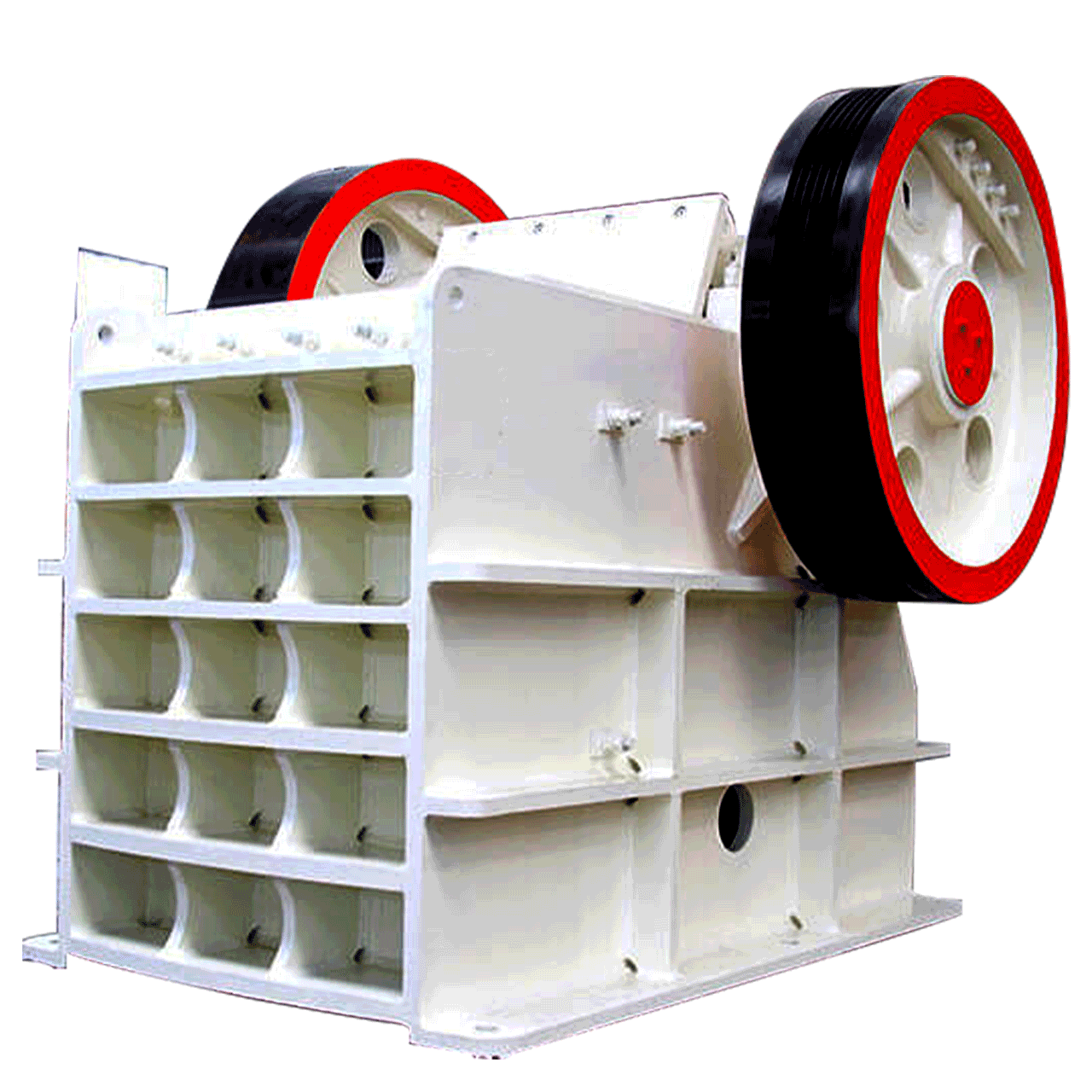

