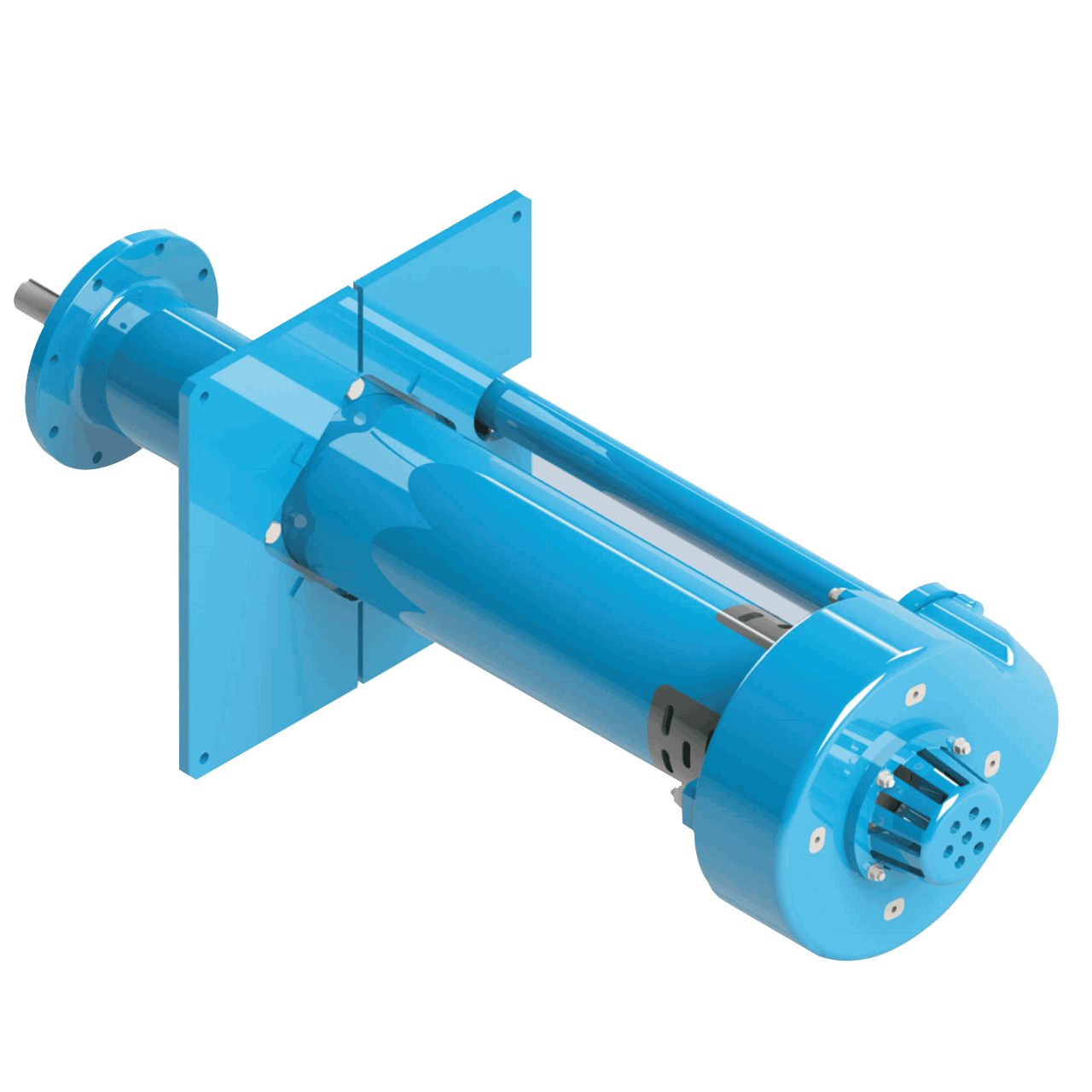

AH25-160 HAH Series Of Heavy Ceramic Slurry Pumps

Manufacturer : MORETEC

Part number : AH25-160

OEM Compatibility :

Category :Pump & Valve / Ceramic Pump

Description

Description

The crystal structure of SiC is the same as the regular tetrahedron of diamond, and it is also a compound that is bound together mainly by covalent bonds. In fact, the hardness of SiC is second only to diamond. The anti-wear performance is 3.51 times that of Cr30.

Silicon carbide has stable chemical properties, can almost withstand various corrosion of inorganic acids, organic acids, and alkalis, and has good oxidation resistance.

