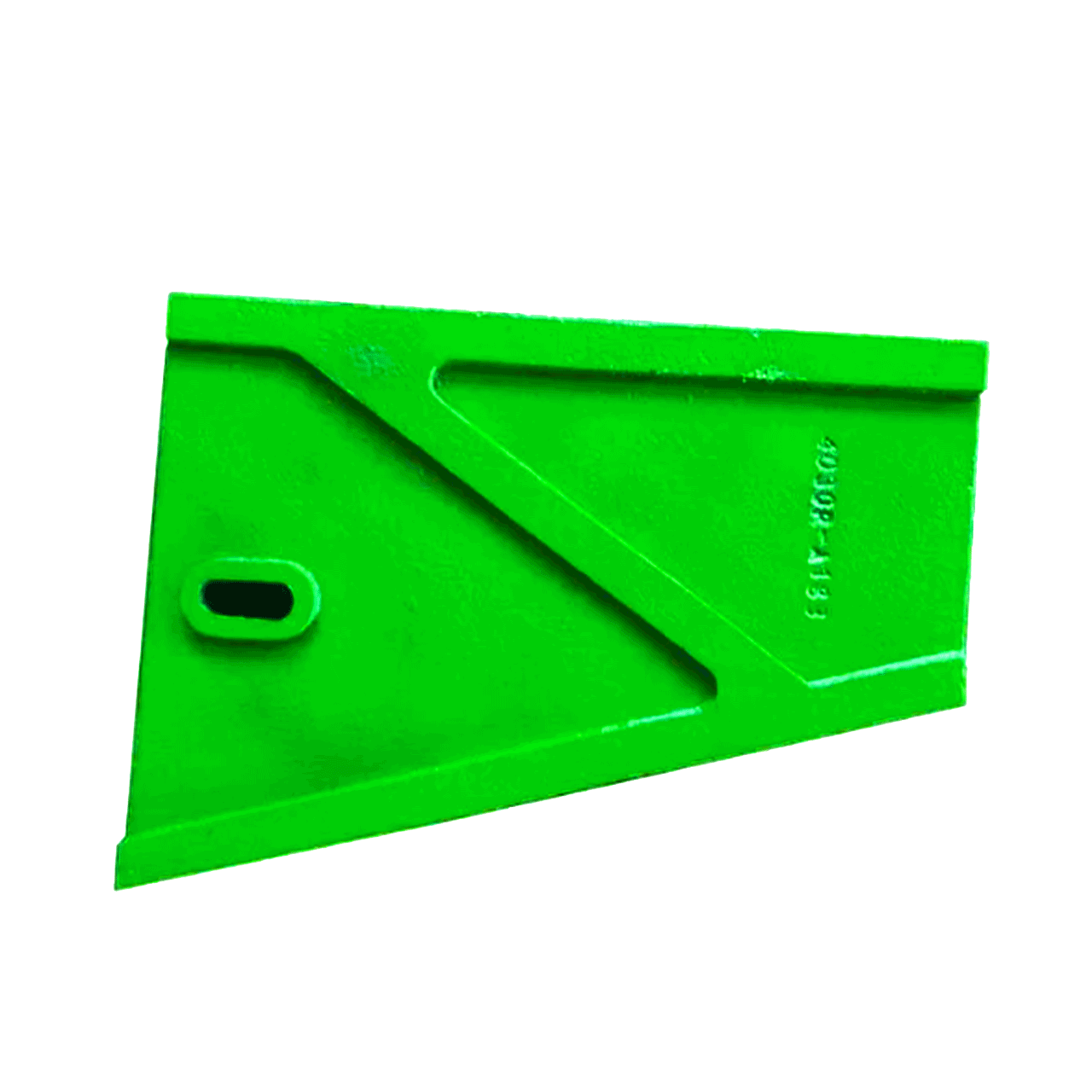

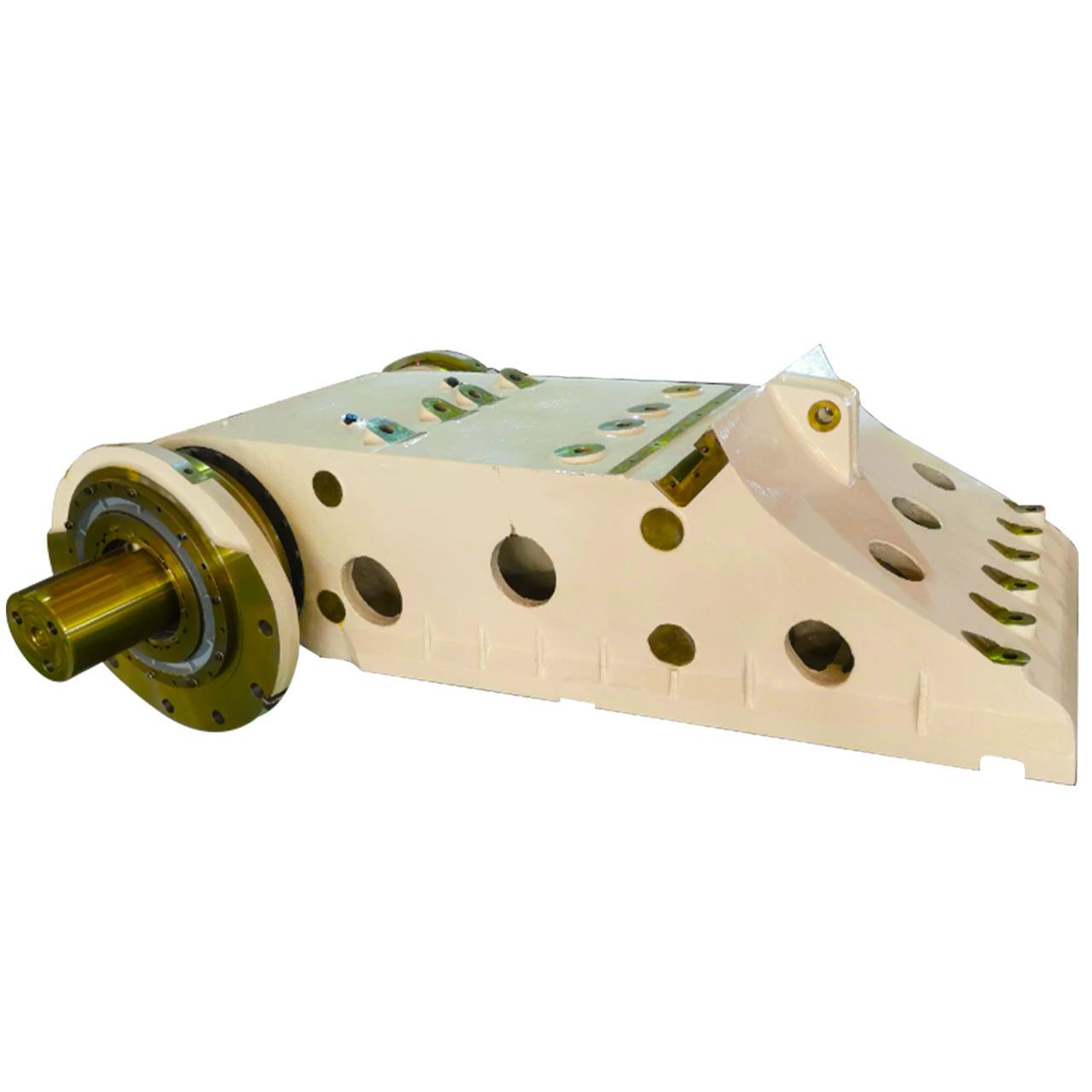

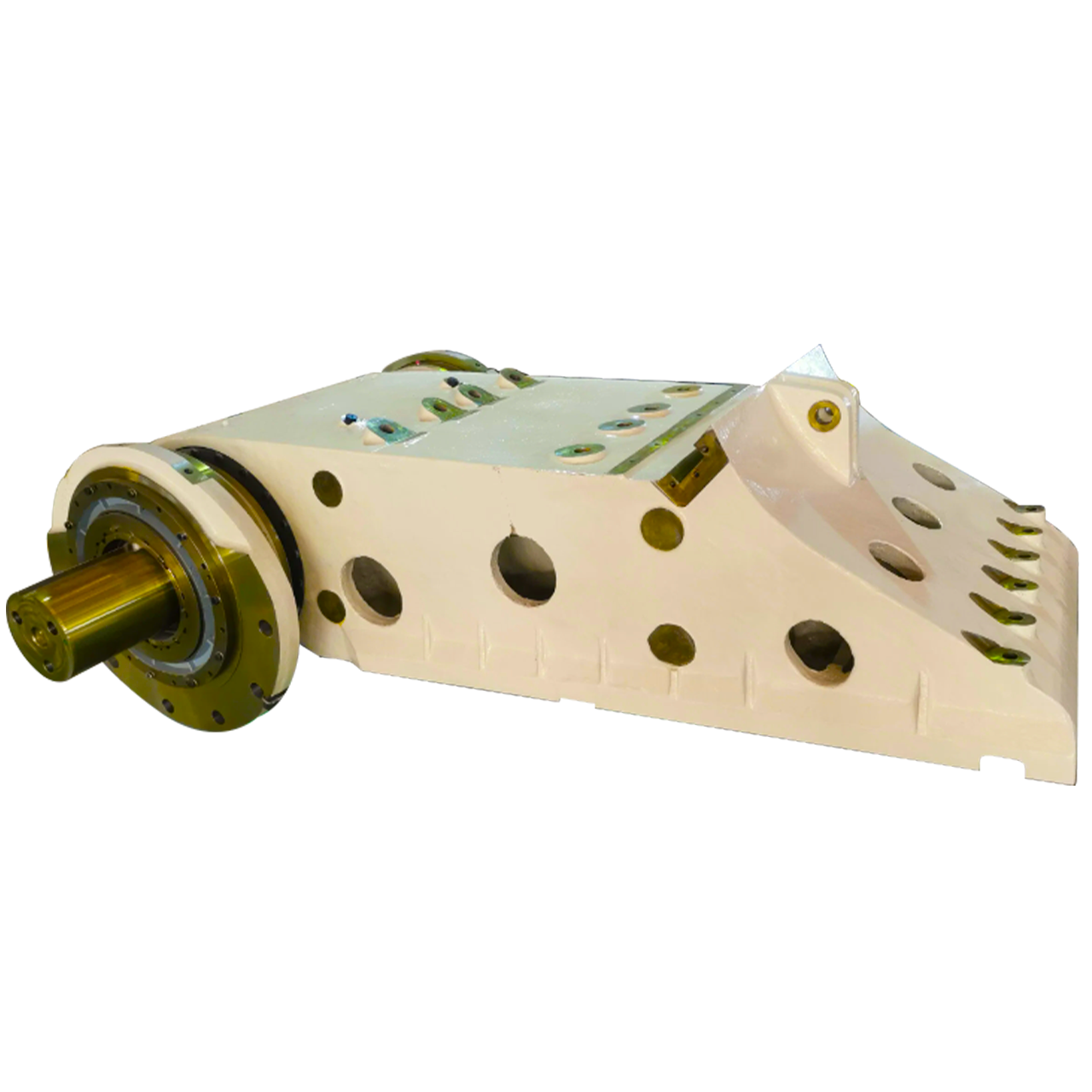

Crushing Jaw Crusher Spare Parts C200 Pitman Assy

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

What is Pitman in Jaw Crusher?

The connecting rod is the main moving part of the jaw crusher and forms the moving side of the jaw plate.

The connecting rod of the jaw crusher has two support points to support it in the body of the jaw crusher. The upper support part of the connecting rod is composed of a flywheel and an eccentric shaft. The lower support consists of a toggle plate, an elbow seat and a pull rod.

The connecting rod realizes movement through the rotation of the eccentric shaft, so that the jaw plate fixed on it crushes the material, just like the jaw chews food.

The connecting rod is the main part of the jaw crusher and constitutes the moving part of the crusher. Its function is to connect the fixed jaw and the mobile jaw. The connecting rod is responsible for transmitting the movement of the eccentric shaft to the remaining parts of the crusher, such as the toggle plate and the swing jaw.

The connecting rod is usually made of cast steel or cast iron and is installed on an eccentric shaft, which is supported by bearings on both sides. The connecting rod rotates with the rotation of the eccentric shaft, causing the connecting rod to move up and down in a reciprocating motion. This movement is then transferred to the remaining parts of the crusher, resulting in the crushing of the material.

The design of the connecting rod is an important factor affecting the efficiency and performance of the jaw crusher. A well-designed connecting rod will have a smaller mass and a longer stroke, which will result in higher crushing force and better use of the power of the crusher.

