Large-linear-vibrating-screen

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Category :Screening / Vibrating Screen

Description

Description

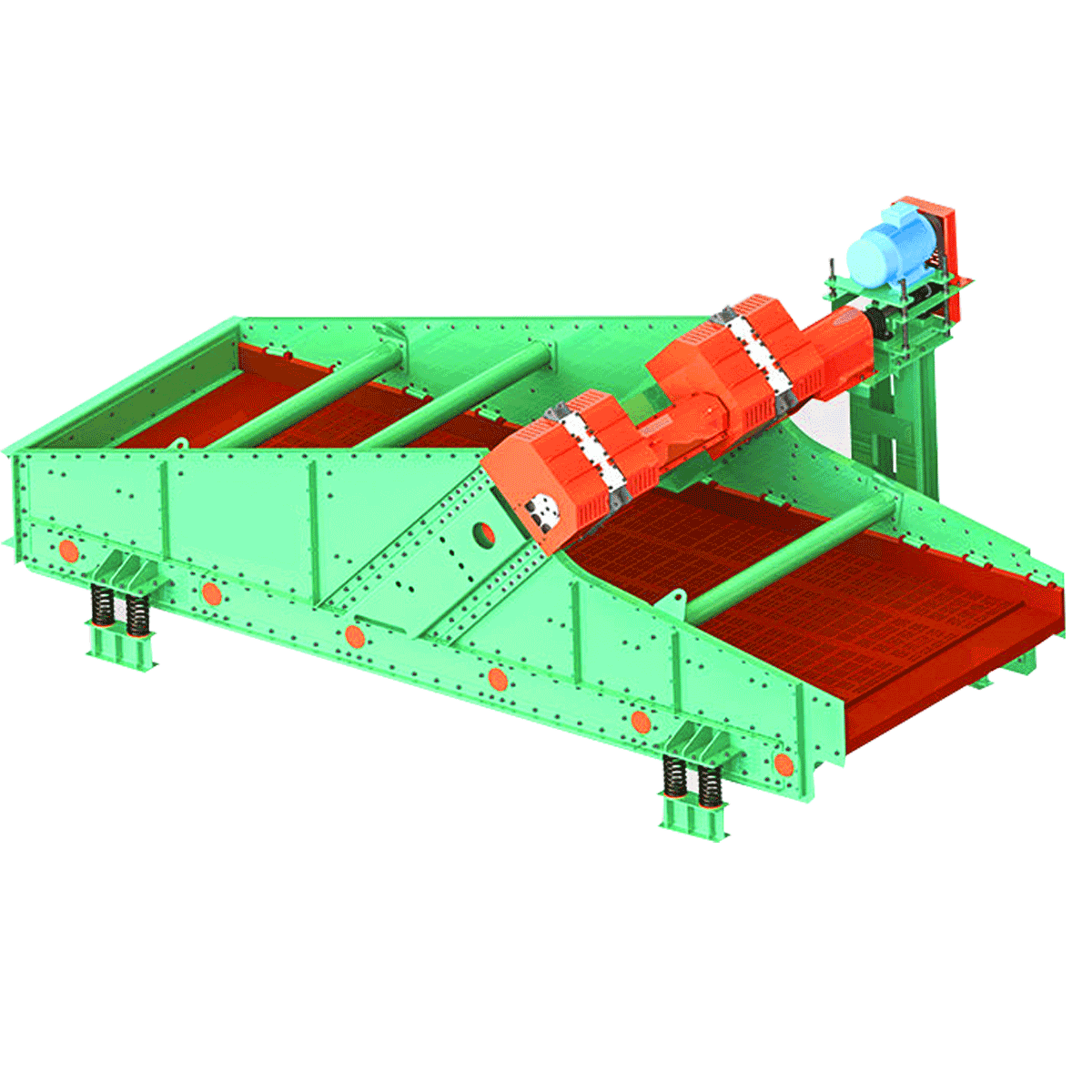

Large linear vibrating screen

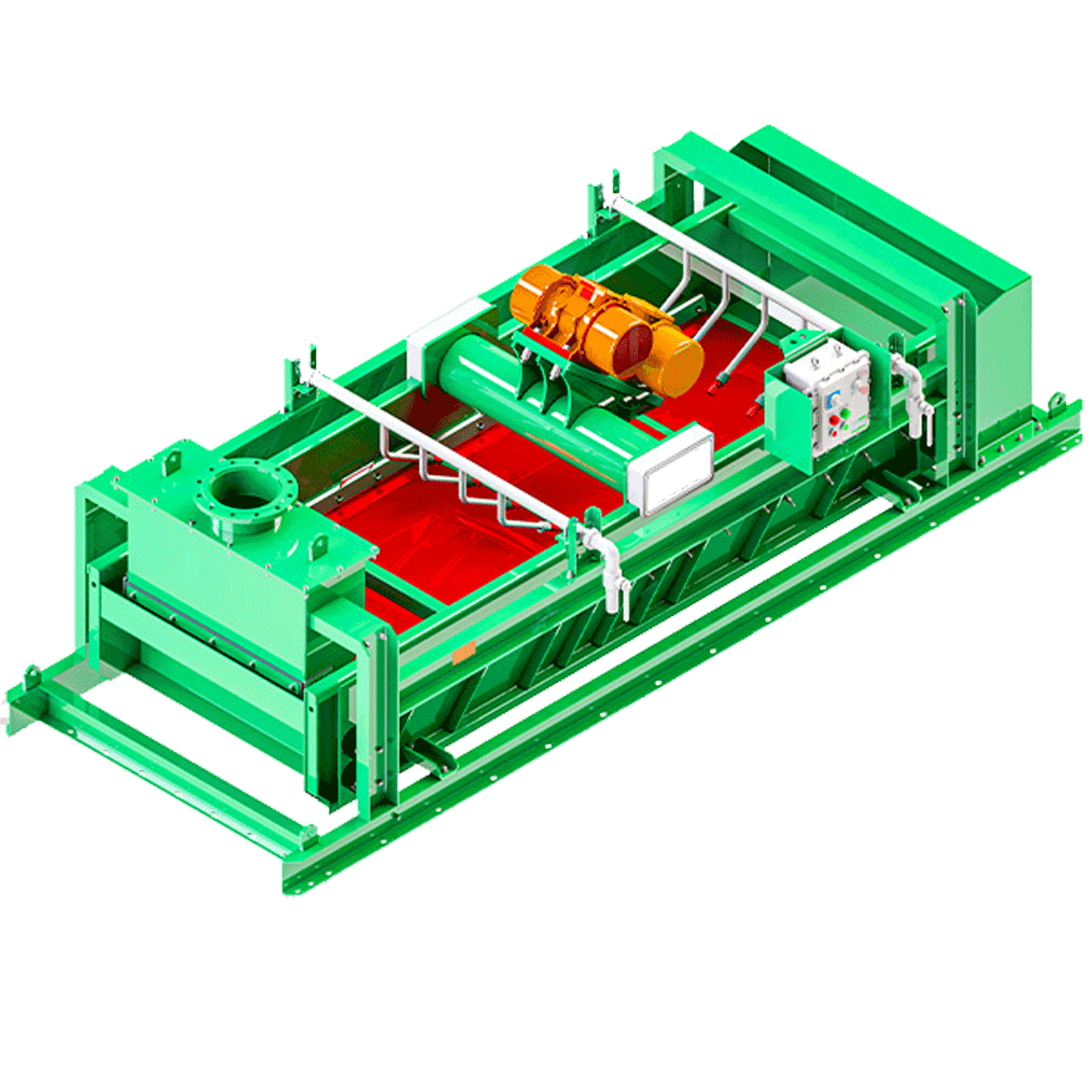

Large linear vibrating screen is mainly composed of box exciter, screen box, vibration damping spring, support and drive device, running amplitude trajectory is straight line.

Large linear grade vibrating screen is installed with two gear box type exciters, using the principle of forced synchronization to make the screen body do reciprocating linear motion.

Large linear vibrating screen is mainly composed of box exciter, screen box, vibration damping spring, support and drive device, running amplitude trajectory is straight line.

