MLMZ1236 Linear Dewatering Vibrating Screen

Manufacturer : MORETEC

Part number : MLMZ1236

OEM Compatibility :

Category :Screening / Vibrating Screen

Description

Description

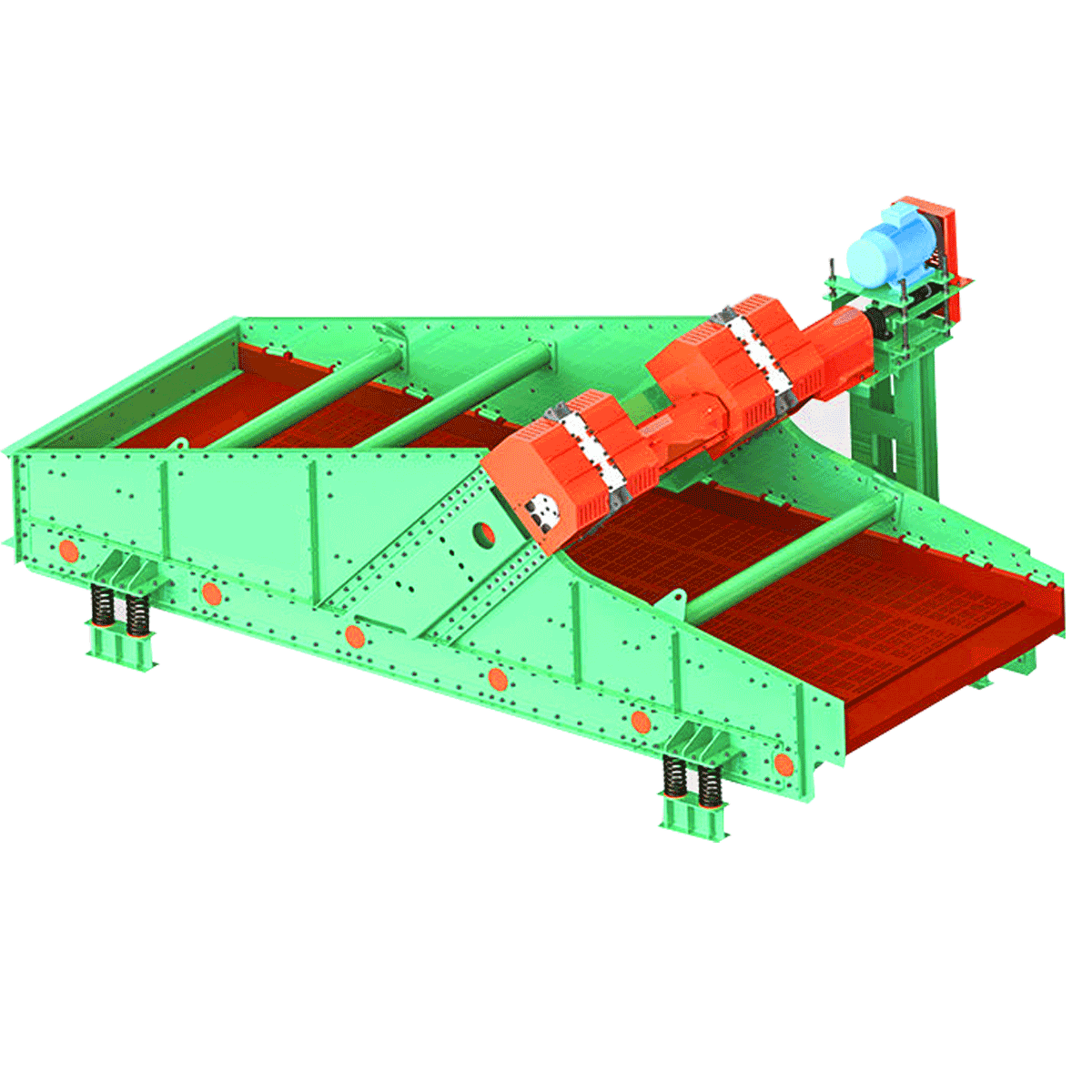

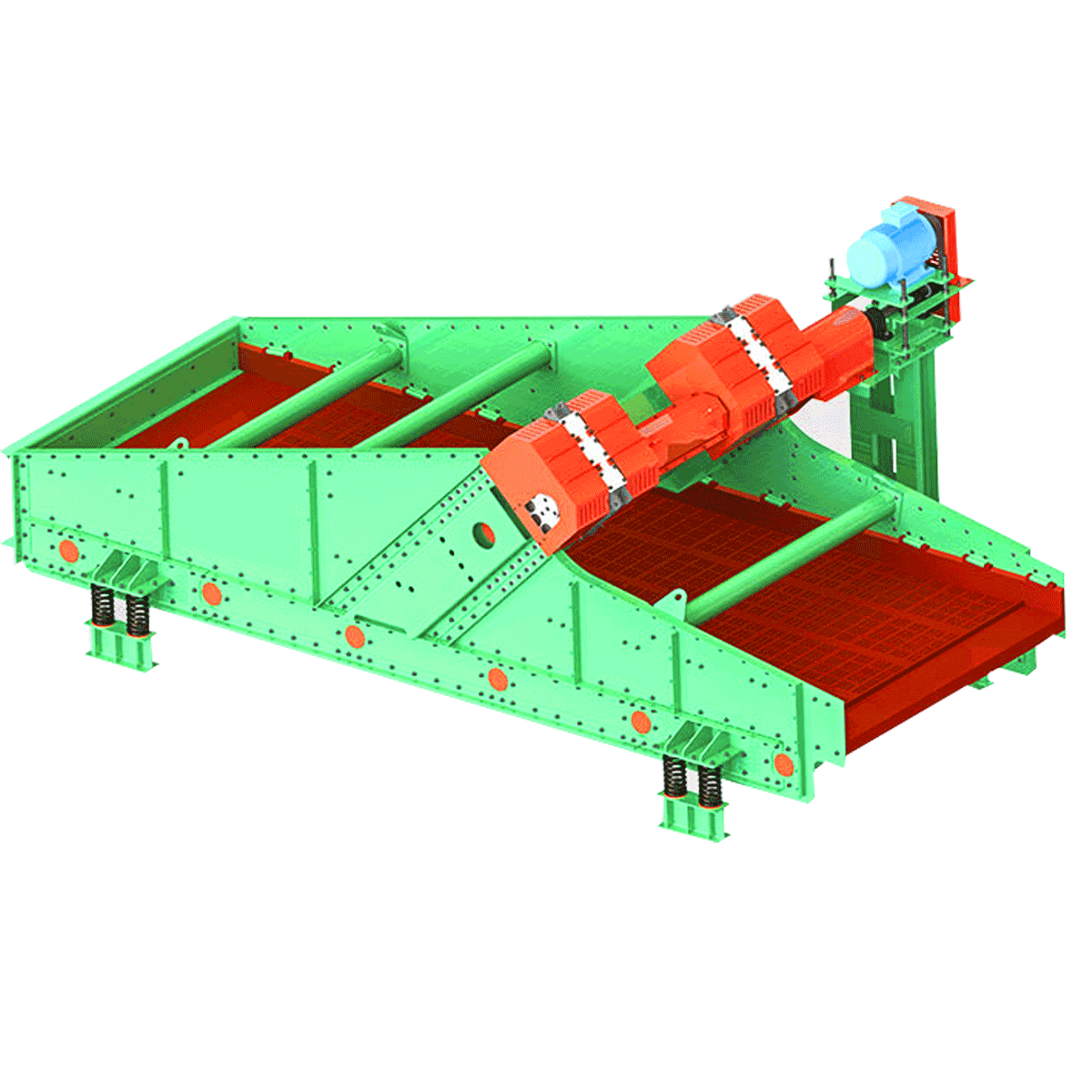

Linear Dewatering Vibrating Screen

Linear Dewatering Vibrating Screen is widely used in mineral processing, coal processing, building materials, metallurgy and chemical industry. In the mineral processing industry, it is commonly used in the desliming, dewatering, demeshing and tailings dry discharge processing of iron ore, nonferrous metal ore, coal mine and other materials.

