MBD2461 Banana Screen

Manufacturer : MORETEC

Part number : MBD2461

OEM Compatibility :

Category :Screening / Vibrating Screen

Description

Description

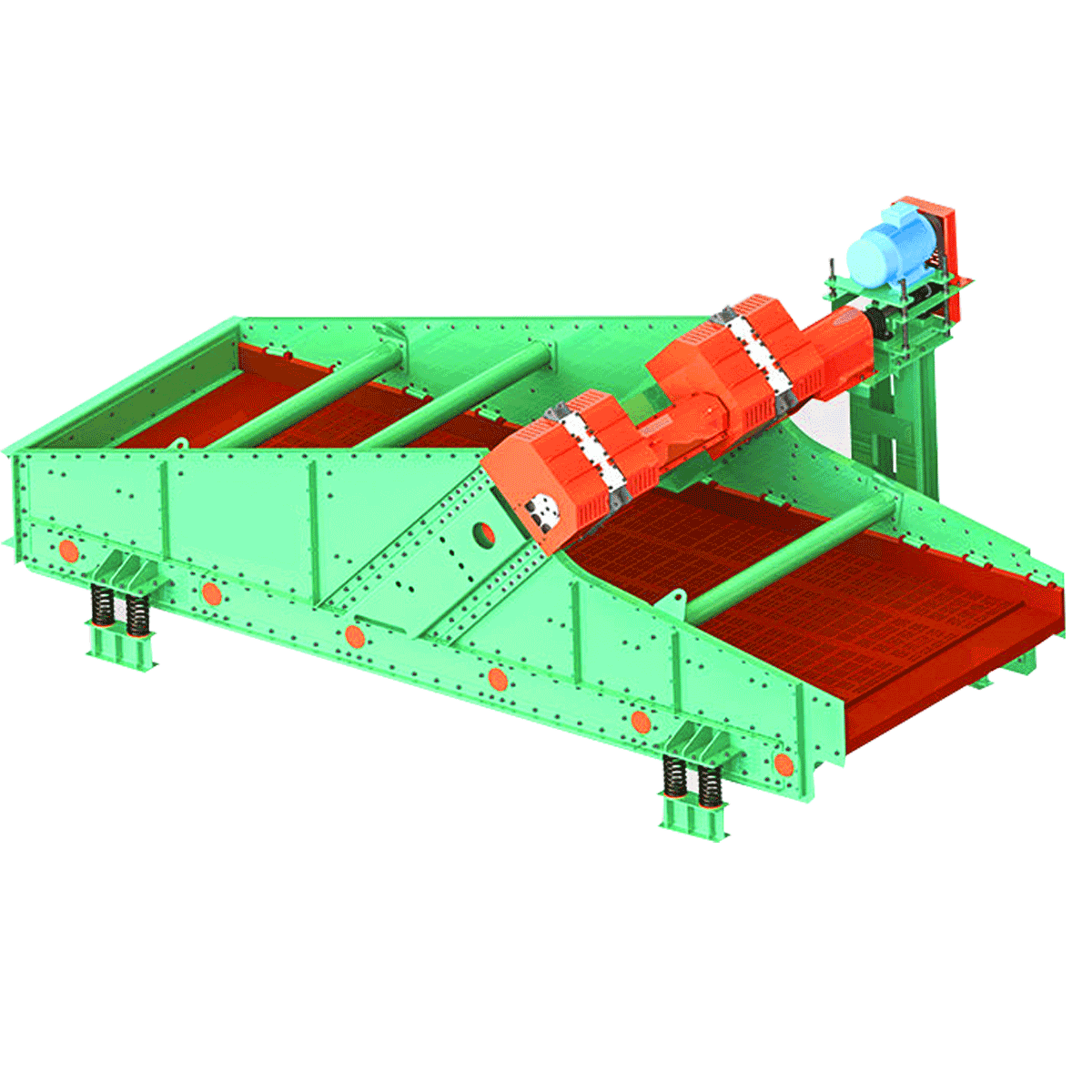

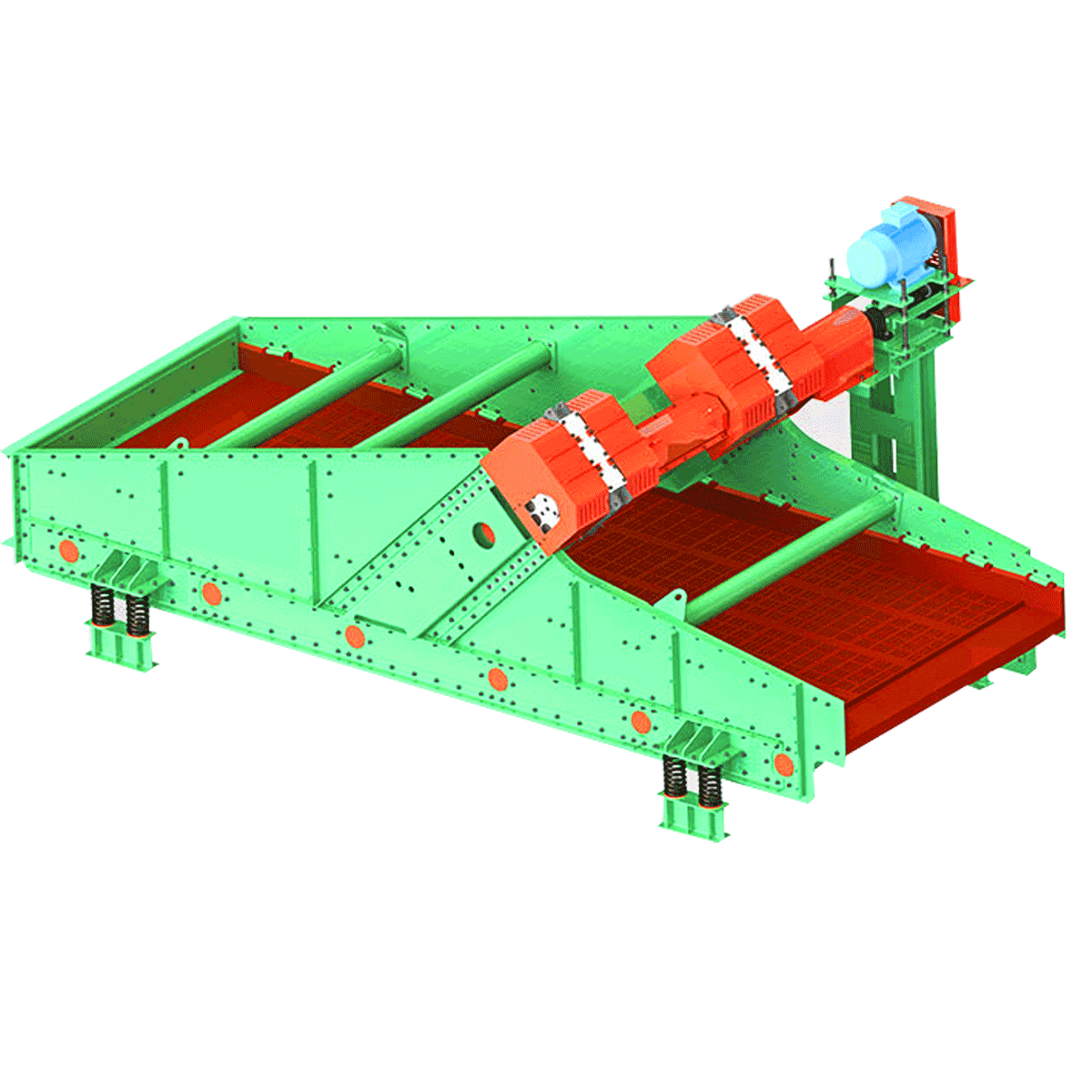

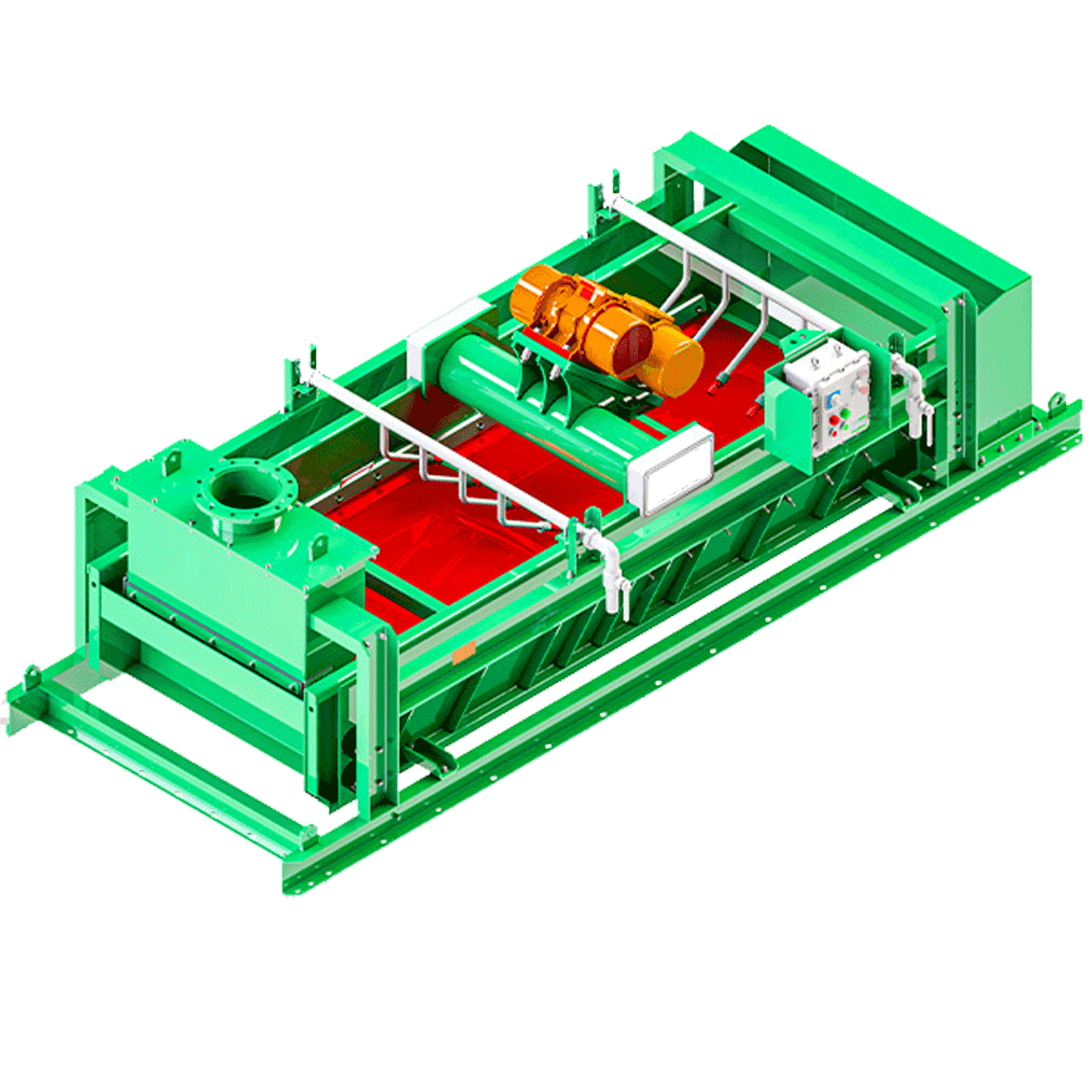

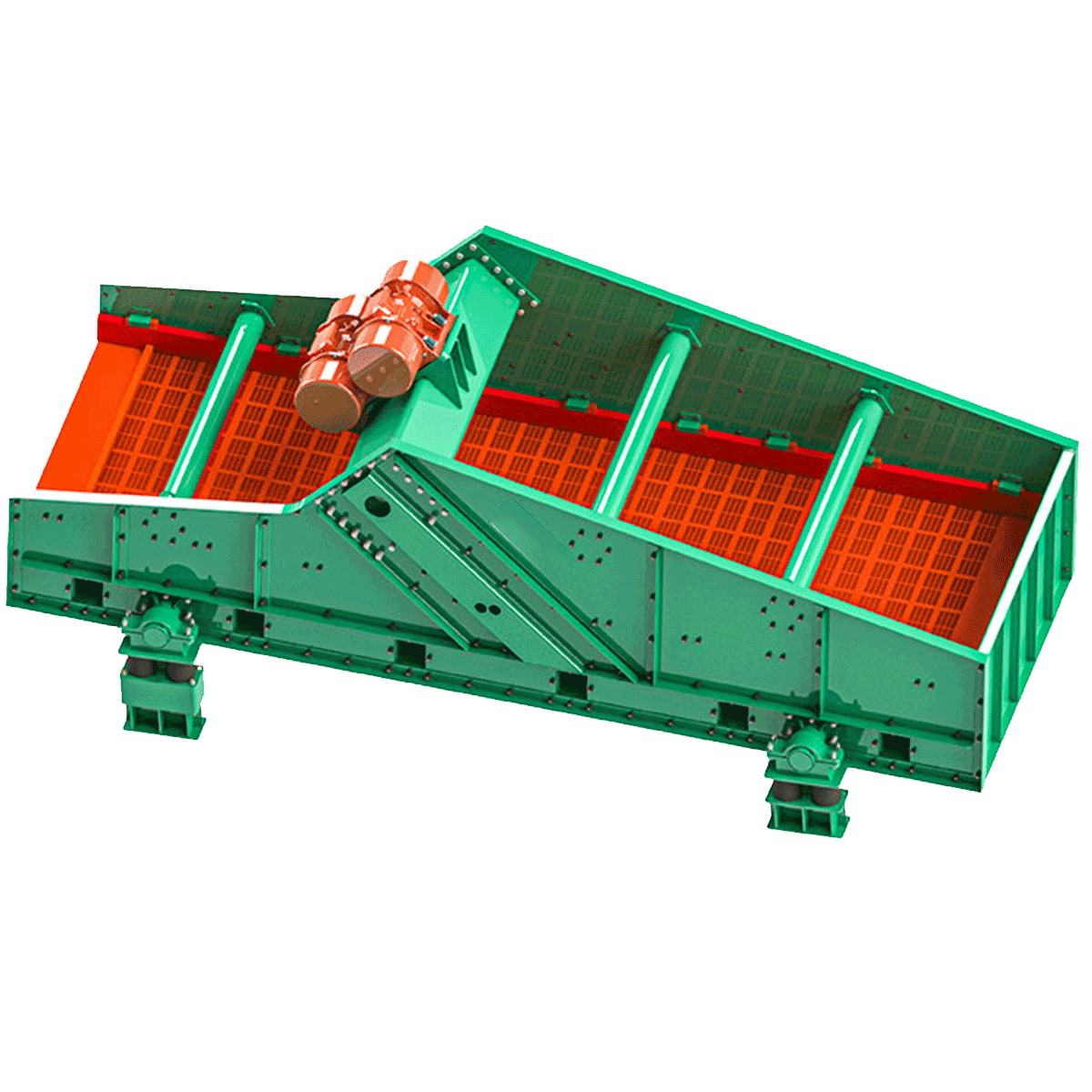

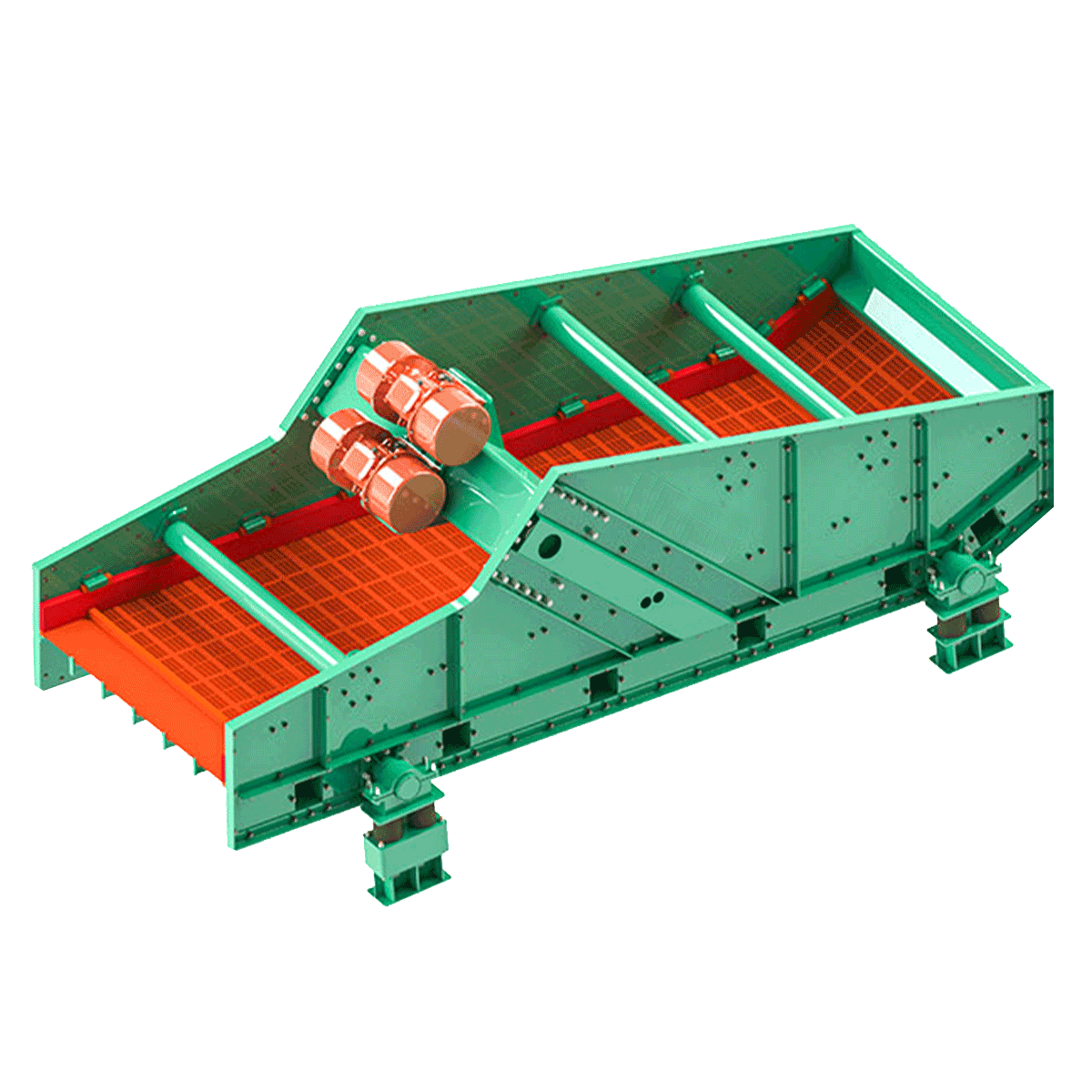

Banana Screen

Large banana screen, also called equal thickness screen, its shape is like a banana and named banana screen. Large banana screen is mainly composed of box exciter, screen box, vibration damping spring, support and drive device, running amplitude trajectory is straight line. Large-scale use of continuous multi-section angle combination of folded screen surface design, the feed end of the screen surface inclination is large, can make the material rapid