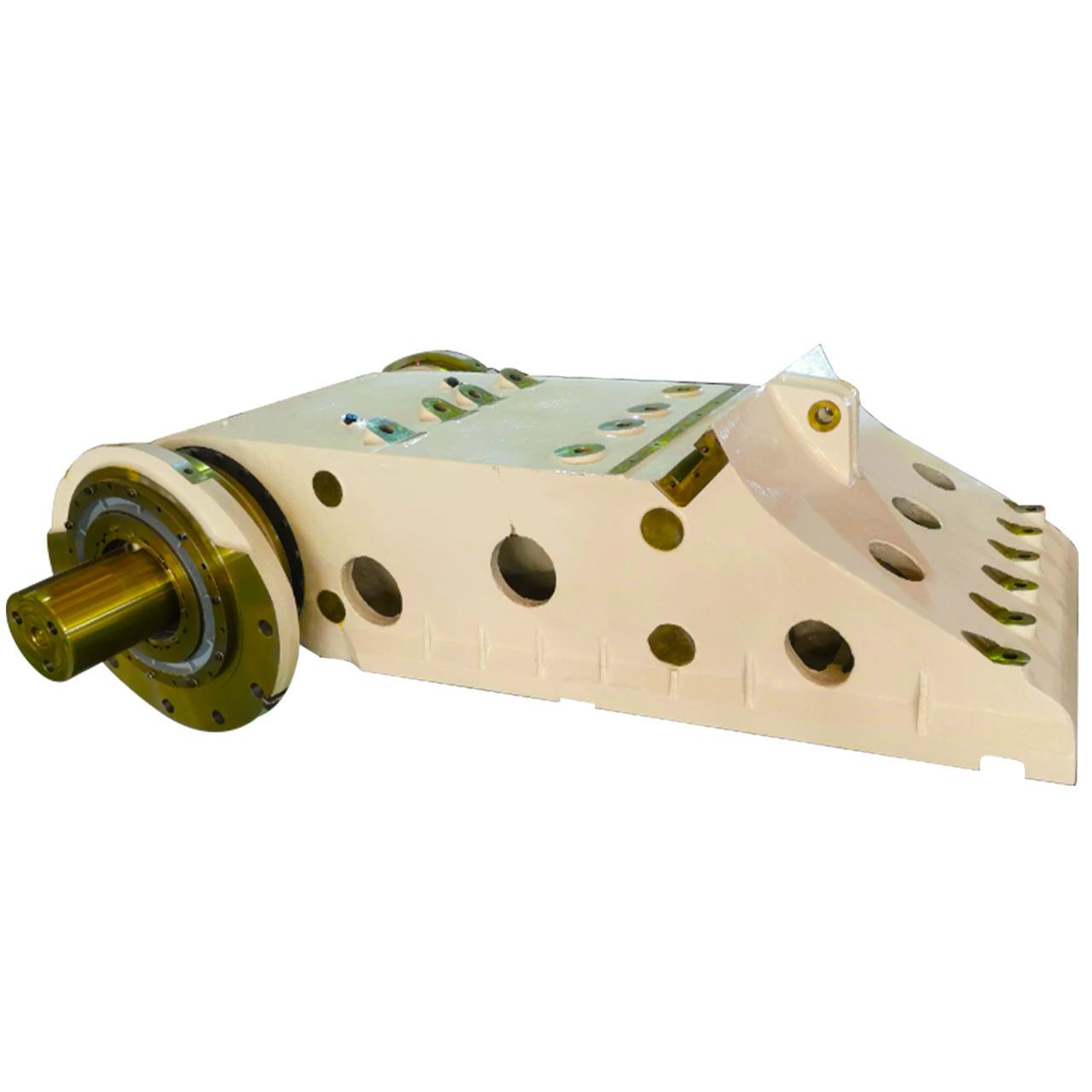

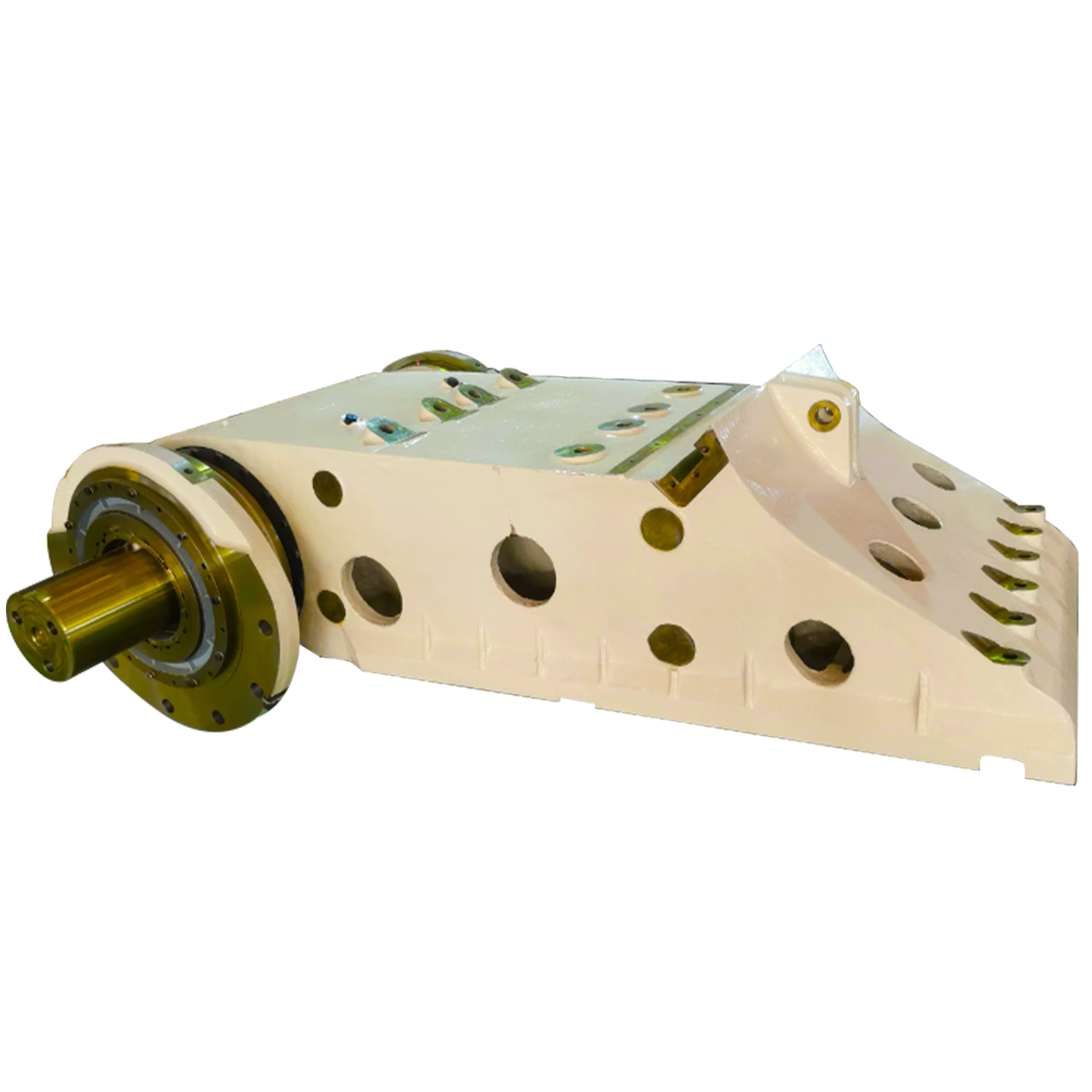

