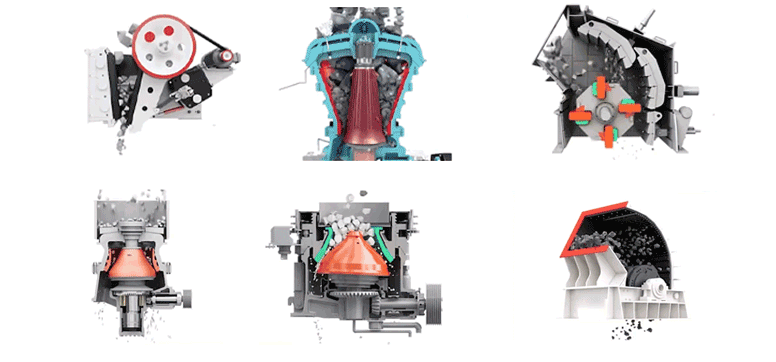

Internal structure and working principle of jaw crusher

Internal structure: mainly composed of static jaw plate, movable jaw plate, frame, upper and lower protective plates, adjustment seat, movable jaw pull rod, and other parts.

Working principle: The jaw crusher mainly relies on bending and squeezing pressure for crushing. The electric motor drives the belt and pulley, causing the movable jaw to swing up and down. When the movable jaw rises, the angle between the bracket and the movable jaw increases, and the movable jaw advances towards the fixed jaw, causing the material to be crushed or chopped; When the moving jaw moves downwards, the angle between the elbow plate and the moving jaw decreases. The moving jaw plate leaves the static jaw plate under the action of the pull rod and spring, and materials that have previously been crushed or split are discharged from the lower discharge port of the jaw plate.

Internal structure and working principle of impact crusher

Internal structure: mainly composed of frame, feed hopper, plate hammer, impact plate, discharge device, motor, transmission device, and other parts.

Working principle: The impact crusher mainly relies on impact energy for crushing. After the material enters the machine body, it collides with the plate hammer on the high-speed rotating rotor. After being hit and broken head-on by the plate hammer, it is driven by inertia to throw away a section of the impact plate and break again. Then, the process is repeated multiple times from the impact plate to the plate hammer, and from the plate hammer to the impact plate.

Internal structure and working principle of cone crusher

Internal structure: mainly including frame, horizontal shaft, moving cone, balance wheel, eccentric sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), hydraulic coupling, lubrication system, hydraulic system, etc.

Working principle: The cone crusher mainly uses the principle of lamination for operation. The rotation of the electric motor is driven by the belt pulley to rotate the transmission shaft. The transmission shaft drives the eccentric sleeve to rotate around the main shaft through large and small bevel gears, and the eccentric sleeve drives the moving cone to rotate and swing, causing the cone crushing wall to approach and leave the surface of the mortar wall fixed on the adjustment sleeve. The material is continuously impacted, squeezed, and bent in the crushing chamber to achieve crushing.

Internal structure and working principle of hammer crusher

Internal structure: mainly composed of casing, rotor, spindle, hammer head, lining plate, grate bar, adjustment frame, and coupling.

Working principle: Driven by an electric motor, the crusher rotor rotates at high speed. After the material enters the crusher, it is immediately impacted by the hammer head. The crushed material uses the force of the hammer head to move towards the baffle inside the frame, and the grate bar is impacted and subjected to secondary crushing. At the same time, the materials collide with each other and are crushed multiple times. Materials smaller than the grate bar gap are discharged from the gap, while larger materials continue to be impacted by the hammer head in the crushing chamber until they are crushed and discharged through the grate bar gap.