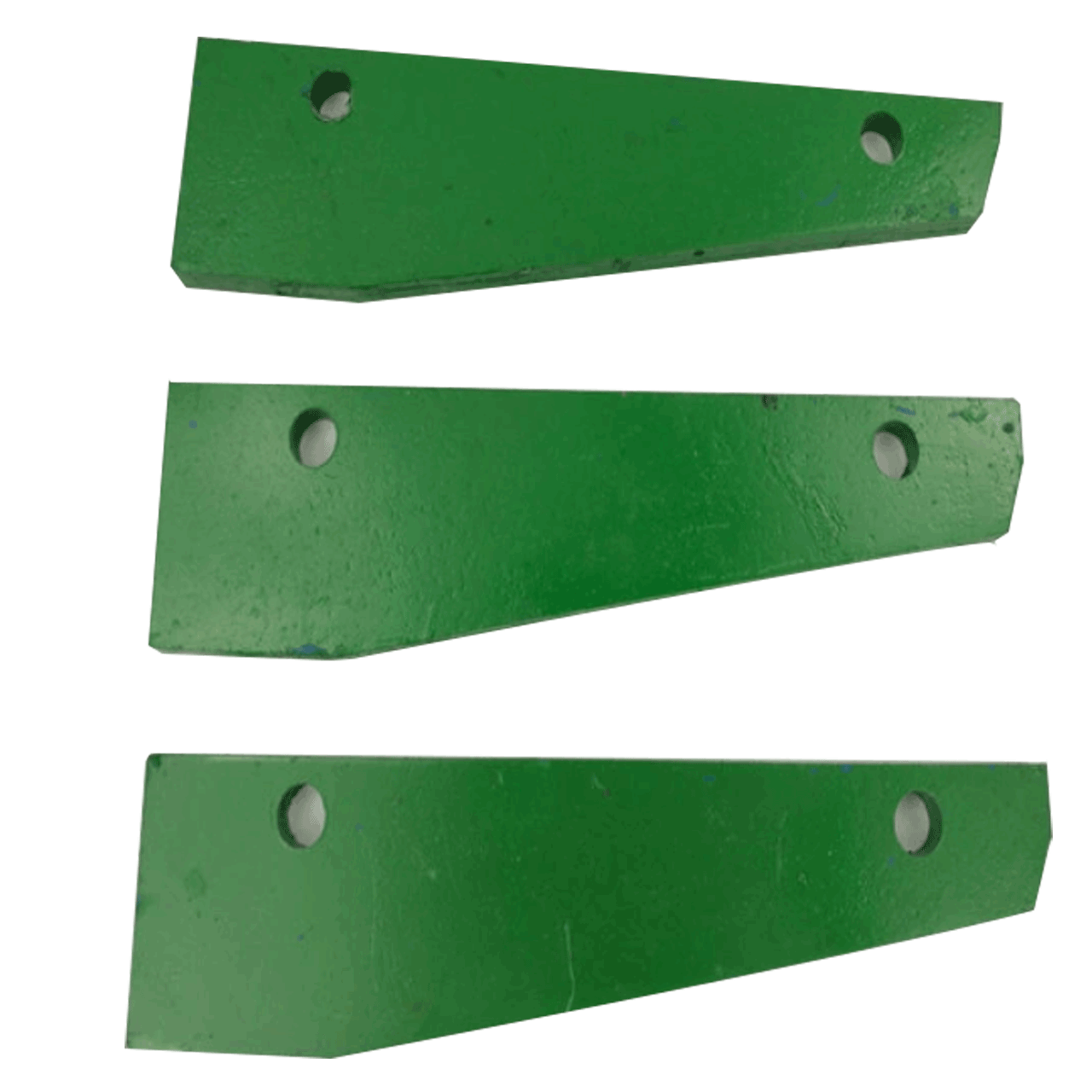

(5) high chromium plate hammer, impact resistance, wear resistance, impact force;

(6) Simple structure, small size, light weight, large production capacity and low production cost. Large feed inlet, high crushing cavity and high hardness of suitable materials;

(7) The crushing ratio is large, up to 40, so the crushing process can be simplified, and the three-stage crushing can be turned into two-stage or one-stage crushing, reducing the equipment cost of the concentrator.