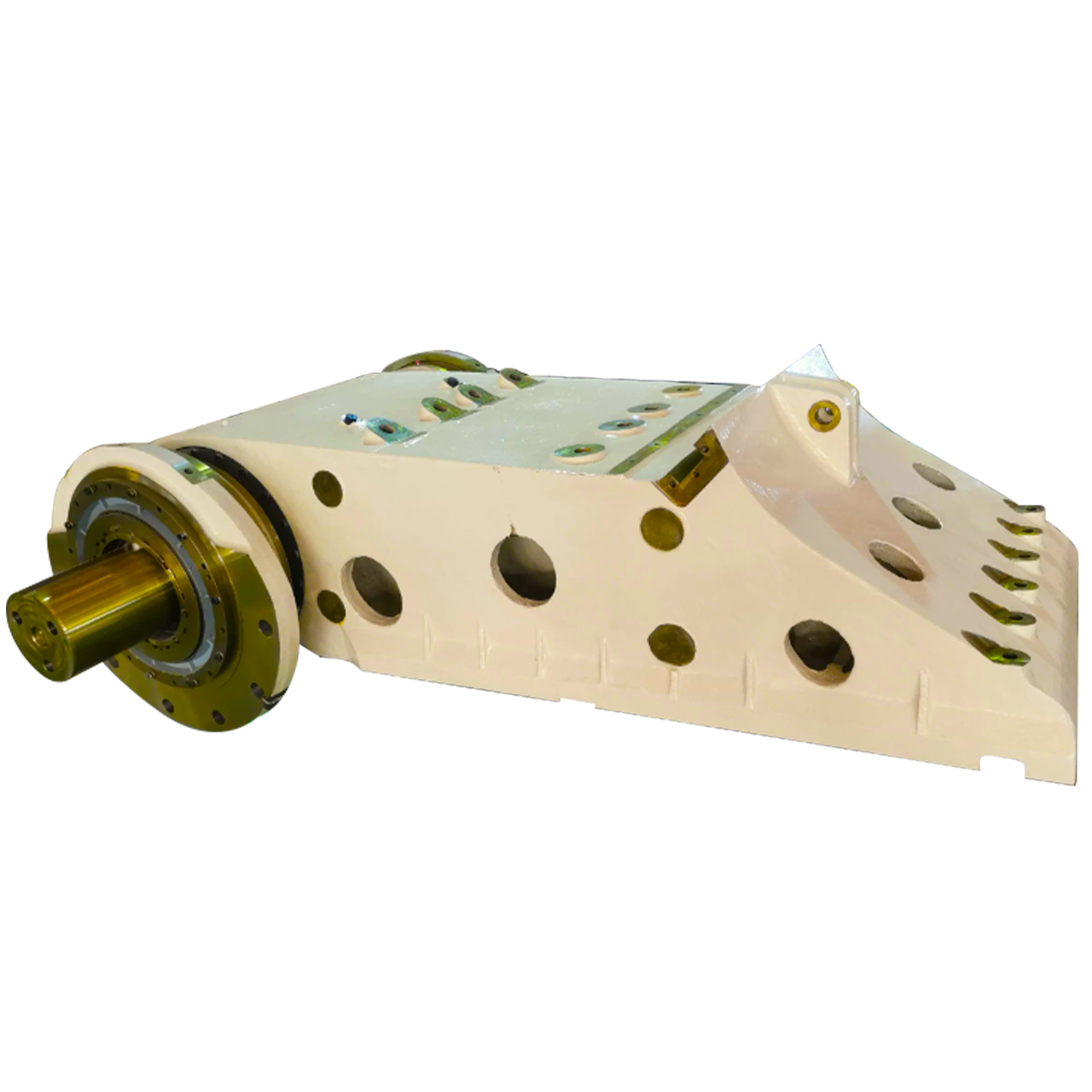

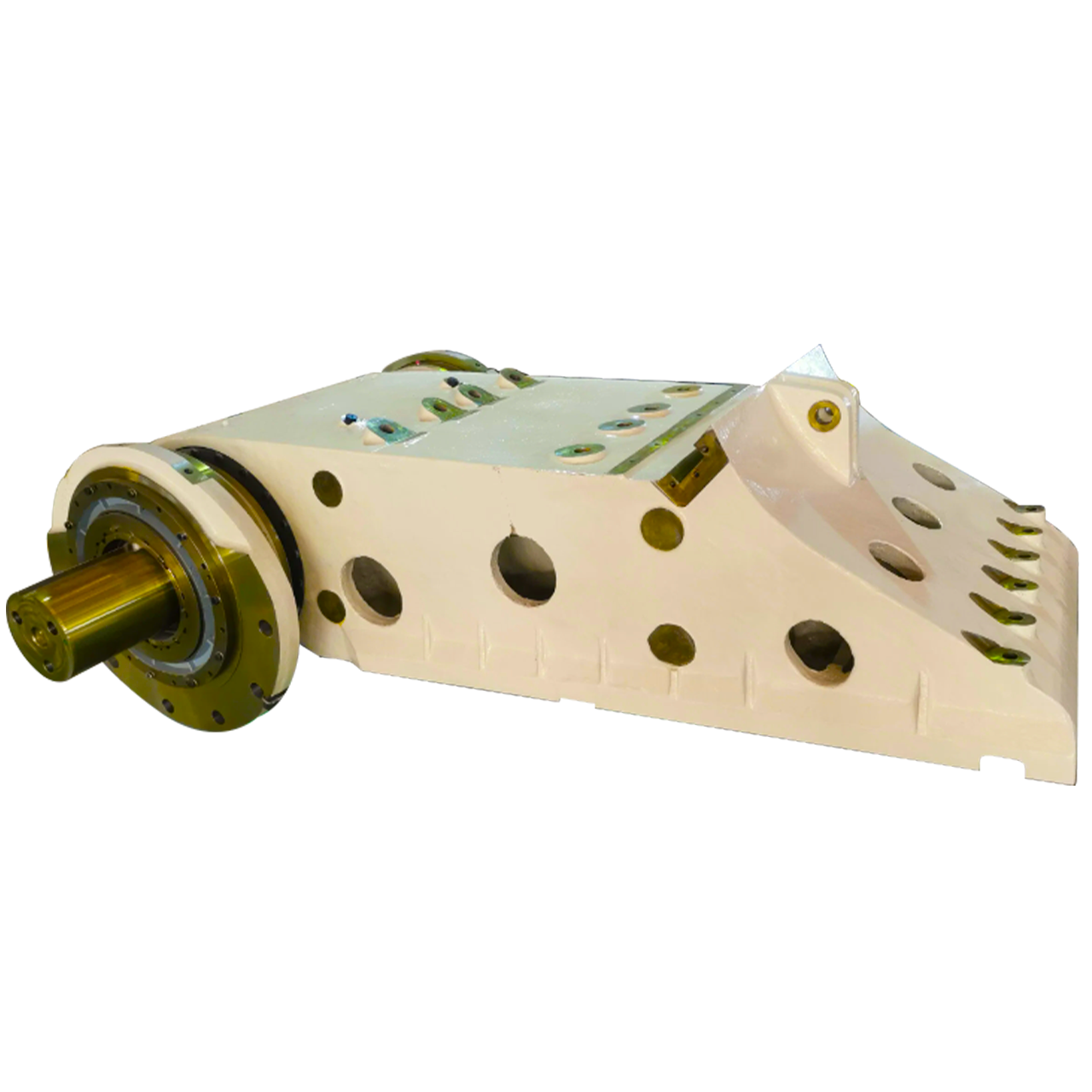

