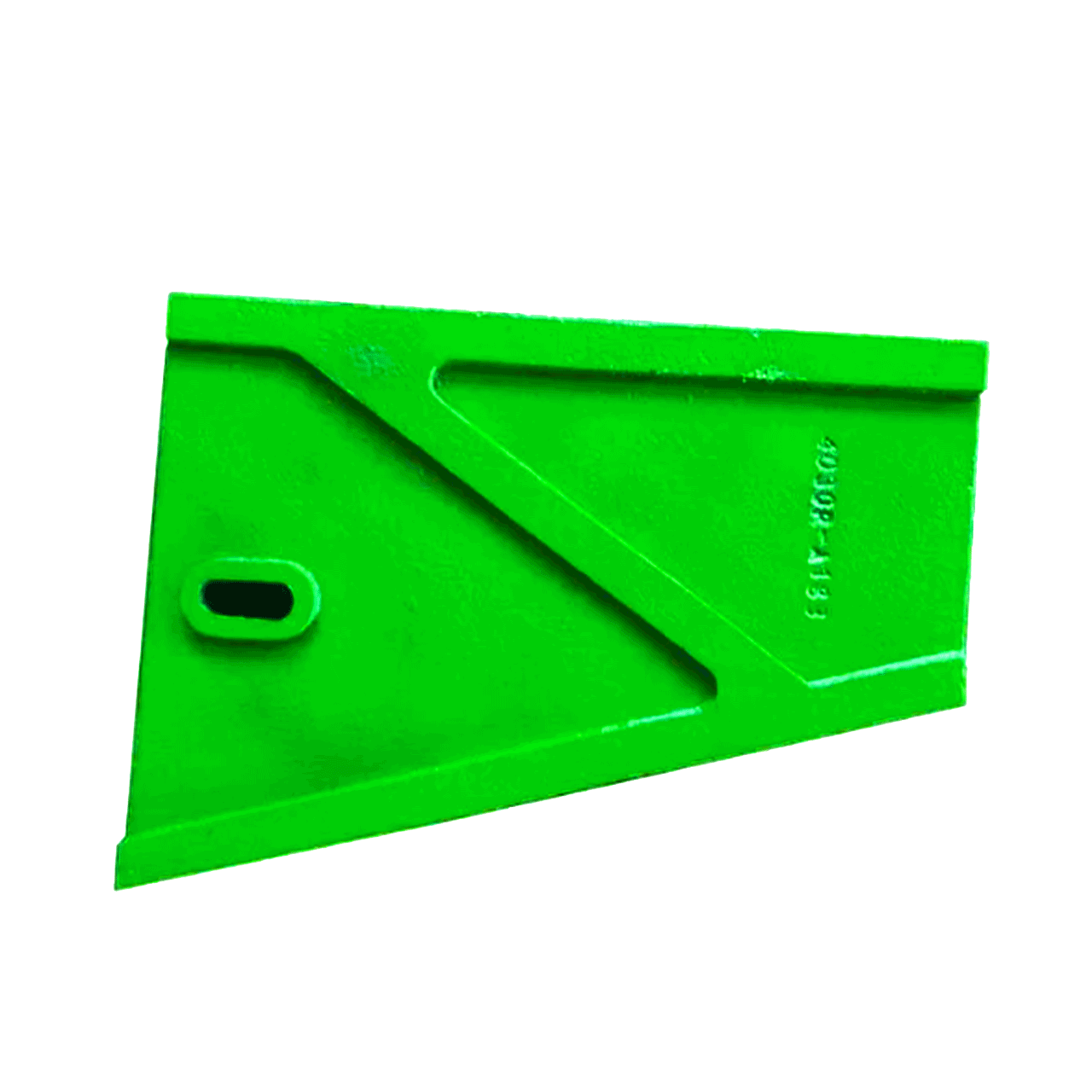

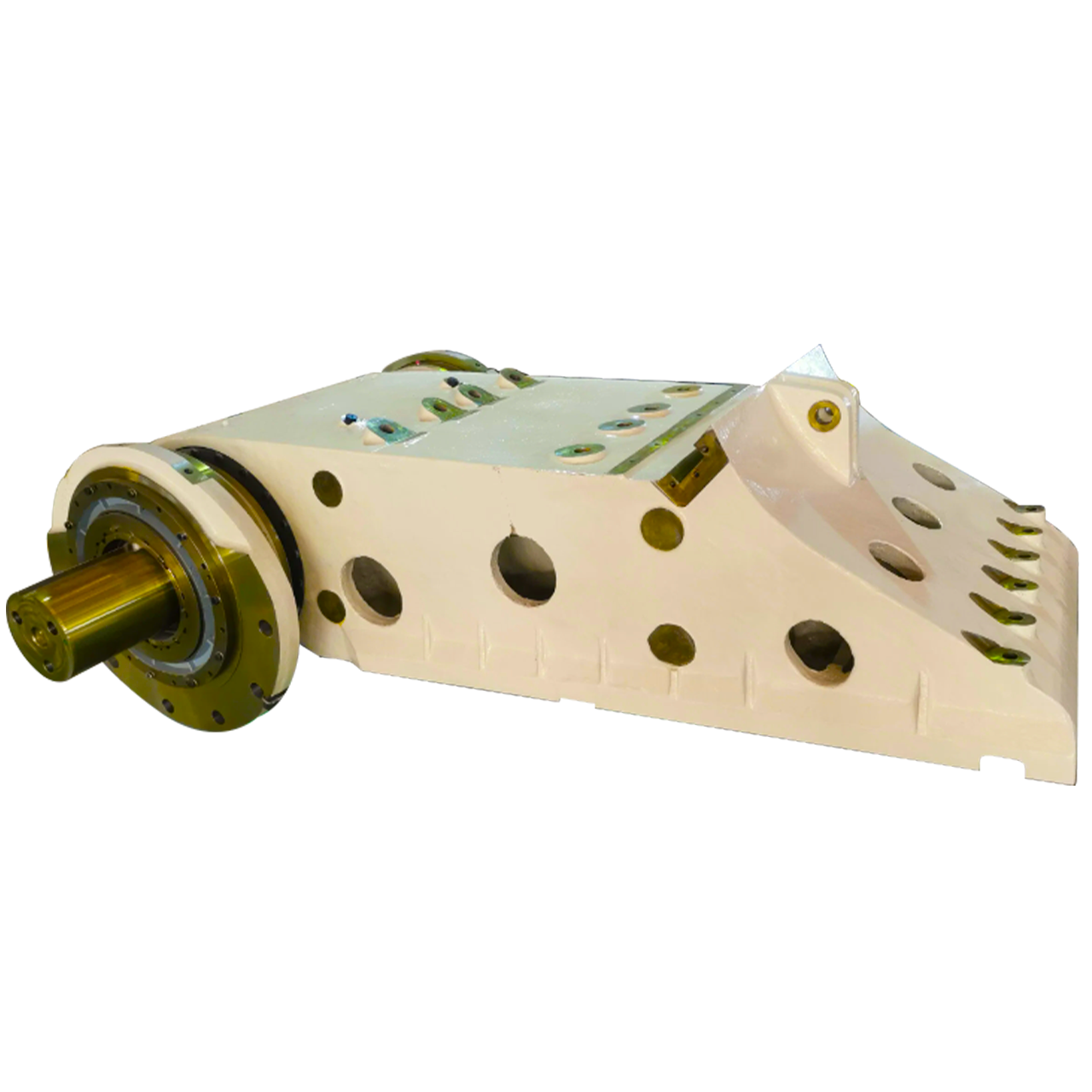

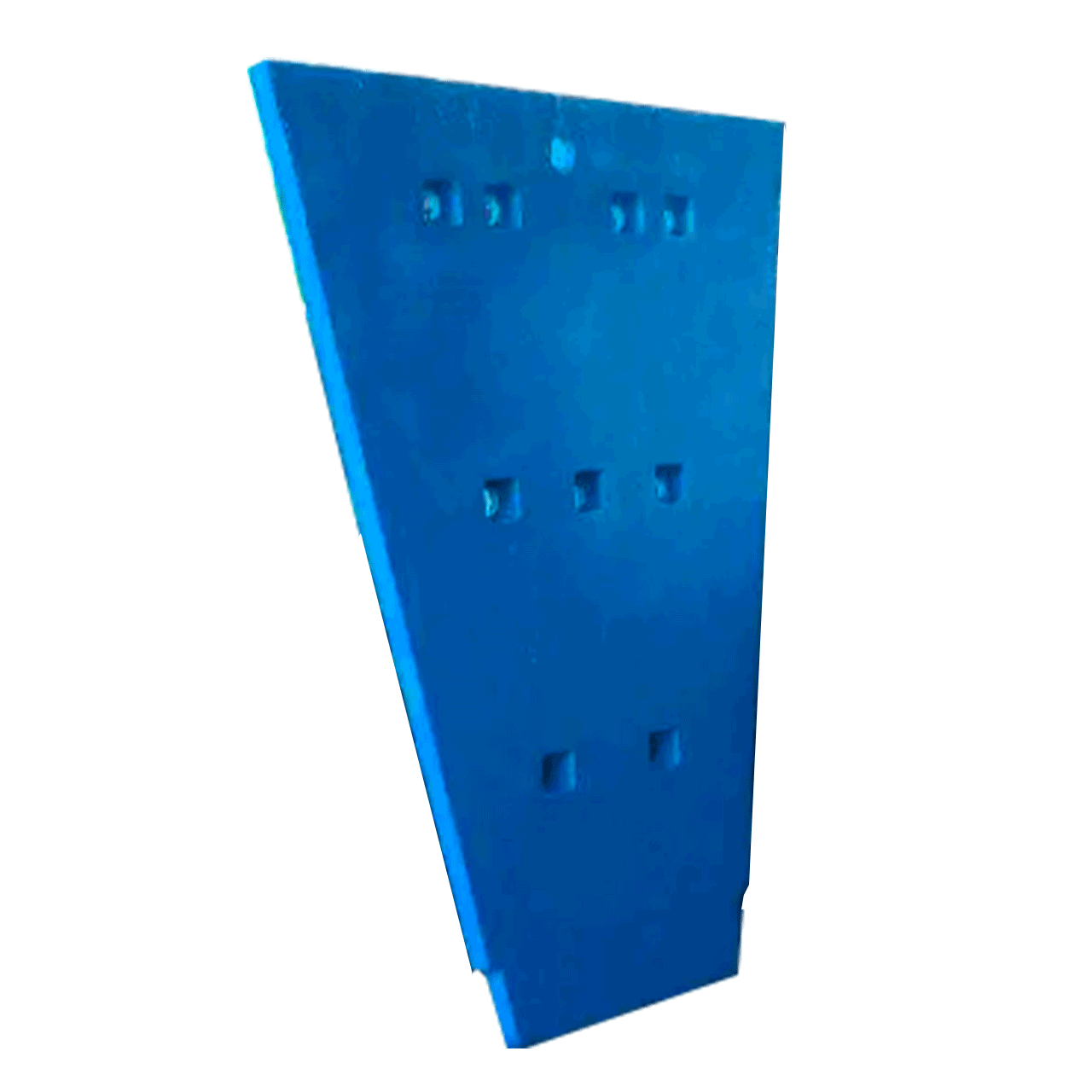

Jaw Crusher Thrust Plate

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

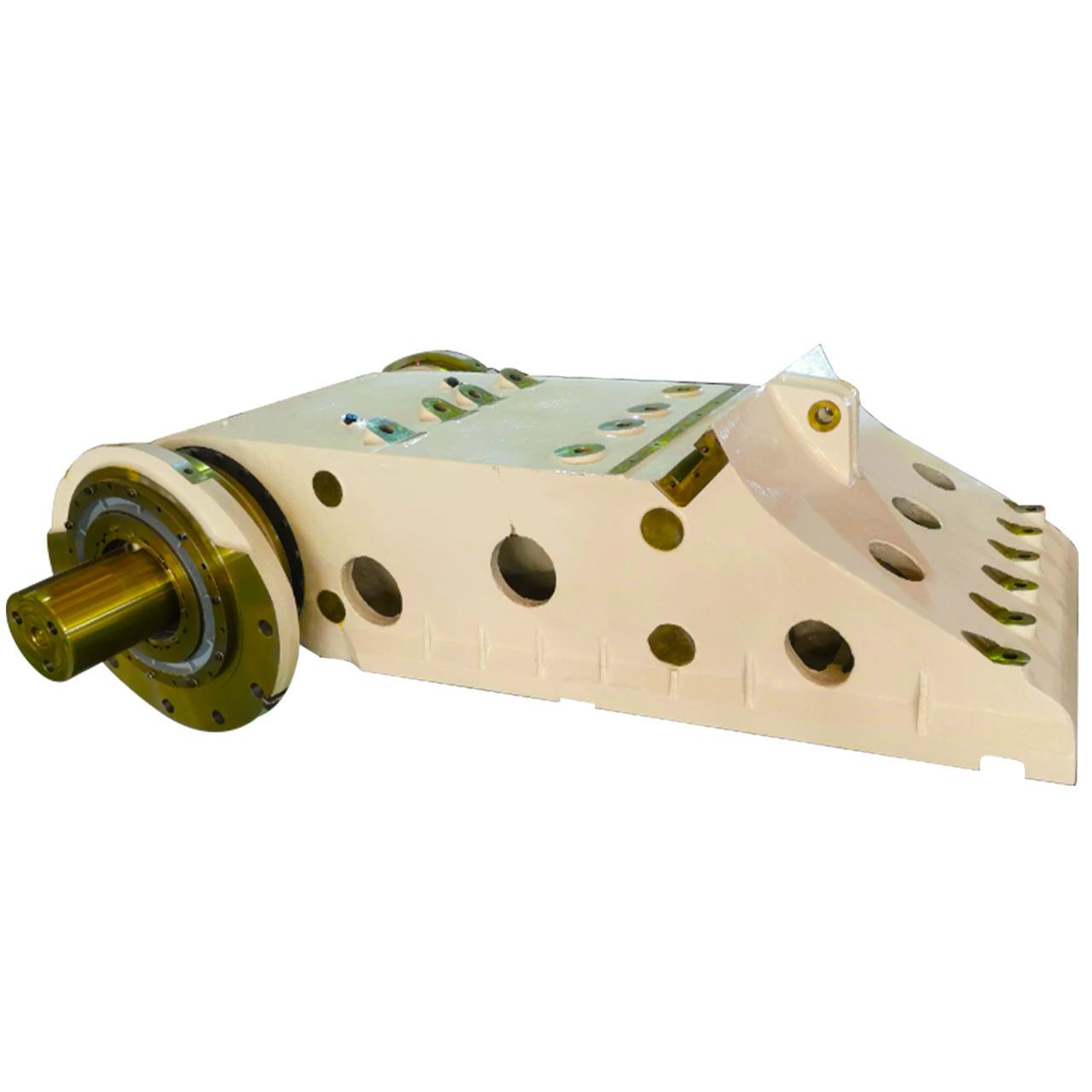

The working principle of the jaw crusher is to crush the materials falling into the crushing chamber by continuously approaching the movable jaw to the fixed jaw. When driving the movable jaw to operate, the thrust plate structure plays an important role. , is the main transmission part of the jaw crusher, and at the same time affects the size of the discharge opening of the jaw crusher. Long-term use will cause the thrust plate to wear to varying degrees. When the wear is serious, it must be replaced to ensure the smooth progress of production.

Effect:

1. Power transmission

The thrust plate is the part that transmits power to the mobile jaw of the crusher. In the jaw crusher, it plays the role of supporting the movable jaw plate, and transmits the crushing force to the rear wall of the frame.

2. Adjust the discharge port

The size of the discharge port of the crusher can be adjusted by replacing the thrust plates of different sizes.

