Single-deck high-frequency fine screen

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Category :Screening / Vibrating Screen

Description

Description

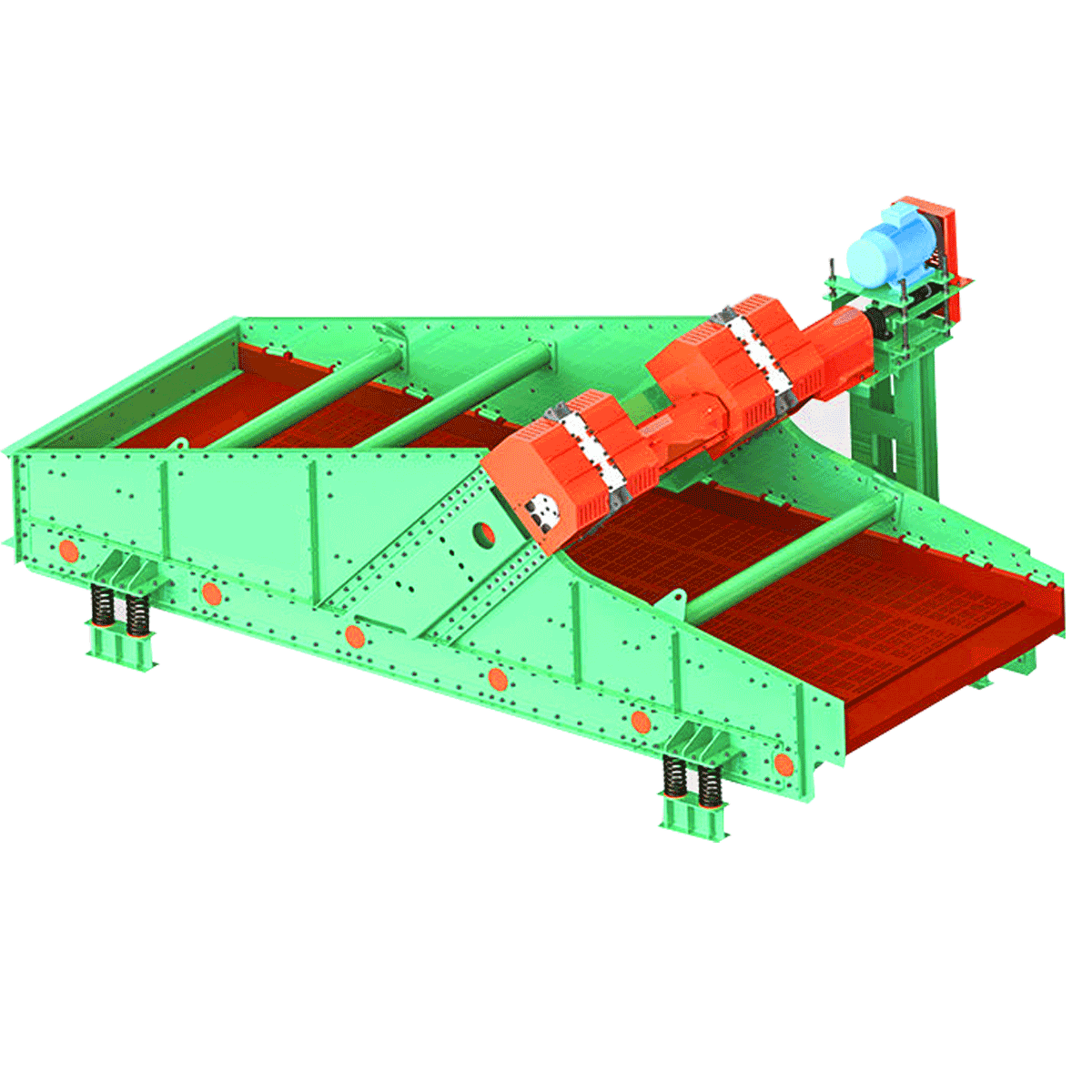

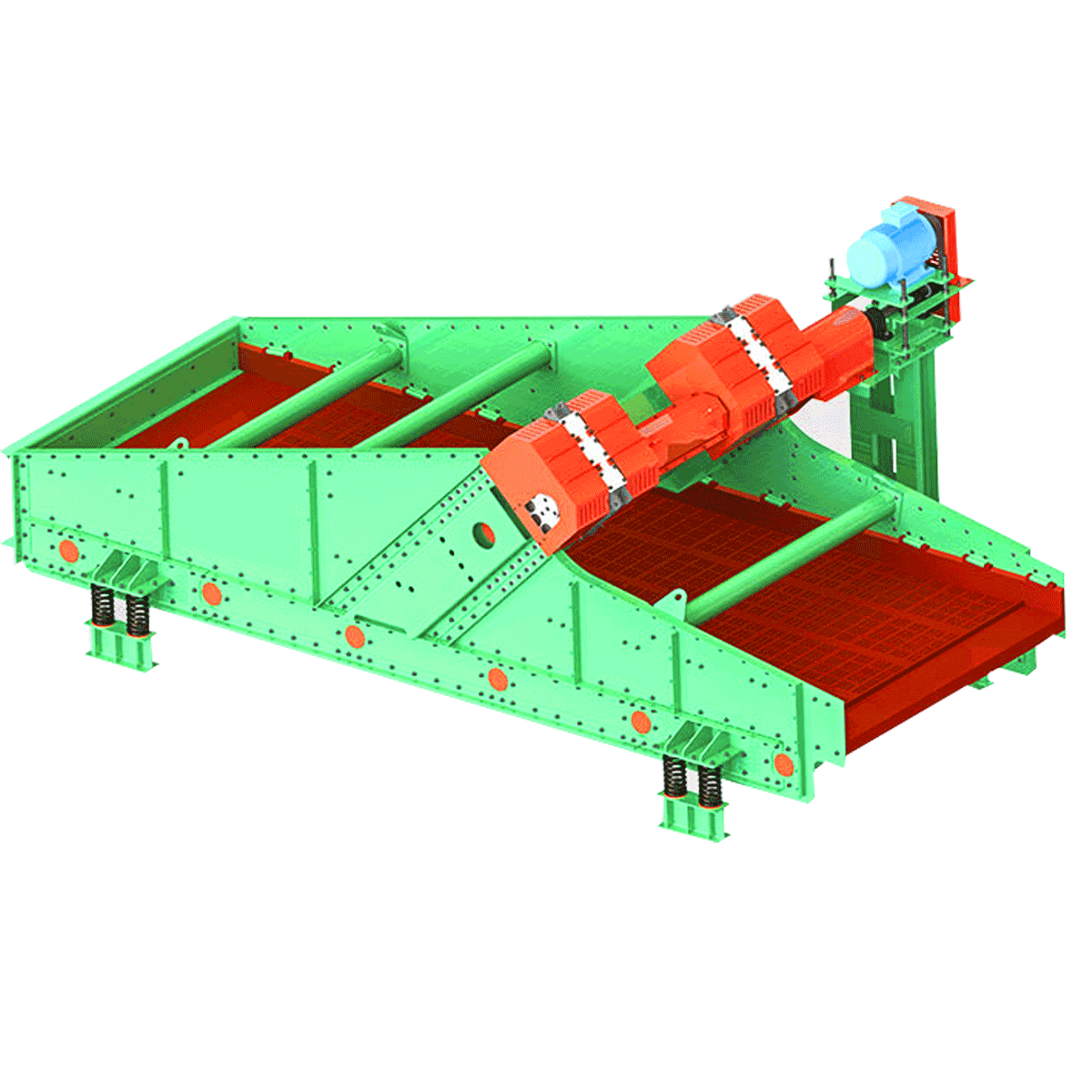

Single deck high frequency fine screen

Mizztech single-deck high-frequency fine screen is adapted to the wet screening, grading and dewatering of fine materials in mineral processing, coal processing and other industries. Single-deck high-frequency fine screen is a product developed by our company, which utilizes the principle of double-degree-of-freedom resonance, and is designed to be driven by a single vibration source (two imported vibration motors) to realize the linear vibration of the whole machine. Single-deck high-frequency fine screen has the advantages of large screening area, adjustable screen box angle, compact structure, excellent performance, high cost-effective.