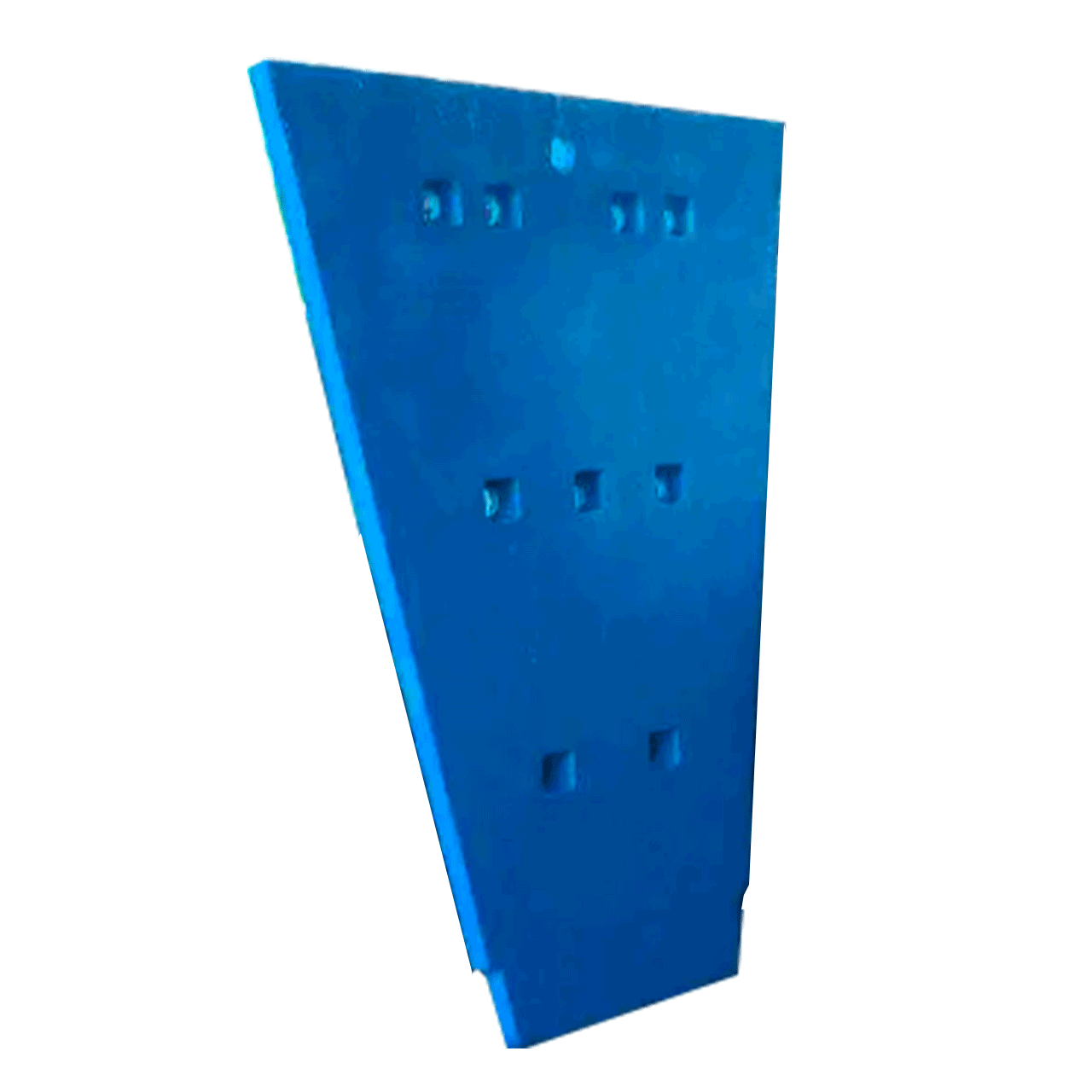

Side Liner Cheek Plate for Jaw Crusher Spare Parts

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

Materials:Cr26, Cr27, Mn13Cr2 , Mn18Cr2, Mn22Cr2...

