Flip-flow screen

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Category :Screening / Vibrating Screen

Description

Description

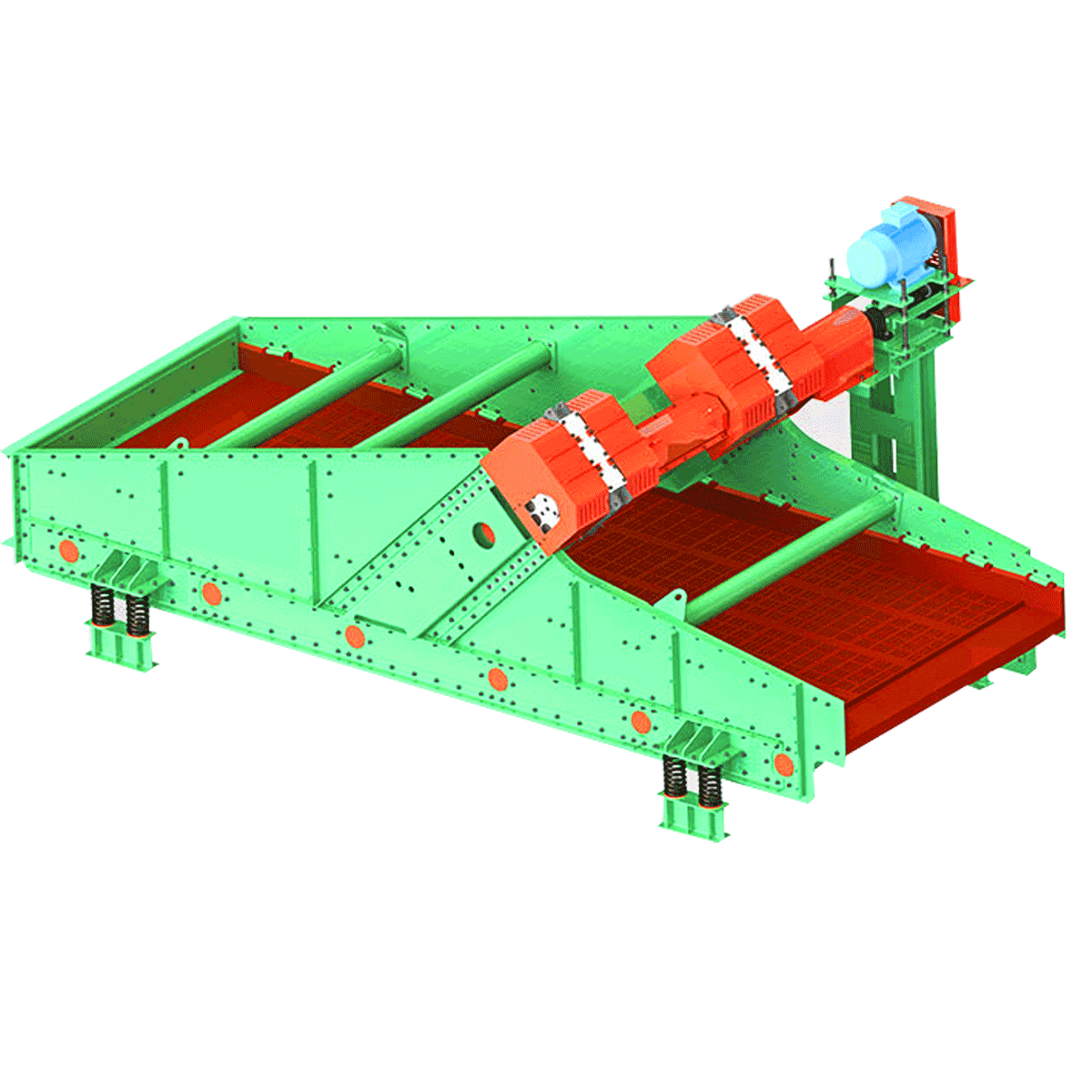

Flip-flow screen

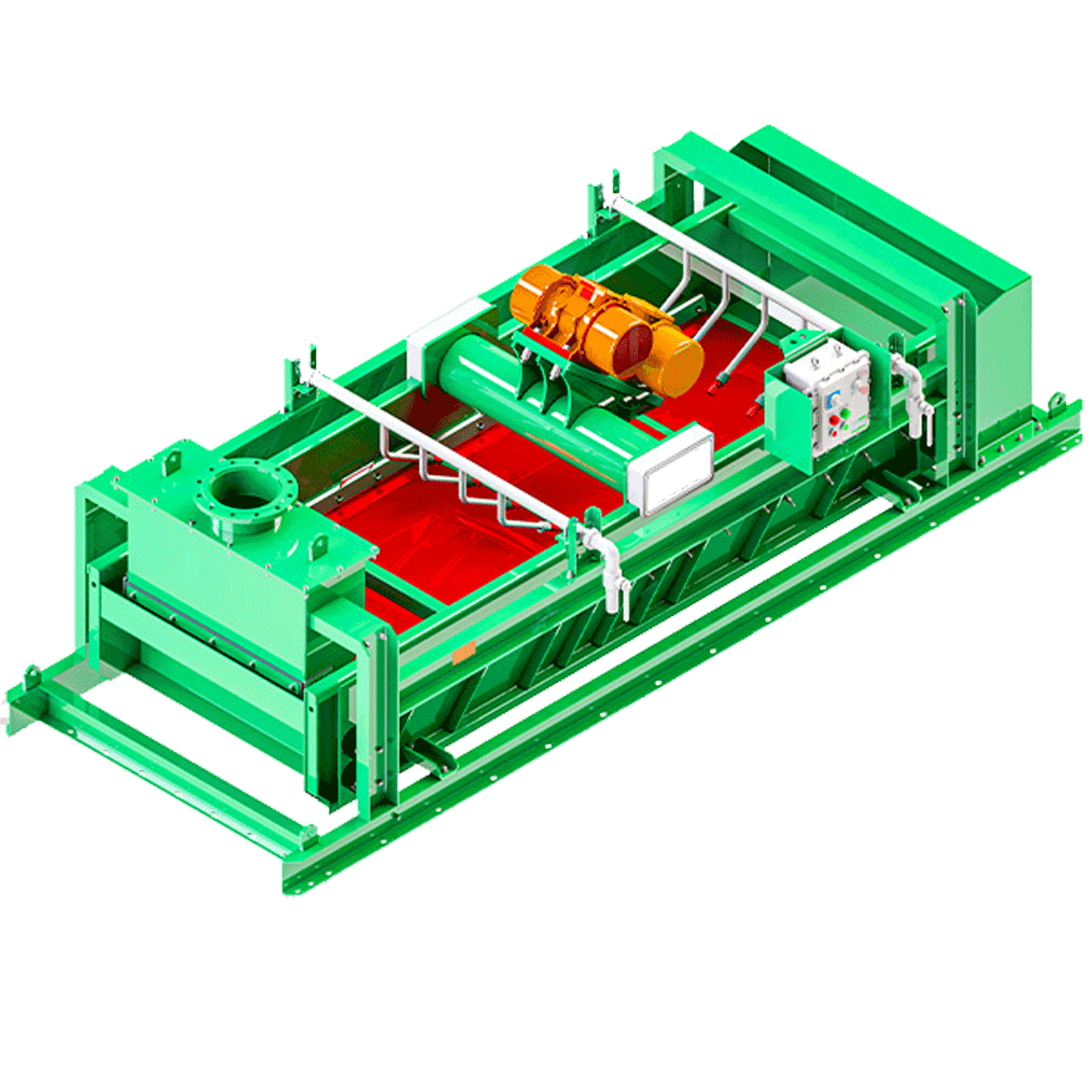

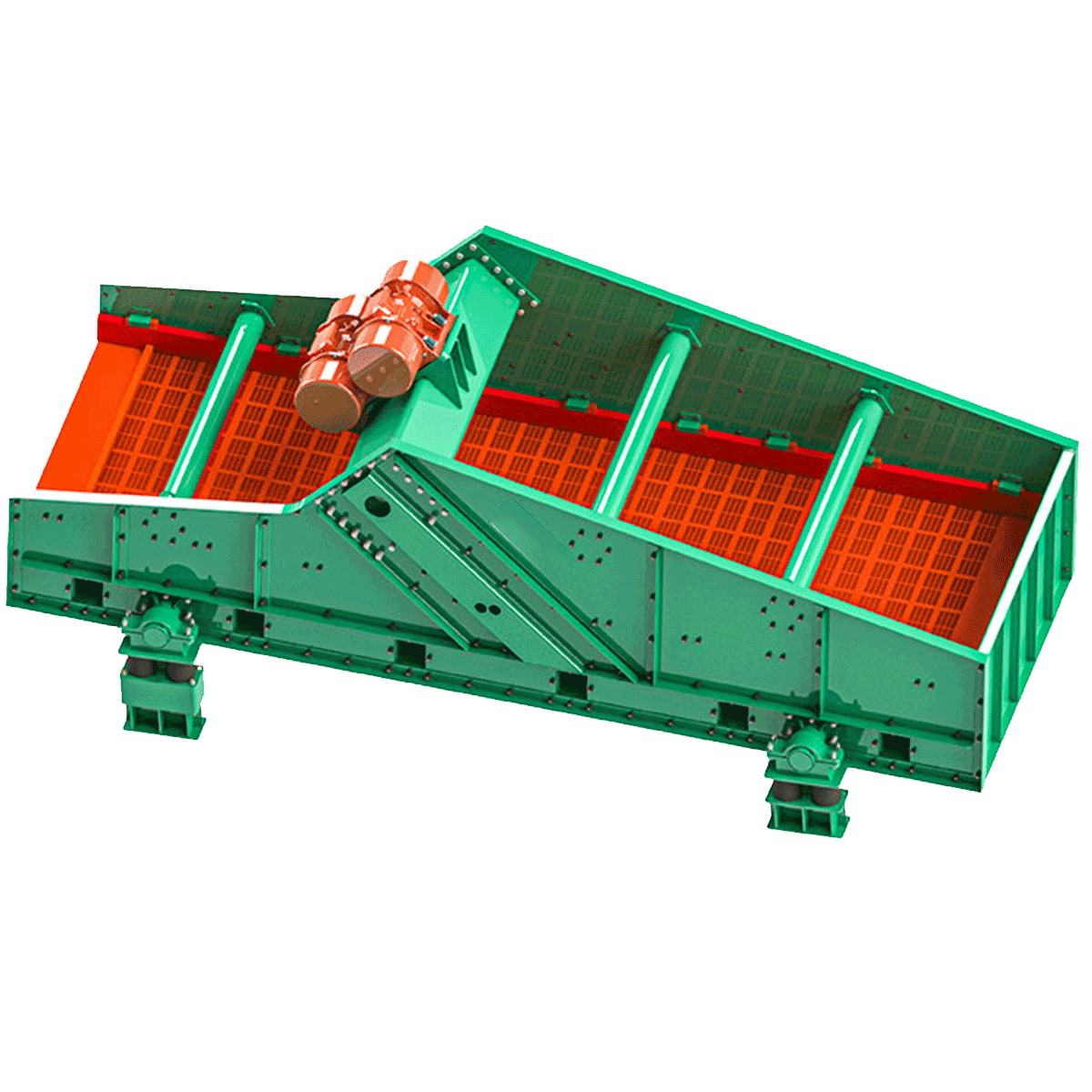

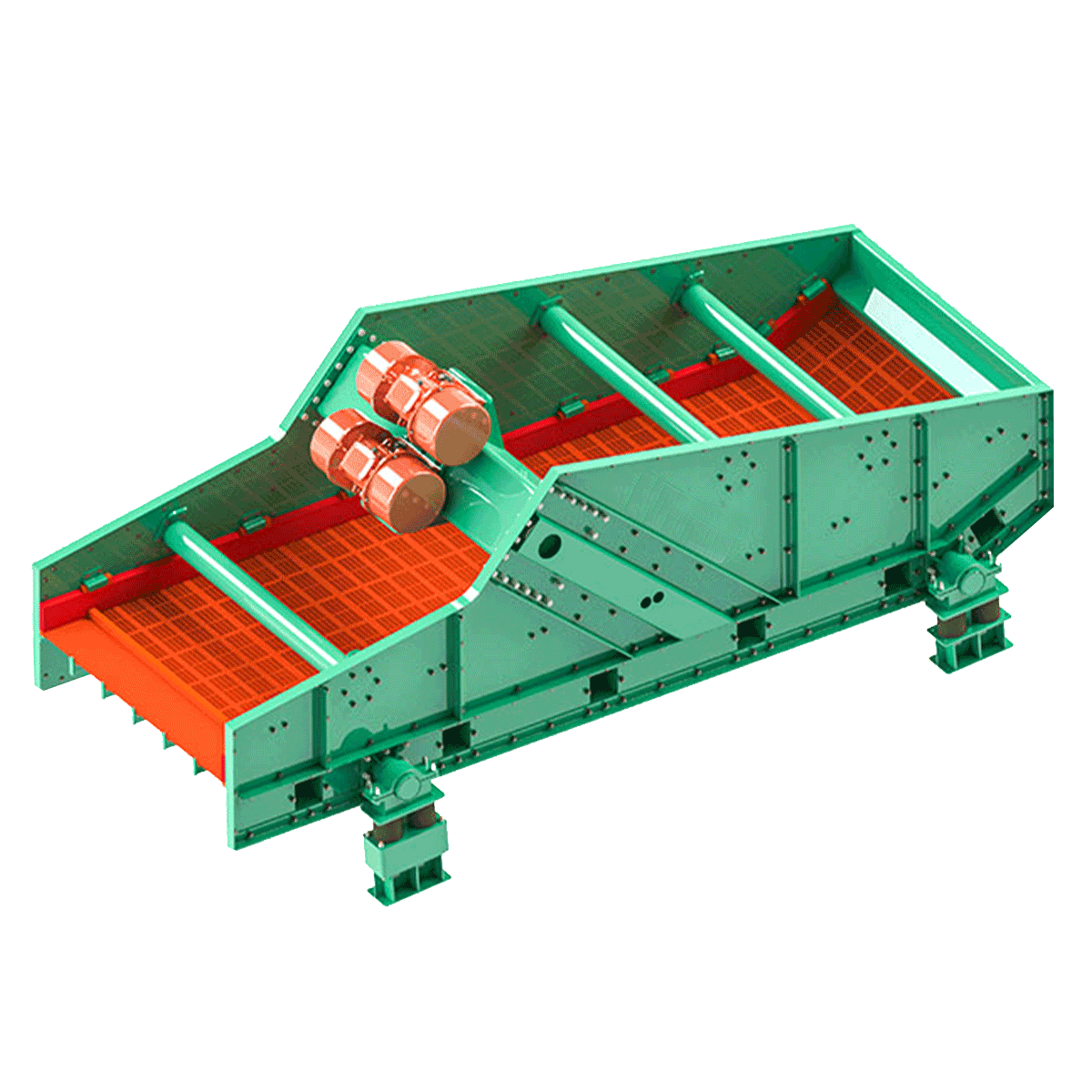

Flip-flow screen mainly consists of box exciter, main vibration screen frame, floating screen frame, shear spring, damping spring, flexible polyurethane screen mesh, support and drive device, running amplitude trajectory is straight line. The relaxation screen adopts the principle of double mass near resonance, a single drive to produce double vibration. The main vibrating screen frame is driven by the excitation force to do the basic vibration, the floating screen frame and the main vibrating screen frame are connected with the shear spring to do the relative motion in the near-resonance state.

