impact cursher Rotor Assembly

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

Impact crusher rotor assembly is one of the core parts of impact crusher, which is mainly used to rotate at high speed and generate impact force to crush materials. It usually consists of the following main parts:

Rotor Shaft: The rotor shaft is the main support part of the rotor, responsible for bearing the load on the rotor and keeping the rotor rotating.

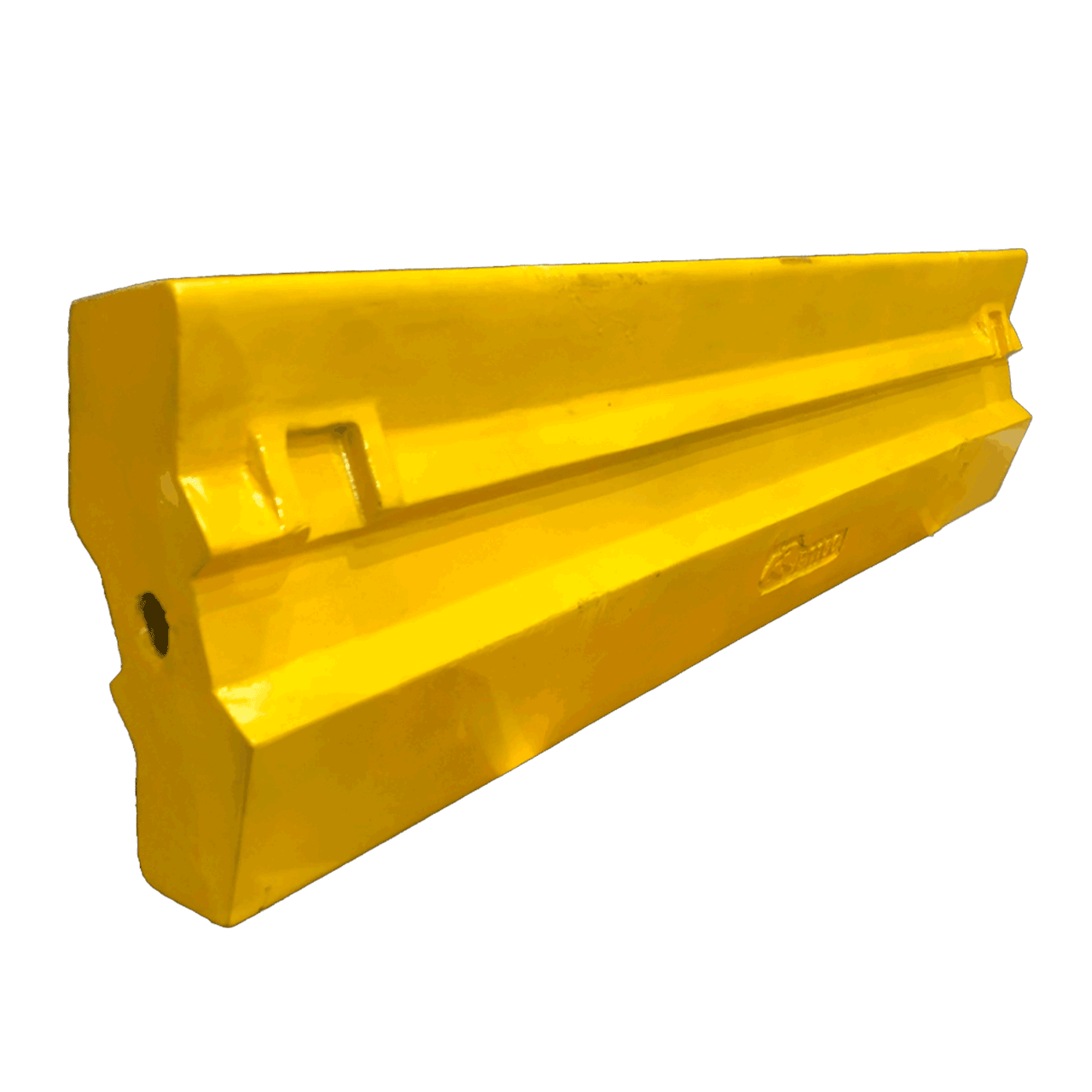

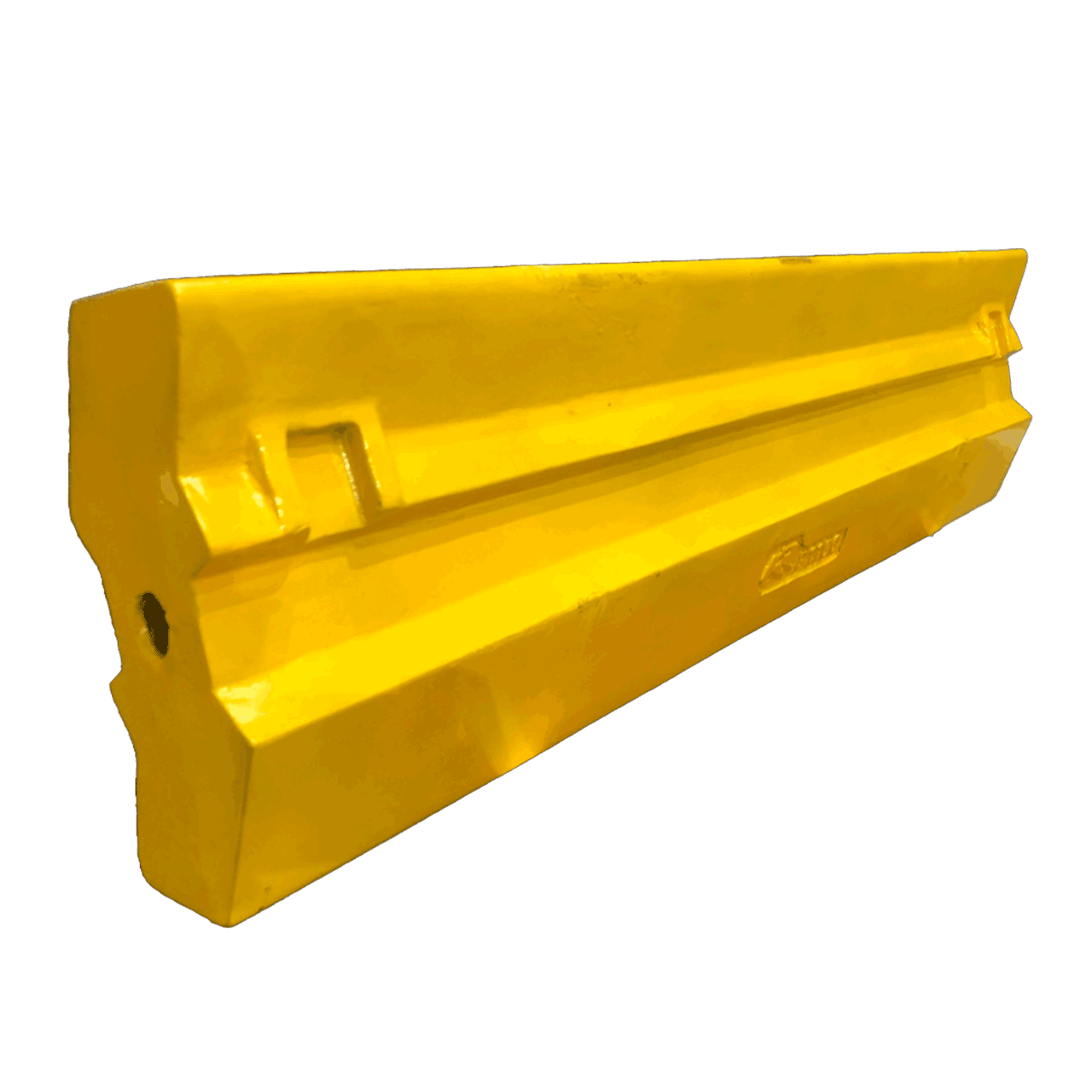

Rotor blades: The rotor blades are usually made of wear-resistant materials and are responsible for throwing the material to the crushing zone at a high speed. The shape and material of the blades are critical to the crushing effect.