Foundry technology :sand casting, lost foam casting

Technical support:drawing , surveying and mapping

In the context of a jaw crusher, the side liner and cheek plate are key components that help protect the machine and improve its efficiency. Here's an overview of their functions:

1. Side Liner

Function: The side liners are wear-resistant plates that are located on the sides of the jaw crusher's crushing chamber. They serve to protect the machine's frame from the abrasiveness of the material being crushed. Without these side liners, the raw material would cause significant wear and tear on the frame, leading to more frequent repairs and increased downtime.

Material: Typically made of high-manganese steel or other wear-resistant materials, the side liners are designed to withstand the crushing forces and abrasive properties of the material being processed.

Location: They are mounted on the inner sides of the crusher's frame, typically around the upper and lower parts of the crushing chamber.

2. Cheek Plates (Cheek Liners)

Function: Cheek plates (or cheek liners) are positioned on the sides of the jaw crusher's frame, directly in contact with the jaw and the material being crushed. These plates prevent the sides of the crusher from being damaged by the abrasive material. They also help guide the material toward the crushing zone, optimizing the material flow during the crushing process.

Material: Like side liners, cheek plates are often made of high-manganese steel, alloy steel, or other durable, wear-resistant materials to protect the crusher’s frame and ensure long-lasting performance.

Location: Cheek plates are typically positioned on the inside of the jaw crusher's stationary part, on both sides of the jaw’s crushing chamber.

Key Differences:

Side Liner: Primarily located on the sides of the crushing chamber and are designed to protect the frame and manage material flow.

Cheek Plate: Positioned specifically on the sides of the stationary jaw of the crusher, these plates have a more direct role in guiding the material and protecting the crusher’s frame from abrasion.

Importance:

Both components are crucial for the smooth operation and longevity of the jaw crusher. They prevent unnecessary damage to the frame and maintain optimal crushing efficiency. As they are subjected to constant wear, they need to be replaced periodically to avoid further damage to the equipment.

By using high-quality materials for these parts, operators can minimize downtime and repair costs, ensuring that the crusher runs efficiently for longer periods.

Foundry technology :sand casting, lost foam casting

Technical support:drawing , surveying and mapping

In the context of a jaw crusher, the side liner and cheek plate are key components that help protect the machine and improve its efficiency. Here's an overview of their functions:

1. Side Liner

Function: The side liners are wear-resistant plates that are located on the sides of the jaw crusher's crushing chamber. They serve to protect the machine's frame from the abrasiveness of the material being crushed. Without these side liners, the raw material would cause significant wear and tear on the frame, leading to more frequent repairs and increased downtime.

Material: Typically made of high-manganese steel or other wear-resistant materials, the side liners are designed to withstand the crushing forces and abrasive properties of the material being processed.

Location: They are mounted on the inner sides of the crusher's frame, typically around the upper and lower parts of the crushing chamber.

2. Cheek Plates (Cheek Liners)

Function: Cheek plates (or cheek liners) are positioned on the sides of the jaw crusher's frame, directly in contact with the jaw and the material being crushed. These plates prevent the sides of the crusher from being damaged by the abrasive material. They also help guide the material toward the crushing zone, optimizing the material flow during the crushing process.

Material: Like side liners, cheek plates are often made of high-manganese steel, alloy steel, or other durable, wear-resistant materials to protect the crusher’s frame and ensure long-lasting performance.

Location: Cheek plates are typically positioned on the inside of the jaw crusher's stationary part, on both sides of the jaw’s crushing chamber.

Key Differences:

Side Liner: Primarily located on the sides of the crushing chamber and are designed to protect the frame and manage material flow.

Cheek Plate: Positioned specifically on the sides of the stationary jaw of the crusher, these plates have a more direct role in guiding the material and protecting the crusher’s frame from abrasion.

Importance:

Both components are crucial for the smooth operation and longevity of the jaw crusher. They prevent unnecessary damage to the frame and maintain optimal crushing efficiency. As they are subjected to constant wear, they need to be replaced periodically to avoid further damage to the equipment.

By using high-quality materials for these parts, operators can minimize downtime and repair costs, ensuring that the crusher runs efficiently for longer periods.

Parts List