VSI Crusher B6150se Rotor Accessories

Manufacturer :

Part number :

OEM Compatibility :

Description

Description

The rotor accessories for a VSI (Vertical Shaft Impact) crusher are essential components that directly influence the crusher's performance and durability. These accessories are designed to enhance the efficiency of the rotor, improve the quality of the output, and extend the overall lifespan of the VSI crusher. Here's an overview of the key rotor accessories and their functions:

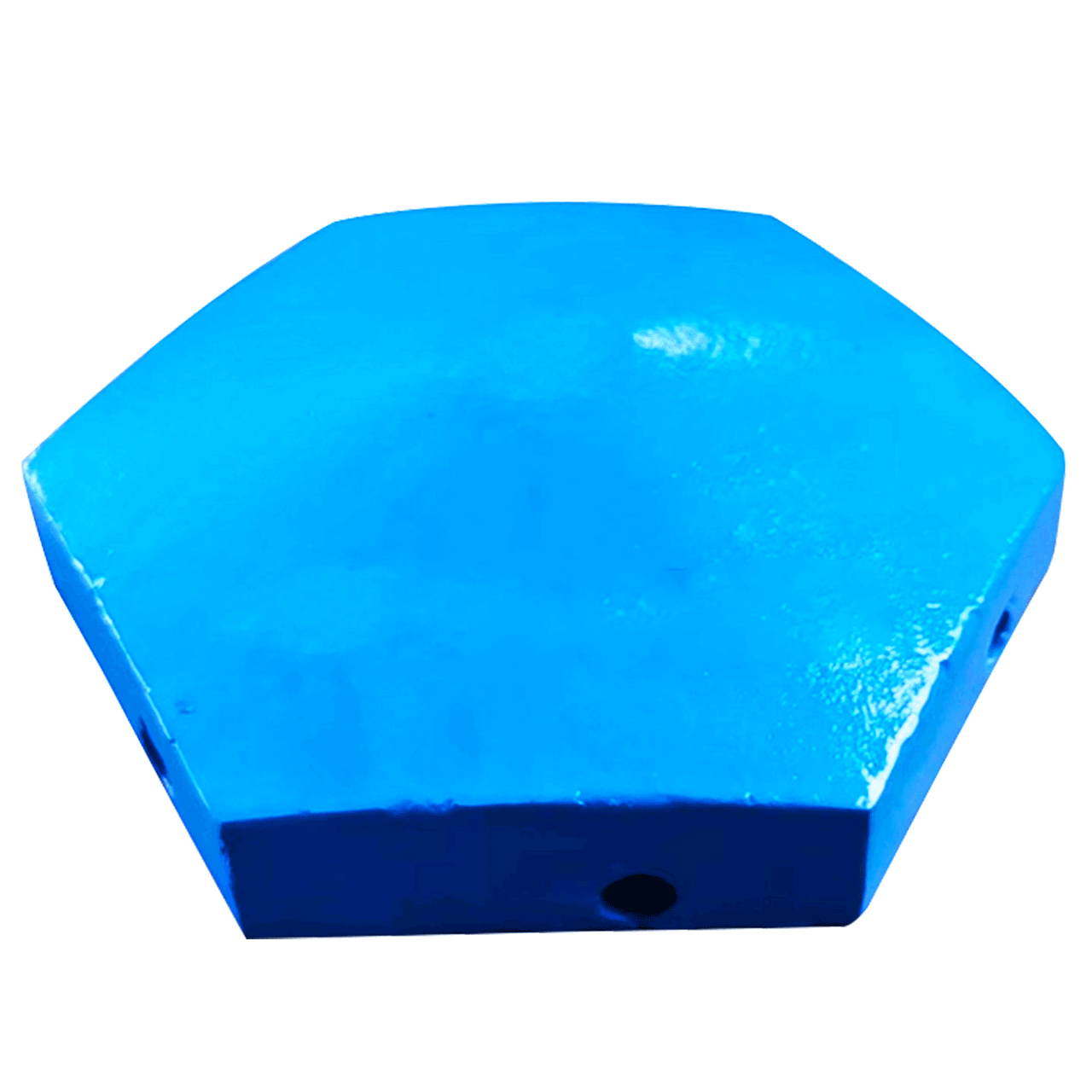

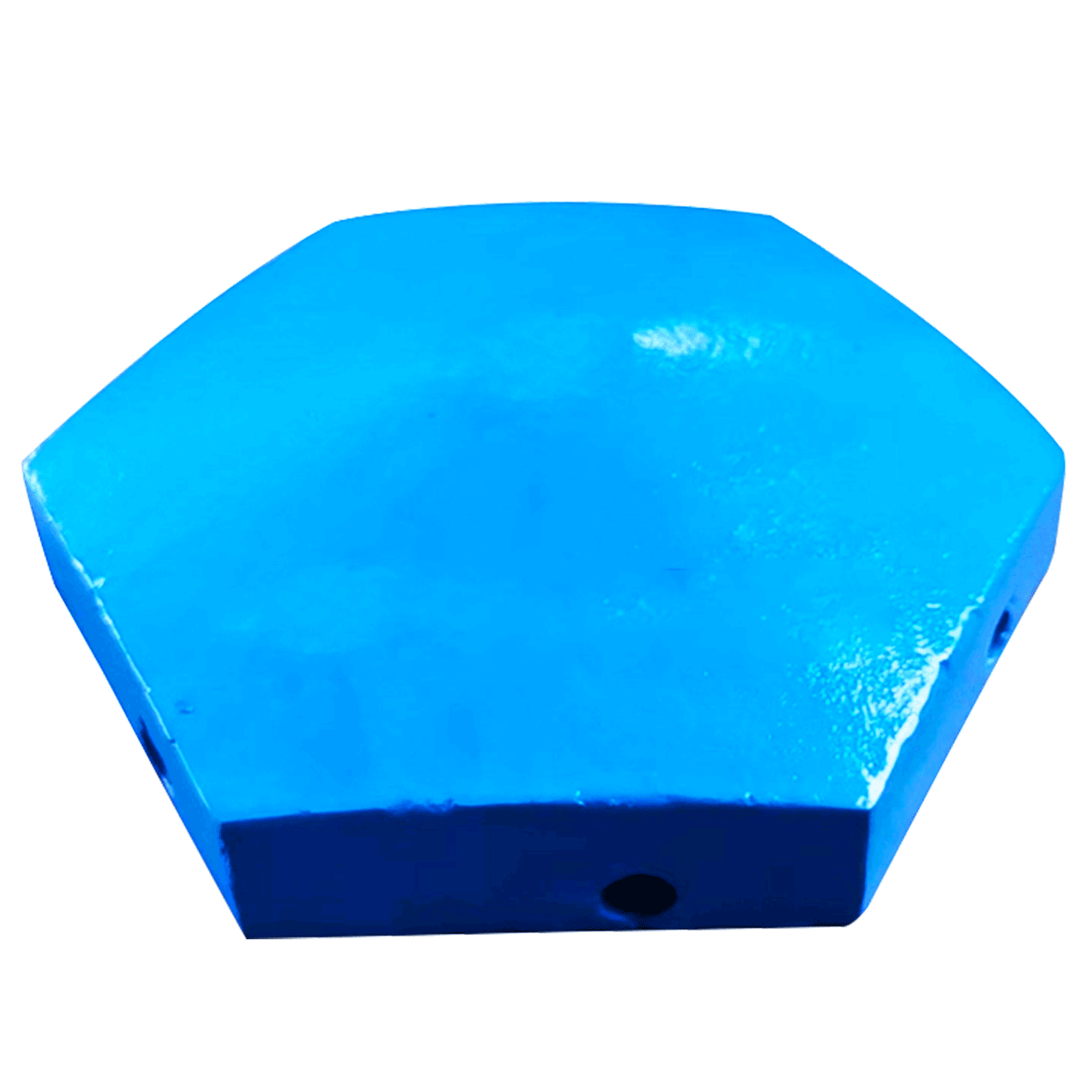

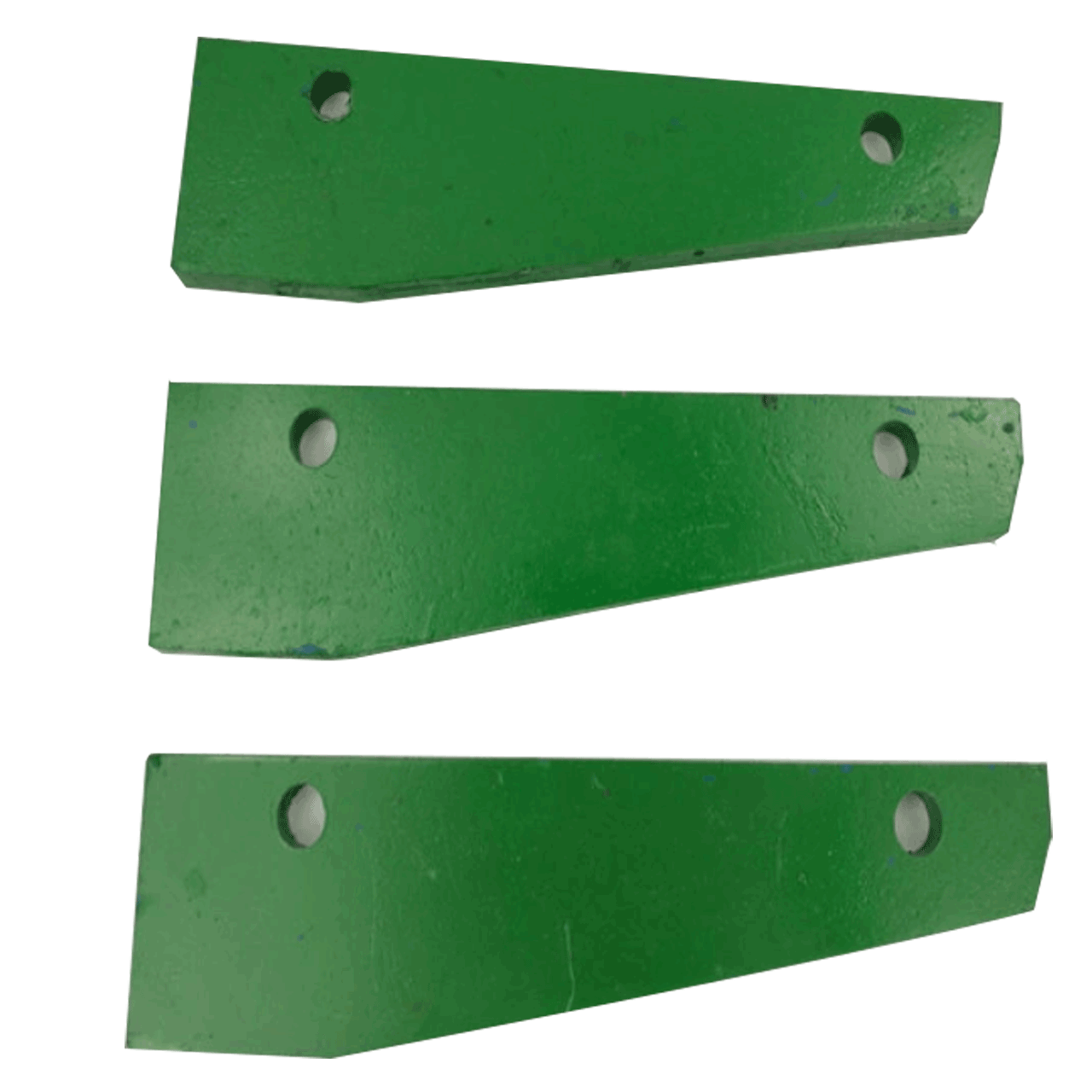

1. Rotor Tips

Description: Rotor tips are the high-wear parts mounted on the edges of the rotor. They are usually made from highly durable materials like tungsten carbide or high-chrome alloys.

Function:

Impact Crushing: Rotor tips are designed to withstand the intense impact forces as the raw material is thrown against them, effectively crushing the material.

Extended Life: They provide enhanced wear resistance, which extends the service life of the rotor.