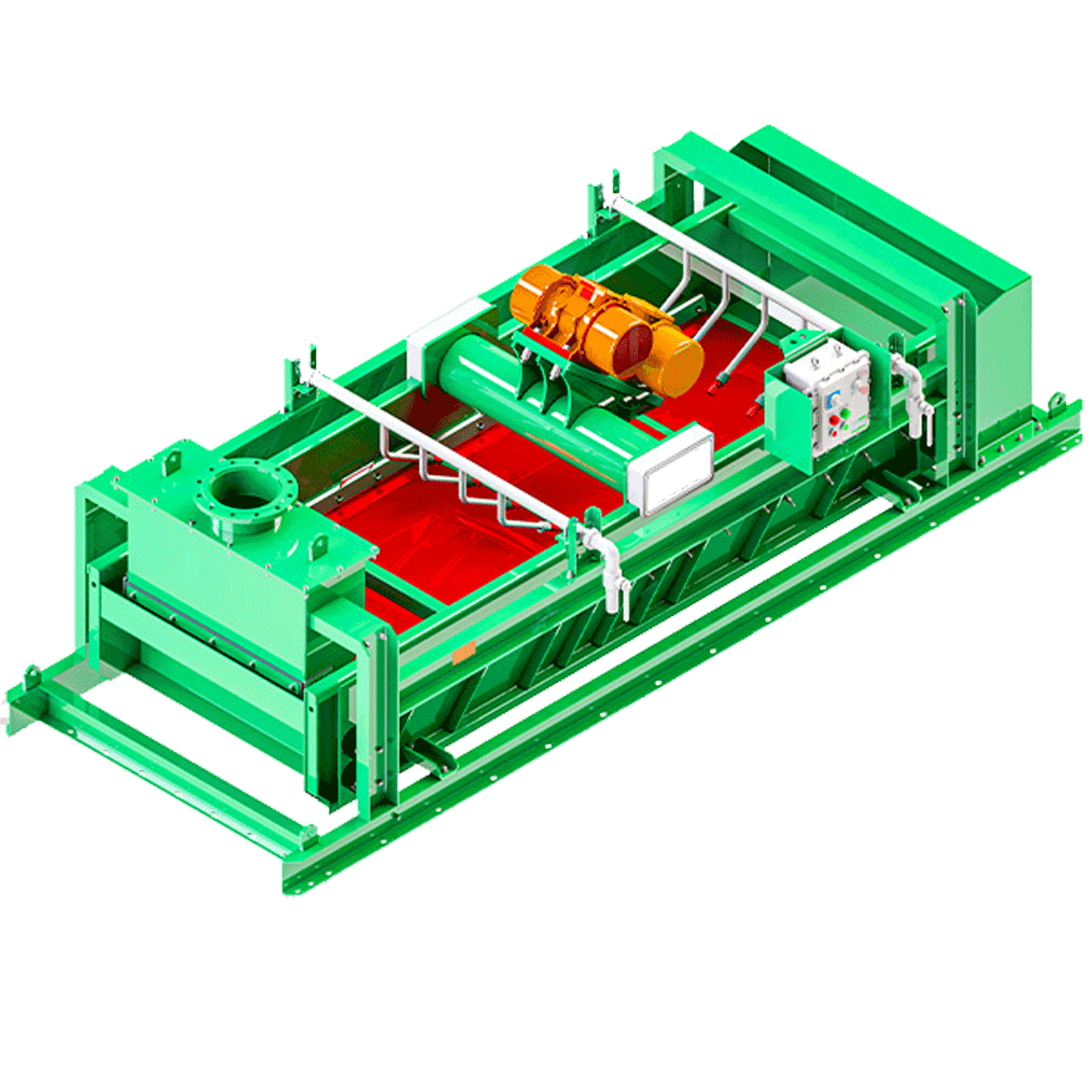

Linear Dewatering Vibrating Screen is widely used in mineral processing, coal processing, building materials, metallurgy and chemical industry. In the mineral processing industry, it is commonly used in the desliming, dewatering, demixing and tailings dry discharge processing of iron ore, nonferrous metal ore, coal mine and other materials. The equipment adopts advanced finite element analysis and anti-fatigue analysis and other design means to ensure that the sieve machine has a reasonable structure, low energy consumption and large capacity of dewatering and dry discharge. It can adapt to all kinds of corrosive and abrasive working conditions. Large handling capacity, high efficiency and stable performance. The size of the screen machine can also be customized according to customer requirements. Guanneng linear dewatering vibrating screen is installed with two vibrating motors, using the reverse self-synchronization principle to make the screen body do linear motion. The screen body drives the screen surface to vibrate synchronously, and the force is transmitted to the material on the screen, and the impact material is thrown up on the screen surface for solid-liquid separation and separation of coarse and fine granular materials. Materials continuously from the feed tank or cyclone directly into the material, through the screen surface for dewatering, de-media processing, screen, screen materials were discharged into the screen and screen receiving tank, into the next process. The direction of the excitation force and the horizontal angle can be designed according to the nature of the material at the customer's site, and this angle determines the running speed of the material on the screen surface and the handling capacity of the equipment.

Linear dewatering vibrating screen features:

The whole machine is installed at a positive inclination angle, and the installation angle is adjustable at 4 degrees, which is suitable for different process material requirements.

Folding surface design of the feeding end of the screen plate is more conducive to the dewatering process and prolong the service life of the screen plate.

Rubber damping spring design, with good damping, good damping effect, low noise, small resonance field, good resilience, stable mechanical properties, long service life, low cost and other advantages.

Wall panels without welding, plate selection more good impact toughness and cold bending steel plate, using imported HUCK rivets hydraulic tension assembly, this advanced design makes the wall panels have no welding residual stress and material defects, to avoid the fatigue strength of the wall panels due to the above defects caused by the reduction of the fatigue strength of the wall panels.

Through finite element analysis, the structural strength and vibration quality of the screen machine are optimized to a greater extent, reducing stress and extending the service life of the equipment.

The overflow parts and wearable parts are sprayed with polyurea by the imported spraying machine from the U.S.A., which is corrosion-resistant, scour-resistant and abrasion-resistant.

The post-welding heat treatment process of the main parts effectively eliminates welding stress.

Product serialization, to meet the production requirements of customers with different process conditions; polyurethane screen plate modularization, more versatile, more convenient replacement.