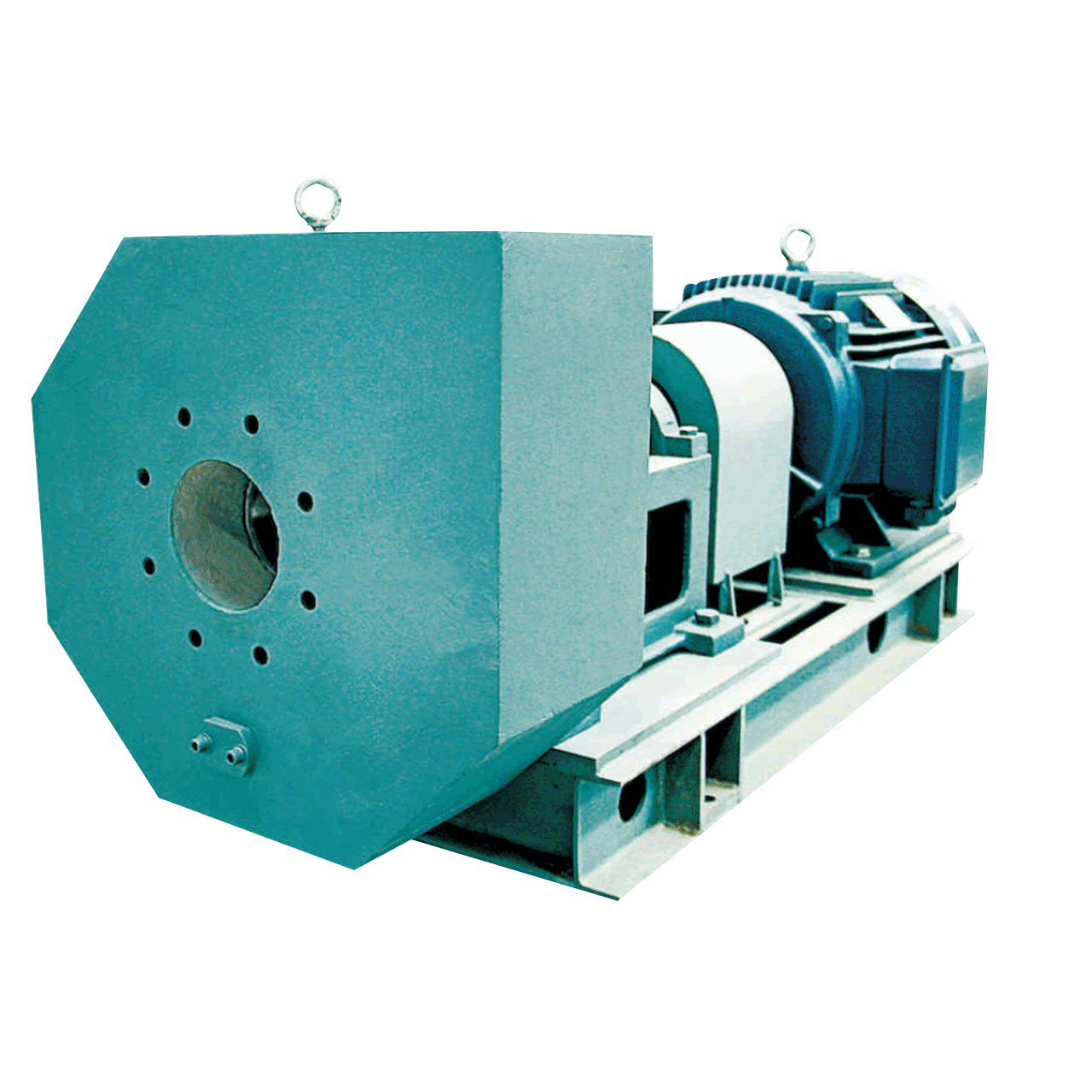

Silicon carbide ceramic pumps are mainly divided into: heavy slurry pump/desulfurization slag slurry circulating pump/light slurry pump/vertical slurry pump according to material characteristics. The pump types involved are ZVT, HAH, HVT, LVT and HL.

Heavy slurry pump is suitable for mining, metallurgy, electric power, coal, chemical industry, building materials and many other industries. It can transport solid particle media with abrasion and corrosion, such as ash, coal slurry transportation in power station, slurry transportation in metallurgical concentrator, coal slurry transportation in coal washing plant and other heavy media transportation. It can be applied to mud with high weight concentration-mortar 45% and slurry 60%.