Single-deck high-frequency fine screen is suitable for wet screening, grading and dewatering of fine materials in mineral processing, coal processing and other industries. Single-deck high-frequency fine screen is a product developed by our company, which utilizes the principle of double-degree-of-freedom resonance, and is designed to be driven by a single vibration source (two imported vibration motors) to realize the linear vibration of the whole machine. Guanneng single-deck high-frequency fine screen has the advantages of large screening area, adjustable screen box angle, compact structure, excellent performance, high cost performance. High-frequency fine screen vibration mode is unique, energy saving, high screening efficiency, large capacity, advanced technology, simple structure, stable and reliable operation, is currently one of the most advanced equipment in the field of fine grain material screening. High-frequency vibration fine screen can be used flexible polyurethane fine screen mesh, high open rate (28-45%), the average life of up to 6 months.

Main features of high frequency single-deck fine screen

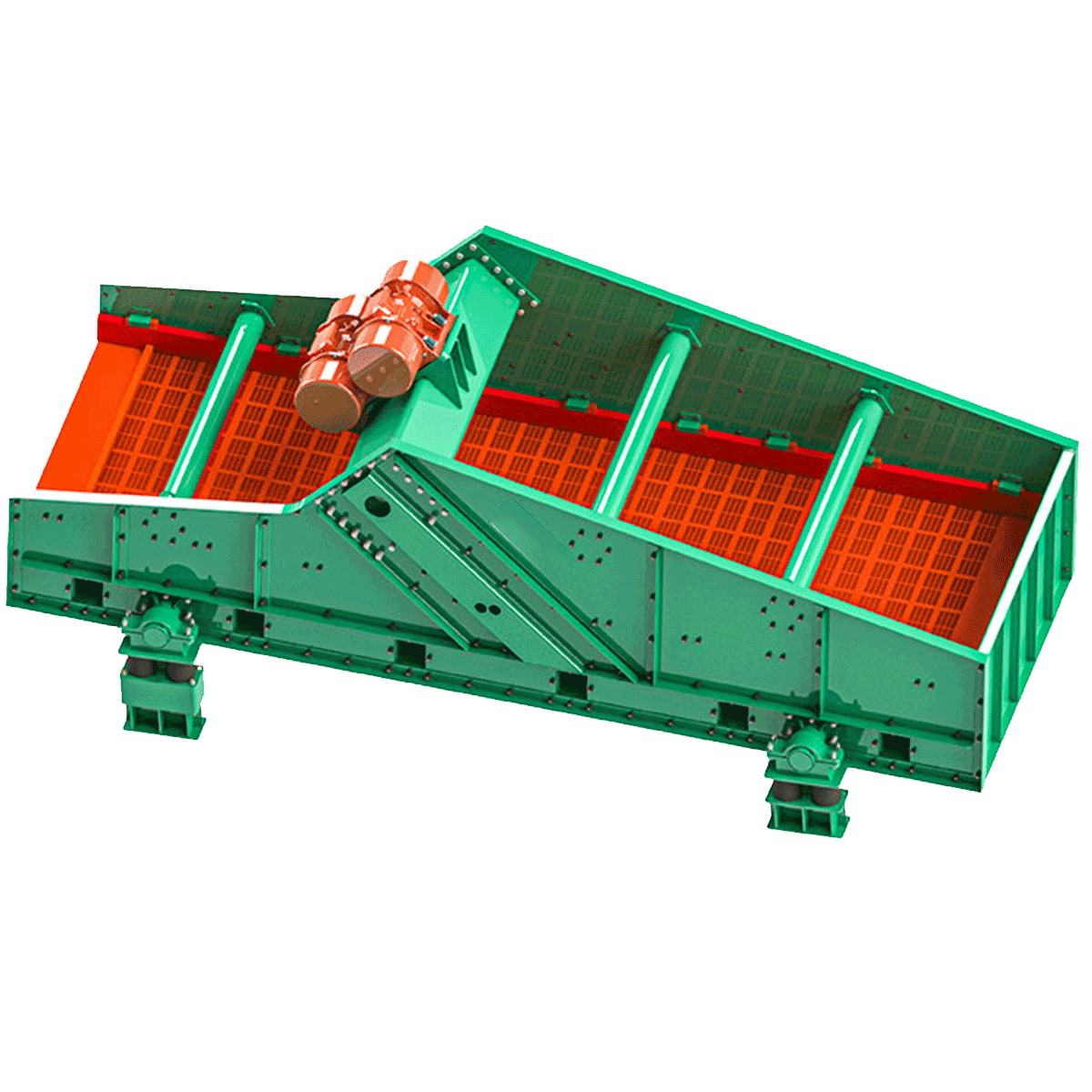

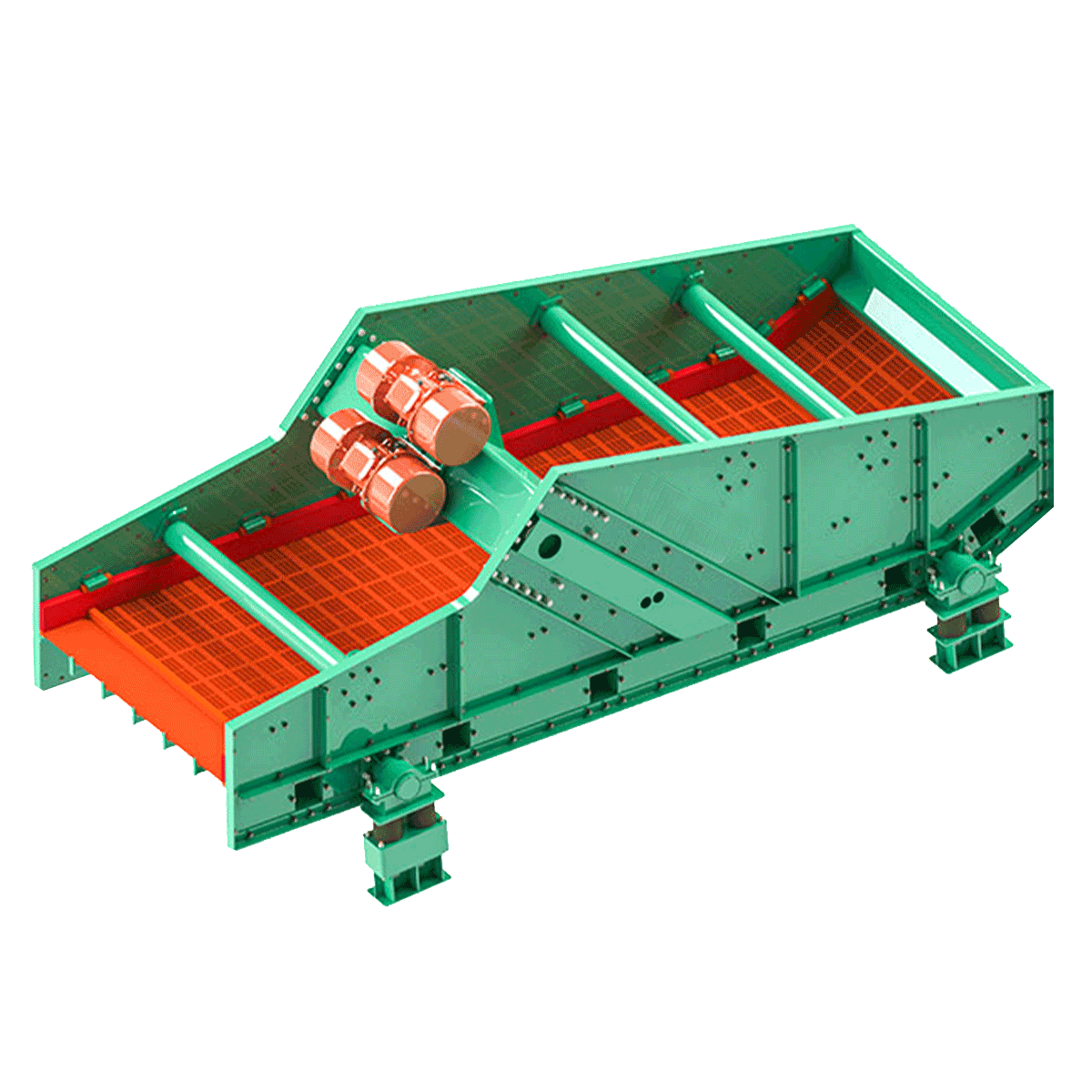

The company's vibrating screen is designed by the principle of self-synchronization of double motors, and the screen box assembly does linear motion.

It adopts advanced technology imported excitation motor (Martin motor or OLI motor), which works reliably and has a long trouble-free operation time.