Tensioned screen is a kind of vibrating screen. Tensioned Screen (Tensioned Screen) through the screen surface in the tension state of reciprocating vibration to achieve the screening of materials. Its working principle is that the screen surface with a certain frequency and amplitude of reciprocating vibration, so that the material jumps or throws on the screen surface, so as to achieve the relative motion between the material and the screen, to achieve the purpose of screening.

The main features of relaxation sieve include:

High-efficiency screening: the screen surface is in a tensioned state, the material jumps and throws more forcefully on the screen surface, which helps to improve the screening efficiency, especially for fine-grained materials.

Reduced clogging: the vibration mode helps to prevent the accumulation of materials on the screen surface, reducing the clogging of the screen holes, especially suitable for screening materials with high water content or viscous materials.

Long life screen: the screen can reduce the impact of the material under tension, thus prolonging the service life of the screen.

Easy to adjust: usually equipped with an adjusting device, it can be convenient to adjust the tension and vibration parameters of the screen surface, in order to adapt to different materials and screening requirements.

Wide applicability: it is suitable for dry screening and wet screening, applicable to mining, building materials, chemical industry, food and many other industries.

The structure of relaxation screen includes screen box, vibrator, transmission system, foundation part, spring part, screen mesh, motor and control box, etc. It has the features of simple structure, stable production performance, smooth operation, easy repair and maintenance. Its design features include multiple sections of screen surface with different inclination angles and box vibrator, which is suitable for particle size classification of large and medium-sized materials with high fines content.

Technical features and advantages of relaxation screens.

Screen wall panels without welding, plate selection of more good impact toughness of high-strength alloy steel plate, the use of imported HUCK rivets hydraulic tension assembly, this advanced design makes the wall panels have no welding residual stress.

Through finite element analysis, optimise the structure and vibration parameters of the screen machine, avoid the inherent frequency of the screen machine at all levels, reduce the impact of resonance, and extend the life of the machine.

The crossbeam under the screen adopts seamless shaped tube design, and the box structure design of the exciter beam is light weight, high strength and good toughness, and the post-welding heat treatment process of the main parts effectively eliminates the welding stress.