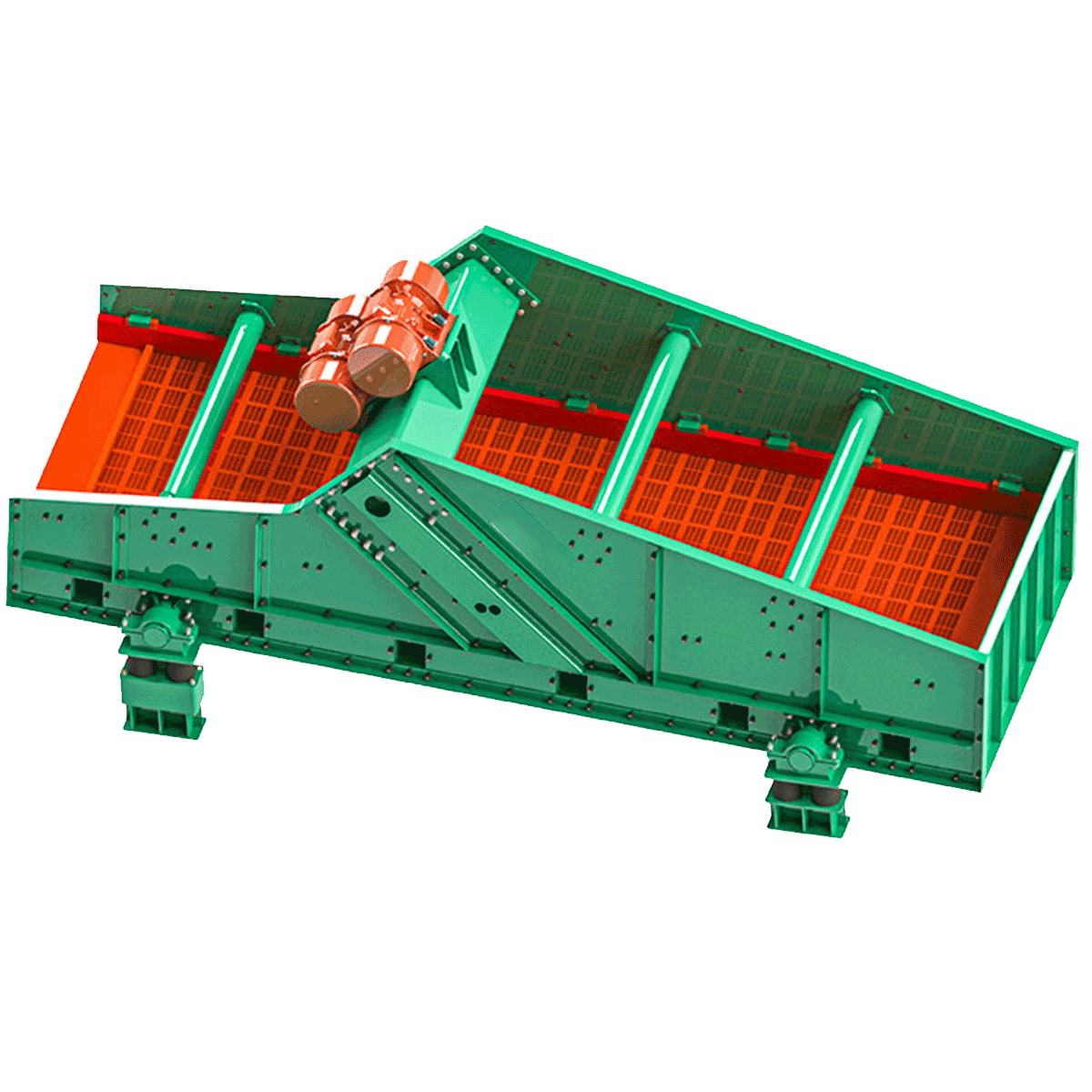

Linear Dewatering Vibrating Screen Screen Plate Installation Features

Polyurethane screen plate modular design, the screen plate can be arbitrarily switched between the position, optimize the utilization rate of the screen plate, to meet the customer's site conditions of use and the environment, but also can be tailored to meet the customer's special needs of the actual application.

Polyurethane sieve plate is made of three-component composite raw material casting at one time, which enhances the elasticity and abrasion resistance of the sieve plate. The excellent elasticity efficiently solves the hole plugging phenomenon and greatly improves the service life of the screen plate.

The sieve plate and the rail base adopt a convenient buckling structure, and the rail base is fixed by the specific profile of our company. The advantage of this structure is that it makes the installation and replacement of the sieve plate more convenient and quick under the state of ensuring sufficient connection strength, thus improving the working efficiency and reducing the labor intensity.

The modular design of the polyurethane screen panels allows the panels to be switched at will, which enhances the utilization rate of the panels and reduces the reserve of spare parts. The screen panels are embedded with sufficiently strong reinforcement to ensure the rigidity of the screen panels.