Large linear grade vibrating screen is installed with two gear box type exciters, using the principle of forced synchronization to make the screen body do reciprocating linear motion.

Sieve machine under the action of the vibration force to drive the screen surface synchronous vibration, the force will be transmitted to the screen material, impact material in the screen surface thrown up for stratification and according to the specified particle size through the sieve level.

The material is continuously fed from the feed chute to the receiving plate buffer input, through the screen surface for screening, grading process, screen, screen materials were discharged into the screen and screen receiving chute, into the next process.

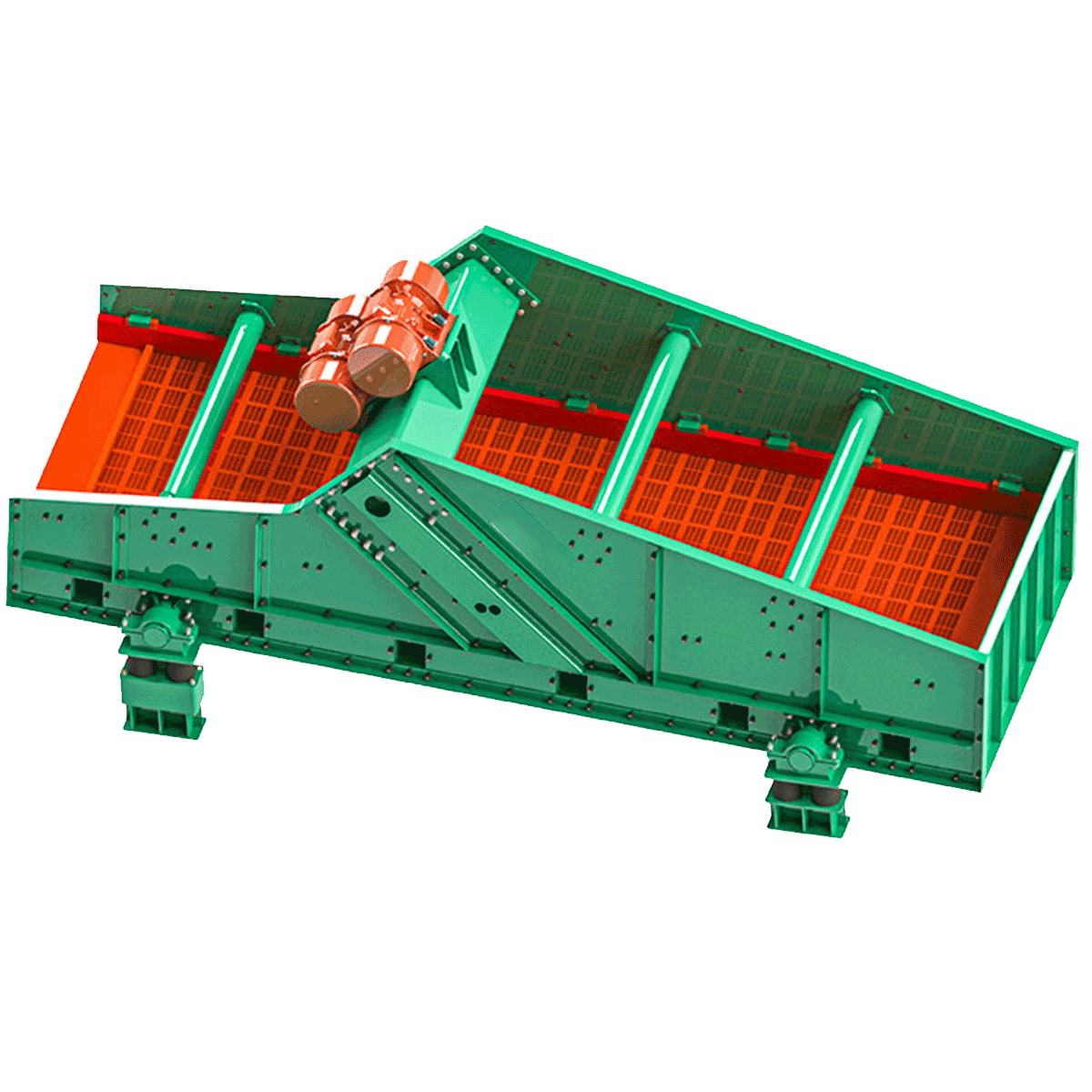

Large linear vibrating screen screen surface structure can be made into a single deck vibrating screen, can also be made into a double deck vibrating screen.