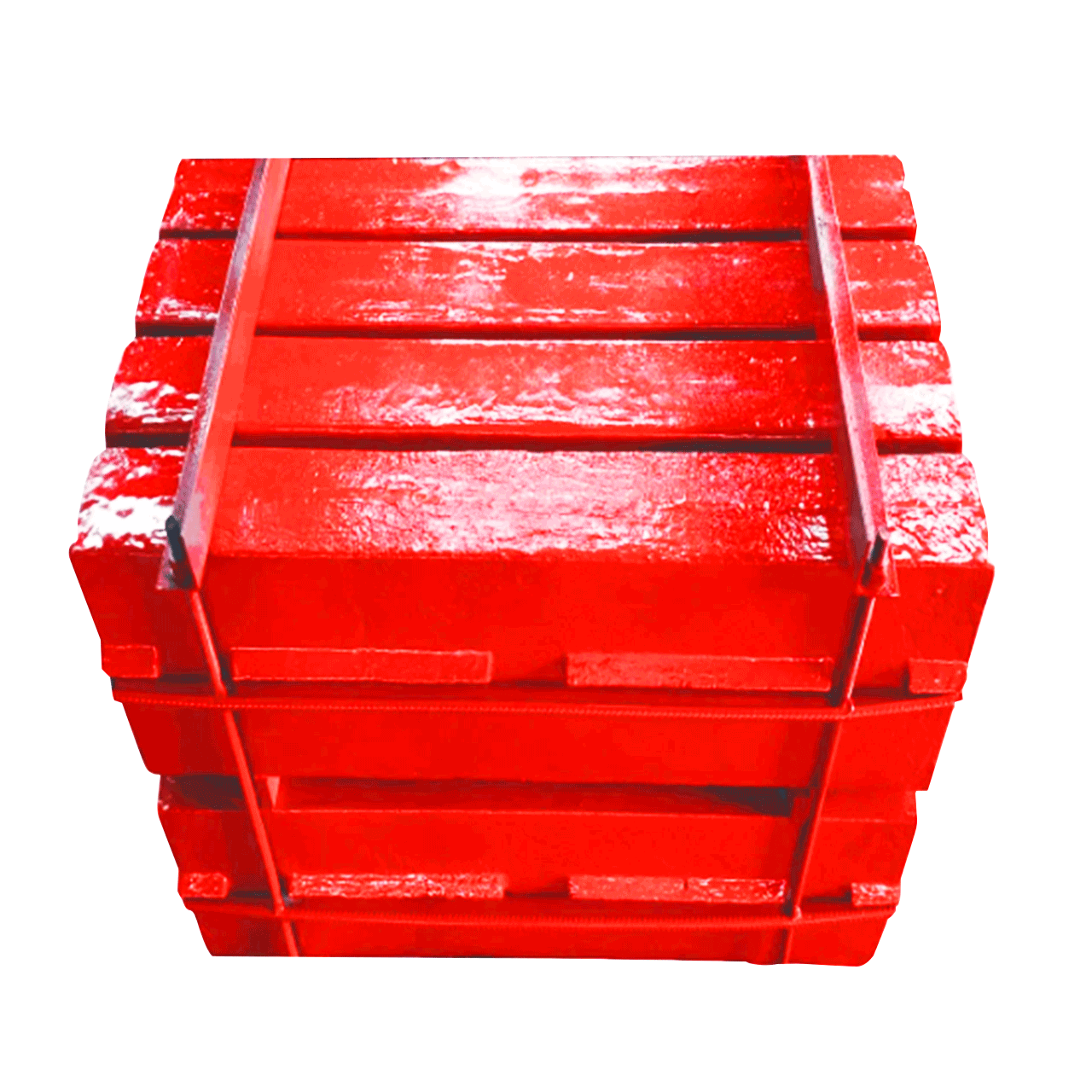

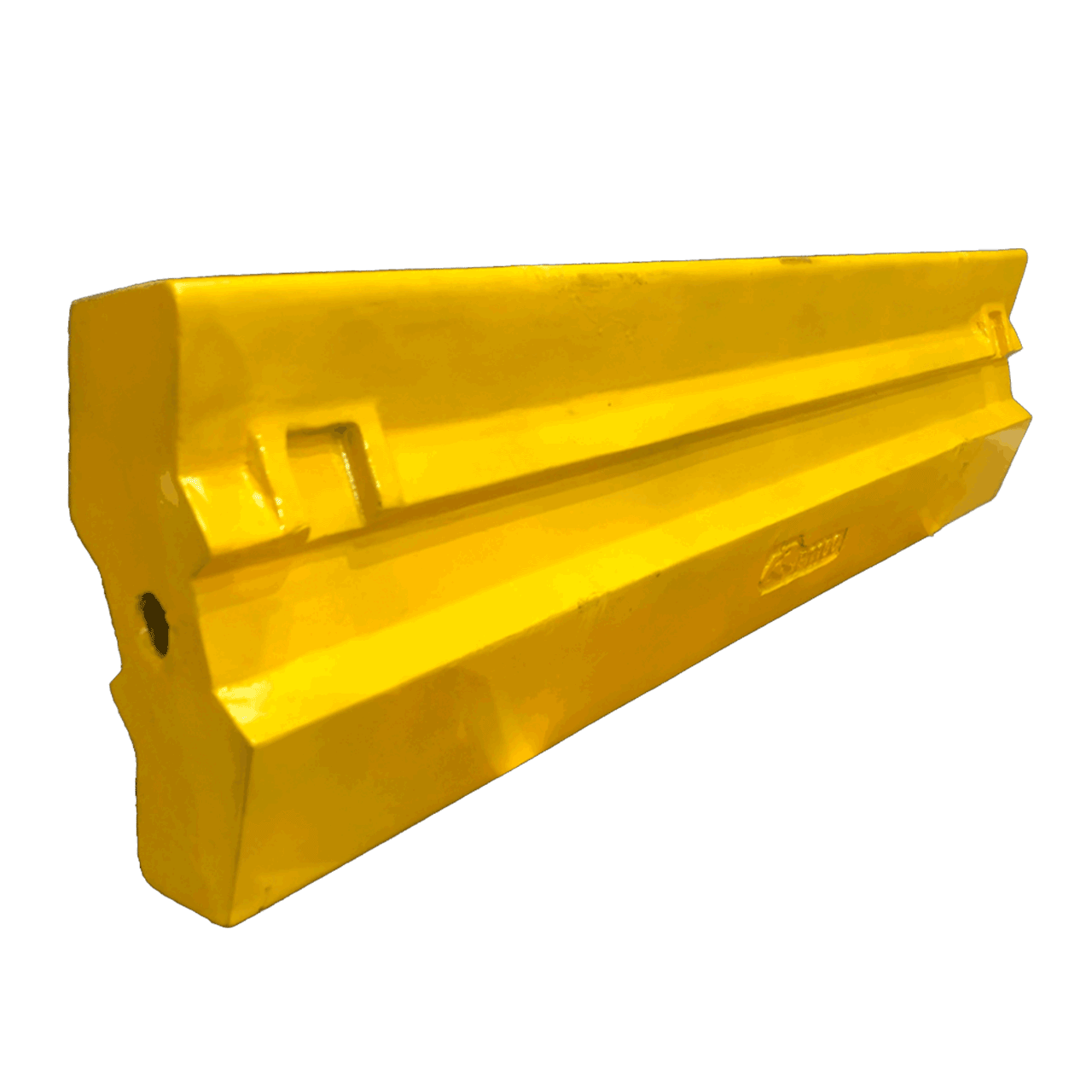

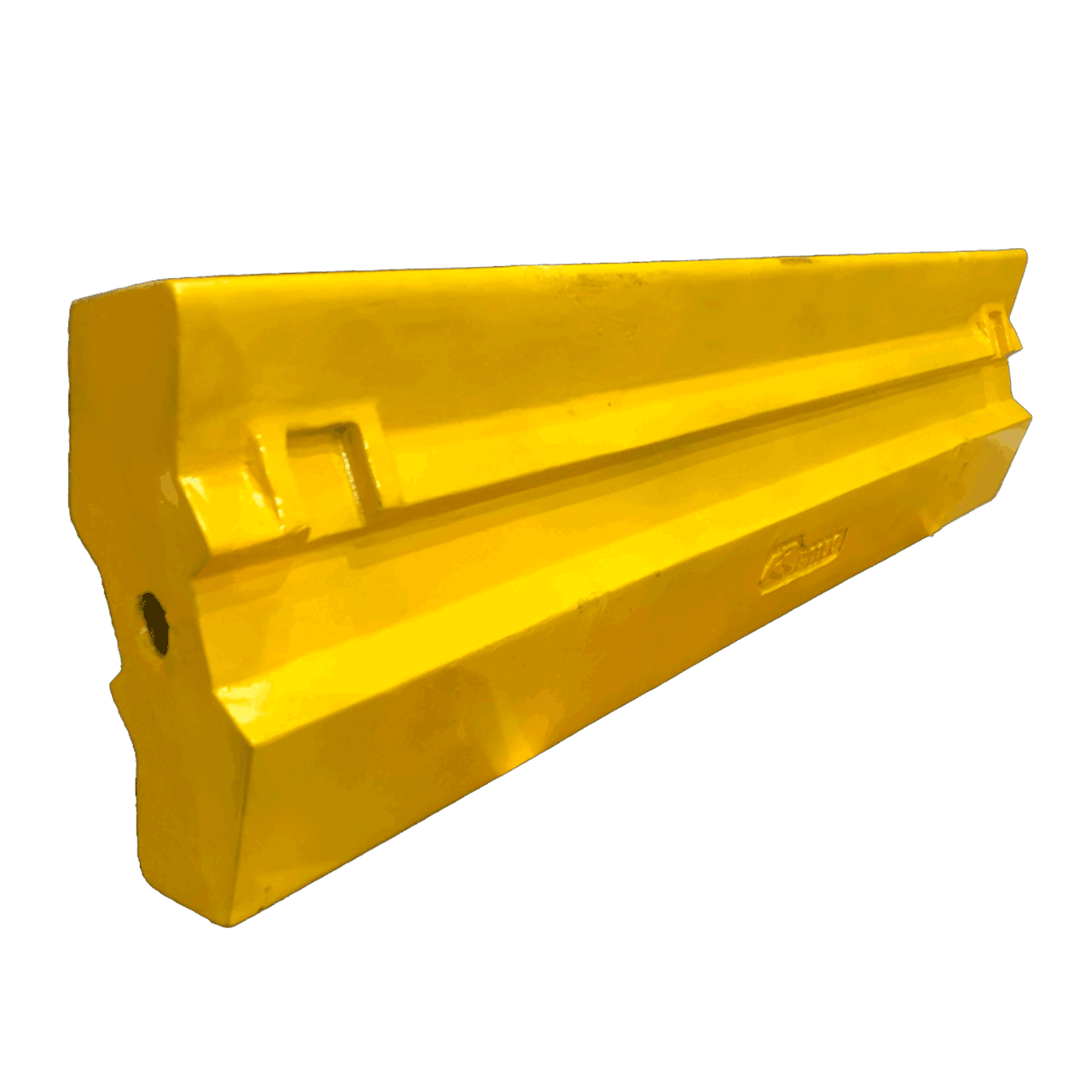

Hammer head: The hammer head is an important crushing tool on the rotor of an impact crusher, which breaks the material by rotating it. The wear resistance and strength of the hammer head directly affects the efficiency of the crusher.