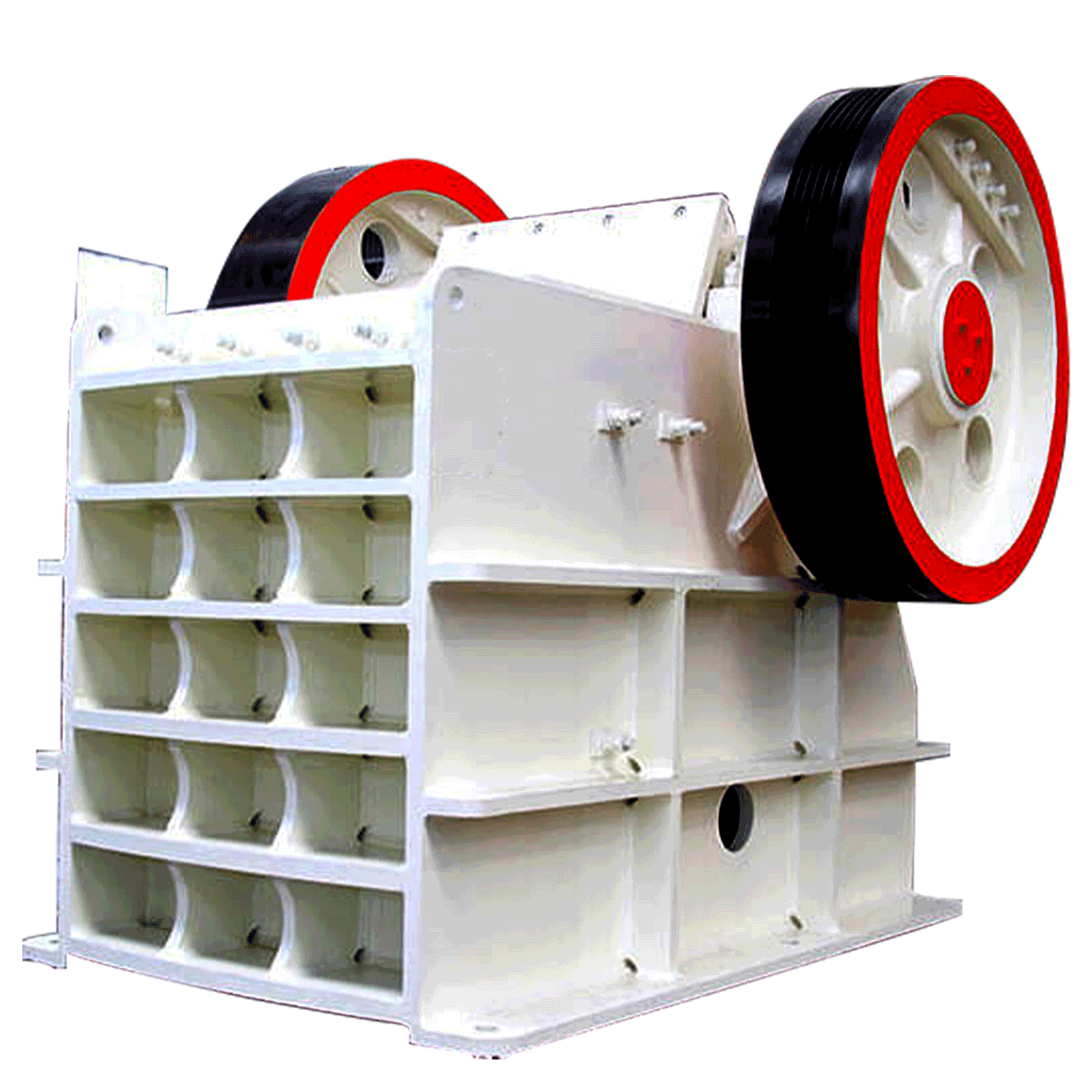

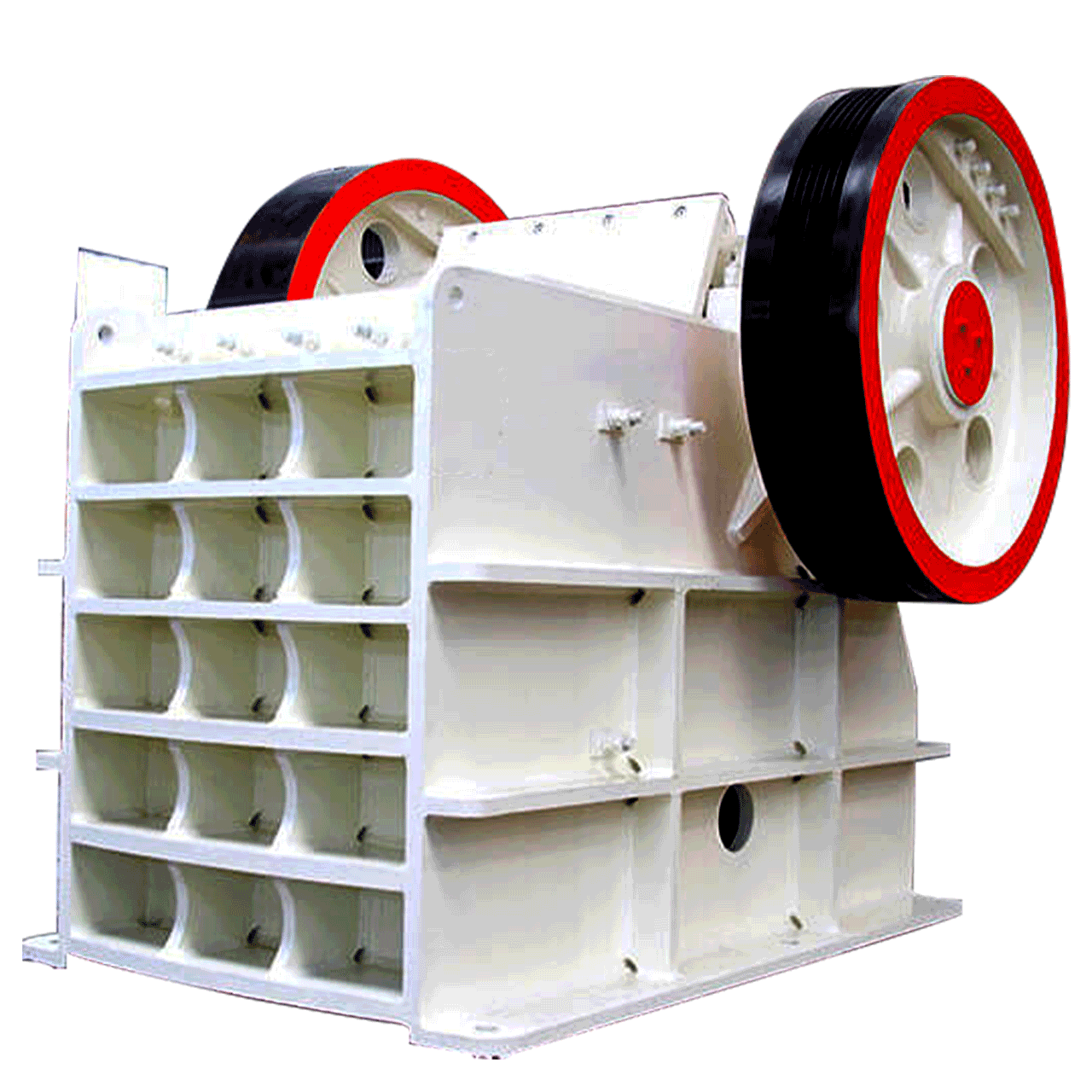