Linear Dewatering Vibrating Screen is widely used in mineral processing, coal processing, building materials, metallurgy and chemical industry. In the mineral processing industry, it is commonly used in the desliming, dewatering, demeshing and tailings dry discharge processing of iron ore, nonferrous metal ore, coal mine and other materials.

Linear Dewatering Vibrating Screen is widely used in mineral processing, coal processing, building materials, metallurgy and chemical industry. In the mineral processing industry, it is commonly used in the desliming, dewatering, demixing and tailings dry discharge processing of iron ore, nonferrous metal ore, coal mine and other materials. The equipment adopts advanced finite element analysis and anti-fatigue analysis and other design means to ensure that the sieve machine has a reasonable structure, low energy consumption and large capacity of dewatering and dry discharge. It can adapt to all kinds of corrosive and abrasive working conditions. Large handling capacity, high efficiency and stable performance. The size of the screen machine can also be customized according to customer requirements. Guanneng linear dewatering vibrating screen is installed with two vibrating motors, using the reverse self-synchronization principle to make the screen body do linear motion. The screen body drives the screen surface to vibrate synchronously, and the force is transmitted to the material on the screen, and the impact material is thrown up on the screen surface for solid-liquid separation and separation of coarse and fine granular materials. Materials continuously from the feed tank or cyclone directly into the material, through the screen surface for dewatering, de-media processing, screen, screen materials were discharged into the screen and screen receiving tank, into the next process. The direction of the excitation force and the horizontal angle can be designed according to the nature of the material at the customer's site, and this angle determines the running speed of the material on the screen surface and the handling capacity of the equipment.

Linear dewatering vibrating screen features:

The whole machine is installed at a positive inclination angle, and the installation angle is adjustable at 4 degrees, which is suitable for different process material requirements.

Folding surface design of the feeding end of the screen plate is more conducive to the dewatering process and prolong the service life of the screen plate.

Rubber damping spring design, with good damping, good damping effect, low noise, small resonance field, good resilience, stable mechanical properties, long service life, low cost and other advantages.

Wall panels without welding, plate selection more good impact toughness and cold bending steel plate, using imported HUCK rivets hydraulic tension assembly, this advanced design makes the wall panels have no welding residual stress and material defects, to avoid the fatigue strength of the wall panels due to the above defects caused by the reduction of the fatigue strength of the wall panels.

Through finite element analysis, the structural strength and vibration quality of the screen machine are optimized to a greater extent, reducing stress and extending the service life of the equipment.

The overflow parts and wearable parts are sprayed with polyurea by the imported spraying machine from the U.S.A., which is corrosion-resistant, scour-resistant and abrasion-resistant.

The post-welding heat treatment process of the main parts effectively eliminates welding stress.

Product serialization, to meet the production requirements of customers with different process conditions; polyurethane screen plate modularization, more versatile, more convenient replacement.

Linear Dewatering Vibrating Screen Screen Plate Installation Features

Polyurethane screen plate modular design, the screen plate can be arbitrarily switched between the position, optimize the utilization rate of the screen plate, to meet the customer's site conditions of use and the environment, but also can be tailored to meet the customer's special needs of the actual application.

Polyurethane sieve plate is made of three-component composite raw material casting at one time, which enhances the elasticity and abrasion resistance of the sieve plate. The excellent elasticity efficiently solves the hole plugging phenomenon and greatly improves the service life of the screen plate.

The sieve plate and the rail base adopt a convenient buckling structure, and the rail base is fixed by the specific profile of our company. The advantage of this structure is that it makes the installation and replacement of the sieve plate more convenient and quick under the state of ensuring sufficient connection strength, thus improving the working efficiency and reducing the labor intensity.

The modular design of the polyurethane screen panels allows the panels to be switched at will, which enhances the utilization rate of the panels and reduces the reserve of spare parts. The screen panels are embedded with sufficiently strong reinforcement to ensure the rigidity of the screen panels.

Parts List