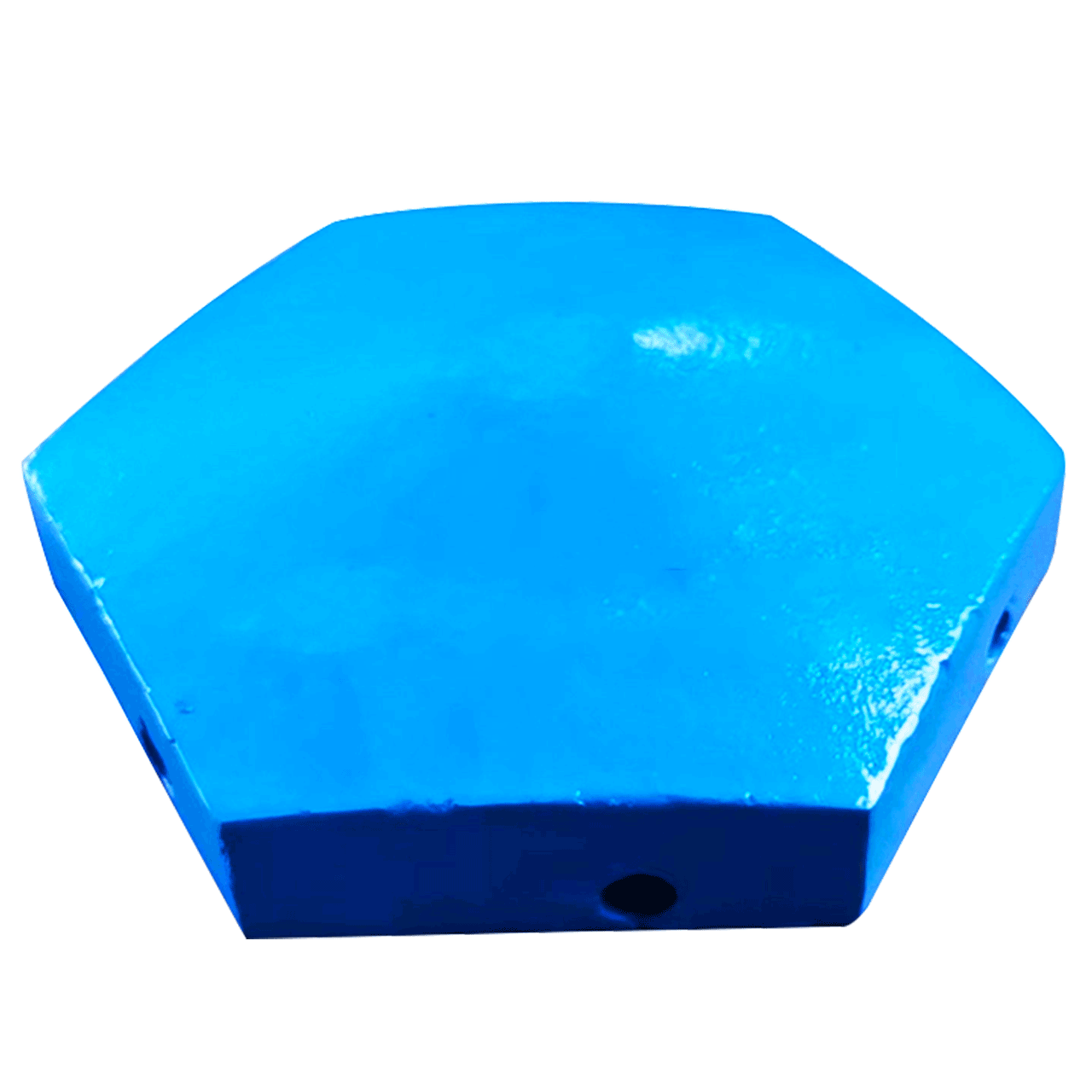

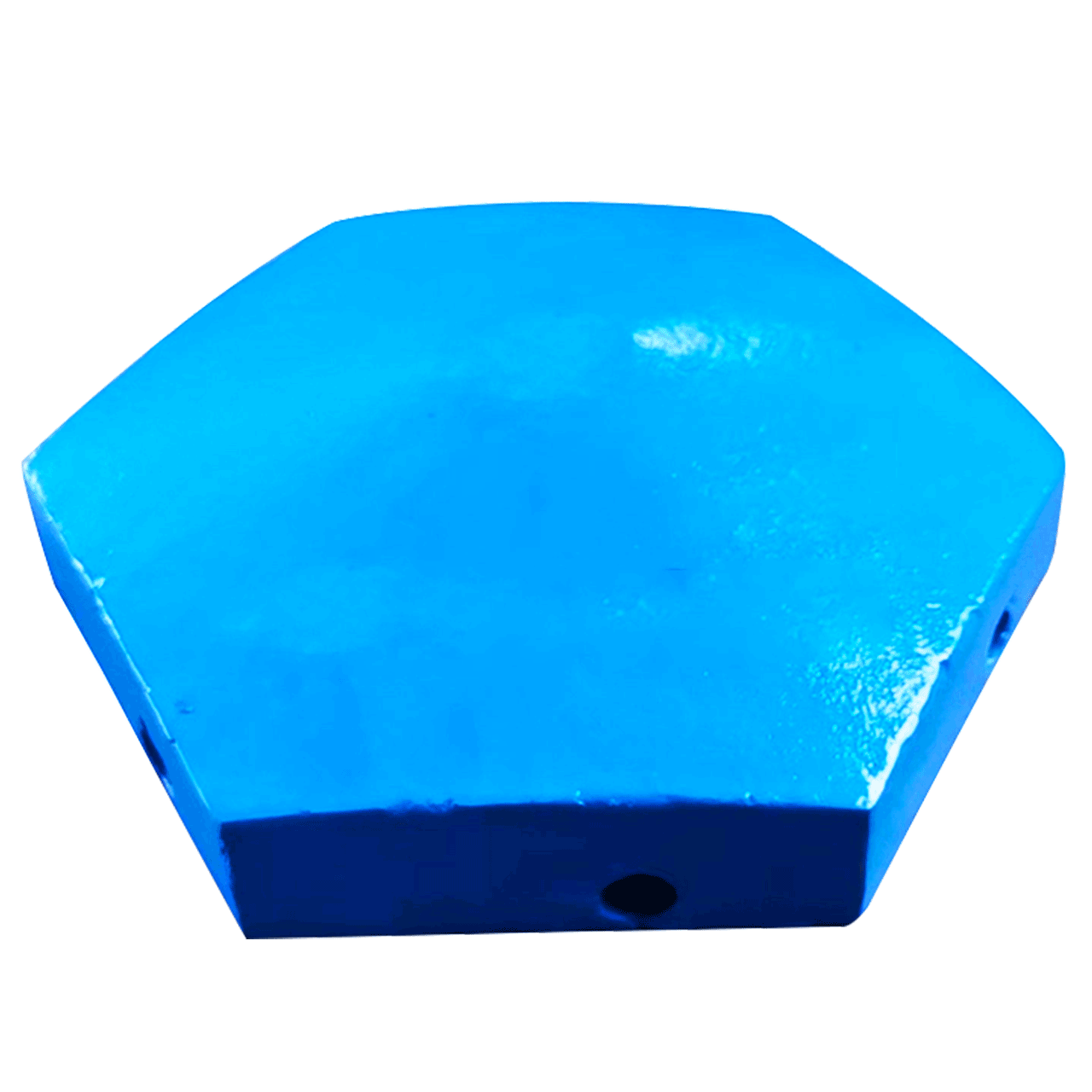

2. Rotor Casing

Description: The rotor casing, or rotor housing, surrounds the rotor and contains the material being processed. It is typically constructed from high-strength steel.

Function:

Containment: It contains the raw material during the crushing process, ensuring that the material is properly guided and directed.

Protection: Protects the rotor and other internal components from excessive wear and impact.

3. Distributor Plates

Description: Distributor plates are located in the rotor assembly and help to distribute the material evenly across the rotor.

Function:

Material Distribution: They ensure that the raw material is evenly spread across the rotor for more consistent and efficient crushing.

Improved Performance: Proper distribution leads to better performance and quality of the final product.

4. Guard Plates

Description: Guard plates are installed on the inside of the rotor to protect the casing from wear.

Function:

Wear Protection: They prevent excessive wear on the rotor casing by taking the brunt of the impact from the crushed material.

Longevity: Extend the life of the rotor casing and reduce maintenance costs.

5. Wear Liners

Description: Wear liners are plates or liners that line the interior of the rotor and other critical areas subject to wear.

Function:

Protective Barrier: They act as a protective barrier to prevent the rotor and other components from direct contact with abrasive materials.

Replacement: Wear liners are designed to be replaced easily once they become worn, minimizing downtime.

6. Anvil Ring

Description: The anvil ring is a stationary part that the material impacts after being thrown by the rotor.

Function:

Material Impact: It provides a surface for the material to strike after being hurled from the rotor, contributing to the crushing process.

Adjustment: Can be adjusted or replaced to control the final product's shape and size.

