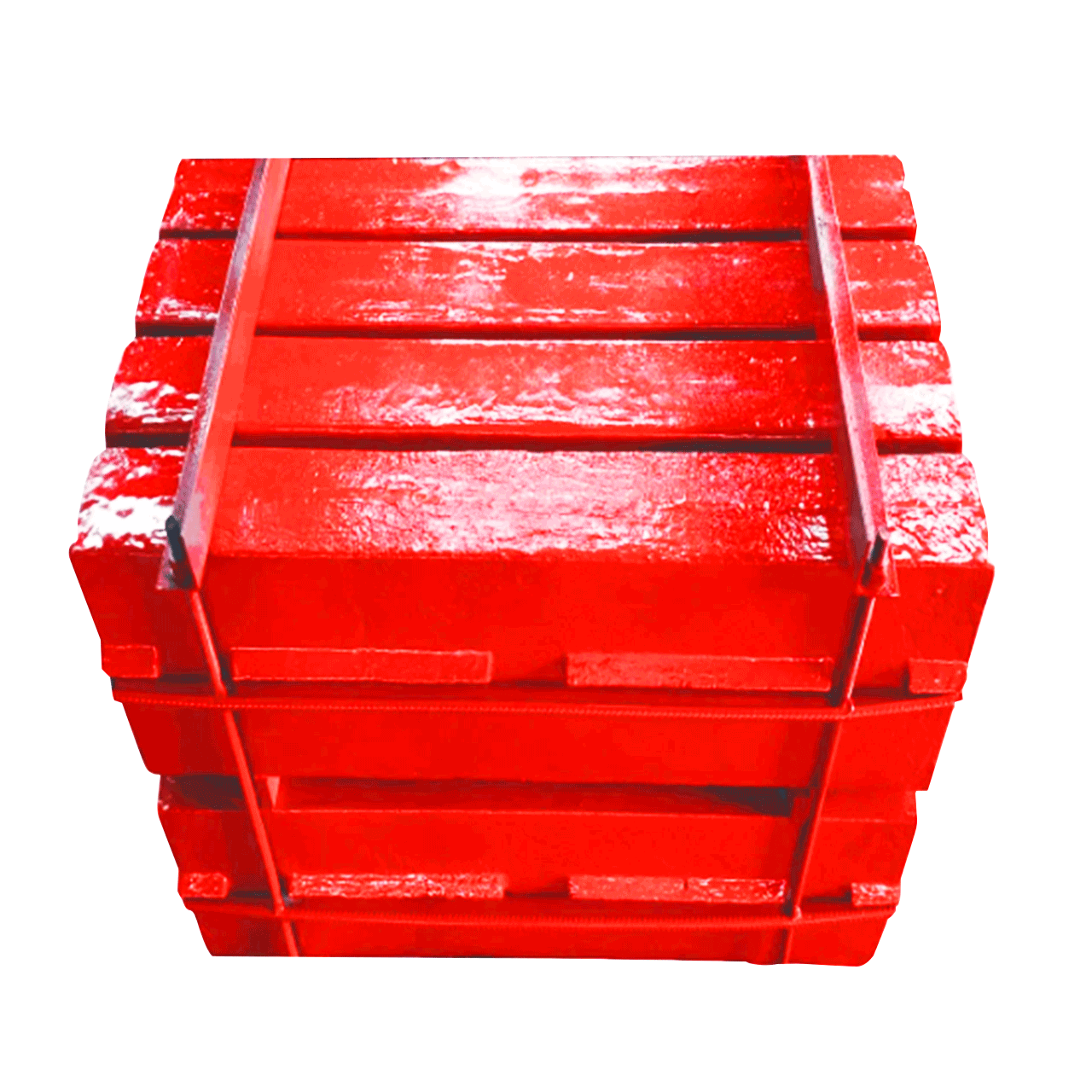

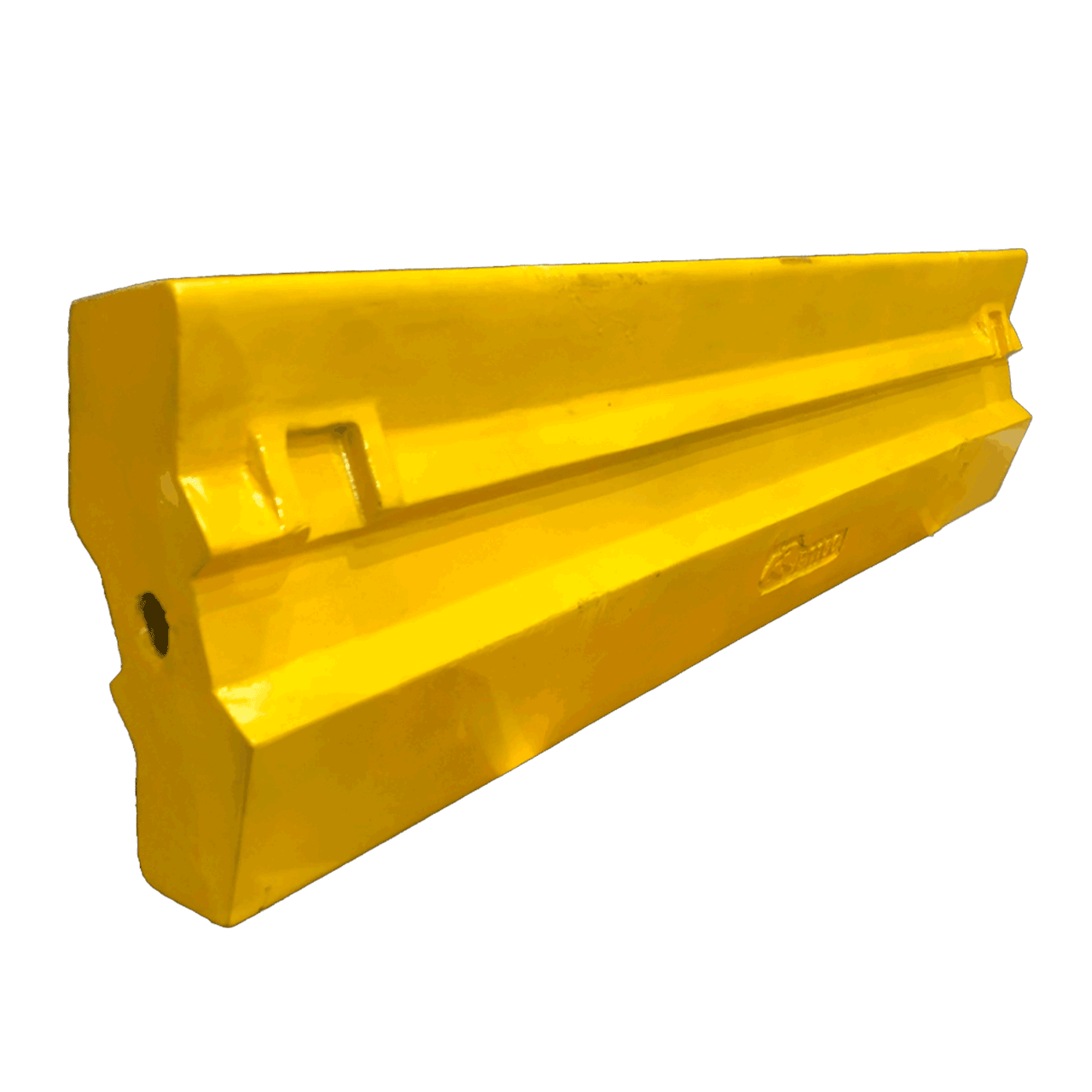

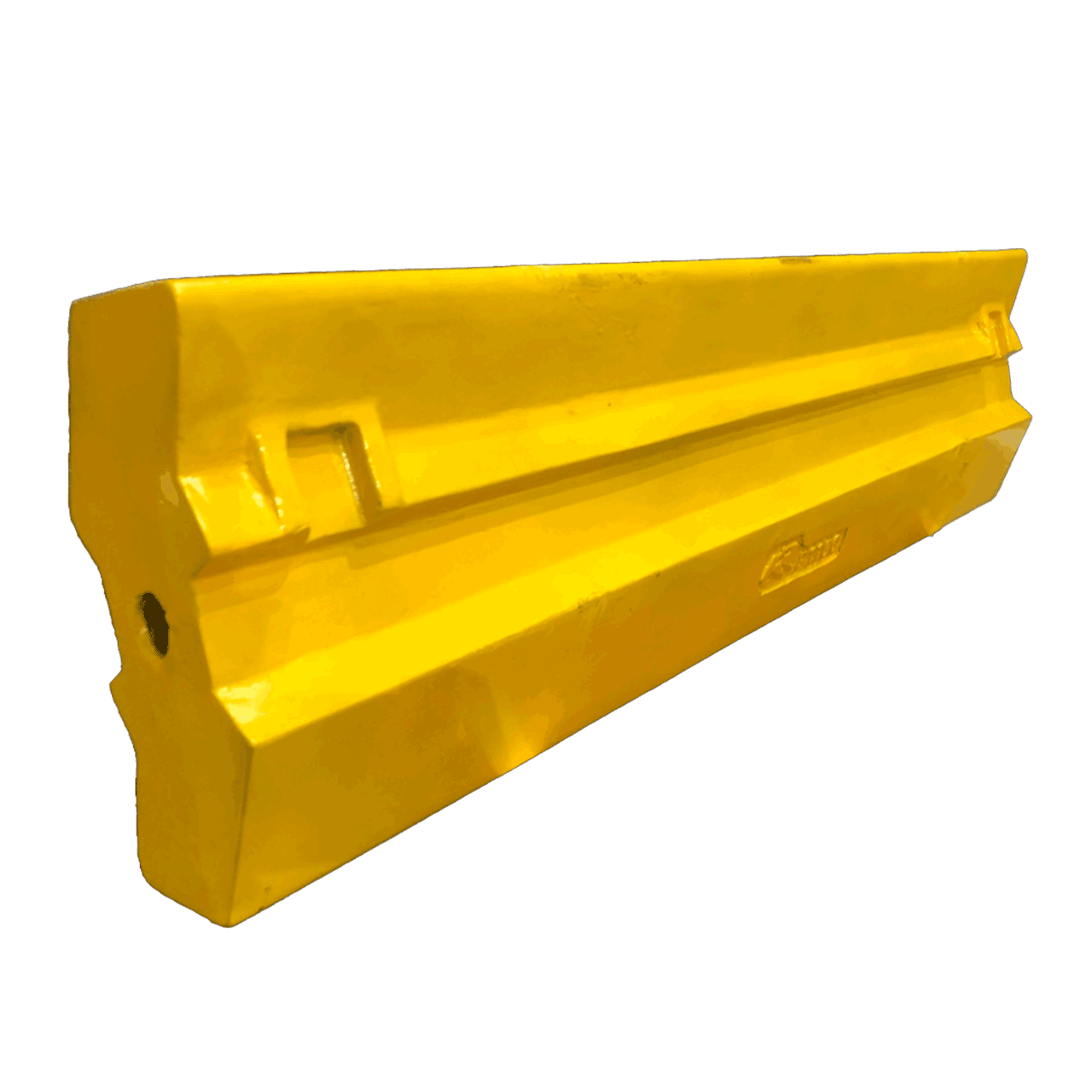

Impact-Crusher-Wear-Parts-Blow-Bar

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

Materials:Cr26, Cr27, Mn13Cr2 , Mn18Cr2, Mn22Cr2...

Foundry technology :sand casting, lost foam casting

Technical support:drawing , surveying and mapping

Why Choose Our Blow Bars for Impact Crusher?

1 .We offer OEM interchangeable impact crusher parts & liners;

2 .We provide a wide range of optional materials for blow bars;