In addition to the function of transmitting the eccentric shaft movement, the connecting rod also plays a key role in the safety of the jaw crusher. Many connecting rod designs include safety features to prevent the crusher from jamming or overloading, which may damage the crusher and may cause operator injury.

In short, the connecting rod is the key component of the jaw crusher and constitutes the moving part of the crusher. It is responsible for transmitting the movement of the eccentric shaft to the rest of the crusher, and plays a key role in the efficiency and safety of the crusher.

Our crusher wear parts are designed and manufactured to provide maximum durability and performance. We use only the highest quality materials and the latest manufacturing techniques to ensure that our products meet the highest standards. Our commitment to quality is reflected in all aspects of our business, from the selection of raw materials to the finished product.

We provide various crusher wear parts, including jaw plates, jaw connecting rods, plate hammers, crushing walls, concave surfaces, etc. All our products are designed to meet the specific requirements of our customers, and we are committed to providing the best solution for their needs.

Moretec crusher wearing parts provide you:

Custom configuration ensures consistent production

Durable manganese steel increases the uptime of the crusher

Reduce equipment wear

The abundant inventory of patterns (covering all major brands and models), as well as all patterns produced only according to the original drawings, ensure fast delivery and a perfect match with the crusher.

Based on our more than 15 years of experience in this field, we can adjust it according to special requirements.

Perfect management, covering your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm the order), delivery (clear photos and test reports are ready for customer confirmation), After-sales (after-sales inspection, size matching, service life inspection, etc. after the goods arrive at the work site). Make sure there is no doubt about each purchase)

Abundant production capacity: about 10000 tons per year to ensure the supply capacity to customers.

The connecting rod is the main moving part of the jaw crusher and forms the moving side of the jaw plate.

The connecting rod of the jaw crusher has two support points to support it in the body of the jaw crusher. The upper support part of the connecting rod is composed of a flywheel and an eccentric shaft. The lower support consists of a toggle plate, an elbow seat and a pull rod.

The connecting rod realizes movement through the rotation of the eccentric shaft, so that the jaw plate fixed on it crushes the material, just like the jaw chews food.

The connecting rod is the main part of the jaw crusher and constitutes the moving part of the crusher. Its function is to connect the fixed jaw and the mobile jaw. The connecting rod is responsible for transmitting the movement of the eccentric shaft to the remaining parts of the crusher, such as the toggle plate and the swing jaw.

The connecting rod is usually made of cast steel or cast iron and is installed on an eccentric shaft, which is supported by bearings on both sides. The connecting rod rotates with the rotation of the eccentric shaft, causing the connecting rod to move up and down in a reciprocating motion. This movement is then transferred to the remaining parts of the crusher, resulting in the crushing of the material.

The design of the connecting rod is an important factor affecting the efficiency and performance of the jaw crusher. A well-designed connecting rod will have a smaller mass and a longer stroke, which will result in higher crushing force and better use of the power of the crusher.

In addition to the function of transmitting the eccentric shaft movement, the connecting rod also plays a key role in the safety of the jaw crusher. Many connecting rod designs include safety features to prevent the crusher from jamming or overloading, which may damage the crusher and may cause operator injury.

In short, the connecting rod is the key component of the jaw crusher and constitutes the moving part of the crusher. It is responsible for transmitting the movement of the eccentric shaft to the rest of the crusher, and plays a key role in the efficiency and safety of the crusher.

Our crusher wear parts are designed and manufactured to provide maximum durability and performance. We use only the highest quality materials and the latest manufacturing techniques to ensure that our products meet the highest standards. Our commitment to quality is reflected in all aspects of our business, from the selection of raw materials to the finished product.

We provide various crusher wear parts, including jaw plates, jaw connecting rods, plate hammers, crushing walls, concave surfaces, etc. All our products are designed to meet the specific requirements of our customers, and we are committed to providing the best solution for their needs.

Moretec crusher wearing parts provide you:

Custom configuration ensures consistent production

Durable manganese steel increases the uptime of the crusher

Reduce equipment wear

The abundant inventory of patterns (covering all major brands and models), as well as all patterns produced only according to the original drawings, ensure fast delivery and a perfect match with the crusher.

Based on our more than 15 years of experience in this field, we can adjust it according to special requirements.