movement and stratification, is conducive to easy to screen materials through the screen. With the decrease of the angle of inclination of the screen surface near the discharge end, the flow rate of the material is reduced, increasing the chances of the material through the screen and improving the screening efficiency.

Large banana screen, also known as equal thickness screen, its shape resembles a banana and named banana screen. Large banana screen is mainly composed of box exciter, screen box, vibration damping spring, support and drive device, running amplitude trajectory is straight. Large-scale use of continuous multi-section angle combination of folded screen surface design, the feed end of the screen surface inclination is large, can make the material rapid movement and stratification, is conducive to easy to screen materials through the screen. With the decrease of the angle of inclination of the screen surface near the discharge end, the flow rate of the material is reduced, increasing the chance of the material through the screen and improving the screening efficiency. Banana screen is mainly used in dry or wet classification, desliming, de-mediation and other processes. Guanneng large banana screen is installed with two gear box exciters, using the principle of forced synchronization to make the screen body do reciprocating linear motion. Banana screen under the action of the excitation force to drive the screen surface synchronous vibration, the force will be transmitted to the screen material, the impact of the material in the screen surface thrown up for layering and according to the specified particle size through the screen level. Banana screen adopts a continuous multi-section angle combination of folded screen surface design, the feed end of the screen surface inclination angle is large, can make the material rapid movement and stratification, is conducive to easy to screen the material through the screen. With the reduction of the angle of inclination of the screen surface near the discharge end, the flow rate of the material is reduced, increasing the chances of the material through the screen, improving the screening efficiency and capacity. Large banana screen excitation force direction and horizontal angle can be designed according to the customer site material properties, this angle determines the running speed of the material on the screen surface and the handling capacity of the equipment.

Single-deck banana screen technical parameters

Double-deck banana screen technical parameters

Advantages of large banana screen

Crown banana screen vibration beam adopts box-type structure design and internal reinforcement, high rigidity and high strength. The main welds are fully penetrated, UT inspection and magnetic particle inspection are carried out, and heat treatment is carried out after welding to eliminate welding stress. Before assembly, all the mating surfaces of the exciter beams are precisely processed by CNC machine tools, which can effectively guarantee the overall assembly quality of the screen machine.

The lower beam of banana screen adopts seamless rectangular tube and high-strength steel plate welding structure, heat treatment after welding to eliminate welding stress, and the two end surfaces are precision machined by CNC machine tools.