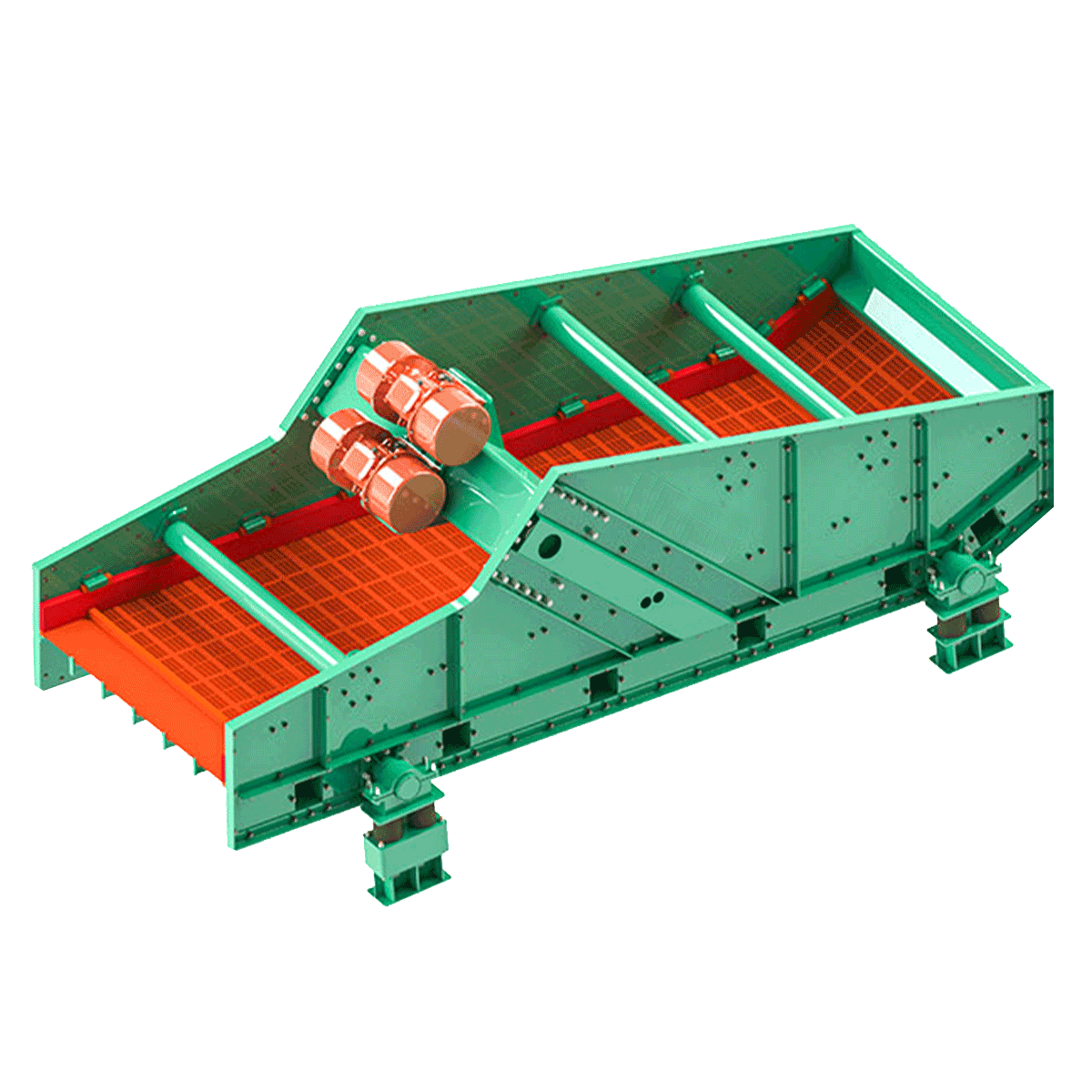

In the way of arrangement, the large linear vibrating screen can be arranged horizontally or inclined at a certain angle.