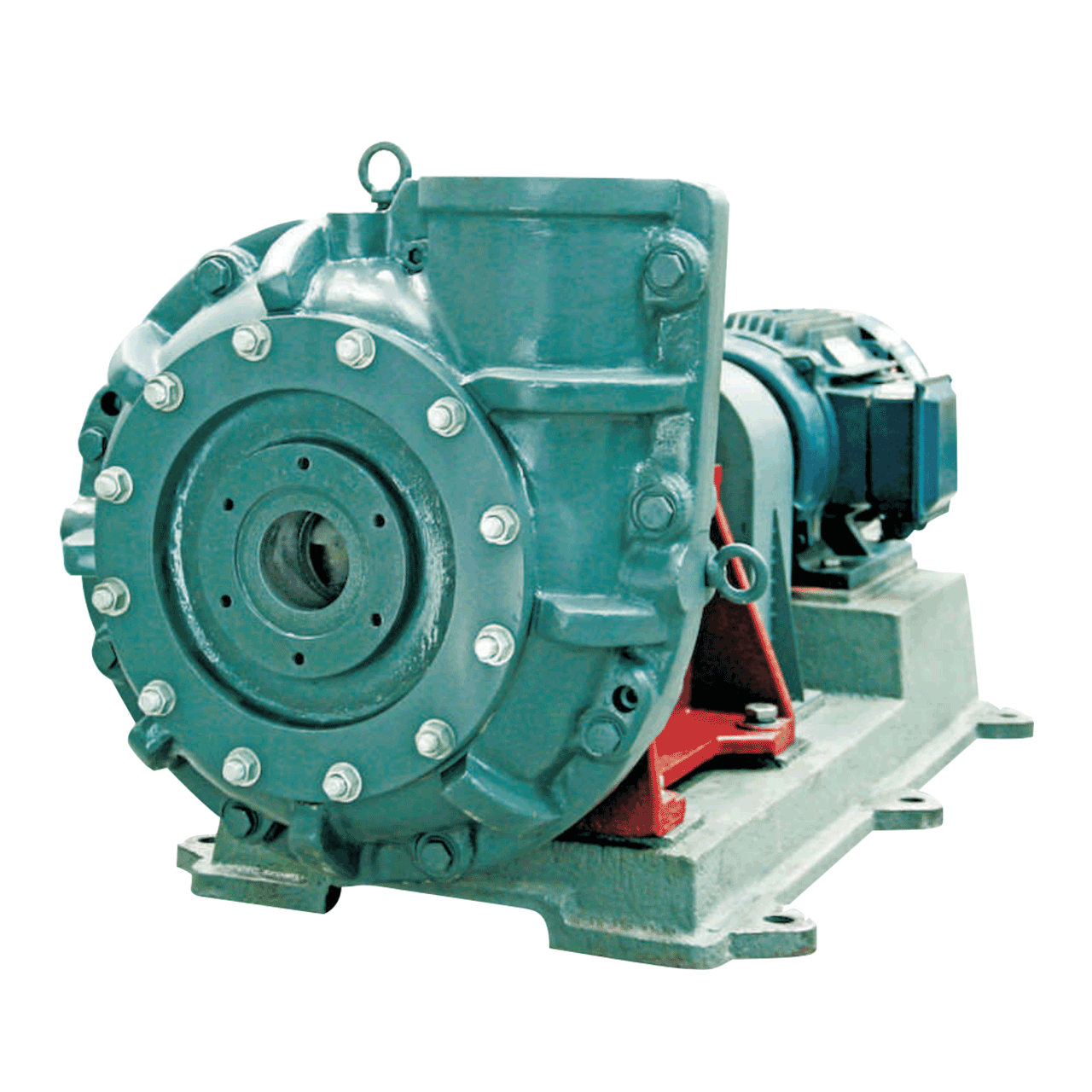

The pump has the characteristics of high efficiency, stable operation, reliability and long service life, which improves the impact resistance and is successfully applied to a certain section of the grinding pump.

Model meaning:

HAH: Pump Series Code

25: Outlet Diameter

160: impeller diameter

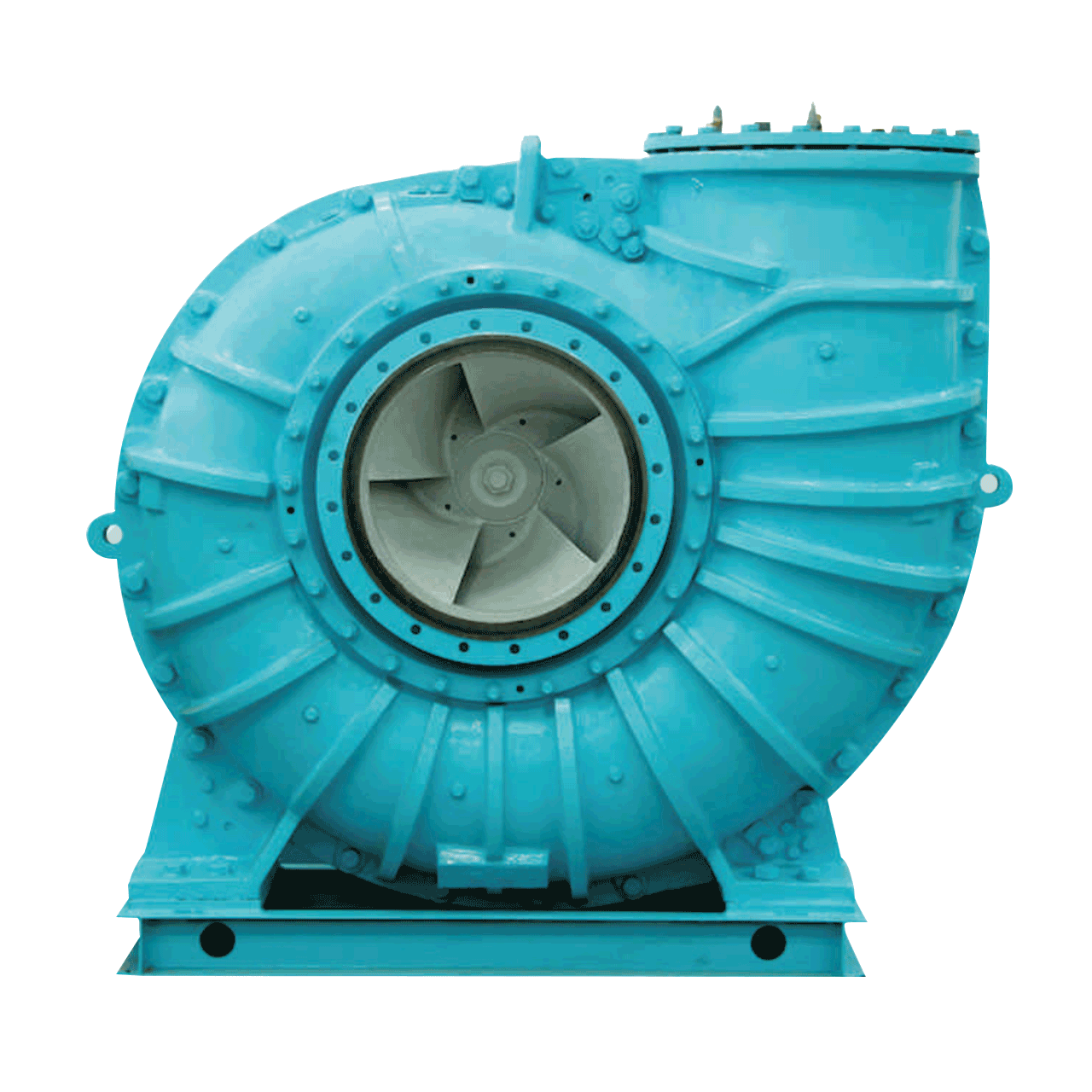

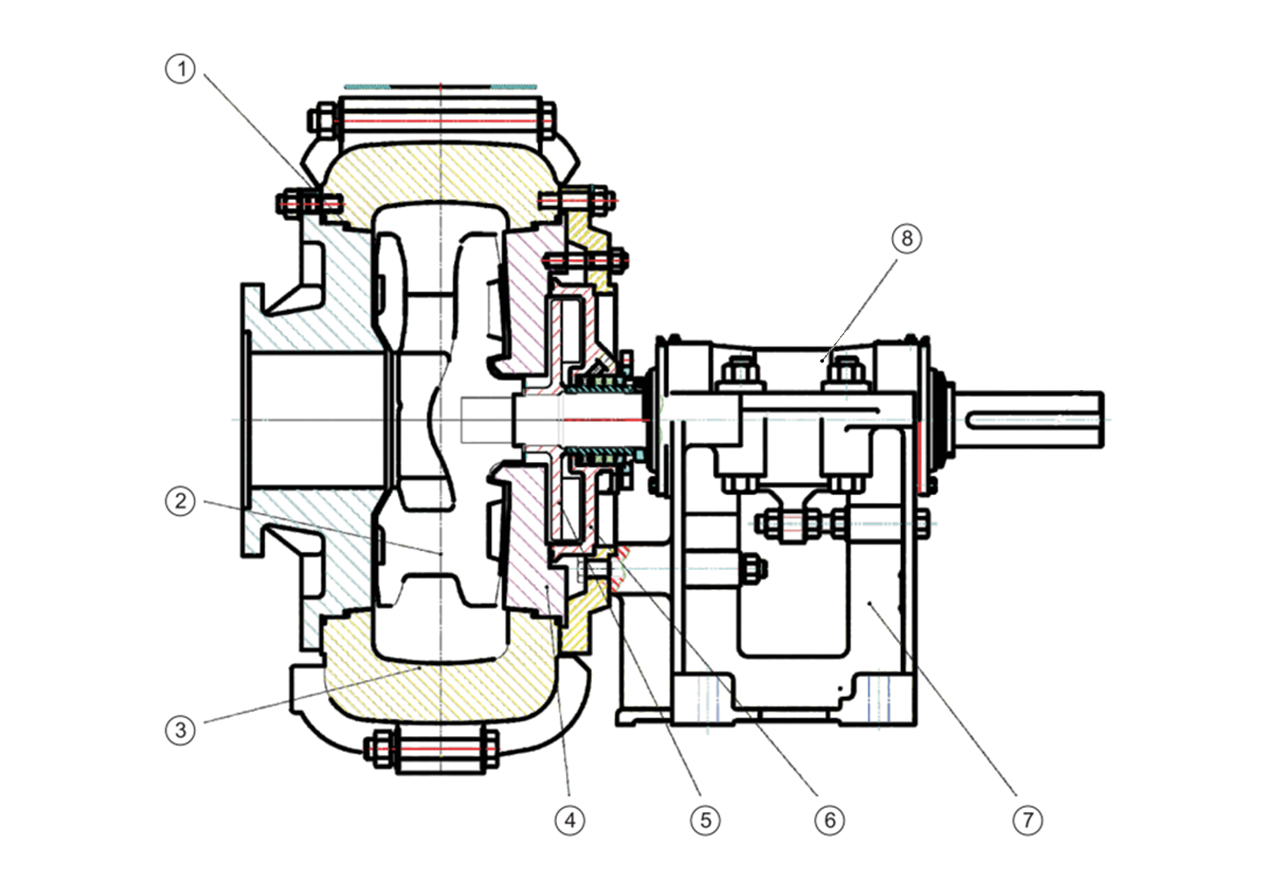

Name of each part of the pump:

(1) Front pump cover (2) Silicon carbide impeller (3) Pump body (4) Rear pump cover (5) Pending impeller (6) Pressure reducing cover (7) Bracket (8) Bearing assembly

Silicon carbide has stable chemical properties, can almost withstand various corrosion of inorganic acids, organic acids, and alkalis, and has good oxidation resistance.

Silicon carbide ceramic pumps are mainly divided into: heavy slurry pump/desulfurization slag slurry circulating pump/light slurry pump/vertical slurry pump according to material characteristics. The pump types involved are ZVT, HAH, HVT, LVT and HL.

Heavy slurry pump is suitable for mining, metallurgy, electric power, coal, chemical industry, building materials and many other industries. It can transport solid particle media with abrasion and corrosion, such as ash, coal slurry transportation in power station, slurry transportation in metallurgical concentrator, coal slurry transportation in coal washing plant and other heavy media transportation. It can be applied to mud with high weight concentration-mortar 45% and slurry 60%.

The pump has the characteristics of high efficiency, stable operation, reliability and long service life, which improves the impact resistance and is successfully applied to a certain section of the grinding pump.

Model meaning:

HAH: Pump Series Code

25: Outlet Diameter

160: impeller diameter

Name of each part of the pump:

(1) Front pump cover (2) Silicon carbide impeller (3) Pump body (4) Rear pump cover (5) Pending impeller (6) Pressure reducing cover (7) Bracket (8) Bearing assembly

| Minimum flow | 12.6 m³/h |

| Maximum flow | 28.8 m³/h |

| Minimum lift | 6 m |

| Max lift | 68 m |

| Minimum speed | 1200 RPM |

| Maximum speed | 3800 RPM |

| Efficient | 40 % |

| Inlet connection size | 1.5 inch |

| Outlet connection size | 1 inch |

Parts List

Parts List

People who seen this item also look

Ratings and Reviews

|

It is the first time to buy and use a ceramic slurry pump. It has been installed and used for a period of time after receiving the goods. It is indeed wear-resistant and corrosion-resistant. If you want enough to buy, you can place an order for purchase.

Thomas, Mar 3 2022

|