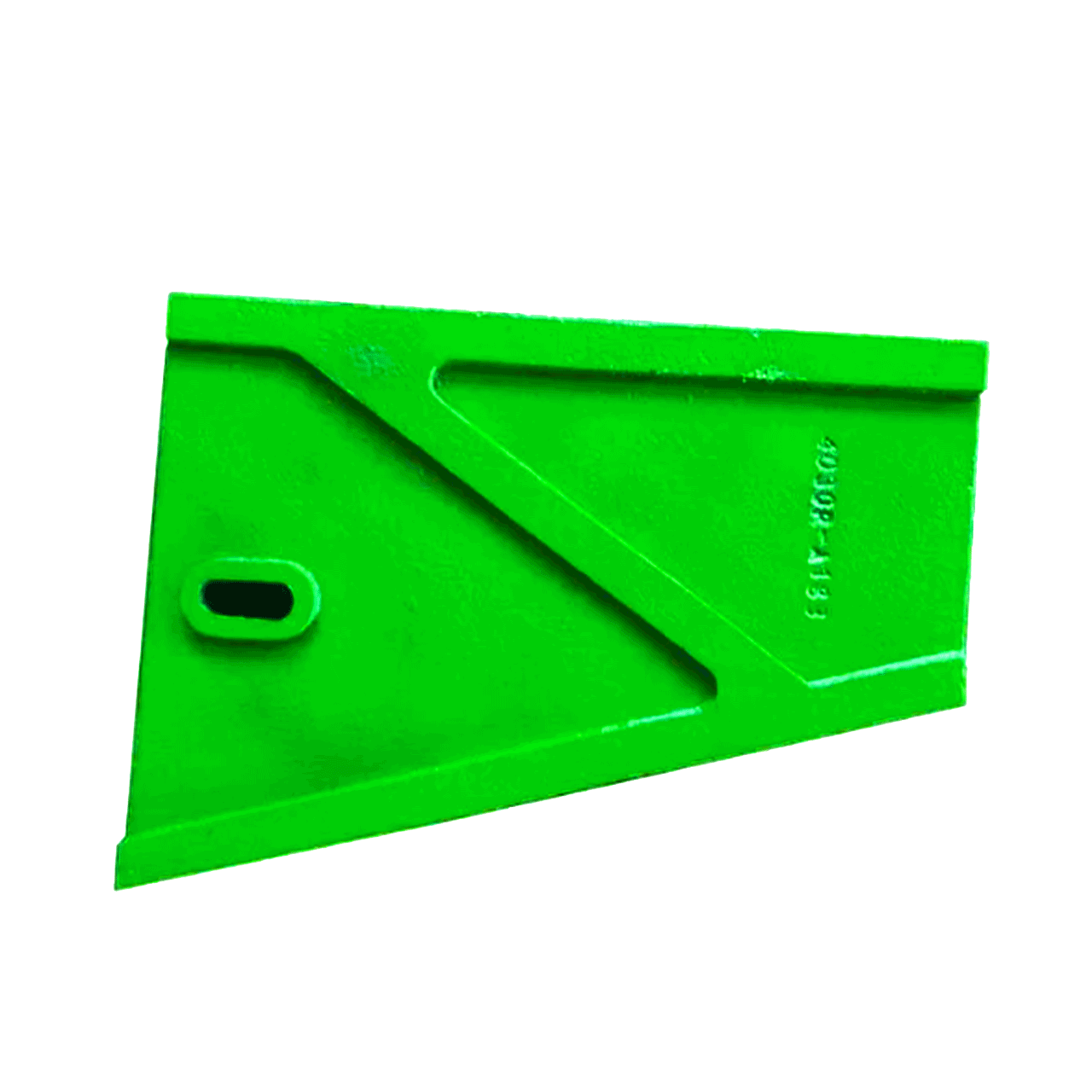

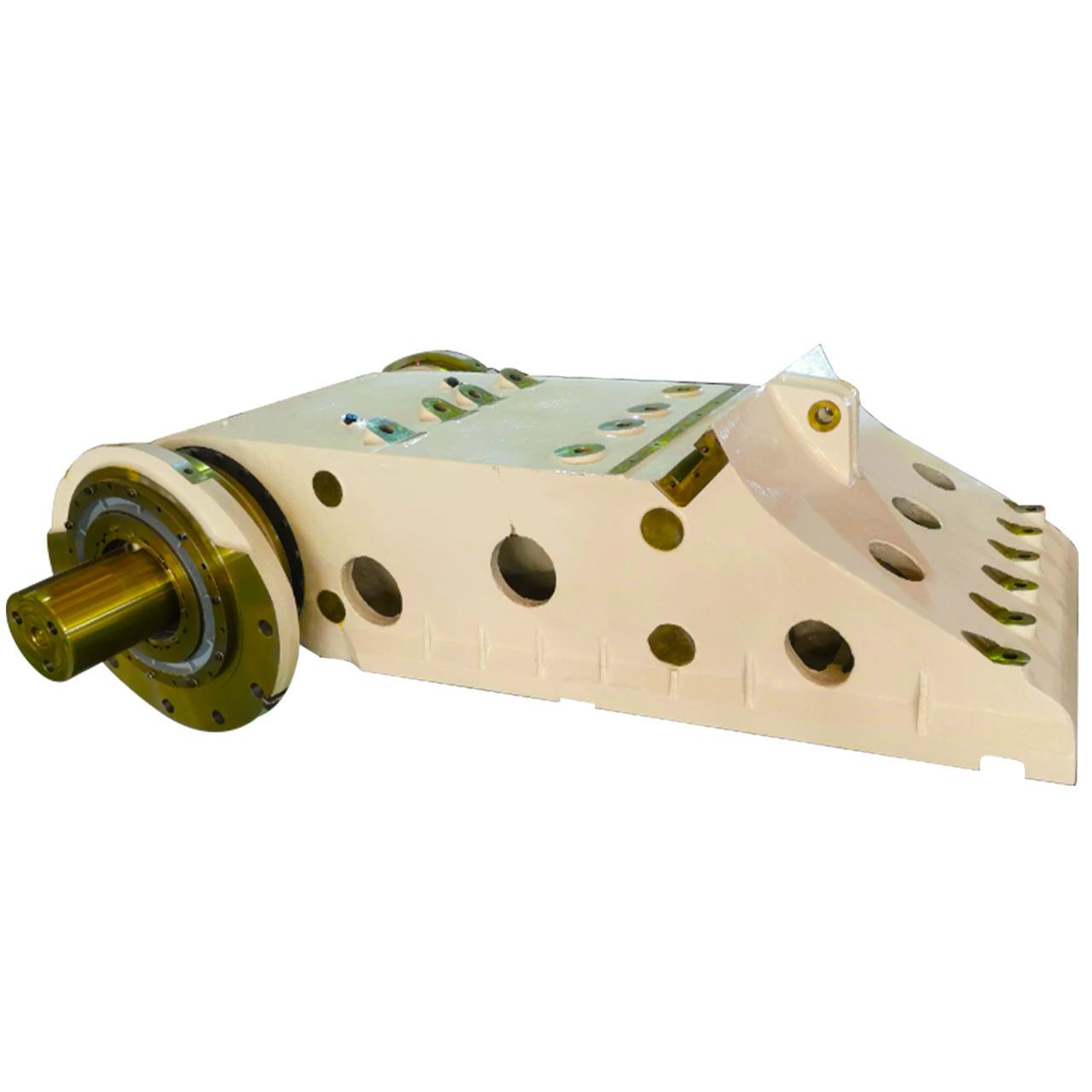

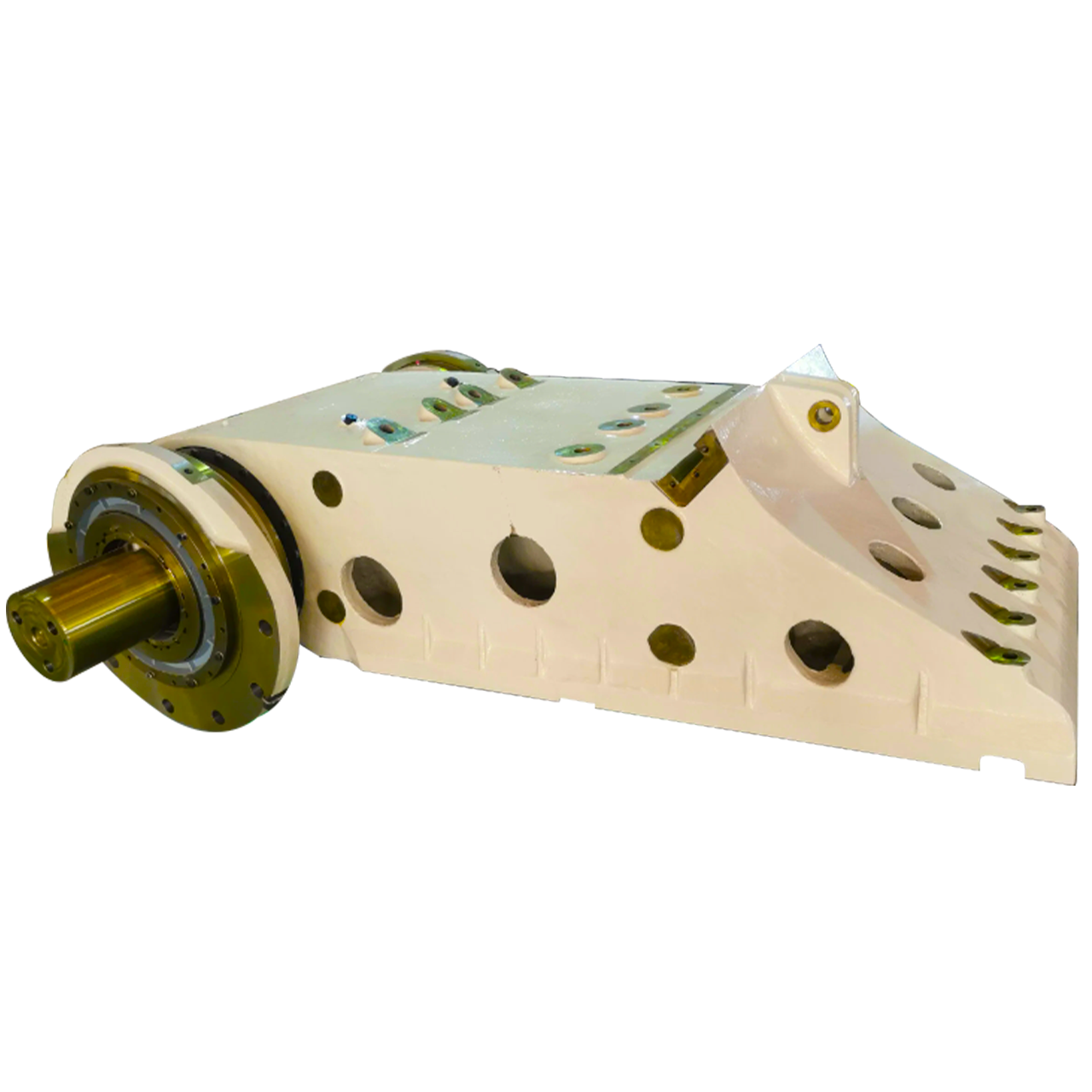

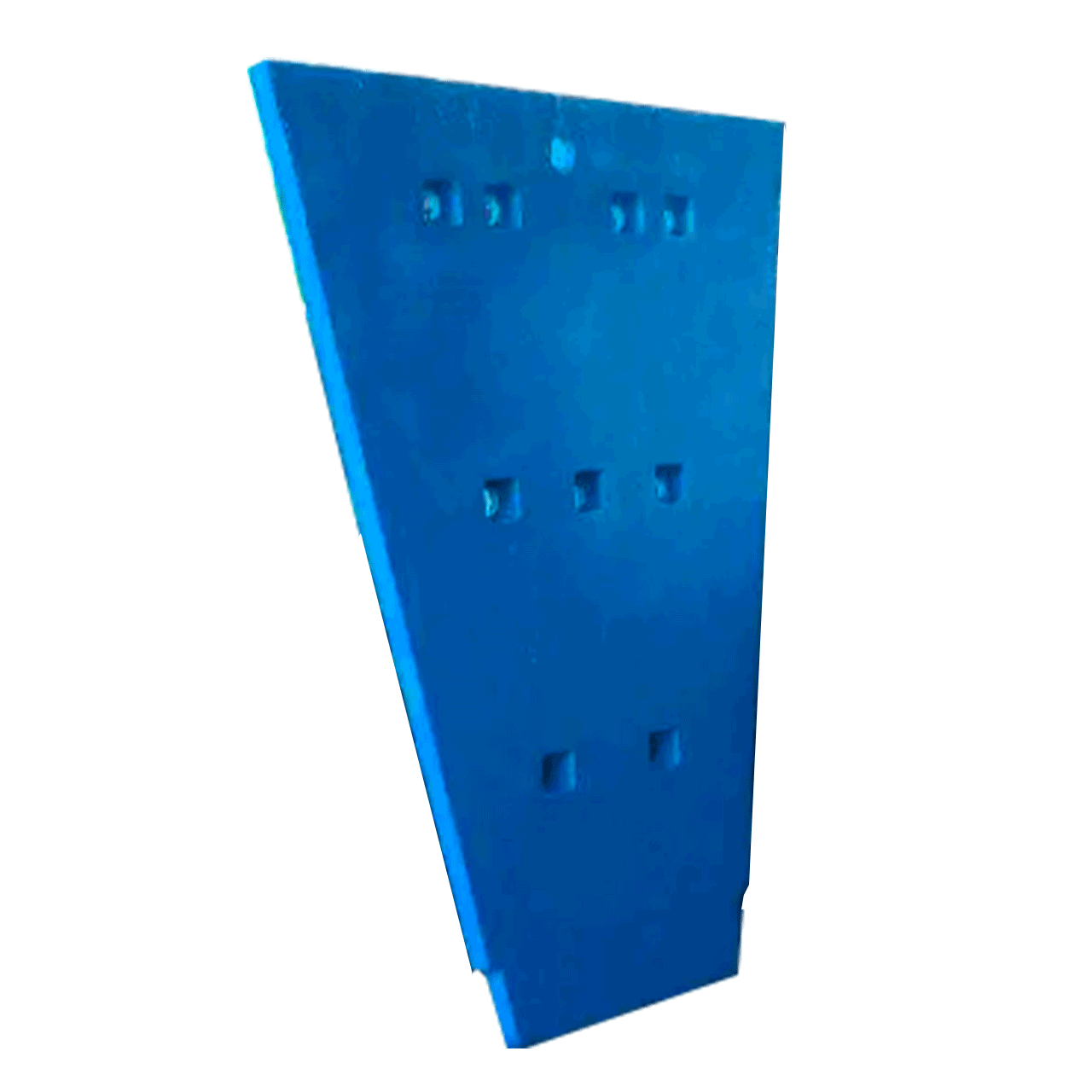

Toggle Plates

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

The toggle plate of the jaw crusher belongs to cast iron. Main materials: medium manganese steel (Mn8), high manganese steel (Mn13-2, Mn13-3, Mn13Gr2), ductile iron. It is suitable for granite, limestone, marble, river pebbles, various ores, construction waste, and crushed materials. The highest compressive strength is 320MPa. It is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries, etc., and is mostly used for primary crushing.

Effect:

· One is to transmit power to support the swing of the lower part of the movable jaw.

· The second is to play an insurance role. When unbreakable materials fall into the crusher and the machine exceeds the normal load, the toggle plate will be broken immediately, and