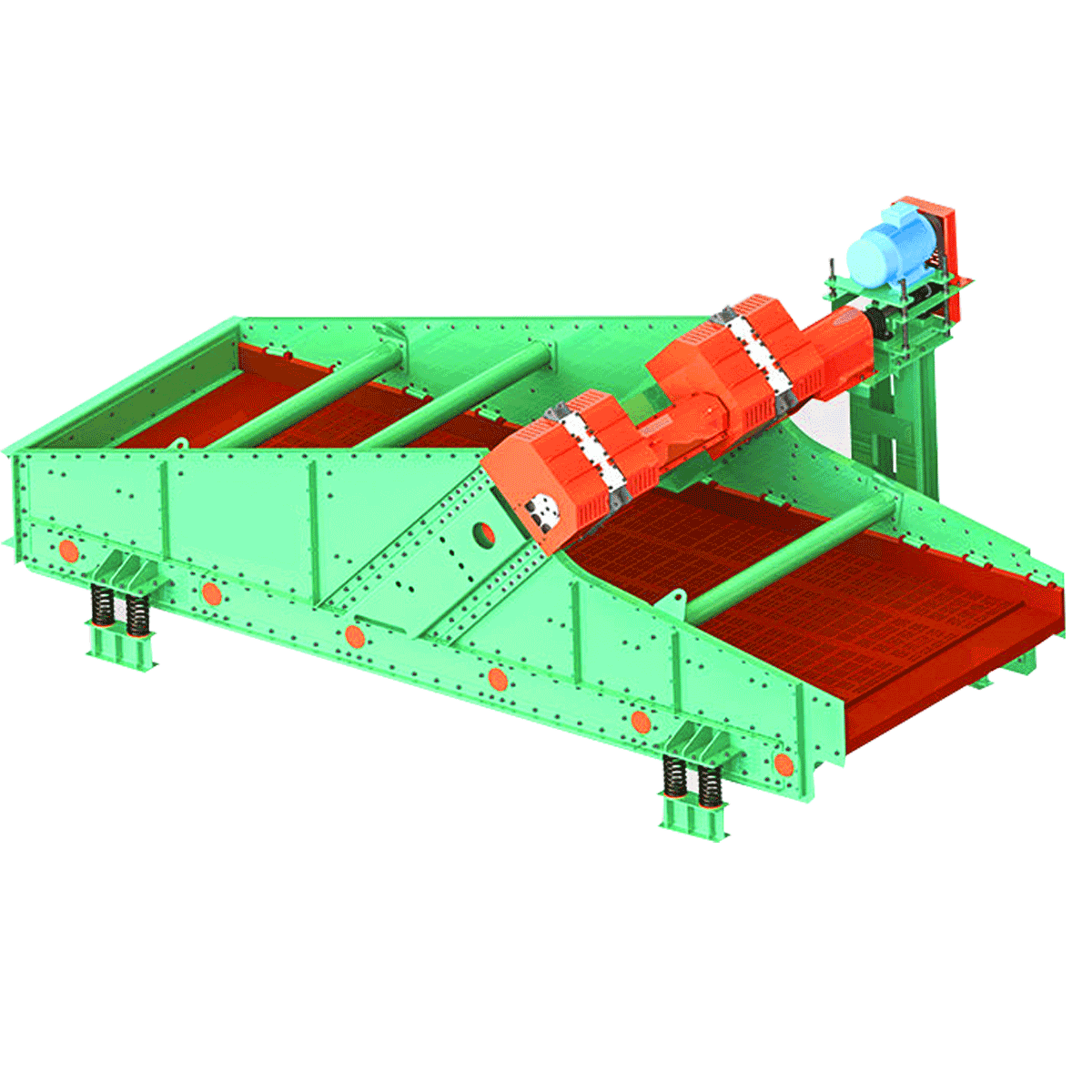

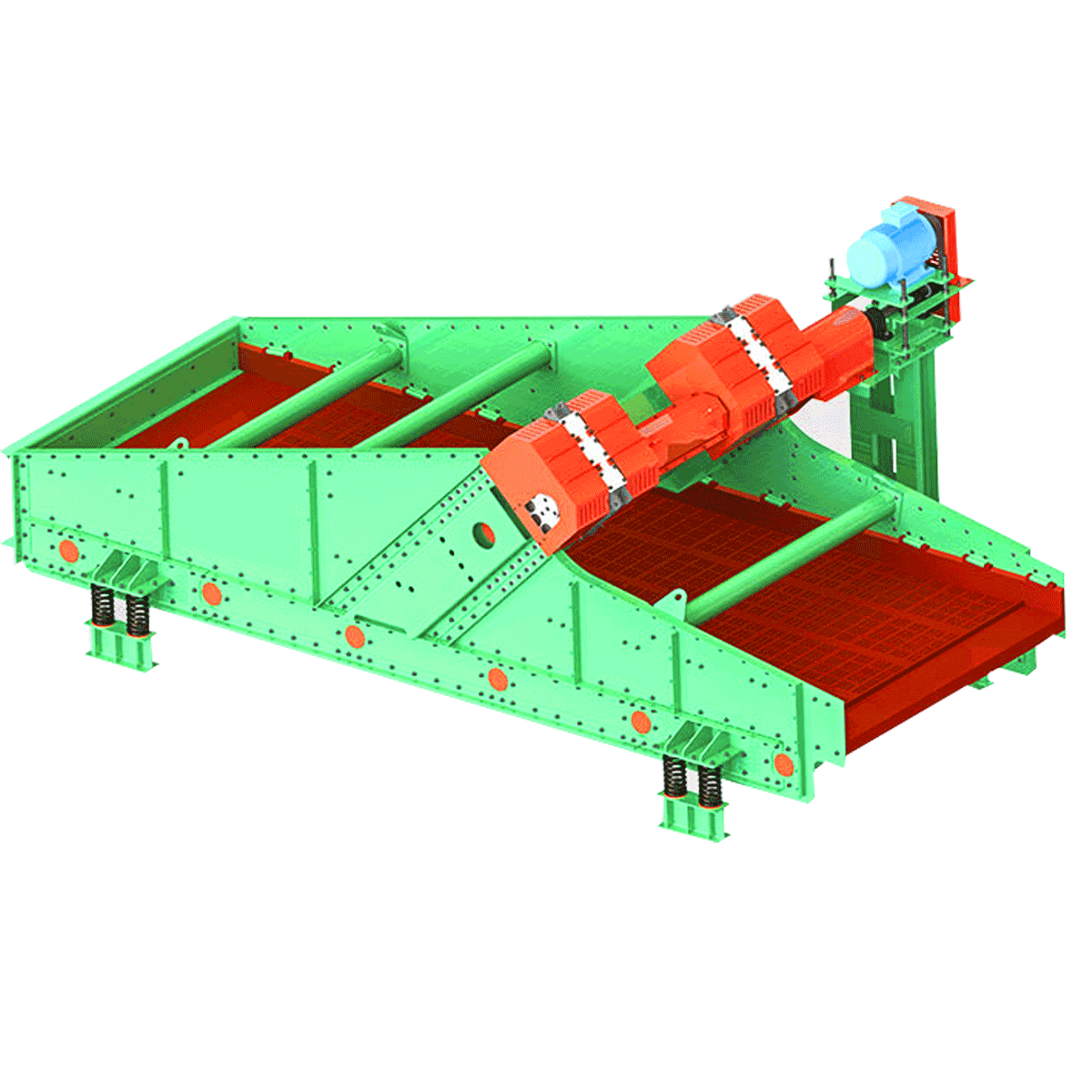

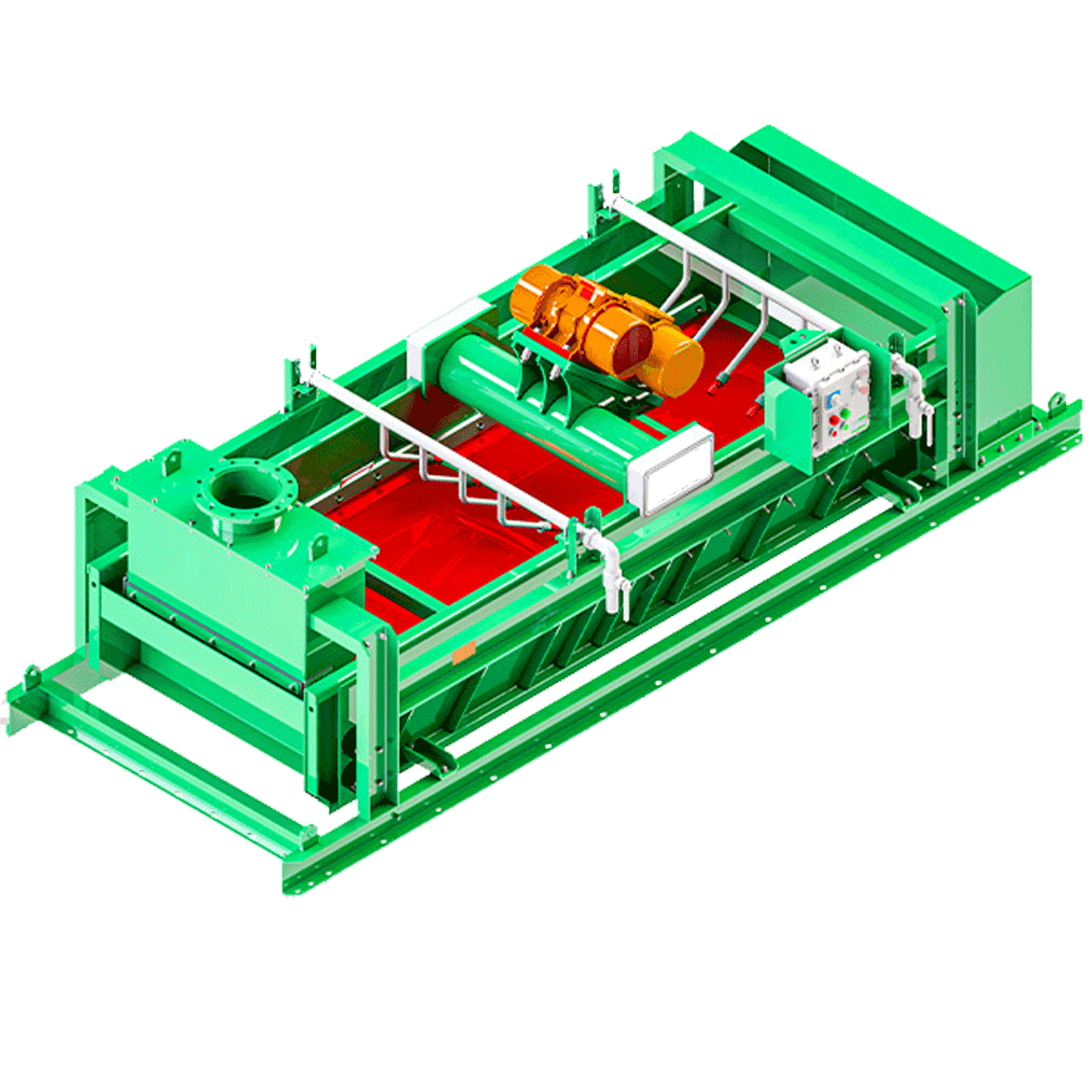

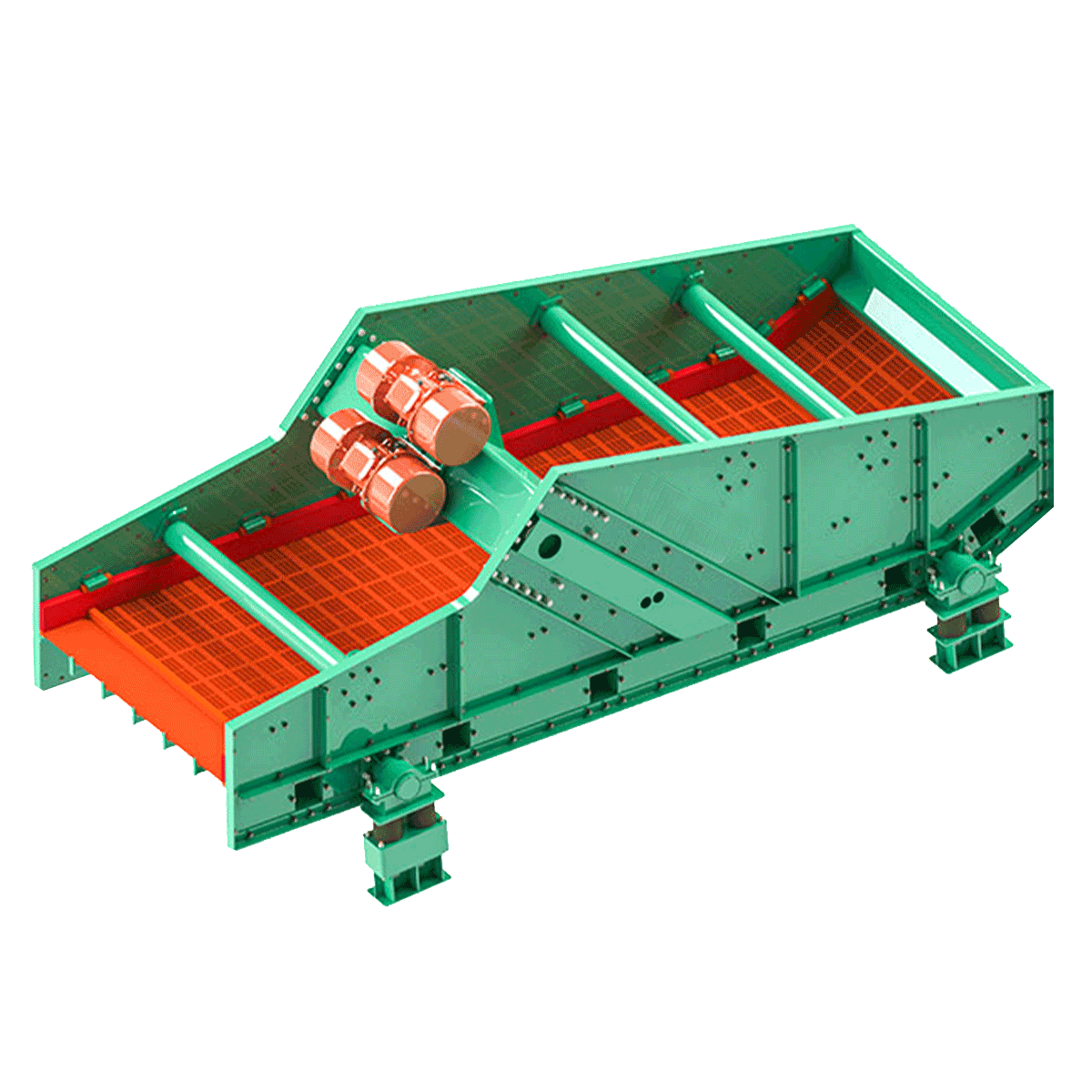

MLMP1236 Linear Classifying Vibrating Screen

Manufacturer : MORETEC

Part number : MLMP1236

OEM Compatibility :

Category :Screening / Vibrating Screen

Description

Description

Linear grading vibrating screen is widely used for grading and screening treatment of materials in iron ore, coal mine, non-ferrous metal mine, building materials, chemical industry and so on.The equipment adopts advanced finite element analysis and anti-fatigue analysis and other design means to ensure the reasonable structure, low energy consumption and large screening and grading capacity of the screen machine. It can adapt to a variety of corrosive and abrasive working conditions. Large handling capacity, high efficiency and stable performance. The size of sieve machine can also be customized according to customer requirements.

