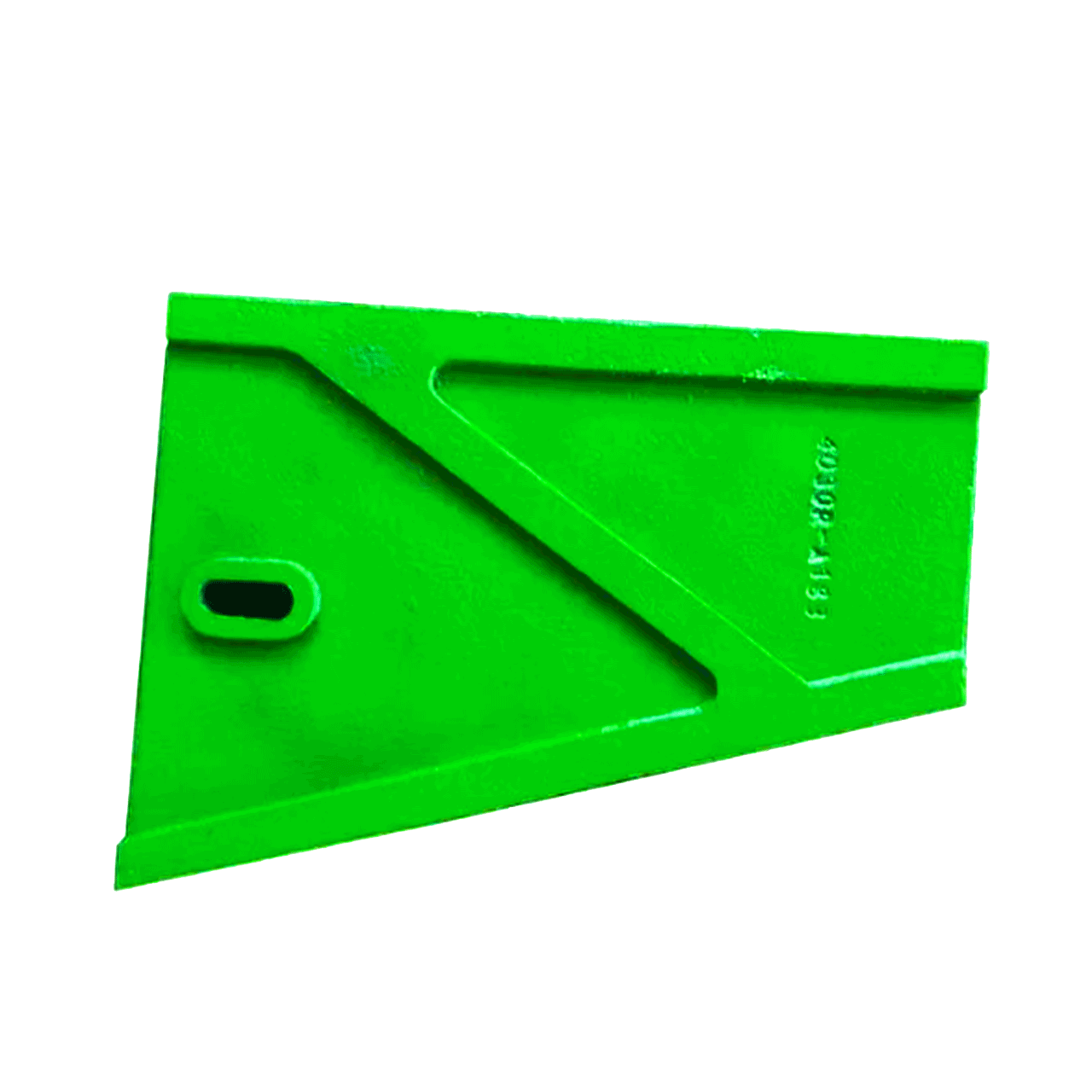

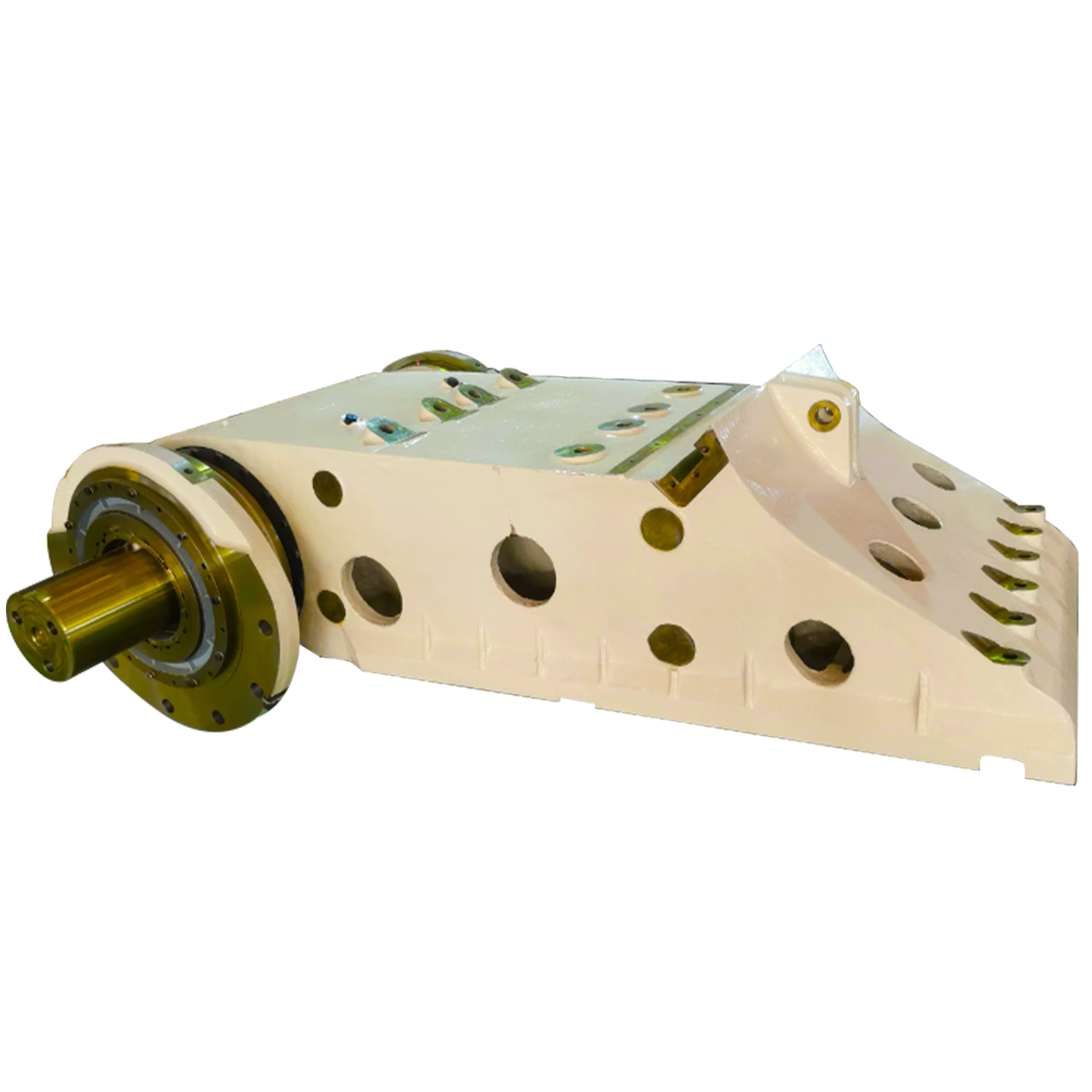

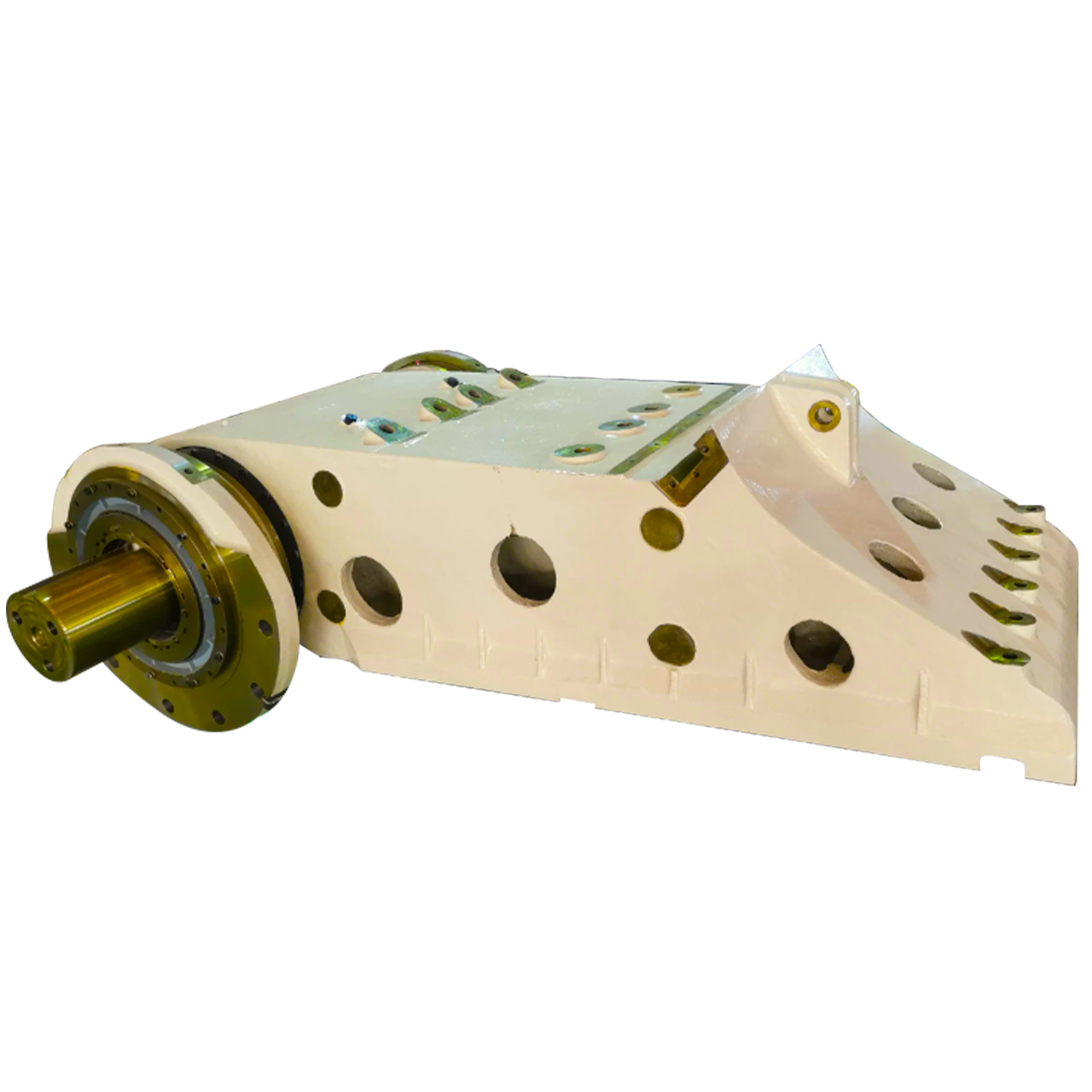

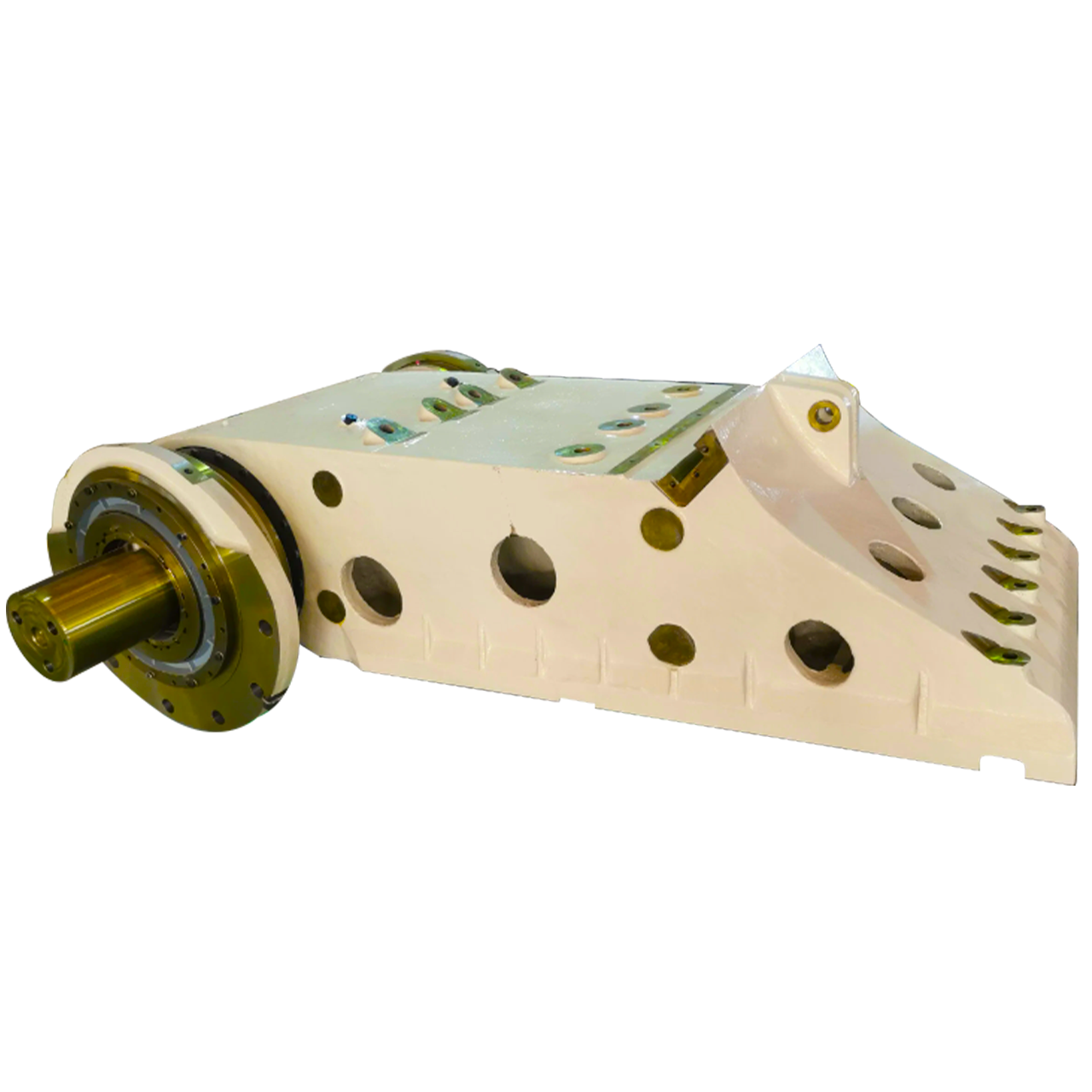

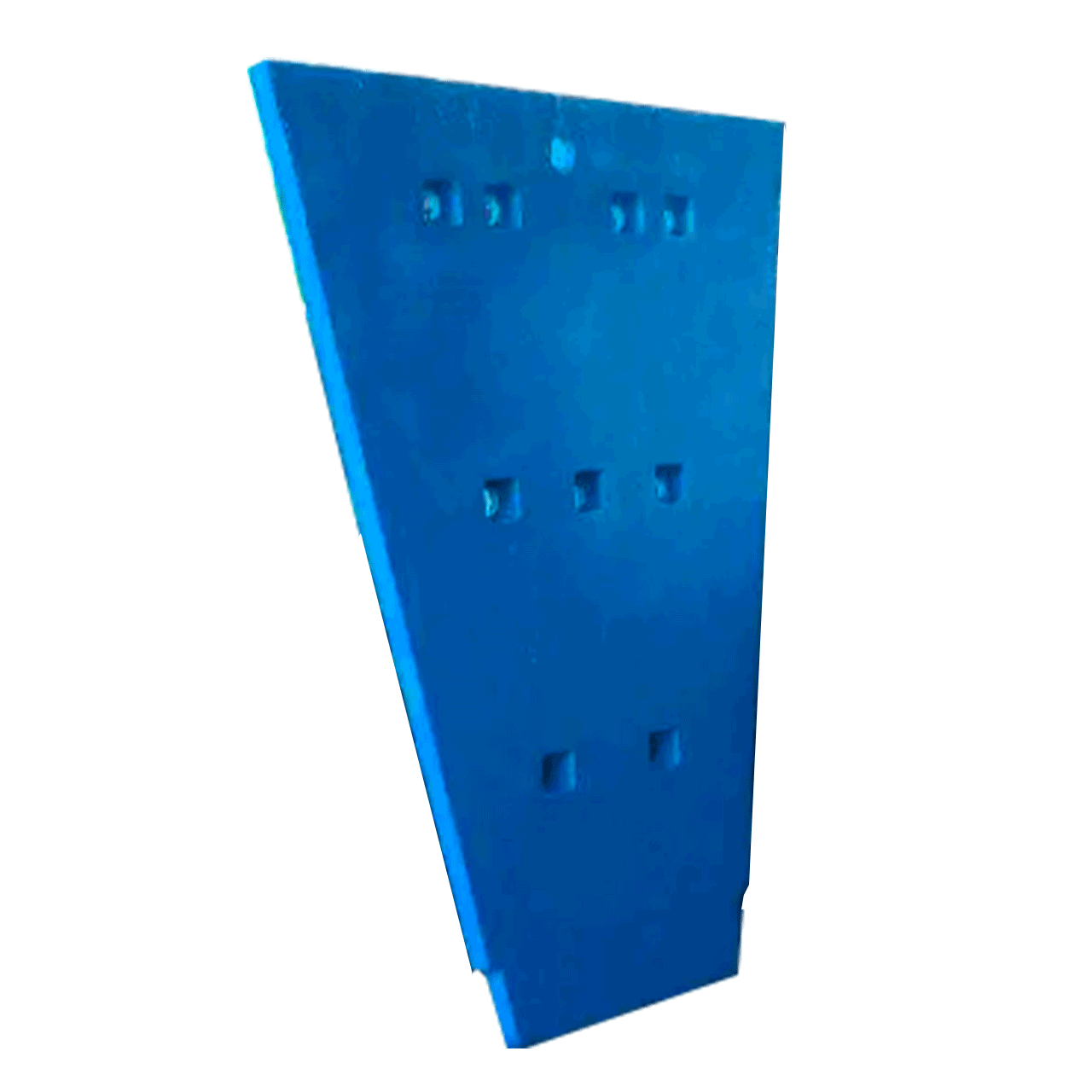

C116 Mining Jaw Crusher Replacements Pitman Suit Assembly Spare Wear Parts

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

The following are detailed information about the “Pitman” in a jaw crusher:

1. Structure and Function

Structure: The Pitman is usually a heavy component made of cast steel or cast iron that connects the Moving Jaw to the Crankshaft. It is designed to allow the reciprocating motion of the Moving Jaw in a Jaw Crusher.

Function: The Rocker Arm converts the rotational motion of the Crankshaft into reciprocating motion of the Moving Jaw. It helps to crush the material by supporting the movement of the moving jaw.

2. Materials and Manufacturing

Materials: Commonly used materials include high-strength cast steel, alloy steel or cast iron, which are able to withstand the huge force generated during the crushing process.

Manufacturing process: Rocker arms are usually produced by casting or forging process to ensure their strength and durability. In some demanding applications, they may also be heat-treated to increase hardness and wear resistance.