the crusher will stop working, thereby protecting the movable jaw bearing, frame and other valuable parts from damage, and protecting the whole machine.

· The third is to adjust the size of the discharge port. Some simple pendulum jaw crushers adjust the size of the discharge opening through toggle plates of different lengths and sizes.

Moretec's crusher wearing parts provide you with:

· Custom configurations ensure consistent production;

· Durable manganese steel increases crusher uptime;

· Reduce equipment wear and tear;;

· Extensive stock of patterns (covering all major makes and models), as well as;

· All patterns produced by paper, ensure fast delivery and perfect match with the shredder;

· Based on our more than 15 years experience in this field, we can make adjustments according to special requirements.

· Perfect management, covering your whole procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm order), delivery (clear photos and test reports are ready for customer confirmation) , After-sales (after-sales inspection after the shipment arrives at the job site, size matching, service life inspection, etc.). Make every purchase question-free);

· Abundant production capacity: about 10,000 tons per year to ensure the supply capacity to customers.

Effect:

· One is to transmit power to support the swing of the lower part of the movable jaw.

· The second is to play an insurance role. When unbreakable materials fall into the crusher and the machine exceeds the normal load, the toggle plate will be broken immediately, and the crusher will stop working, thereby protecting the movable jaw bearing, frame and other valuable parts from damage, and protecting the whole machine.

· The third is to adjust the size of the discharge port. Some simple pendulum jaw crushers adjust the size of the discharge opening through toggle plates of different lengths and sizes.

Moretec's crusher wearing parts provide you with:

· Custom configurations ensure consistent production;

· Durable manganese steel increases crusher uptime;

· Reduce equipment wear and tear;;

· Extensive stock of patterns (covering all major makes and models), as well as;

· All patterns produced by paper, ensure fast delivery and perfect match with the shredder;

· Based on our more than 15 years experience in this field, we can make adjustments according to special requirements.

· Perfect management, covering your whole procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm order), delivery (clear photos and test reports are ready for customer confirmation) , After-sales (after-sales inspection after the shipment arrives at the job site, size matching, service life inspection, etc.). Make every purchase question-free);

· Abundant production capacity: about 10,000 tons per year to ensure the supply capacity to customers.

Parts List