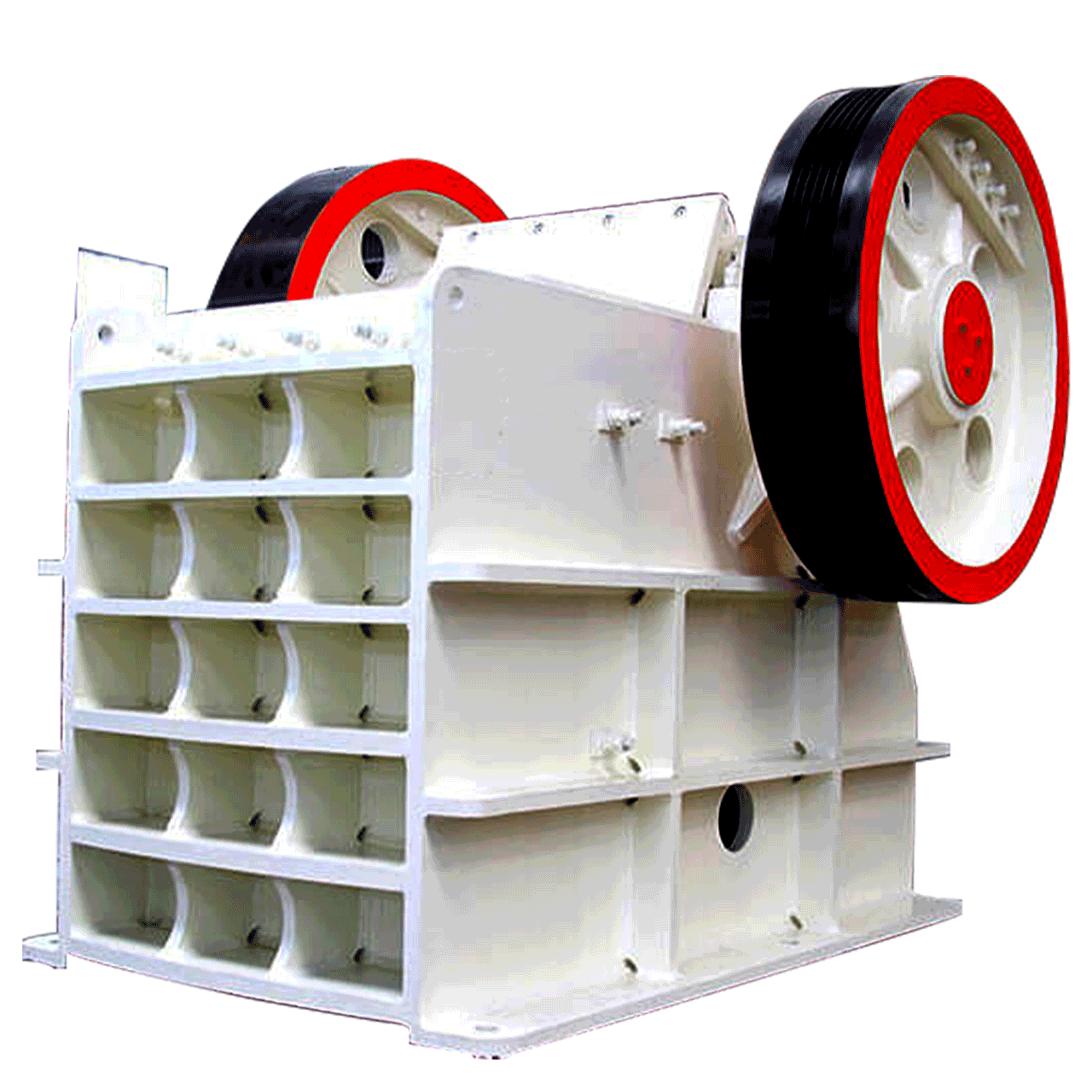