3. Maintenance and Replacement

Inspection: Periodically inspect rocker arms for cracks, wear or deformation. Focus on inspection of joints and areas of heavy wear.

Replacement: If the rocker arm shows severe wear or cracks, it should be replaced promptly. The replacement process usually involves removing the movable jaws and associated components and then installing the new rocker arm in place.

4. Performance Impact

Durability: The durability of the rocker arms directly affects the overall performance of the crusher. Worn or damaged rocker arms can cause uneven movement of the moving jaws, which can affect crushing efficiency.

Maintenance intervals: Depending on the use of the crusher and the type of material being processed, the maintenance intervals for the rocker arms may vary. Crushers that operate at high intensity or process hard materials require more frequent inspection and maintenance.

5. Application examples

Mining industry: For crushing ores, the rocker arms are subjected to high impact forces and wear.

Construction: For processing concrete blocks or construction waste, the rocker arms need to be resistant to high pressure and wear.

Moretec has the crusher wear parts for you:

Customized configurations to ensure consistent production

Durable manganese steel increases crusher uptime

Reduced equipment wear

An extensive range of patterns in stock (covering all major makes and models), as well as all patterns produced from original drawings only, ensures fast delivery and a perfect fit to the crusher.

Based on our more than 15 years of experience in this field, we can adapt to special requirements.

Perfect management covering your entire purchasing process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirmation of all necessary information, confirmation of order), delivery (clear photos and test reports ready for customer confirmation), after-sales (after-sales inspection after the shipment arrives at the work site, size matching, service life check, etc.). (Ensuring no questions asked in every purchase)

Abundant production capacity: approximately 10,000 tons per year to ensure supply capacity to customers.

1. Structure and Function

Structure: The Pitman is usually a heavy component made of cast steel or cast iron that connects the Moving Jaw to the Crankshaft. It is designed to allow the reciprocating motion of the Moving Jaw in a Jaw Crusher.

Function: The Rocker Arm converts the rotational motion of the Crankshaft into reciprocating motion of the Moving Jaw. It helps to crush the material by supporting the movement of the moving jaw.

2. Materials and Manufacturing

Materials: Commonly used materials include high-strength cast steel, alloy steel or cast iron, which are able to withstand the huge force generated during the crushing process.

Manufacturing process: Rocker arms are usually produced by casting or forging process to ensure their strength and durability. In some demanding applications, they may also be heat-treated to increase hardness and wear resistance.

3. Maintenance and Replacement

Inspection: Periodically inspect rocker arms for cracks, wear or deformation. Focus on inspection of joints and areas of heavy wear.

Replacement: If the rocker arm shows severe wear or cracks, it should be replaced promptly. The replacement process usually involves removing the movable jaws and associated components and then installing the new rocker arm in place.

4. Performance Impact

Durability: The durability of the rocker arms directly affects the overall performance of the crusher. Worn or damaged rocker arms can cause uneven movement of the moving jaws, which can affect crushing efficiency.

Maintenance intervals: Depending on the use of the crusher and the type of material being processed, the maintenance intervals for the rocker arms may vary. Crushers that operate at high intensity or process hard materials require more frequent inspection and maintenance.

5. Application examples

Mining industry: For crushing ores, the rocker arms are subjected to high impact forces and wear.

Construction: For processing concrete blocks or construction waste, the rocker arms need to be resistant to high pressure and wear.

Moretec has the crusher wear parts for you:

Customized configurations to ensure consistent production

Durable manganese steel increases crusher uptime

Reduced equipment wear

An extensive range of patterns in stock (covering all major makes and models), as well as all patterns produced from original drawings only, ensures fast delivery and a perfect fit to the crusher.

Based on our more than 15 years of experience in this field, we can adapt to special requirements.

Perfect management covering your entire purchasing process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirmation of all necessary information, confirmation of order), delivery (clear photos and test reports ready for customer confirmation), after-sales (after-sales inspection after the shipment arrives at the work site, size matching, service life check, etc.). (Ensuring no questions asked in every purchase)

Abundant production capacity: approximately 10,000 tons per year to ensure supply capacity to customers.

Parts List