The screen box assembly is arranged in multiple sections, which has the advantages of large handling capacity, high screening efficiency, low power consumption, small dynamic load, simple operation, stable performance, safety and durability, and small maintenance.

Mechanical angle adjustment of screen box assembly is convenient and reliable.

The overall heat treatment of the screen box can meet the high vibration intensity for a long time.

International brand electrical components, Siemens or Schneider components.

Flexible polyurethane screen mesh, good elasticity, not easy to block the screen, can be installed three to four screens.

The screen mesh is fixed by pulling mesh bolt assembly, which is convenient to operate and reliable to fasten.

The surface treatment of vibrating screen adopts sand blasting treatment process, spraying heavy anticorrosion paint with good anticorrosion performance, and the contact surface with materials adopts the form of spraying polyurea resin wear-resistant anticorrosion layer to protect the surface of the sieve machine and prolong the service life of the sieve machine.

High-frequency single-deck fine screen mesh adopts flexible polyurethane material

Flexible polyurethane screen is a kind of high polymer polyurethane elastomer, with excellent physical and mechanical properties: high strength, high elasticity, high wear resistance. After repeated tests to determine the excellent formula, using precision mold processing technology and unique advanced molding technology manufacturing, product performance is excellent. The product is suitable for metallurgical mining, coal, non-ferrous metal and other industries.

Sieve mesh characteristics

The service life of the highly wear-resistant polyurethane screen is 3-10 times higher than that of the woven metal screen, which improves the operation rate and increases the economic benefits.

Unique structure, suitable elasticity and elasticity, not only can make the jammed material be squeezed through the sieve holes or escape from the sieve holes, and become the product under or on the sieve, but also can make the fine-grained material due to the second high-frequency vibration of the sieve bar can not be adhered to reduce the jamming of the holes, clean the surface of the product, and improve the efficiency of the sieving process.

Polyurethane screen mesh effectively absorbs impact, reduces noise and improves the working environment.

Transverse tensioning, light weight, good flexibility, easy to install and dismantle, convenient transportation and storage.

Mizztech single-deck high-frequency fine screen is adapted to the wet screening, grading and dewatering of fine materials in mineral processing, coal processing and other industries. Single-deck high-frequency fine screen is a product developed by our company, which utilizes the principle of double-degree-of-freedom resonance, and is designed to be driven by a single vibration source (two imported vibration motors) to realize the linear vibration of the whole machine. Single-deck high-frequency fine screen has the advantages of large screening area, adjustable screen box angle, compact structure, excellent performance, high cost-effective.