3. We produce more wear-resistant products;

4 .We extend the service life of the impact crusher liners;

5. We provide more reasonable and competeable prices;

6. We provide more professional services and suggestions.

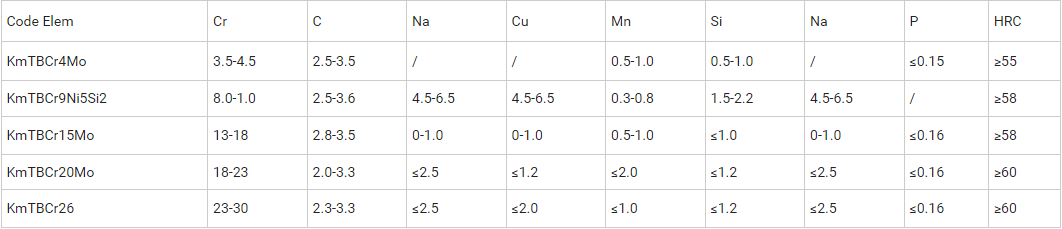

CHROME STEEL

With chrome steel, the carbon is chemically bonded in the form of chromium carbide. The wear resistance of chrome steel is based on these hard carbides of the hard matrix, whereby the movement is hindered by offsets, which provides for a high degree of strength but at the same time less toughness.

To prevent the material from becoming brittle, the blow bars must be heat-treated. It must thereby be observed that the temperature and annealing time parameters are exactly adhered to. Chrome steel typically has a hardness of 60 to 64 HRC and a very low impact strength of 10 J/cm².

To prevent breakage of chrome steel blow bars, there may not be any unbreakable elements in the feed material.

Foundry technology :sand casting, lost foam casting

Technical support:drawing , surveying and mapping

Why Choose Our Blow Bars for Impact Crusher?

