Reasonable selection is to improve the service life of the pump is one of the key factors, to confirm the required pump type should be based on the following process

First, determine the application background and environmental conditions

According to the engineering environment, to confirm the installation location of the pump, space limitations and special conditions of the working environment.

Determine the flow rate of slurry to be transported (usually in cubic meters / hour).

Determine the head to be overcome by the slurry pump, i.e. the outlet pressure of the pump. The head is usually determined by the difference in height of the pipeline and the pressure requirements of the system.

Analyze the properties of the slurry such as density, viscosity, particle size, and temperature. Slurries that are dense, viscous, or contain large particles may require specially designed pumps.

Pumps of different materials have different properties at different temperatures, and special materials or configurations may be required when the temperature is too high or too low.

Second, choose the basic pump type

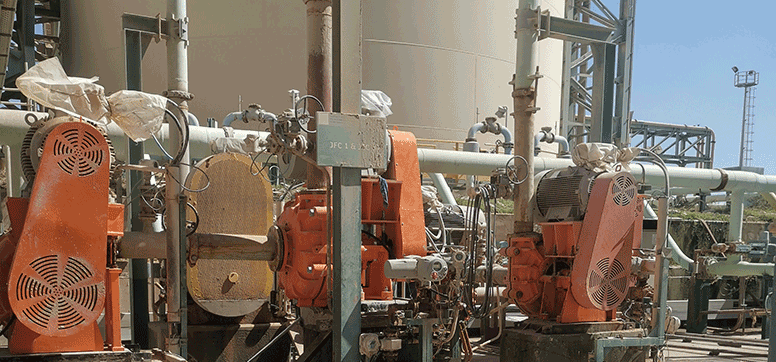

With the world's advanced level of Mizztech pump slurry pumps, for example, according to different slurry characteristics and working conditions, the selection of suitable pump type is crucial. The following are some basic selection suggestions:

L type pump for low abrasive slurry: for low abrasive slurry, you can consider choosing L type pump from Mizztech pump.

KSH type pumps for high concentration strongly abrasive slurries: for slurries with high concentration and strong abrasive properties, Mizztech Pumps' KSH type pumps are an ideal choice.

KSS type pumps for high level change and invasive submerged work: for high level change and submerged work, Mizztech pumps' KSS type pumps are a good choice.

ZGB and KSHH type pumps for high head transfer: when high head transfer is required, consider choosing Mizztech Pumps' ZGB and KSHH type pumps.

KWPSA series is used for low concentration, medium-low abrasion, non-clogging conditions: KWPSA series can be selected from different materials in different working condition applications.

Third, the system performance parameters to determine

1. speed selection for high concentration of highly abrasive slurry, choose a low speed pump to improve pump stability and reduce wear. Multiple pumps can be connected in series to meet the system's flow and head requirements. 2.

2. Flow range limitations

For high concentration of strong abrasive slurry, the flow rate should be selected in the range of 40%-80% of the corresponding flow rate of the pump's maximum efficiency. For low concentration of less abrasive slurry, the flow range can be selected in the maximum efficiency of the pump corresponding to the flow rate of 40% -100% range, to avoid choosing more than 100% of the range.

3. head margin to select a reasonable margin to ensure that the pump in operation can be maintained for a long time in the rated condition near, improve service life.

Fourth, according to the specific conditions of the slurry pump components for fine-tuning is to ensure that the pump can effectively run the important steps

1. overflow parts material selection

According to the characteristics of slurry conveying, including particle composition, particle size, shape, hardness and concentration, etc., choose the appropriate material of over-flow parts. According to the chemical characteristics of slurry (acidity, alkalinity, oil, etc.), to ensure that the overflow parts have good corrosion resistance.

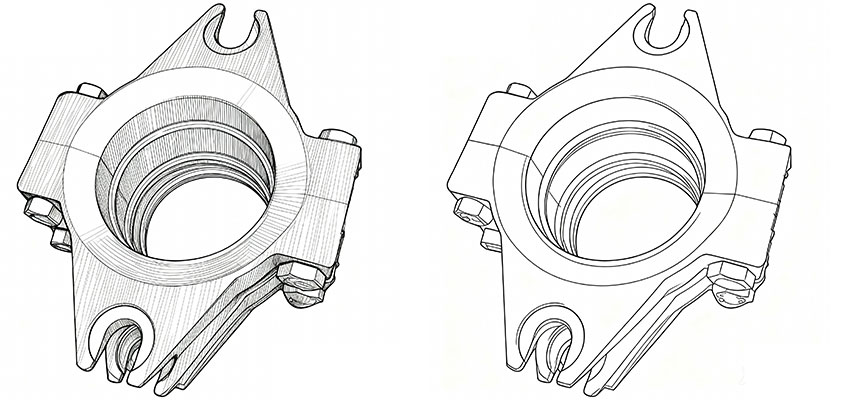

2. Selection of shaft seal type

3. According to the specific working conditions to choose the appropriate form of shaft seal, such as packing seal, vice impeller power seal and mechanical seal. For backing up work, the use of vice impeller seal can be considered, but need to pay attention to the high pipe pressure should be less than 10% of the pump outlet pressure, while need to consider the increased power consumption.

For packing seals, make sure there is enough shaft sealing water, the water pressure is usually equal to the pump outlet pressure plus 3.5 meters head.

3. Transmission mode selection

The transmission mode of slurry pump, including V-type triangular belt drive, coupling drive, gear reduction gearbox drive, hydraulic coupling drive, variable frequency drive and so on.

Considering the cost and convenience, coupling and V-type triangle belt is more economical and easy to disassemble the choice.

Note that the V-belt may increase power consumption by 5%, which needs to be considered comprehensively.