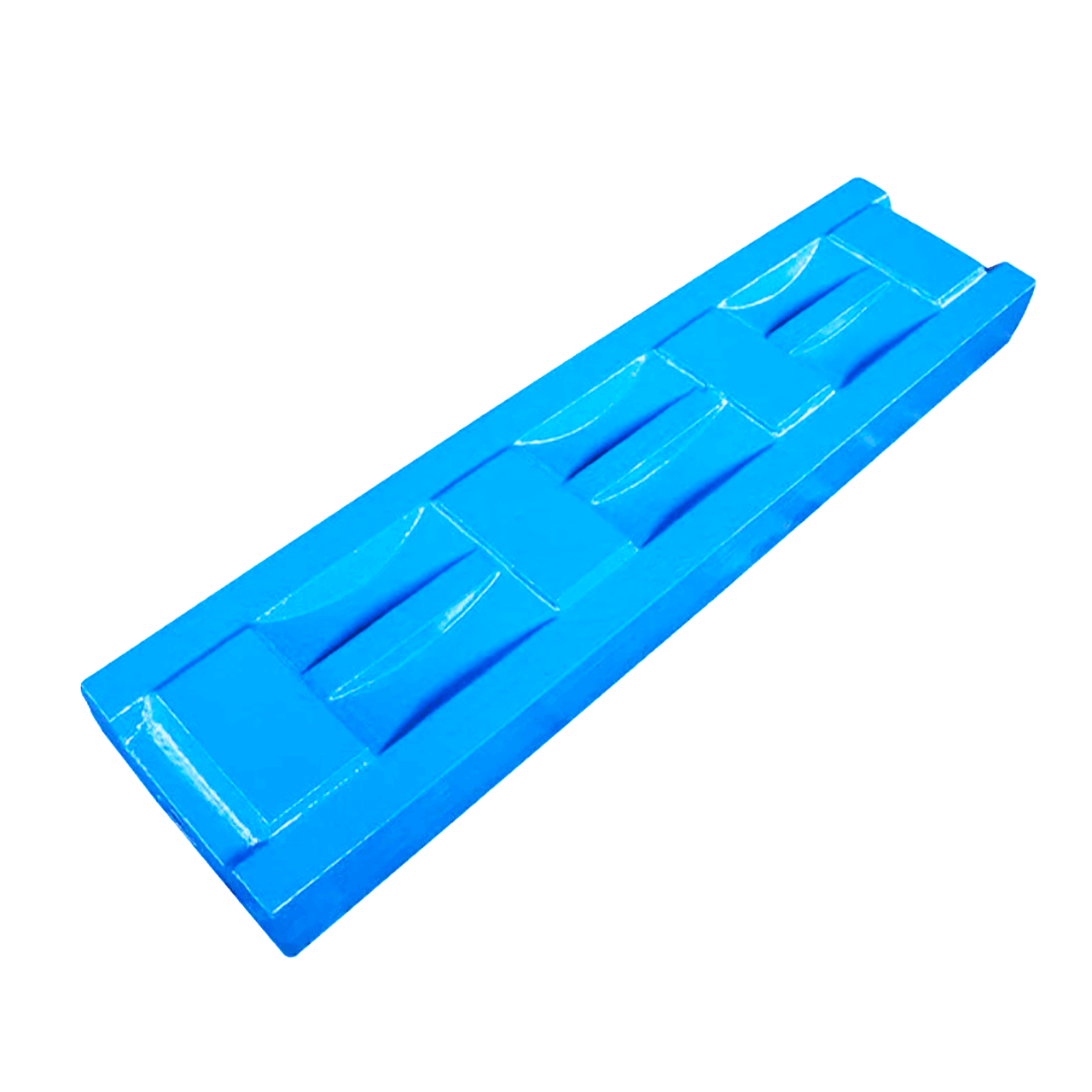

Liner: The liner is installed in the crushing chamber and works with the rotor to help the material to be crushed effectively. The service life of the liner has a great impact on the performance of the crusher.

Balancing device: In order to ensure the smooth operation of the rotor, some impact crushers are also designed with balancing devices to minimize the vibration caused by the unbalanced rotor.

Bearings: Bearings support the rotation of the rotor shaft and bear the load and impact of the rotor. Commonly used bearings are rolling bearings and plain bearings.

The design and manufacturing quality of the impact crusher rotor assembly is directly related to the efficiency and service life of the crusher. In order to ensure the efficient work of the machine, the material selection, processing precision and maintenance of the rotor assembly are very critical.

Rotor Shaft: The rotor shaft is the main support part of the rotor, responsible for bearing the load on the rotor and keeping the rotor rotating.

Rotor blades: The rotor blades are usually made of wear-resistant materials and are responsible for throwing the material to the crushing zone at a high speed. The shape and material of the blades are critical to the crushing effect.

Hammer head: The hammer head is an important crushing tool on the rotor of an impact crusher, which breaks the material by rotating it. The wear resistance and strength of the hammer head directly affects the efficiency of the crusher.

Liner: The liner is installed in the crushing chamber and works with the rotor to help the material to be crushed effectively. The service life of the liner has a great impact on the performance of the crusher.

Balancing device: In order to ensure the smooth operation of the rotor, some impact crushers are also designed with balancing devices to minimize the vibration caused by the unbalanced rotor.

Bearings: Bearings support the rotation of the rotor shaft and bear the load and impact of the rotor. Commonly used bearings are rolling bearings and plain bearings.

The design and manufacturing quality of the impact crusher rotor assembly is directly related to the efficiency and service life of the crusher. In order to ensure the efficient work of the machine, the material selection, processing precision and maintenance of the rotor assembly are very critical.

Parts List