1 .We offer OEM interchangeable impact crusher parts & liners;

2 .We provide a wide range of optional materials for blow bars;

3. We produce more wear-resistant products;

4 .We extend the service life of the impact crusher liners;

5. We provide more reasonable and competeable prices;

6. We provide more professional services and suggestions.

CHROME STEEL

With chrome steel, the carbon is chemically bonded in the form of chromium carbide. The wear resistance of chrome steel is based on these hard carbides of the hard matrix, whereby the movement is hindered by offsets, which provides for a high degree of strength but at the same time less toughness.

To prevent the material from becoming brittle, the blow bars must be heat-treated. It must thereby be observed that the temperature and annealing time parameters are exactly adhered to. Chrome steel typically has a hardness of 60 to 64 HRC and a very low impact strength of 10 J/cm².

To prevent breakage of chrome steel blow bars, there may not be any unbreakable elements in the feed material.

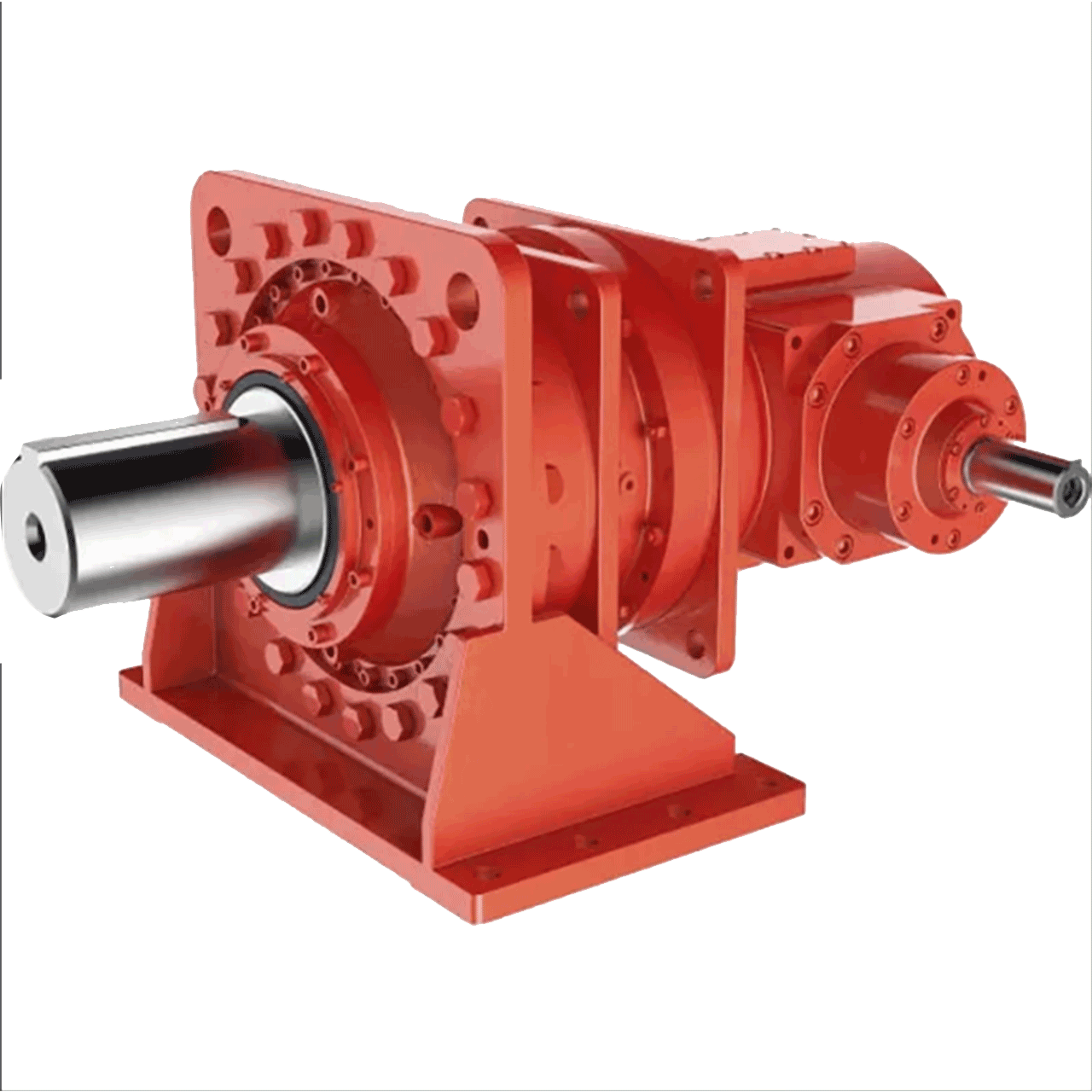

Parts List