Features

1. The back plate of the rotor can withstand the extremely high moment of inertia of the rotor and the impact crushing force of the hammer;

2. The optimized design is a low-speed, multi-crushing cavity impact crusher, whose linear speed is reduced by 20%-25% compared with the general counterattack, and high production capacity is obtained with low energy consumption;

3. It has the function of three-stage crushing and shaping, so the crushing ratio is large, the product shape is cubic, and the advantages of selective crushing are the advantages;

4, reasonable plate hammer structure, with the advantages of fast loading and unloading, multi transposition, etc., can shorten the time of changing the plate hammer;

5, with new manufacturing technology, successfully developed a high wear resistance, high toughness of chromium, molybdenum, vanadium alloy material, to solve the hard material crushing problem. Greatly improve the service life of the plate hammer;

6. The shape of the product is cube, and the size of the discharge is adjustable;

7. Simplify the crushing process;

8. Full hydraulic opening, easy to repair and replace wearing parts;

Working principle

Impact crusher is a kind of crushing machinery that uses impact energy to crush materials. When the material enters the action area of the plate hammer, it is broken by the high-speed impact of the plate hammer, and is thrown to the counterattack device installed above the rotor to be broken again, and then bounces back to the action area of the plate hammer from the counterattack liner to be broken again. This process is repeated until the material is crushed to the required particle size and discharged from the lower part of the machine. Adjusting the gap between the counterattack frame and the rotor frame can achieve the purpose of changing the particle size and shape of the material. The machine adopts spring safety device behind the counterattack plate. When the non-broken materials enter the crushing chamber, the front and rear counterattack frames retreat and the non-broken materials are discharged from the machine.

Counterattack construction waste crusher energy-saving mine crushing equipment crushing industry

Scope of application

Impact crushers are widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries for medium and fine crushing materials. Its discharge size can be adjusted, crushing specifications diversification.

It is a kind of crushing machinery that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at high speed. When the material enters the action area of the plate hammer, it collides with the plate hammer on the rotor and is then thrown to the counterattack device to be broken again, and then bounces back to the action area of the plate hammer from the counterattack liner to be broken again. This process is repeated. The material enters the three counterattack cavities of the 1. 2. from large to small to be broken until the required size, discharge from the discharge port. Adjusting the gap between the counter-attack frame and the rotor can achieve the purpose of changing the material discharge particle size and material shape. The stone directly falls into the high-speed rotating turntable from the upper part of the machine. Under the action of high-speed centrifugal force, high-speed collision and high-density crushing will occur with the flying stones distributed around the turntable in an umbrella-shaped manner. After hitting each other, the stone will form eddy current motion between the turntable and the casing, causing multiple mutual blows, friction and crushing, and will be discharged through the lower part. Form a closed circuit for many times, controlled by the screening equipment to achieve the required particle size.

Large impact crusher strictly control quality

Counterattack crusher is widely used in artificial sand making, crushing and other industries. Its discharge size can be adjusted. Counterattack crusher has a unique structure, equipped with high-chromium plate hammer and counterattack liner, and can be used for crushing hard rock. The shape of the product after crushing is cubic and can be crushed selectively.

Performance characteristics of impact crusher

Crushing ratio, high crushing efficiency, convenient maintenance and other characteristics, the product is a cube, is the ideal processing equipment for road surface and hydropower construction with aggregates. High chromium plate hammer, wear-resistant counterattack liner; Unique tooth-type counterattack liner; Especially suitable for hard rock crushing, high efficiency and energy saving; The shape of the product is cubic, the size of the discharge is adjustable, simplifying the crushing process.

working principle of impact crusher:

Impact crusher is a kind of crushing machinery that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at high speed. When the material enters the hammer action area, it collides with the hammer on the rotor and is crushed again. Then it is thrown to the counterattack device to be crushed again, and then it bounces back to the hammer action area from the counterattack liner to be crushed again. This process is repeated. The material enters the counterattack cavity of the 1. 2. from large to small and is repeatedly crushed until the required size, discharge from the discharge port. Adjusting the gap between the counter-attack frame and the rotor can achieve the purpose of changing the material discharge particle size and material shape.

Impact crusher is a crushing equipment widely used in the market at present. The equipment is mainly used for intermediate crushing operation of crushed materials. It is very targeted for crushing materials. It is widely used in building materials, mining, metallurgy, chemical industry, water conservancy, hydropower, highway, railway and other fields, and is favored by the majority of users.