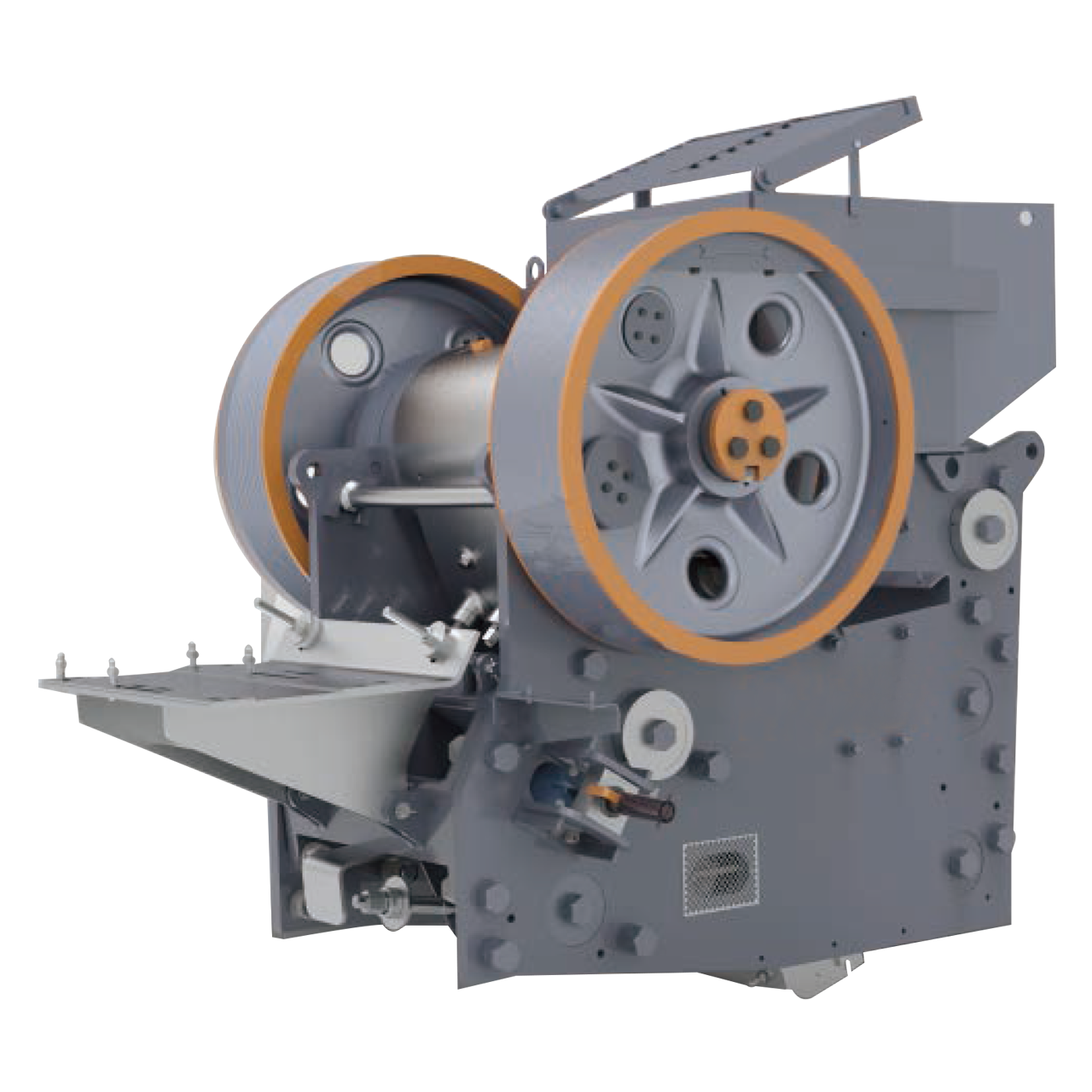

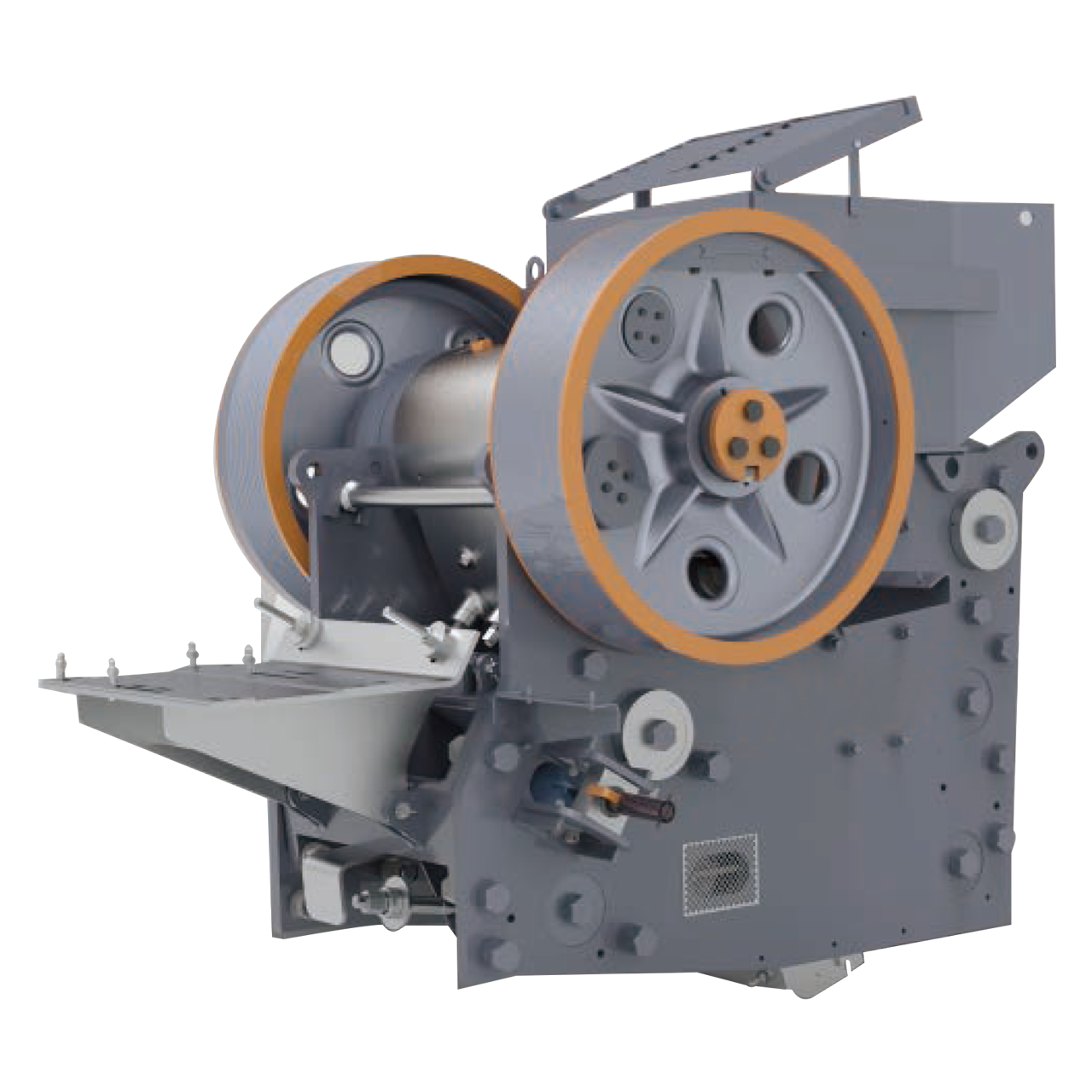