Single-deck high-frequency fine screen is suitable for wet screening, grading and dewatering of fine materials in mineral processing, coal processing and other industries. Single-deck high-frequency fine screen is a product developed by our company, which utilizes the principle of double-degree-of-freedom resonance, and is designed to be driven by a single vibration source (two imported vibration motors) to realize the linear vibration of the whole machine. Guanneng single-deck high-frequency fine screen has the advantages of large screening area, adjustable screen box angle, compact structure, excellent performance, high cost performance. High-frequency fine screen vibration mode is unique, energy saving, high screening efficiency, large capacity, advanced technology, simple structure, stable and reliable operation, is currently one of the most advanced equipment in the field of fine grain material screening. High-frequency vibration fine screen can be used flexible polyurethane fine screen mesh, high open rate (28-45%), the average life of up to 6 months.

Main features of high frequency single-deck fine screen

The company's vibrating screen is designed by the principle of self-synchronization of double motors, and the screen box assembly does linear motion.

It adopts advanced technology imported excitation motor (Martin motor or OLI motor), which works reliably and has a long trouble-free operation time.

The screen box assembly is arranged in multiple sections, which has the advantages of large handling capacity, high screening efficiency, low power consumption, small dynamic load, simple operation, stable performance, safety and durability, and small maintenance.

Mechanical angle adjustment of screen box assembly is convenient and reliable.

The overall heat treatment of the screen box can meet the high vibration intensity for a long time.

International brand electrical components, Siemens or Schneider components.

Flexible polyurethane screen mesh, good elasticity, not easy to block the screen, can be installed three to four screens.

The screen mesh is fixed by pulling mesh bolt assembly, which is convenient to operate and reliable to fasten.

The surface treatment of vibrating screen adopts sand blasting treatment process, spraying heavy anticorrosion paint with good anticorrosion performance, and the contact surface with materials adopts the form of spraying polyurea resin wear-resistant anticorrosion layer to protect the surface of the sieve machine and prolong the service life of the sieve machine.

High-frequency single-deck fine screen mesh adopts flexible polyurethane material

Flexible polyurethane screen is a kind of high polymer polyurethane elastomer, with excellent physical and mechanical properties: high strength, high elasticity, high wear resistance. After repeated tests to determine the excellent formula, using precision mold processing technology and unique advanced molding technology manufacturing, product performance is excellent. The product is suitable for metallurgical mining, coal, non-ferrous metal and other industries.

Sieve mesh characteristics

The service life of the highly wear-resistant polyurethane screen is 3-10 times higher than that of the woven metal screen, which improves the operation rate and increases the economic benefits.

Unique structure, suitable elasticity and elasticity, not only can make the jammed material be squeezed through the sieve holes or escape from the sieve holes, and become the product under or on the sieve, but also can make the fine-grained material due to the second high-frequency vibration of the sieve bar can not be adhered to reduce the jamming of the holes, clean the surface of the product, and improve the efficiency of the sieving process.

Polyurethane screen mesh effectively absorbs impact, reduces noise and improves the working environment.

Transverse tensioning, light weight, good flexibility, easy to install and dismantle, convenient transportation and storage.

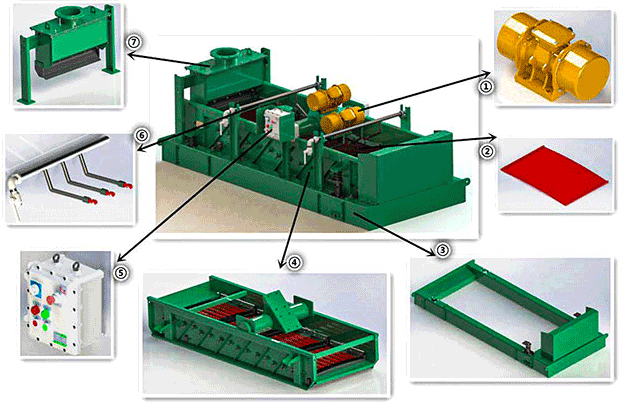

Parts List