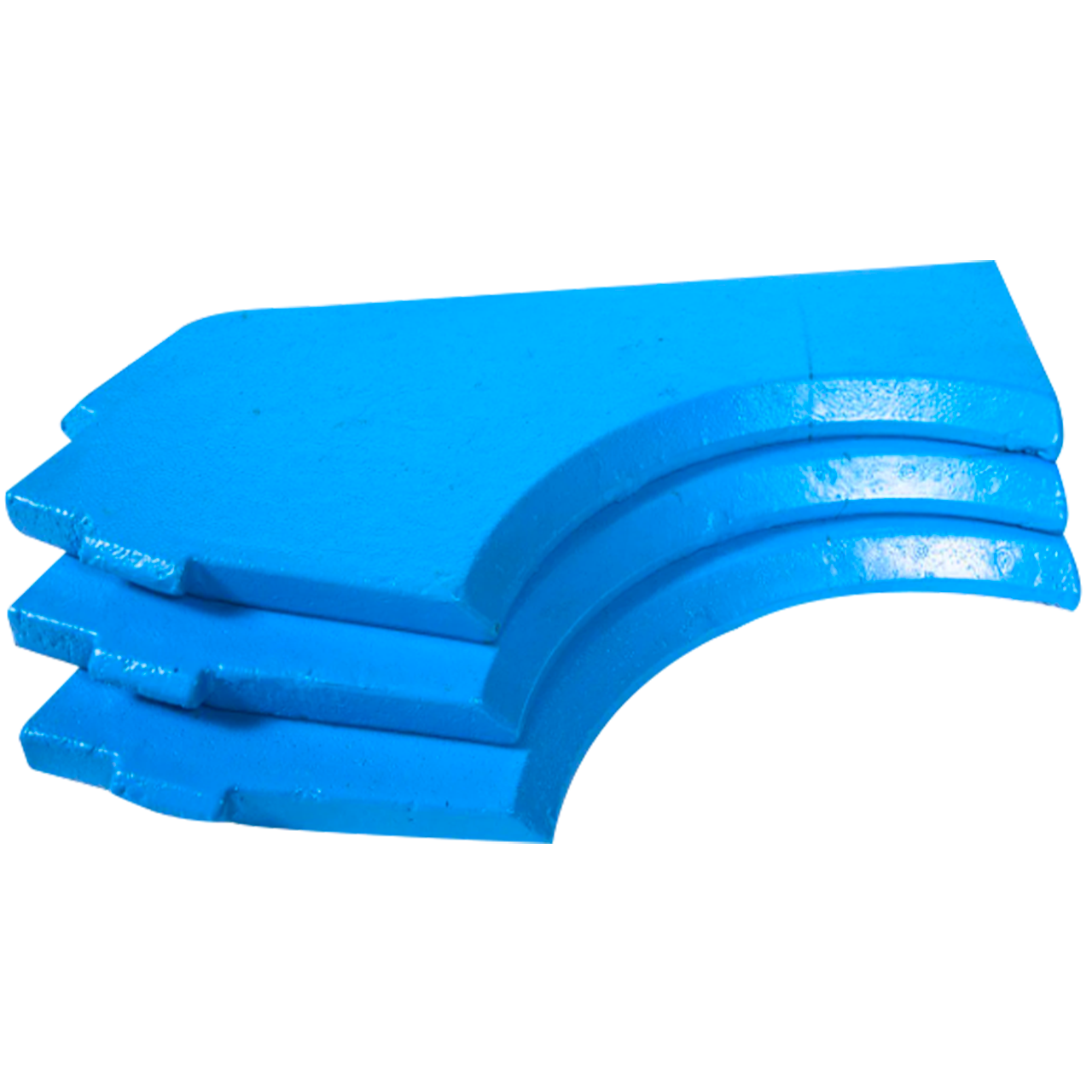

7. Back-up Plates

Description: Back-up plates are additional wear-resistant plates placed behind the rotor tips.

Function:

Support: They provide additional support and protection to the rotor tips and help in maintaining rotor stability.

Extended Life: Enhance the overall lifespan of the rotor tips by reducing direct wear and impact.

8. Centrifugal Feed Pipes

Description: These pipes direct the feed material into the rotor.

Function:

Material Feeding: Ensure that the raw material is fed into the rotor in a controlled manner, optimizing the crushing process.

Maintenance and Replacement

Regular Inspections: Regularly inspect all rotor accessories for signs of wear or damage.

Timely Replacement: Replace worn or damaged parts promptly to avoid excessive wear on other components and maintain optimal performance.

Quality Parts: Use high-quality, compatible parts to ensure the best performance and longevity of the VSI crusher.

In summary, the rotor accessories of a VSI crusher play crucial roles in enhancing the crusher's efficiency, protecting its components, and ensuring a high-quality output. Proper maintenance and timely replacement of these accessories are essential for optimal operation and extended equipment life.