Working principle of impact crusher

First, the impact crusher motor drives the rotor to rotate through the triangular belt. At this time, the plate hammer on the rotor is in a radioactive state under the action of centrifugal force. When the material enters the rotation range of the plate hammer from the material inlet, it is impacted by the high-speed operation plate hammer and thrown to the impact plate along the tangential direction of the plate hammer rotation. Then, it returns from the counter plate to the rotation space of the plate hammer and enters the impact zone of the second counter plate. The material is subjected to the repeated impact of the plate hammer, the counterattack plate and the impact in the crushing cavity, which continuously produces cracks along the joint surface of the joint itself, and the internal organization is damaged, loosened and fragmented. Particles smaller than the crushing requirements are discharged out of the machine along the gap between the hammer and the counterattack plate, which becomes the crushed product.

The main products of the Moretec are various types of dental plate, frame, jaw type stone breaker, roller machine, hammer head, roller skin, side guard plate, vibrating screen, hammer crusher. (production and processing) Main: high manganese steel roller skin, dental plate, hammer head, high hardness, all kinds of mine crushing equipment. All kinds of ball mill accessories, rotary kiln accessories, counterattack parts, dryer accessories, large ring gear, small gear, plate hammer, jaw plate, roller, tug, roller belt, roller ring, coupling, eight hole pad, liner, crusher and other accessories.

Installation of impact crusher

1. Before installing the impact crusher, carefully check the size of the equipment bolt hole and the foundation bolt, as well as whether the center position of the equipment and the motor and its height difference are consistent with the actual object;

2. During installation, the equipment level of the impact crusher should be strictly found, and the horizontal tolerance of the shaft should not exceed 2 mm/m;

3. According to the crushing size requirements of the impact crusher, the gap between the impact plate and the outer edge of the rotor is correctly adjusted through the nut of the spring device.

Empty load test run inspection of impact crusher

1. Open the inspection hole of the impact crusher and check the fixing and connection of each impact plate;

2. Whether the clearance between the impact plate and the outer edge of the rotor meets the requirements;

3, single test motor rotation direction, whether the thread head is reversed;

4. Check the oil quality and quantity of each lubrication point;

5. Fastening condition of each fixing piece.

After the above inspection, it is sure that there is no problem, the impact crusher can be tested in empty load.

Main use

The impact crusher can handle materials with a side length of 100-500mm or less, has a compressive strength of up to 350 MPa, and has the advantages of large crushing ratio, cube particles after crushing, etc. Widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries for medium and fine materials. Its discharge size can be adjusted, crushing specifications diversification.

Advantages

(1) The clearance between the counterattack plate and the plate hammer can be easily adjusted, the discharge particle size can be effectively controlled, and the particle shape is good;

(2) The ore is broken along the joint surface, so the power consumption is low and the efficiency is high;

(3) No key connection, convenient maintenance, economical and reliable;

(4) full crushing function, high productivity, small parts wear, high comprehensive benefits;

(5) high chromium plate hammer, impact resistance, wear resistance, impact force;

(6) Simple structure, small size, light weight, large production capacity and low production cost. Large feed inlet, high crushing cavity and high hardness of suitable materials;

(7) The crushing ratio is large, up to 40, so the crushing process can be simplified, and the three-stage crushing can be turned into two-stage or one-stage crushing, reducing the equipment cost of the concentrator.

Features

1. The back plate of the rotor can withstand the extremely high moment of inertia of the rotor and the impact crushing force of the hammer;

2. The optimized design is a low-speed, multi-crushing cavity impact crusher, whose linear speed is reduced by 20%-25% compared with the general counterattack, and high production capacity is obtained with low energy consumption;

3. It has the function of three-stage crushing and shaping, so the crushing ratio is large, the product shape is cubic, and the advantages of selective crushing are the advantages;

4, reasonable plate hammer structure, with the advantages of fast loading and unloading, multi transposition, etc., can shorten the time of changing the plate hammer;

5, with new manufacturing technology, successfully developed a high wear resistance, high toughness of chromium, molybdenum, vanadium alloy material, to solve the hard material crushing problem. Greatly improve the service life of the plate hammer;

6. The shape of the product is cube, and the size of the discharge is adjustable;

7. Simplify the crushing process;

8. Full hydraulic opening, easy to repair and replace wearing parts;

Parts List