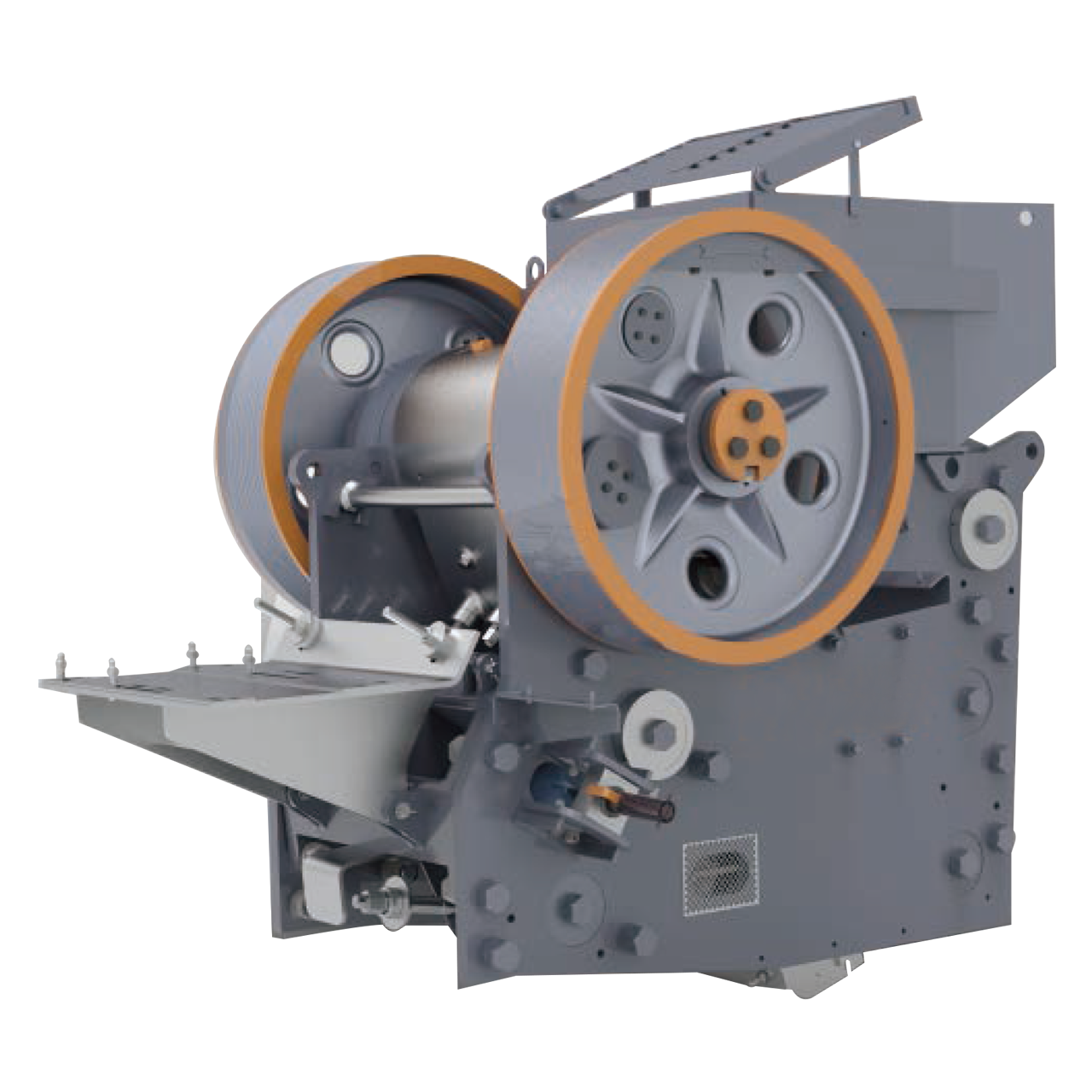