Contact Us

Linear grading vibrating screen is widely used in grading and screening processing of materials such as iron ore, coal mine, nonferrous metal mine, building materials, chemical industry and so on. The equipment adopts advanced finite element analysis and anti fatigue analysis and other design means to ensure the reasonable structure of the screen machine, low energy consumption and large screening and grading capacity. It can adapt to a variety of corrosive and abrasive working conditions. Large handling capacity, high efficiency and stable performance. The size of the screen machine can also be customized according to customer requirements. Guanneng linear grading vibrating screen is installed with two vibrating motors, using the reverse self-synchronization principle to make the screen body do linear motion. The screen body drives the screen surface synchronous vibration, the force will be transmitted to the screen material, the impact of the material in the screen surface thrown up for layering and according to the specified particle size through the sieve classification. Materials continuously from the feed trough to the receiving plate buffer input, through the screen surface for screening, grading process, screen, screen materials were discharged into the screen and screen receiving trough, into the next process. The direction of the excitation force and the horizontal angle can be designed according to the nature of the material at the customer's site, and this angle determines the running speed of the material on the screen surface and the handling capacity of the equipment。

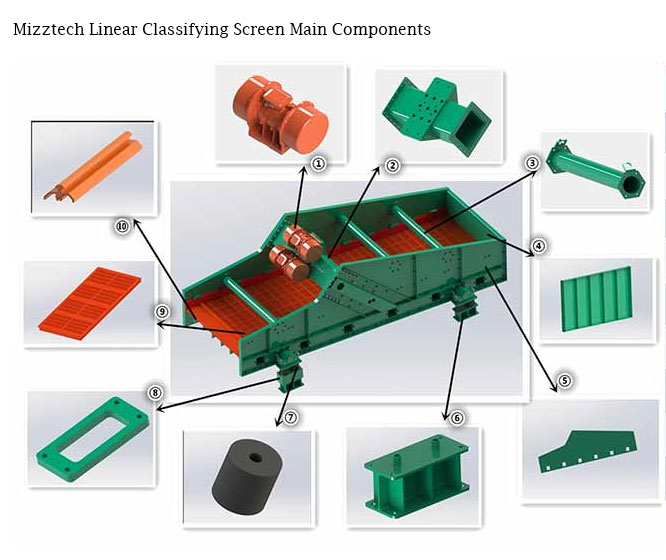

Linear grading vibrating screen main components

Contact Us

Linear grading vibrating screen is widely used in grading and screening processing of materials such as iron ore, coal mine, nonferrous metal mine, building materials, chemical industry and so on. The equipment adopts advanced finite element analysis and anti fatigue analysis and other design means to ensure the reasonable structure of the screen machine, low energy consumption and large screening and grading capacity. It can adapt to a variety of corrosive and abrasive working conditions. Large handling capacity, high efficiency and stable performance. The size of the screen machine can also be customized according to customer requirements. Guanneng linear grading vibrating screen is installed with two vibrating motors, using the reverse self-synchronization principle to make the screen body do linear motion. The screen body drives the screen surface synchronous vibration, the force will be transmitted to the screen material, the impact of the material in the screen surface thrown up for layering and according to the specified particle size through the sieve classification. Materials continuously from the feed trough to the receiving plate buffer input, through the screen surface for screening, grading process, screen, screen materials were discharged into the screen and screen receiving trough, into the next process. The direction of the excitation force and the horizontal angle can be designed according to the nature of the material at the customer's site, and this angle determines the running speed of the material on the screen surface and the handling capacity of the equipment。

Linear grading vibrating screen main components

| Layer Dimension | 4.32 ㎡ |

| Power | 0 kW |

| vibration frequency |

Parts List