Large linear vibrating screen is widely used in wet classification, dewatering, demixing, tailings dry discharge and other processes in mineral processing, coal processing, sand and gravel aggregate, building materials, chemical industry and other industries.

Linear Vibrating Screen Technical Features and Advantages.

Sieve machine wall panels without welding, plate selection more good impact toughness of high-strength alloy steel plate, using imported HUCK rivets hydraulic tension assembly, this advanced design makes the wall panels without welding residual stress.

Through finite element analysis, optimize the screen machine structure and vibration parameters, avoid the screen machine at all levels of intrinsic frequency, reduce the impact of resonance, and extend the life of the whole machine.

The lower crossbeam of the screen adopts rectangular tube design, the box structure design of the exciter beam is light weight, high strength and good toughness, and the post-weld heat treatment process of the main parts effectively eliminates the welding stress.

The surface of the beam adopts the American imported sprayer to complete the polyurea spraying operation, easy to impact, easy to wear parts can also be designed to protect the rubber parts, resistant to scouring and abrasion.

High-efficiency helical gear box shaker, large excitation force, ultra-low noise, smooth operation, long service life; eccentric block set outside the shaker box, so that it is easy to adjust the amplitude by changing the counterweight settings.

Product serialization, to meet the customer's production requirements of different process conditions; polyurethane screen plate modularity, more versatile, more convenient replacement.

Large linear vibrating screen is mainly composed of box exciter, screen box, vibration damping spring, support and drive device, running amplitude trajectory is straight line.

Large linear grade vibrating screen is installed with two gear box type exciters, using the principle of forced synchronization to make the screen body do reciprocating linear motion.

Large linear vibrating screen is mainly composed of box exciter, screen box, vibration damping spring, support and drive device, running amplitude trajectory is straight line.

Large linear grade vibrating screen is installed with two gear box type exciters, using the principle of forced synchronization to make the screen body do reciprocating linear motion.

Sieve machine under the action of the vibration force to drive the screen surface synchronous vibration, the force will be transmitted to the screen material, impact material in the screen surface thrown up for stratification and according to the specified particle size through the sieve level.

The material is continuously fed from the feed chute to the receiving plate buffer input, through the screen surface for screening, grading process, screen, screen materials were discharged into the screen and screen receiving chute, into the next process.

Large linear vibrating screen screen surface structure can be made into a single deck vibrating screen, can also be made into a double deck vibrating screen.

In the way of arrangement, the large linear vibrating screen can be arranged horizontally or inclined at a certain angle.

Large linear vibrating screen is widely used in wet classification, dewatering, demixing, tailings dry discharge and other processes in mineral processing, coal processing, sand and gravel aggregate, building materials, chemical industry and other industries.

Linear Vibrating Screen Technical Features and Advantages.

Sieve machine wall panels without welding, plate selection more good impact toughness of high-strength alloy steel plate, using imported HUCK rivets hydraulic tension assembly, this advanced design makes the wall panels without welding residual stress.

Through finite element analysis, optimize the screen machine structure and vibration parameters, avoid the screen machine at all levels of intrinsic frequency, reduce the impact of resonance, and extend the life of the whole machine.

The lower crossbeam of the screen adopts rectangular tube design, the box structure design of the exciter beam is light weight, high strength and good toughness, and the post-weld heat treatment process of the main parts effectively eliminates the welding stress.

The surface of the beam adopts the American imported sprayer to complete the polyurea spraying operation, easy to impact, easy to wear parts can also be designed to protect the rubber parts, resistant to scouring and abrasion.

High-efficiency helical gear box shaker, large excitation force, ultra-low noise, smooth operation, long service life; eccentric block set outside the shaker box, so that it is easy to adjust the amplitude by changing the counterweight settings.

Product serialization, to meet the customer's production requirements of different process conditions; polyurethane screen plate modularity, more versatile, more convenient replacement.

Parts List