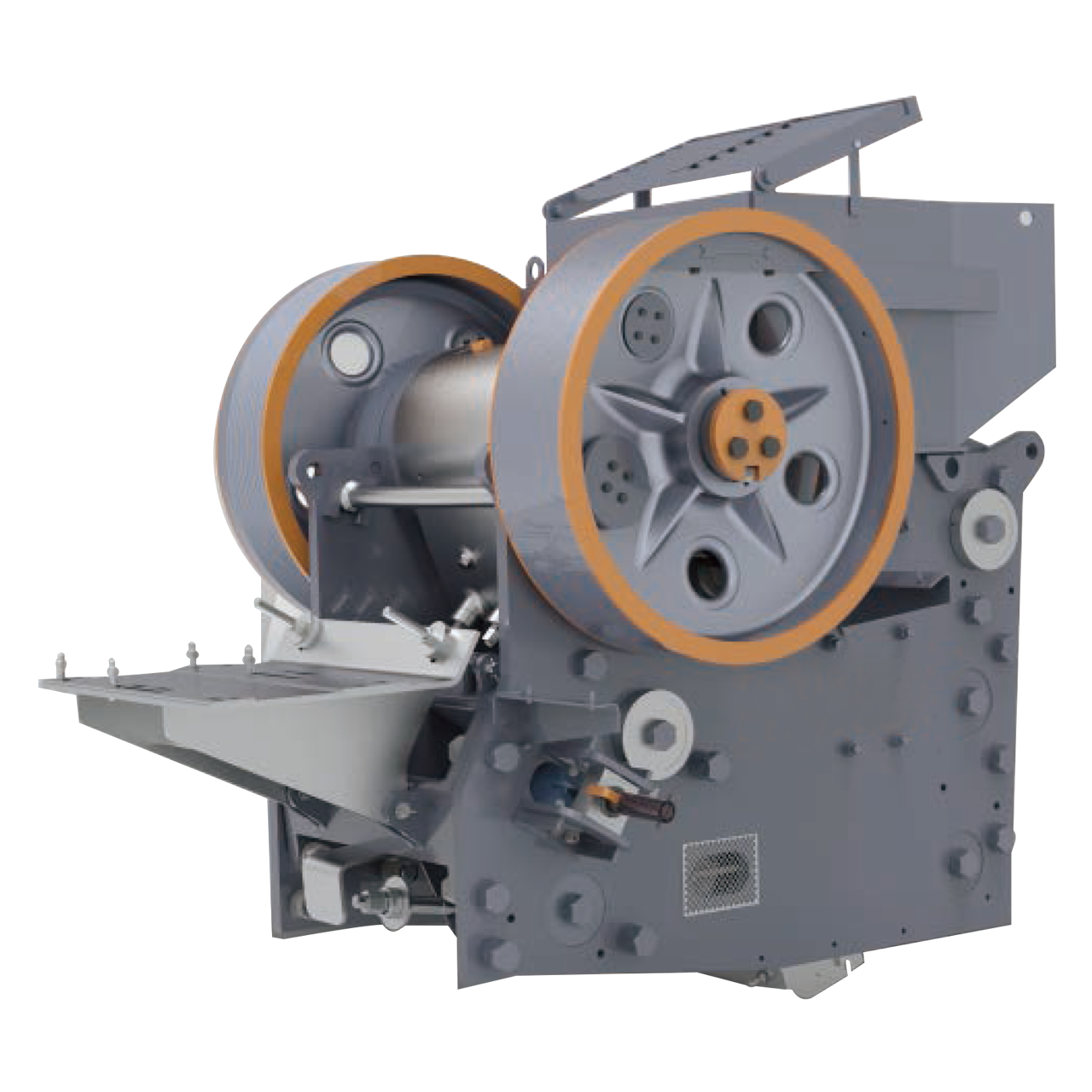

ME80 ME series jaw crusher

Manufacturer : MORETEC

Part number : ME80

OEM Compatibility :