3. Act as a safety device

The thrust plate is the safety device in the whole machine. When feeding, when falling into too hard hard-to-break material blocks or unbreakable metal blocks and other sundries, the thrust plate will break by itself to protect other parts from damage.

Replace

1. During the crushing production process of the jaw crusher, if the thrust plate is severely worn or broken, the ore in the jaw crusher should be cleaned first.

2. Then, take out the worn or broken thrust plate from the jaw crusher, and check whether the toggle plate on the movable jaw and connecting rod is damaged.

3. Pull the movable jaw to the vicinity of the fixed jaw, lubricate the working surface of the toggle plate with dry oil and replace it with a new thrust plate.

4. After the thrust plate is in contact with the working surface of the toggle plate slowly, tighten the horizontal tie rod so that the movable jaw clamps the thrust plate and tighten the safety cover.

5. Then connect the thrust plate of the jaw crusher to the lubrication system to ensure that the lubrication system is normal.

6. Finally, adjust the size of the discharge opening according to the needs of users.

Moretec's crusher wearing parts provide you with:

· Custom configurations ensure consistent production;

· Durable manganese steel increases crusher uptime;

· Reduce equipment wear and tear;

· Extensive stock of patterns (covering all major makes and models), as well as based on original drawings only;

All patterns produced by paper, ensure fast delivery and perfect match with the shredder;

Effect:

1. Power transmission

The thrust plate is the part that transmits power to the mobile jaw of the crusher. In the jaw crusher, it plays the role of supporting the movable jaw plate, and transmits the crushing force to the rear wall of the frame.

2. Adjust the discharge port

The size of the discharge port of the crusher can be adjusted by replacing the thrust plates of different sizes.

3. Act as a safety device

The thrust plate is the safety device in the whole machine. When feeding, when falling into too hard hard-to-break material blocks or unbreakable metal blocks and other sundries, the thrust plate will break by itself to protect other parts from damage.

Replace

1. During the crushing production process of the jaw crusher, if the thrust plate is severely worn or broken, the ore in the jaw crusher should be cleaned first.

2. Then, take out the worn or broken thrust plate from the jaw crusher, and check whether the toggle plate on the movable jaw and connecting rod is damaged.

3. Pull the movable jaw to the vicinity of the fixed jaw, lubricate the working surface of the toggle plate with dry oil and replace it with a new thrust plate.

4. After the thrust plate is in contact with the working surface of the toggle plate slowly, tighten the horizontal tie rod so that the movable jaw clamps the thrust plate and tighten the safety cover.

5. Then connect the thrust plate of the jaw crusher to the lubrication system to ensure that the lubrication system is normal.

6. Finally, adjust the size of the discharge opening according to the needs of users.

Moretec's crusher wearing parts provide you with:

· Custom configurations ensure consistent production;

· Durable manganese steel increases crusher uptime;

· Reduce equipment wear and tear;

· Extensive stock of patterns (covering all major makes and models), as well as based on original drawings only;

All patterns produced by paper, ensure fast delivery and perfect match with the shredder;

Parts List