Perfect management, covering your entire procurement process: pre-sales (technical consultant, drawing number confirmation, etc.), sales (confirm all necessary information, confirm the order), delivery (clear photos and test reports are ready for customer confirmation), After-sales (after-sales inspection, size matching, service life inspection, etc. after the goods arrive at the work site). Make sure there is no doubt about each purchase)

Abundant production capacity: about 10000 tons per year to ensure the supply capacity to customers.

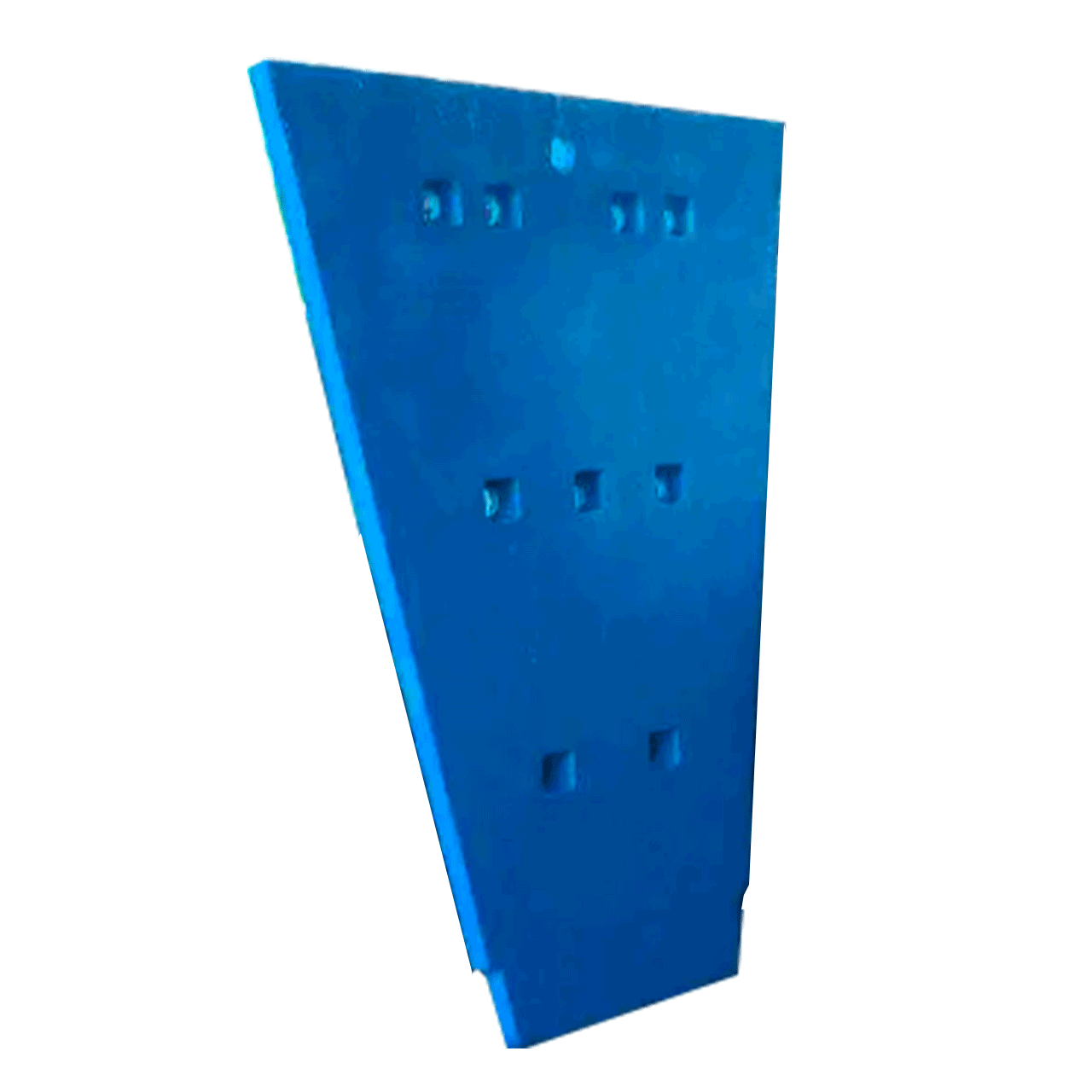

Parts List