OUR SERVICES AND PRODUCTS

Our company offers a wide range of mining equipment and services, including but not limited:

Mining machinery and equipment: provide equipment for ore mining, ore crushing, transportation, screening and processing, such as excavators, crushers, conveyor belts, etc.

Mine safety equipment: Provide safety equipment and solutions to ensure the safety of mine operators, including mine ventilation systems, safety helmets, protective clothing, etc.

Mining Engineering and Design: Provide a full range of services from mining engineering planning to equipment layout design to ensure the smooth operation of mine projects.

Technical support and maintenance: provide comprehensive support services such as equipment installation and commissioning, maintenance and technical training to ensure long-term stable operation of equipment.

1. Rotor Tips

Description: Rotor tips are the high-wear parts mounted on the edges of the rotor. They are usually made from highly durable materials like tungsten carbide or high-chrome alloys.

Function:

Impact Crushing: Rotor tips are designed to withstand the intense impact forces as the raw material is thrown against them, effectively crushing the material.

Extended Life: They provide enhanced wear resistance, which extends the service life of the rotor.

2. Rotor Casing

Description: The rotor casing, or rotor housing, surrounds the rotor and contains the material being processed. It is typically constructed from high-strength steel.

Function:

Containment: It contains the raw material during the crushing process, ensuring that the material is properly guided and directed.

Protection: Protects the rotor and other internal components from excessive wear and impact.

3. Distributor Plates

Description: Distributor plates are located in the rotor assembly and help to distribute the material evenly across the rotor.

Function:

Material Distribution: They ensure that the raw material is evenly spread across the rotor for more consistent and efficient crushing.

Improved Performance: Proper distribution leads to better performance and quality of the final product.

4. Guard Plates

Description: Guard plates are installed on the inside of the rotor to protect the casing from wear.

Function:

Wear Protection: They prevent excessive wear on the rotor casing by taking the brunt of the impact from the crushed material.

Longevity: Extend the life of the rotor casing and reduce maintenance costs.

5. Wear Liners

Description: Wear liners are plates or liners that line the interior of the rotor and other critical areas subject to wear.

Function:

Protective Barrier: They act as a protective barrier to prevent the rotor and other components from direct contact with abrasive materials.

Replacement: Wear liners are designed to be replaced easily once they become worn, minimizing downtime.

6. Anvil Ring

Description: The anvil ring is a stationary part that the material impacts after being thrown by the rotor.

Function:

Material Impact: It provides a surface for the material to strike after being hurled from the rotor, contributing to the crushing process.

Adjustment: Can be adjusted or replaced to control the final product's shape and size.

7. Back-up Plates

Description: Back-up plates are additional wear-resistant plates placed behind the rotor tips.

Function:

Support: They provide additional support and protection to the rotor tips and help in maintaining rotor stability.

Extended Life: Enhance the overall lifespan of the rotor tips by reducing direct wear and impact.

8. Centrifugal Feed Pipes

Description: These pipes direct the feed material into the rotor.

Function:

Material Feeding: Ensure that the raw material is fed into the rotor in a controlled manner, optimizing the crushing process.

Maintenance and Replacement

Regular Inspections: Regularly inspect all rotor accessories for signs of wear or damage.

Timely Replacement: Replace worn or damaged parts promptly to avoid excessive wear on other components and maintain optimal performance.

Quality Parts: Use high-quality, compatible parts to ensure the best performance and longevity of the VSI crusher.

In summary, the rotor accessories of a VSI crusher play crucial roles in enhancing the crusher's efficiency, protecting its components, and ensuring a high-quality output. Proper maintenance and timely replacement of these accessories are essential for optimal operation and extended equipment life.

OUR SERVICES AND PRODUCTS

Our company offers a wide range of mining equipment and services, including but not limited:

Mining machinery and equipment: provide equipment for ore mining, ore crushing, transportation, screening and processing, such as excavators, crushers, conveyor belts, etc.

Mine safety equipment: Provide safety equipment and solutions to ensure the safety of mine operators, including mine ventilation systems, safety helmets, protective clothing, etc.

Mining Engineering and Design: Provide a full range of services from mining engineering planning to equipment layout design to ensure the smooth operation of mine projects.

Technical support and maintenance: provide comprehensive support services such as equipment installation and commissioning, maintenance and technical training to ensure long-term stable operation of equipment.

Parts List