Category :Crusher / Jaw crusher

Description

Description

MORETEC is a professional manufacturer and service provider of mine crushing and screening equipment.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. Customers are all over the world, and the Moretec has carried out all-round cooperation with many well-known state-owned enterprises and private enterprises in terms of spare parts agency sales, equipment transformation, technology, etc.

ME series jaw crusher

MORETEC ME series jaw crusher is mainly suitable for coarse crushing in mining and aggregate industry. When used in conjunction with MORETEC MVF series lattice feeder, the processing capacity of coarse crushing is 60-1500 t/h, which can meet the needs of medium and small crushing. Most of them are medium and large coarse pieces.

ME · characteristics

The welding-free frame structure design is adopted to improve the service life.

High quality cast steel moving jaw, cast iron flywheel, forged heavy eccentric shaft and international famous brand bearing assembly.

The integrated motor base design makes the overall equipment more compact, higher space utilization and more convenient installation.

The crusher does not need anchor bolts to install the foundation, which reduces the requirements for the foundation.

Equipped with a double-block hydraulic adjustment system, mechanical or hydraulic wedge type can be selected without manual gasket.

Note: Capacity is only an approximation of crusher performance. The corresponding conditions are open-circuit crushing and dry blasting granite, the bulk density of the material is 1600kg/m3, and its maximum particle size meets the maximum feed particle size allowed by the crusher. The minimum tight side discharge port for normal operation of the crusher depends on the particle size distribution of the feed, the crushability (Wi) of the material, the impurity content of the feed, the type of jaw plate installed and the type of raw material. Materials.

MORETEC products cover various types and models of crushing and screening mining equipment, including gyratory crushers, jaw crushers, cone crushers, impact crushers and vibrating screens, feeders, sand making machines, etc. The rich product line can fully meet the medium and fine crushing and sand making of coarse, metal and non-metal mines, aggregates, cement and engineering construction.

MORETEC is also a professional exporter of crushing and screening equipment and spare parts. MORETEC products have been exported to more than 50 countries and regions around the world. MORETEC has become the designated supplier of many world-class mining companies and cement groups in China. Customers are all over the world, and the Moretec has carried out all-round cooperation with many well-known state-owned enterprises and private enterprises in terms of spare parts agency sales, equipment transformation, technology, etc.

ME series jaw crusher

MORETEC ME series jaw crusher is mainly suitable for coarse crushing in mining and aggregate industry. When used in conjunction with MORETEC MVF series lattice feeder, the processing capacity of coarse crushing is 60-1500 t/h, which can meet the needs of medium and small crushing. Most of them are medium and large coarse pieces.

ME · characteristics

The welding-free frame structure design is adopted to improve the service life.

High quality cast steel moving jaw, cast iron flywheel, forged heavy eccentric shaft and international famous brand bearing assembly.

The integrated motor base design makes the overall equipment more compact, higher space utilization and more convenient installation.

The crusher does not need anchor bolts to install the foundation, which reduces the requirements for the foundation.

Equipped with a double-block hydraulic adjustment system, mechanical or hydraulic wedge type can be selected without manual gasket.

Note: Capacity is only an approximation of crusher performance. The corresponding conditions are open-circuit crushing and dry blasting granite, the bulk density of the material is 1600kg/m3, and its maximum particle size meets the maximum feed particle size allowed by the crusher. The minimum tight side discharge port for normal operation of the crusher depends on the particle size distribution of the feed, the crushability (Wi) of the material, the impurity content of the feed, the type of jaw plate installed and the type of raw material. Materials.

| Minimum Capacity | 60 t/h |

| Crusher weight | 9.5 ton |

| Crusher power | 75 kW |

| Discharge opening adjustment range | 40-175mm |

| Feeding size | 800*510mm |

| Maximum Capacity | 375 t/h |

Parts List