Floating screen frame amplitude adjustable, amplitude adjustment is achieved by changing the number of shear springs.

High-efficiency helical gear box exciter, large excitation force, ultra-low noise, smooth operation, long service life; eccentric block is set outside the exciter box, so that it is convenient to adjust the amplitude by changing the counterweight settings.

The polyurethane screen mesh adopts press-in installation, which is more convenient for replacement. The elastic deformation of the screen mesh has the function of self-cleaning the screen holes, which can effectively solve the problem of blocking the holes of fine, wet and sticky materials.

Fixed and floating beams are connected with the internal bolts of the track base to ensure the connection strength and convenient replacement.

The side track holders adopt bullhorn design to protect the wall panels and prevent the material on the screen from leaking to the bottom of the screen.

The surface of the crossbeam is protected by polyurea spraying or adhesive wear-resistant rubber plate, which ensures the service life of the crossbeam with resistance to scouring and corrosion.

Flip-flow screen mainly consists of box exciter, main vibration screen frame, floating screen frame, shear spring, damping spring, flexible polyurethane screen mesh, support and drive device, running amplitude trajectory is straight line. The relaxation screen adopts the principle of double mass near resonance, a single drive to produce double vibration. The main vibrating screen frame is driven by the excitation force to do the basic vibration, the floating screen frame and the main vibrating screen frame are connected with the shear spring to do the relative motion in the near-resonance state.

Tensioned screen is a kind of vibrating screen. Tensioned Screen (Tensioned Screen) through the screen surface in the tension state of reciprocating vibration to achieve the screening of materials. Its working principle is that the screen surface with a certain frequency and amplitude of reciprocating vibration, so that the material jumps or throws on the screen surface, so as to achieve the relative motion between the material and the screen, to achieve the purpose of screening.

The main features of relaxation sieve include:

High-efficiency screening: the screen surface is in a tensioned state, the material jumps and throws more forcefully on the screen surface, which helps to improve the screening efficiency, especially for fine-grained materials.

Reduced clogging: the vibration mode helps to prevent the accumulation of materials on the screen surface, reducing the clogging of the screen holes, especially suitable for screening materials with high water content or viscous materials.

Long life screen: the screen can reduce the impact of the material under tension, thus prolonging the service life of the screen.

Easy to adjust: usually equipped with an adjusting device, it can be convenient to adjust the tension and vibration parameters of the screen surface, in order to adapt to different materials and screening requirements.

Wide applicability: it is suitable for dry screening and wet screening, applicable to mining, building materials, chemical industry, food and many other industries.

The structure of relaxation screen includes screen box, vibrator, transmission system, foundation part, spring part, screen mesh, motor and control box, etc. It has the features of simple structure, stable production performance, smooth operation, easy repair and maintenance. Its design features include multiple sections of screen surface with different inclination angles and box vibrator, which is suitable for particle size classification of large and medium-sized materials with high fines content.

Technical features and advantages of relaxation screens.

Screen wall panels without welding, plate selection of more good impact toughness of high-strength alloy steel plate, the use of imported HUCK rivets hydraulic tension assembly, this advanced design makes the wall panels have no welding residual stress.

Through finite element analysis, optimise the structure and vibration parameters of the screen machine, avoid the inherent frequency of the screen machine at all levels, reduce the impact of resonance, and extend the life of the machine.

The crossbeam under the screen adopts seamless shaped tube design, and the box structure design of the exciter beam is light weight, high strength and good toughness, and the post-welding heat treatment process of the main parts effectively eliminates the welding stress.

Floating screen frame amplitude adjustable, amplitude adjustment is achieved by changing the number of shear springs.

High-efficiency helical gear box exciter, large excitation force, ultra-low noise, smooth operation, long service life; eccentric block is set outside the exciter box, so that it is convenient to adjust the amplitude by changing the counterweight settings.

The polyurethane screen mesh adopts press-in installation, which is more convenient for replacement. The elastic deformation of the screen mesh has the function of self-cleaning the screen holes, which can effectively solve the problem of blocking the holes of fine, wet and sticky materials.

Fixed and floating beams are connected with the internal bolts of the track base to ensure the connection strength and convenient replacement.

The side track holders adopt bullhorn design to protect the wall panels and prevent the material on the screen from leaking to the bottom of the screen.

The surface of the crossbeam is protected by polyurea spraying or adhesive wear-resistant rubber plate, which ensures the service life of the crossbeam with resistance to scouring and corrosion.

Parts List