Crown banana screen overflow parts, easy to wear parts using the whole piece of shot blasting treatment, wear-resistant polyurea material surface spraying process, to extend the service life of parts.

Crown banana screen for customers with special material working conditions, vibrating screen can choose to spray polyurea and bonding wear-resistant rubber plate double wear-resistant process, to ensure that the equipment for long-term effective application.

Guanneng's excellent technology and design capabilities, processing and manufacturing capabilities to meet the actual needs of customers in a variety of working conditions. In order to ensure the good operation of the equipment, each piece of equipment is carefully assembled and rigorously tested under no-load operation before delivery.

Crown's design complies with BS7608 (fatigue design and evaluation of steel products) standard, and the stress and displacement analysis of important parts are carried out in advance through finite element stress analysis to ensure the normal operation of vibrating screen at customer's site.

Large banana screen, also called equal thickness screen, its shape is like a banana and named banana screen. Large banana screen is mainly composed of box exciter, screen box, vibration damping spring, support and drive device, running amplitude trajectory is straight line. Large-scale use of continuous multi-section angle combination of folded screen surface design, the feed end of the screen surface inclination is large, can make the material rapid movement and stratification, is conducive to easy to screen materials through the screen. With the decrease of the angle of inclination of the screen surface near the discharge end, the flow rate of the material is reduced, increasing the chances of the material through the screen and improving the screening efficiency.

Large banana screen, also known as equal thickness screen, its shape resembles a banana and named banana screen. Large banana screen is mainly composed of box exciter, screen box, vibration damping spring, support and drive device, running amplitude trajectory is straight. Large-scale use of continuous multi-section angle combination of folded screen surface design, the feed end of the screen surface inclination is large, can make the material rapid movement and stratification, is conducive to easy to screen materials through the screen. With the decrease of the angle of inclination of the screen surface near the discharge end, the flow rate of the material is reduced, increasing the chance of the material through the screen and improving the screening efficiency. Banana screen is mainly used in dry or wet classification, desliming, de-mediation and other processes. Guanneng large banana screen is installed with two gear box exciters, using the principle of forced synchronization to make the screen body do reciprocating linear motion. Banana screen under the action of the excitation force to drive the screen surface synchronous vibration, the force will be transmitted to the screen material, the impact of the material in the screen surface thrown up for layering and according to the specified particle size through the screen level. Banana screen adopts a continuous multi-section angle combination of folded screen surface design, the feed end of the screen surface inclination angle is large, can make the material rapid movement and stratification, is conducive to easy to screen the material through the screen. With the reduction of the angle of inclination of the screen surface near the discharge end, the flow rate of the material is reduced, increasing the chances of the material through the screen, improving the screening efficiency and capacity. Large banana screen excitation force direction and horizontal angle can be designed according to the customer site material properties, this angle determines the running speed of the material on the screen surface and the handling capacity of the equipment.

Single-deck banana screen technical parameters

Double-deck banana screen technical parameters

Advantages of large banana screen

Crown banana screen vibration beam adopts box-type structure design and internal reinforcement, high rigidity and high strength. The main welds are fully penetrated, UT inspection and magnetic particle inspection are carried out, and heat treatment is carried out after welding to eliminate welding stress. Before assembly, all the mating surfaces of the exciter beams are precisely processed by CNC machine tools, which can effectively guarantee the overall assembly quality of the screen machine.

The lower beam of banana screen adopts seamless rectangular tube and high-strength steel plate welding structure, heat treatment after welding to eliminate welding stress, and the two end surfaces are precision machined by CNC machine tools.

Crown banana screen overflow parts, easy to wear parts using the whole piece of shot blasting treatment, wear-resistant polyurea material surface spraying process, to extend the service life of parts.

Crown banana screen for customers with special material working conditions, vibrating screen can choose to spray polyurea and bonding wear-resistant rubber plate double wear-resistant process, to ensure that the equipment for long-term effective application.

Guanneng's excellent technology and design capabilities, processing and manufacturing capabilities to meet the actual needs of customers in a variety of working conditions. In order to ensure the good operation of the equipment, each piece of equipment is carefully assembled and rigorously tested under no-load operation before delivery.

Crown's design complies with BS7608 (fatigue design and evaluation of steel products) standard, and the stress and displacement analysis of important parts are carried out in advance through finite element stress analysis to ensure the normal operation of vibrating screen at customer's site.

Parts List